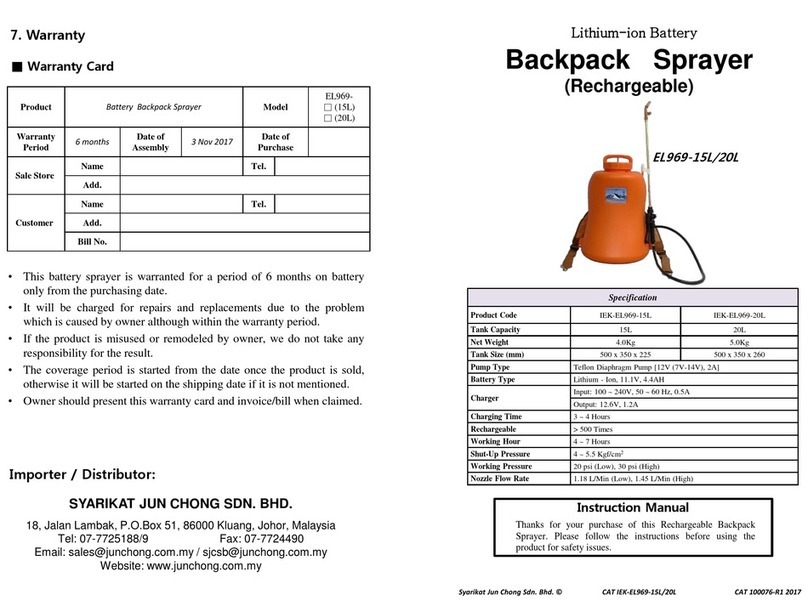

1) The lance [331(F)] with twin elbow [TE/2A(P1)]

and SCA/4 nozzle are screwed onto the automatic

release completed [321(P1)] with hose [346/(P2)] and

connected to sprayer. Fix the Filter IEM-DC(9) onto

the tank base.

2) Check all the joints are tightened properly

with washer to prevent leaking.

3) Fill the chemical mixture into the sprayer tank

through the strainer (303) in order to filtrate the dirt

and sediments. To avoid overflow.

4)Shoulder straps (337) are fully adjustable to

ensure operator’s comfort in fieldwork.

7) The Volmeter (EPB-EC05) show the voltage

reading. The spraying power will stop upon the reading

of Volmeter (EPB-EC05) shown below 10.0V.

1) To clean the sprayer After spraying job, fill sprayer tank with clean water at least 2 liters, then on the

power and squeezing the Automatic Release [321(P1)], to allow the clean water

to flow into Water Pump (EPB-WP2.6L), Spraying Lance [331(F)] and Nozzle

until blow out air only. Please to repeat the step at least 2 times, lastly keep

littleclean water in the tank to moisturize the Water Pump before storage.

Maintenance Guides

Problems and Remedies

337

338

339P

304

EPB-EC02

EPB-EC03

EPB-EC05

6)Rocket Switch (EPB-EC02),

i) Press down (=), power on, then adjust the

Governor Switch (EPB-EC03) to control the

flow as you needed.

ii) Press up (-), power on, the power is fixed

and the flow is dependent on type of nozzle

use [Recommended SCA/4(R) nozzle or any

nozzle which provided a flow rate below 0.8

L/Min at pressure 3 Bar].

iii) To off the power, press back to (0).

Attention: To save battery power, please to

disconnect or take out the battery when

storage. The Volmeter is off to confirm the

battery disconnected.

331(F)

TE/2A(P1)

SCA/4 321(P1)

5) To carry the sprayer, the shoulder strap hook

(339P) hooked on the stand guard (304).

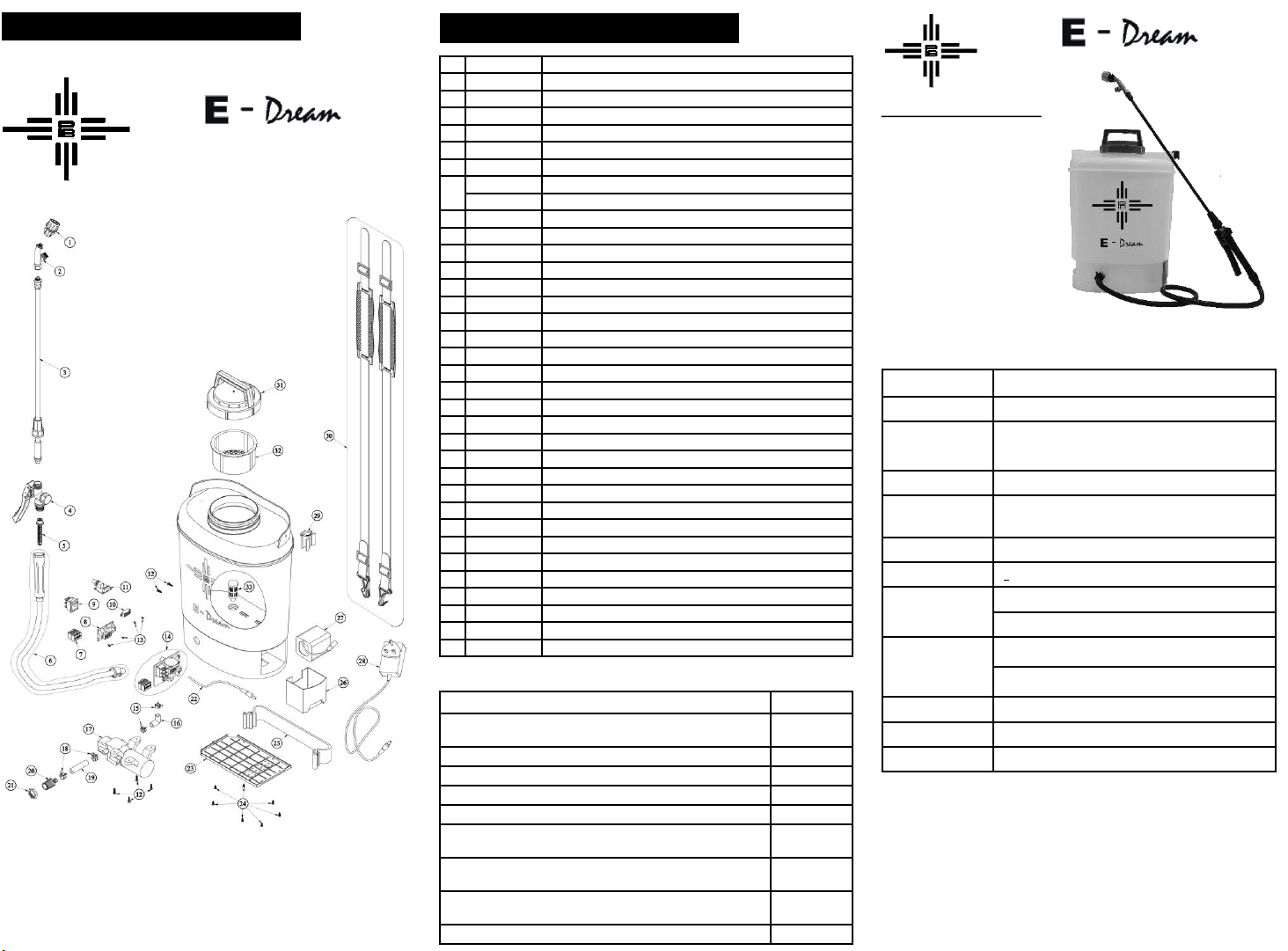

Battery Casing Lock

Draw Battery Casing Instruction

Pic. 1 Pic. 2 Pic. 3

Battery Casing (EPB-TK07) Battery (EPB-BT-6.6AH)

Press the battery casing lock upward and push the casing out as pic.1 & 2 shown. Then, use your finger to pull

battery casing out fully as pic. 3 shown, now you can take out the battery easily. Please scan the QR code for

details.

Installation of Battery Instruction

Pic. 1

Replace battery into the battery casing and make sure the position of the battery cable outlet at your right hand

side at arrow upward position as pic.1 & pic.2 shown. Place the cable and the connector as pic. 3 shown before

push in the battery casing fully into the battery housing as pic.4 shown. Please scan the QRcode for details.

Battery Cable Outlet Battery Housing

Battery Cable Connector

Charging Battery Instruction

Remember to charge the Battery (EPB-BT-6.6AH) each time after use. The following are the charging instruction

details:-

2) To wash the nozzle

(SCA/4) and filter

[322(P1)]

Remove the nozzle cap (SCA/4/1), suction filter (IEM-DC9) inside the tank and

the filter [322(P1)] from cleaning chamber for cleaning purpose. Then, replace

them back after cleaning.

3) Disconnect or take

out the battery

(EPB-BT- 6.6AH)

Remember to disconnect or take out the battery after spraying job to prevent

wastage of the power. Charge the battery if necessary.

SCA/4/1

Caution

4.) Only use the original Battery Charger (EPB-CG-UK) to charge the battery and unplug the Battery Charger

after 3 to 4 hours charging to prolong the life span of Battery Charger and the Battery (EPB-BT-6.6AH).

7.) Always dry the sprayer body and electrical control area before storage. Please store the sprayer under roof

and cool dry place.

1.) Not recommend to use powder form agrochemical in this sprayer due to the Water Pump design. If

unavoidable condition, please dissolve the powder form chemical in water perfectly then fill into the sprayer tank

through Strainer (303). Please clean the sprayer according to Maintenance Guide immediate after spraying job to

prevent the stuck of Water Pump.

2.) Thinner,Solvents and Petrochemical Solvents are prohibited to used.

Operating Instruction

Battery (EPB-BT-6.6AH)

Pic. 2 Pic. 3 Pic. 4

3.) To avoid chemical solution overflow from tank when filling. This is to protect electrical components from

wet.

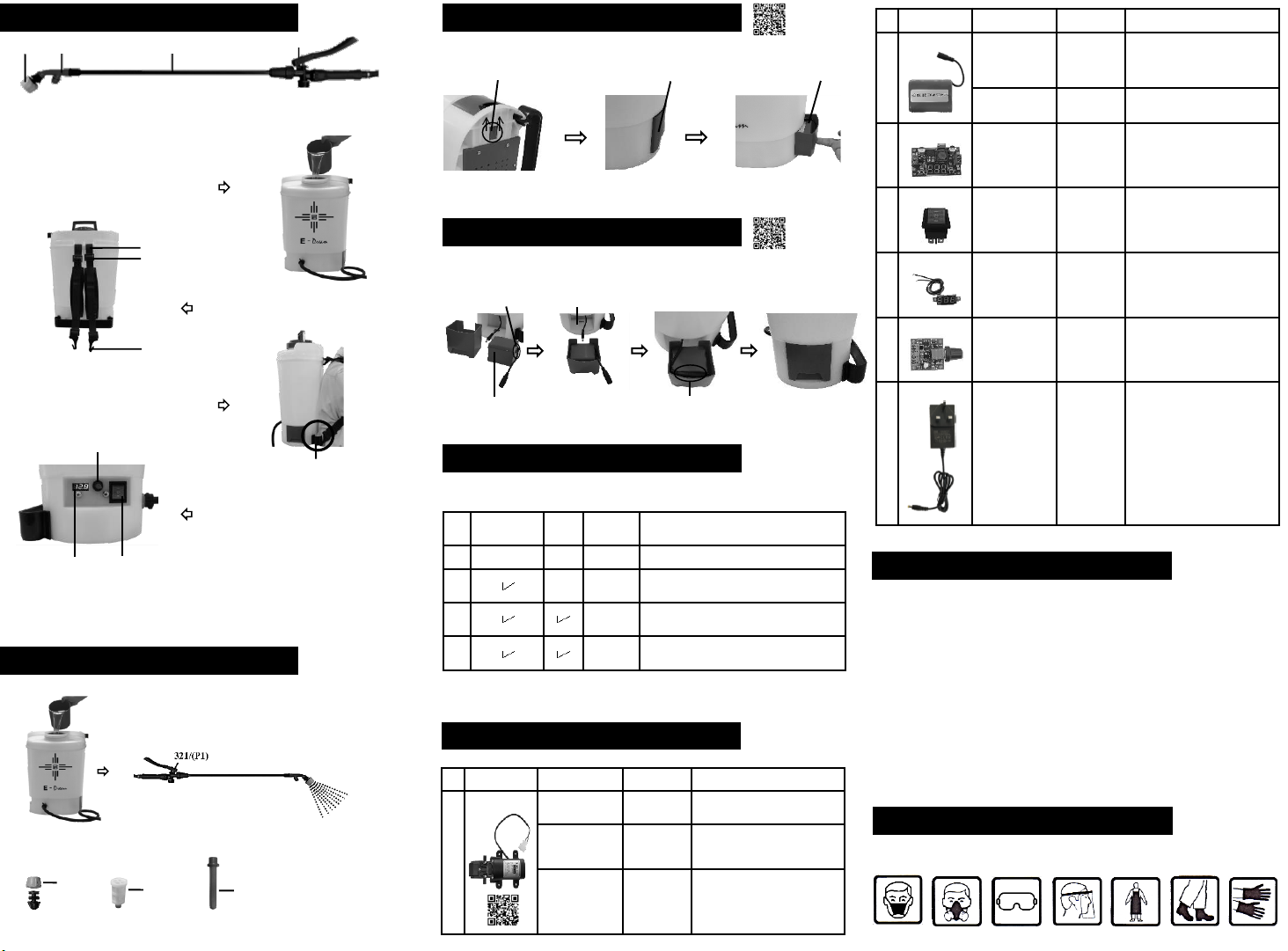

Practical Guide of Protective Clothing

To wear the appropriate personal protective clothing as pictograms below to prevent

direct contact or splashing of agrochemical during doing spraying job

Respirator Face Shield Hand GloveBoots

Apron

Goggle

No.