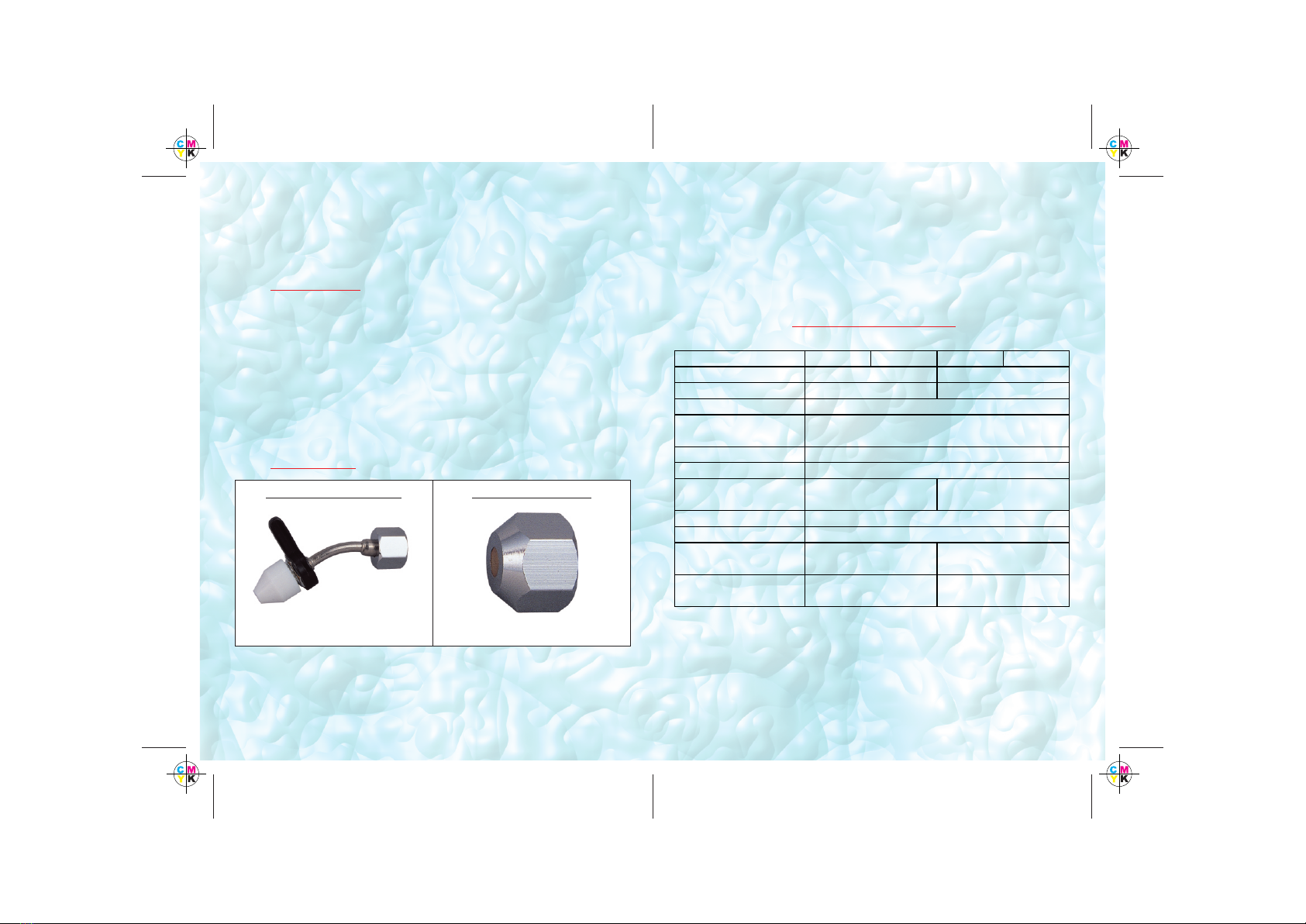

3. The spray is inconsistent.

Check if the nozzle has been blocked by contaminants /

foreign objects. If yes, clear the blockage by using

compressed air or by gently removing the object by use of

a wire brush or nozzle cleaner (spare provided). Be

careful not to damage the orifice of the nozzle, as this will

render it useless. If there are no contaminants and still the

spray is inconsistent, then the nozzle will have to be

replaced with a new one. Contact the nearest Service

Center for supply of a new nozzle.

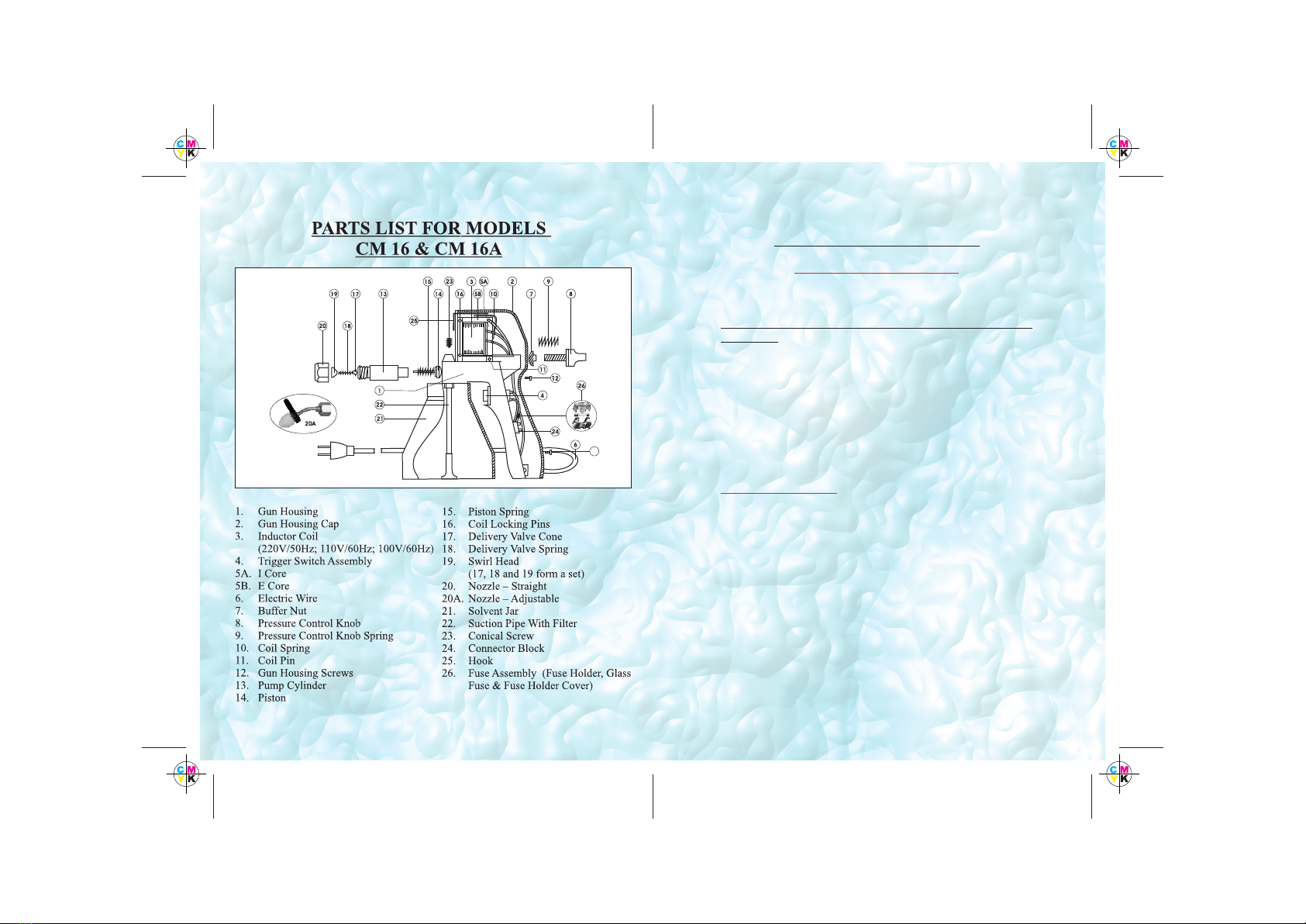

4. The unit is on, but there is no vibration. Instead there is a

humming sound.

Open the cylinder and check if the piston is seized. If yes,

gently remove the piston, clean the cylinder and the piston

and assemble back.

For any other problem please contact the Manufacturer

/nearest Service Centre for Repairs and Assistance.

9. Keeping the unit upright, point the nozzle towards the

fabric/item to be cleaned and switch on the gun by

pressing the trigger switch(part no.4). The trigger

switch is of the press to on/release to off type. The unit

can be switched off by removing the finger from the

switch.

10. The unit normally takes a few seconds to prime and

begin to spray the solvent.

11. The unit vibrates while in operation and this is the

normal working condition. A certain degree of sound is

also generated.

12. If the unit does not spray the solvent, turn the pressure-

control knob anticlockwise.

13. Once the unit begins to spray the solvent, adjust the

spray pressure by adjusting the pressure control knob

clockwise/anticlockwise. Turning the knob

anticlockwise increases the pressure and is more

suitable for thick fabrics, while turning the knob

clockwise, decreases the pressure, and is more suitable

for lighter fabrics.

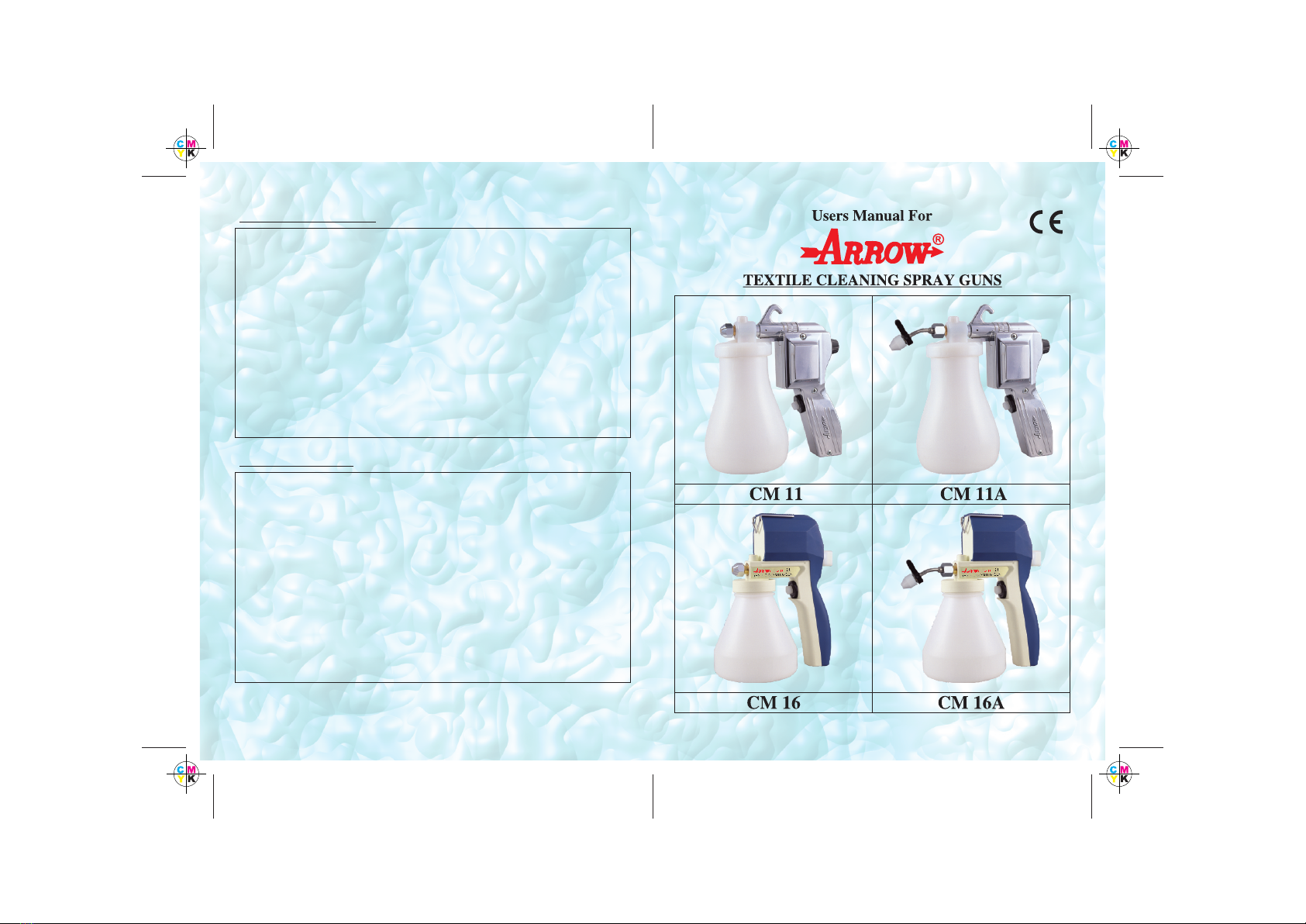

14. If the unit is fitted with the adjustable nozzle (in models

CM11A and CM16A only), the spray velocity and

spread can be further adjusted by turning the

adjustment knob on the nozzle. The nozzle is capable

of delivering a fine mist spray to a piercing straight-

line spray, by making suitable adjustments.

15. Maintain a distance of between 5-40 centimeters

between the nozzle and the fabric/item depending on

the type and thickness of the fabric, nature of item,

nature of spot/stain, and pressure adjusted.

16. Rinse out the dirt stain/clean the item by spraying the

solvent in a circular manner moving from outside of

the stain/dirt patch to the inside.

17. Once the stain has been removed, release the trigger

switch to switch off the unit.

Page 13 of 18 Page 6 of 18