Nothern Industrial tools Plasma 275 User manual

32497

Please read and save these instructions. Read through this owner’s manual carefully before

using product. Protect yourself and others by observing all safety information, warnings, and

cautions. Failure to comply with these instructions could result in personal injury and/or damage

to product or property. Please retain instructions for future reference.

1

Plasma 275

O

p

eratin

g

Instructions and Parts Manual Plasma Cutter

Description

The Plasma 275 is an IGBT inverter

plasma cutter with thermal overload

protection, a Trafimet torch and a built-in gas

regulator. This easy to use plasma cutter has

the power to cut up to 1/8 in. materials and a

pilot arc that makes cutting expanded metal

possible. This machine required single-phase

120V , 60 Hz input power.

Specifications and Dimensions

DESCRIPTION SPECIFICATION

Power Supply 1ph-120V-60HZ

No-load Voltage 320V

Output Range 16A

Duty Cycle 50% @ 16A

Air Pressure 4.5 CFM@ 60 PSI

Power Switch 125VAC 20Amps

Dimension (L x W x H) 17.7”x6.7”x9”

Weight 21 lbs

Removing from carton

1.1 Remove cartons, bags or Styrofoam containing the welder and accessories.

1.2 Check the contents with the packing list below.

1.3 After unpacking unit, inspect carefully for any damage that may have

occurred during transit. Check for loose, missing, or damaged parts. Shipping

damage claim must be filed with carrier.

ITEM QTY.

Plasma Cutter 1 unit

Grounding Cable 1 pc

TRAFIMET Cutting Torch 1 pc

Electrode 3 pcs

Nozzle 3 pcs

Operator’s Manual 1set

″

2

Plasma Cutter

O

p

eratin

g

Instructions and Parts Manual

Plasma Cutter

Plasma 275

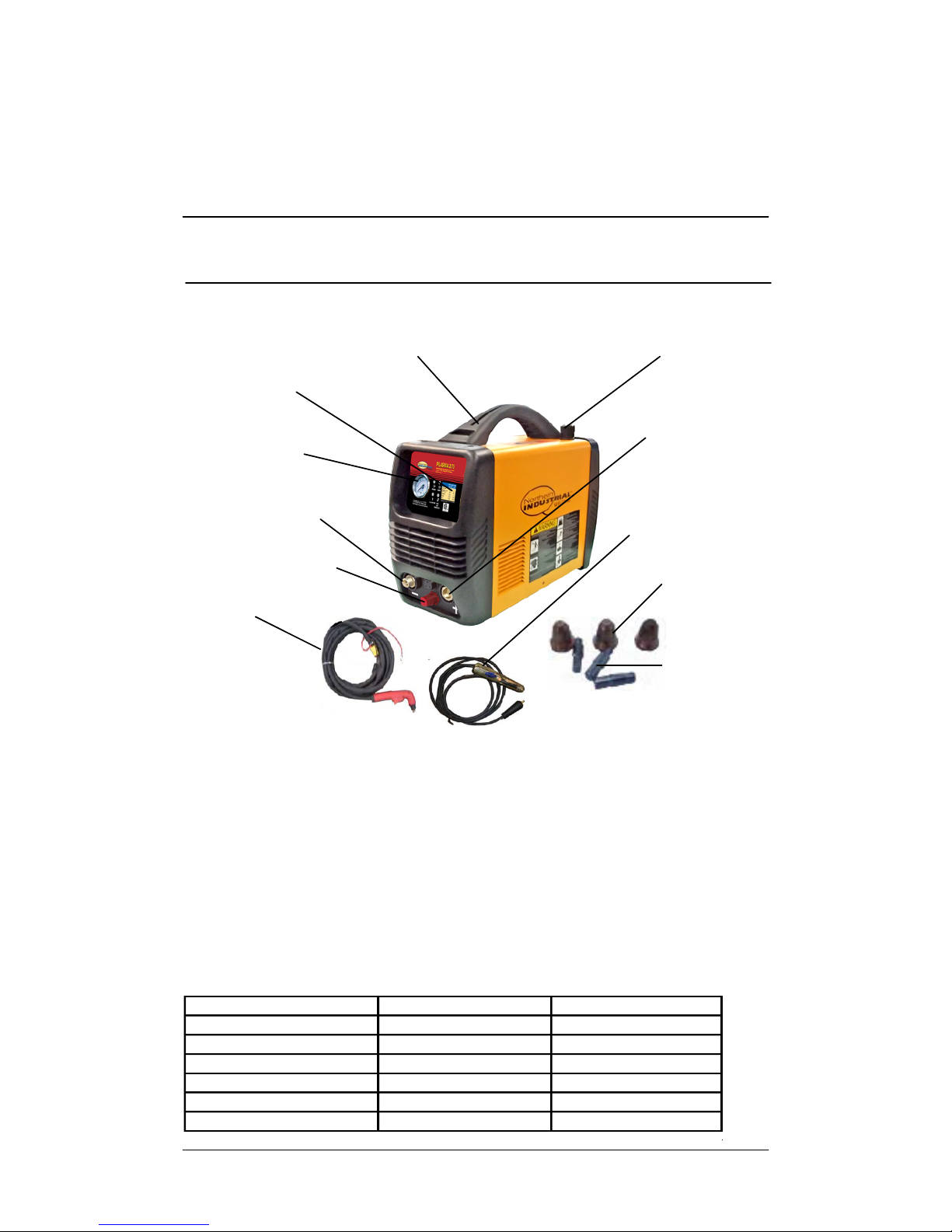

Know your Welder

Gas Pressure Display

The built-in gas display is used for reading the output gas pressure when cutting.

Gas Pressure Adjustor

It is used for adjusting the gas pressure. The gas pressure can be read from the

gas pressure display on the front panel. Normally, the pressure should be

adjusted between 55-90psi.

When cutting, this light is on to show the unit is on working mode.

Work Indicator

Cutting Chart

Handle

Gas Pressure

Cutting chart

Display

Gas Pressure

Adjustor

Connector for

Cutting Torch

Connector for

Grounding Cable

Connector for Torch

Arc Starting Cable

Cutting Torch

Grounding Cable

with Clamp

Nozzle

Electrode

This chart indicates the thickness of different types of materials that .

this unit can cut at a rate of 10 inches per minute.It also shows sever capacity.

Sever thicknesses may take more time than 10 inches per minute

Material Clean cut Sever

Mild steel 5/32″ 1/4″

Stainless steel 1/8″ 3/16″

Galvanized 1/8″ 5/32″

Aluminum 3/32″ 1/8″

Copper 1/16″ 3/32″

Brass 1/16″ 3/32″

3

Plasma Cutter

O

p

eratin

g

Instructions and Parts Manual

Plasma Cutter

Plasma 275

Low Gas Indicator Light

This light will be on when the gas flow is low.

Ground Cable Connection

Connect the ground cable to the postive (+) receptacle on the front of the plasma

cutter. The ground cable clamp connects to your work piece.

Torch Control Cable Connection

The black cable on the torch connects to the 3-Prong receptacle on the front of

the machine. Push on to snap in place. This is the control cable for the torch.

Torch Arc Starting Cable Connection

This connector is for the red cable of the torch. It is used to help the arc starting.

Torch Connection

Connect the torch to the negative (-) receptacle.

Protection indicator Light

When the unit is in thermal overload, is over voltage or lacking voltage, the

indicator will be on and the machine will stop working. When the unit is cooled

down and voltage stabilizes, the unit will return to work automatically.

Power indicator Light

This light will turn on when the input power cord is plugged into the power supply

and the power switch on the back of the plasma cutter is in the "ON" position.

Gas Hose Connection

The gas hose connection is on the back panel of the plasma cutter. This

connections requires a 1/4 inch NPT connection (Not supplied). The other end of

the gas hose connects to an air compressor or compressed air supply.

Power switch

It is the on/off switch. After the machine is connected to the input power supply,

turn on this switch. The power indicator on the front panel will turn on.

Power cord

Specification Table

The specification table is located on the back panel of the plasma cutter. The

Serial Number of this unit is listed on the specification table.

General Safety Information

1.1 Your Welding/Cutting Environment

-Keep the environment that you will be we

Plug this unit into a grounded 20 Amp 120V Circuit

lding/cutting in free from flammable

materials.

-Always keep a fire extinguisher within reach.

-Always have a qualified person install and operate this equipment.

-Make sure the area is clean, dry and well ventilated. Do not operate the plasma

cutter in humid, wet or poorly ventilated areas.

-Always have your plasma cutter maintained by a qualified technician in

accordance with local, state and national codes.

4

Plasma Cutter

O

p

eratin

g

Instructions and Parts Manual

Plasma Cutter

Plasma 275

-Always be aware of your work environment. Be sure to keep other people,

especially children, away from you while you are cutting.

-Keep harmful arc rays shielded from the view of others.

-Mount the plasma cutter on a secure bench or cart that will keep the welder

secure and prevent it from tipping over or falling.

1.2 Your Plasma Cutter’s Condition

-Check all cables, power cord and torch to be sure the insulation is not damaged.

Always replace or repair damaged components before using the plasma cutter.

-Check all components to ensure they are clean and in good operating condition

before use.

1.3 Use of Your Plasma Cutter

Do not operate the plasma cutter if the torch is wet. Do not immerse the plasma

torch. Do not stand in water while using this plasma cutter. These components

and the plasma cutter must be completely dry before attempting to use it.

-Follow the instructions in this manual.

-Keep the plasma cutter in the off position when not in use.

-Connect ground lead as close to the area being cut as possible to ensure a

good ground.

-Do not allow any body part to come in contact with the material being cut, or to

the ground or electrode from another plasma cutter or welder.

-Do not cut if you are in an awkward position. Always have a secure stance while

cutting to prevent accidents. Wear a safety harness if working above ground.

-Do not drape cables over or around your body.

- Wear eye protection (see ANSI Z49.1 safety standard) while cutting to protect

your eyes from harmful UV and IR ray’s.

-Wear proper gloves and protective clothing to prevent your skin from being

exposed to hot metals, UV and IR rays.

-Do not overuse or overheat your plasma cutter. Allow proper cooling time

between duty cycles.

-Keep hands and fingers away from moving parts.

- Do not point the Plasma torch at any body part or at anyone else.

-Always use this plasma cutter in the rated duty cycle to prevent excessive heat

and failure.

1.4 Specific Areas of Danger,

Caution or Warning

Electrical Shock

Plasma cutters can produce a shock that can cause injury or death.

Touching electrically live parts can cause fatal shocks and severe

burns. While cutting, all metal components connected to the wire

are electrically hot. Poor ground connections are a hazard, so secure the ground

lead before cutting.

-Wear dry protective apparel: coat, shirt, gloves and insulated footwear.

Table of contents

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual