NOVABO SQUEALER-GSM User manual

SQUEALER-GSM –manual

To avoid problems in operating the unit, it is recommended to read this manual

thoroughly before using it. Do not interfere with construction or carry out

repairs yourself. Maintenance or repair work should be carried out by qualified

personnel (installer or company service). The manufacturer assumes no

responsibility for any damage resulting from improper assembly, malfunction

(device, software) or damage to the controller.

Description

SQUEALER controller is a modern microprocessor device for continuous monitoring

of the status of selected probes (MAX, OILER, SLUDO). The basic parameters of the

controller are 3 inputs, 3 relay output, LEDs indicating normal state, failure status and

alarm status, buzzer generating an alarm signal, alarm output, relay output, activated

at the time of alarm.

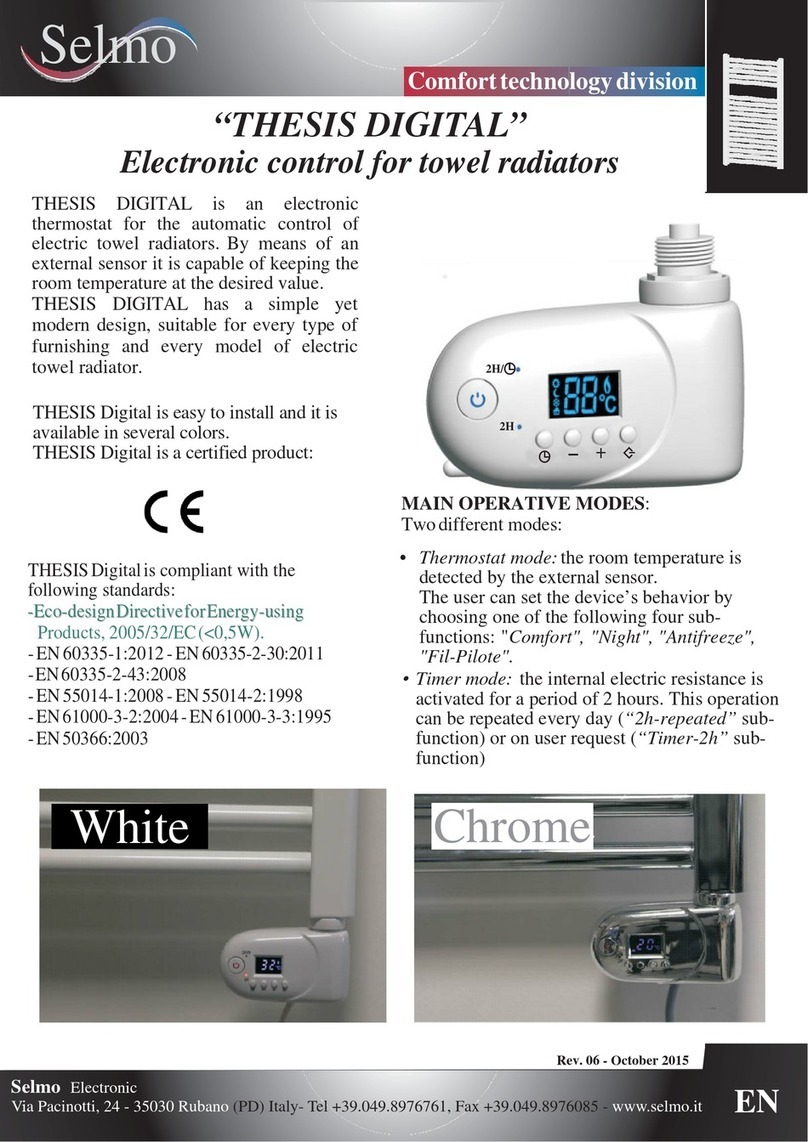

Front panel description

- LED lights continuously when the

power of the device is ON.

- the number of the LED flashes

indicates the GSM signal strength

(max. 4 flashes).

- LED lights when the

probe detects ALARM

- LED is ON constantly,

when the sensors are

connected and the dipswitches are

properly set. Blinking LED indicates an

alarm sensor.

- The alarm is shown by the steady

light of the red LED + acoustic signal.

- A short press [<1] s button - delete

the buzzer alarm. Long press button

[> 2s]- clearing the alarm and restore the

relay to the state without an alarm.

- Checking the optical and acoustic

signals and relay outputs. Test can be

activated only when there is no alarm

sensors. Each time you press the button

activates / deactivates the function test.

- 3 inputs

- 3 output

- PS 230V

- battery input

The alarm module, powered by

230V, is used to measure and

control the level of the sludge

layer, oil substances, grease,

petroleum substances and

overflow of the tank.

SQUEALER-GSM –manual

Cooperating Devices

MAX - optical probe for overflow

or maximal level.

COUPLER-01 –

hermetic coupling

plug

OILER - thickness measurement of

fat, oil, mineral oil, organic,

petroleum substances.

NFIX-01 –set for

mounting the

probe

SLUDO - detecting the sediment

layer in the separator or the

maximum level

CABLE-5, CABLE-10

–sensor extension

cable

Probes assembly

-Lower the sensor so that the measuring

point is at a exceeding level.

-Attach the sensor cable to the mounting

bracket NFIX.

-Use the COUPLER connector to lengthen

the cable

MAX sensor

The probe with a standard length of 5 m should

be hung on the FIX holder, which should be

placed directly under the manhole - preferably

in the inspection hole in the separator cover.

OILER sensor

The probe should be placed at the appropriate

depth / height and the sensor cable should be

wound around the mounting eye (FIX) in such

a way that the cable is blocked and the probe

does not change its position on the handle

during operation.

SLUDO sensor

The mounting height of the sensor depends on

the volume of the sludge in the separator. The

amount of accumulated sludge can not exceed

1/3 ÷ 1/2 of the height between the bottom of

the outlet pipe and the bottom of the tank.

When installing the sensor, it should be noted

that the deposit usually accumulates in the

measurement zone at different heights, which

depends mainly on the speed of the flowing

sewage. Where the flow velocity is the smallest, it will gather the most and vice versa.

Connect the probe with a 5 m standard cable to the holder. The handles should be

placed directly under the hatch - preferably in the inspection hole in the separator

cover.

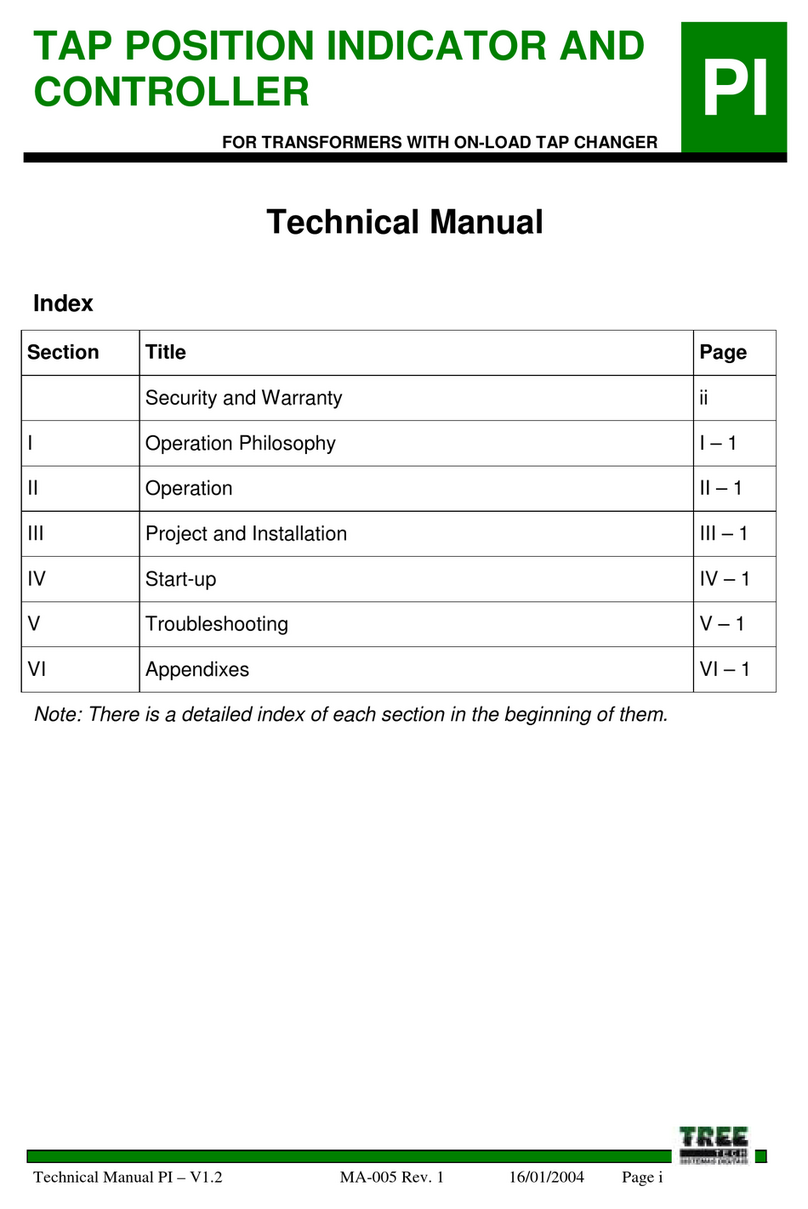

2

Relay

outputs

Power supply

230V AC

DIP

switches

Front panel

connector

Transformer

Battery

OILER

sensor

MAX

sensor

SLUDO

sensor

Clock

battery

GSM

modul

SIM card

socket

USB

Tamper

SQUEALER-GSM –manual

Description of controller connectors

Programming from PC

a) visit WWW.NOVABO.COM

b) install the driver for the USB cable:

www.novabo.com >>> products >>> USB driver

c) Install the NCONFIG program:

www.novabo.com >>> products >>> Nconfig

DIP SWITCH configuration

DIP1

"ON" - SENSOR MAX active - probe 1 connected

"OFF" - SENSOR MAX inactive - probe 1 not connected

DIP2

"ON" - SENSOR OILER active - probe 2 connected

"OFF" - SENSOR OILER inactive - probe 2 not connected

DIP3

"ON" - SENSOR SLUDO active - probe 3 connected

"OFF" - SENSOR SLUDO inactive - probe 3 not connected

DIP4

"ON" - alarm delay time from the input 5 sec

"OFF" - alarm delay time from the input 30 s (recommended)

DIP5

"ON" - inverse input logic SENSOR 1 (15mA - normal)

"OFF" - normal input logic SENSOR 1 (9mA - normal)

DIP6

"ON" - alarm on 3 relays parallel

"OFF" - alarm on 3 relays separately IN1>OUT1, IN2>OUT2, IN3>OUT3,

3

SQUEALER-GSM –manual

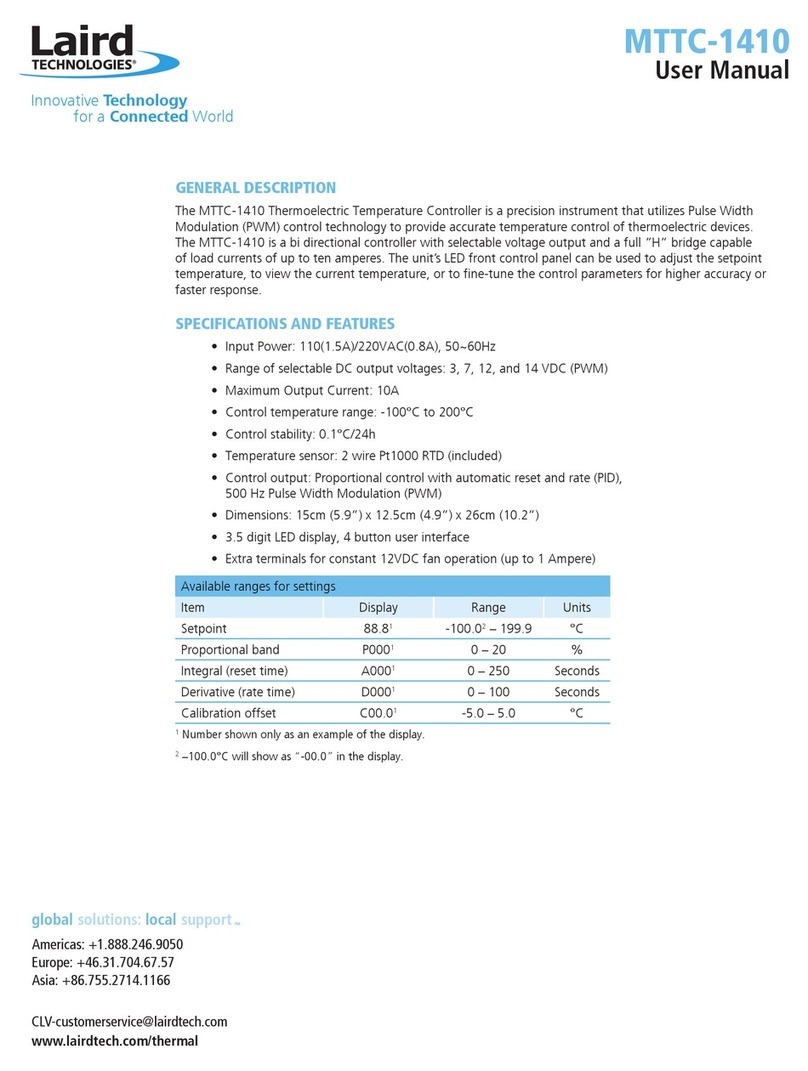

Technical Data

Supply voltage

230V

Max. fuse

1.25A

Power (nominal)

2.2 VA

Output:

NO/NC relays potential-free, 2A/120VAC or 2A/24VDC

Ambient temperature

-30°C ÷ +60°C

Degree of protection

IP 65

Dimensions without glands

187x122x90mm

Cable glands

M12, cable dimensions Ø 4.0-6.0 mm

Mounting method

Vertical

CE conformity

Directive EMC 2004/108/WE

EMC/immunity: PN-EN 50130-4:2012, PN-EN 61000-6-

1:2008

EMC/ immunity: PN-EN 55022:2011, PN-EN 61000-6-

3:2008+A1:2012

Instructions for safe use

The device should be used for its intended purpose. Before installing, please read the

device's instructions. Check its technical condition. Ensure that there is no

mechanical damage to the housing and cable. During maintenance work, the device

must be disconnected from the power supply.

When installing in places with a potentially explosive atmosphere, comply with the

regulations in force in your country. When servicing, checking and repairing in

explosive atmospheres, the national standards must be observed.

Checks and inspections

The manufacturer recommends inspections of the entire system once every 6

months or during the emptying of the separator. During the inspection, clean the

probe and check that it has no mechanical damage. Then, perform an operation test

in cooperation with the SQUEALER controller.

4

Popular Controllers manuals by other brands

OCEM

OCEM DIAM3200 IGBT Use and maintenance manual

HighPoint

HighPoint RocketRAID 644L Quick installation guide

Quick

Quick QCC DRV CH4 Manual of use and maintenance

Nordmann Engineering

Nordmann Engineering SBC Installation and operating instructions

IAI

IAI PCON-CA user guide

Samsung

Samsung MWR-WE13N Quick Reference Technical Handbook