PCON-CA/CFA/CB/CFB/CGB/CGFB,

ACON-CA/CB/CGB, DCON-CA/CB/CGB

First Step Guide Seventh Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (DVD) included with the product in addition to

this First Step Guide to ensure correct use. This First Step Guide is original manual written by only this product.

• Using or copying all or part of this Instruction Manual without permission is prohibited.

• The company names, names of products and trademarks of each company shown in the sentences are registered

trademarks.

Product Check

The standard configuration of this product is comprised of the following parts.

If you find any fault with the product you have received, or any missing parts, contact us or our distributor.

1. Parts

No. Part Name Model Reference

1 Controller Main Body Refer to “How to read the model plate”,

“How to read the model of the controller”

Accessories

2 Field Network Connector MSTB2.5/5-STF-5.08AU (CC-Link)

MSTB2.5/5-STF-5.08AUM (DeviceNet)

Prepare for separately except for CC,

DV type.

3 Power Connector FMC1.5/8-ST-3.5

(Supplier : PHOENIX CONTACT)

Recommended cable size AWG16 to 20

(1.25 to 0.5mm2)

4 Dummy plug DP-5 For the safety category compliant type

5 Absolute Battery (Option) AB-7 or SEP-ABU* If applicable for Simple Absolute Type

6 Serial Absolute Battery (Option) AB-5 If applicable for Serial Absolute Type

(for ACON only)

7 First Step Guide

8 Instruction Manual (DVD)

9 Safety Guide

2. Teaching Tool (to be purchased separately)

A teaching tool, such as PC Software, is necessary when performing programming and commissioning, such

as editing position data or parameters.

Please utilise any of the following teaching tools.

(Note) TB-01/01D/01DR are not applicable for CC-Link IE.

No. Part Name Model

1 PC Software

(with RS232C converter adapter + external equipment communication cable) RCM-101-MW

2 PC Software

(with USB converter adapter + USB cable + external equipment communication cable) RCM-101-USB

3

Touch Panel Teaching TB-01 (Standard / with Deadman Switch Attached on the Left/ Right side)

TB-01/01D/01DR

4 Touch Panel Teaching TB-02 (Standard / with Deadman Switch Attached) TB-02/02D

5 Data Setter TB-03 TB-03

3. Instruction Manuals related to this product, which are contained in the Instruction Manual (DVD).

No. Name Manual No.

1 PCON-CA/CFA Controller Instruction Manual ME0289

2 PCON-CB/CFB Controller Instruction Manual ME0342

3 ACON-CA, DCON-CA Controller Instruction Manual ME0326

4 ACON-CB Series Contoroller, DCON-CB Series Contoroller Instruction Manual ME0343

5 PC Software RCM-101-MW/RCM-101-USB Instruction Manual ME0155

6 Touch Panel Teaching TB-01/TB-02/TB-03 Position Controller Instruction Manual

ME0324/ME0355/ME0376

7 Instruction Manual for the Serial Communication [for Modbus] ME0162

8 CC-Link Instruction Manual ME0254

9 DeviceNet Instruction Manual ME0256

10 PROFIBUS-DP Instruction Manual ME0258

11 CompoNet Instruction Manual ME0220

12 MECHATROLINK-Ⅰ/Ⅱ Instruction Manual ME0221

13 MECHATROLINK-Ⅲ Instruction Manual ME0317

14 EtherCAT Instruction Manual ME0273

15 EtherNet/IP Instruction Manual ME0278

16 PROFINET-IO Instruction Manual ME0333

17 MECHATROLINK-Ⅲ Instruction Manual ME0317

18 CC-Link IE Instruction Manual ME0389

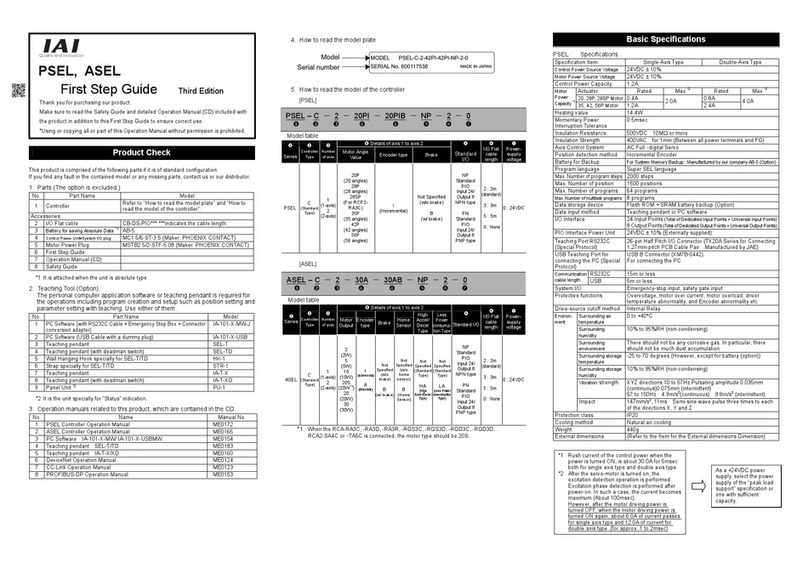

4. How to read the model plate

5. How to read the model of the controller

z PCON PCON-CA-56P WAI-EP-2-0-ABU-DN-**

z ACON

ACON-CA-30 I-EC-2-0-AB-DN-**

z DCON

DCON-CA-3 I-EP-2-0-DN-**

Basic Specifications

PCON List of Specifications

Description

Item PCON-CA/CB/CGB PCON-CFA/CFB/CGFB

Number of controlled axes 1-axis

Power-supply Voltage 24V DC ±10%

20P, 28P, 28SP MAX. 1A

35P, 42P, 56P MAX. 2.2A

RCP2

RCP3

Motor

Type

60P, 86P MAX. 6A

High-thrust function

is disabled MAX.2.2A

28P, 35P, 42P,

56P

High-thrust function

is enabled

Rated 3.5A /

MAX. 4.2A

Load

Capacity

(including

control side

current

consumption)

(Note1)

RCP4

RCP5

RCP6

Motor

Type

56SP, 60P, 86P MAX. 6A

Power Supply for Electromagnetic Brake

(for actuator equipped with brake) 24V DC ±10% 0.15A (MAX.)

RCP2 , RCP3 5W 26.4W Heat Generation

RCP4 to RCP6 3W

Rush Current (Note2) 8.3A 10A

Transient Power Cutoff Durability MAX. 500μs

Motor Control System Weak field-magnet vector control

RCP2 to RCP5 Incremental Encoder, Battery-less Absolute Encoder Resolution 800pulse/rev Corresponding

Encoder RCP6 Battery-less Absolute Encoder Resolution 8192pulse/rev

Actuator Cable Length MAX. 20m

Serial Communication Interface

(SIO Port)

RS485 : 1 CH (based on Modbus Protocol RTU/ASCII)

Speed : 9.6 to 230.4Kbps

Control available with serial communication in the modes other than the pulse train

PIO Type Signal I/O dedicated for 24V DC (selected from NPN/PNP) … Input 16 points max.,

output 16 points max.

Cable length MAX. 10m

External

Interface

Fieldbus Type DeviceNet, CC-Link, PROFIBUS-DP, CompoNet, MECHATROLINK-Ⅰ/Ⅱ,

EtherCAT, EtherNet/IP, PROFINET-IO, MECHATROLINK-Ⅲ*, CC-Link IE*

(* Some types cannot connect it.)

Data Setting and Input PC Software, Touch Panel Teaching, Teaching Pendant, Data Setter

Data Retention Memory Saves position data and parameters to non-volatile memory

(There is no limitation to the number of times data may be written.)

Operation Mode Positioner Mode/Pulse Train Control Mode (selected by parameter setting)

Number of Positions in Positioner Mode Standard 64 points, MAX. 512 points (PIO Type)

(Note) Number of positions differs depending on the selection in PIO pattern.

Differential System (Line Driver System) : MAX. 200kpps

Cable length MAX. 10m

Input Pulse Frequency

Open Collector System : Not applicable.

* If the host applies the open collector output, prepare AK-04 (option) separately to

convert to the differential type.

Command Pulse Multiplying Factor

(Electrical Gear : A/B)

1/50 < A/B < 50/1

Setting Range of A and B (set to parameter) : 1 to 4096

Pulse

Train

Interface

Feedback Pulse Output None

LED Display

(mounted on Front Panel)

SV (GN)/ALM (RD)

: Servo ON/Alarm generated

STS0 to 3

: Status display

RDY (GN)/ALM (RD)

: Absolute function in normal / absolute function error (for the

simple absolute type)

1, 0 (GN) (RD)

: Absolute function status display (for the simple absolute type)

Electromagnetic Brake Compulsory Release

Switch (mounted on Front Panel)

Switching NOM (standard)/BK RLS (compulsory release)

Insulation Resistance 500V DC 10MΩ or more

Protection Function against Electric Shock

Class I basic insulation

Incremental Type Screw fixed type : 250g or less

DIN rail fixed type : 285g or less

Screw fixed type : 270g or less

DIN rail fixed type : 305g or less

Weight

(Note3)

Simple Absolute Type

(including 190g for battery)

Screw fixed type : 450g or less

DIN rail fixed type : 485g or less

Cooling Method Natural air-cooling Forced air-cooling

External dimensions Screw fixed type : 35W×178.5H×69.6D

DIN rail fixed type : 35W×185H×78.1D

Screw fixed type : 35W×190H×69.6D

DIN rail fixed type : 35W×196.5H×78.1D

Surrounding Air Temperature 0 to 40°C

Surrounding Humidity 85%RH or less (non-condensing)

Surrounding Environment [Refer to Installation Environment]

Surrounding Storage

Temperature

-20 to 70°C (Excluding battery)

Usage Altitude 1000m or less

Protection Class IP20

Environment

Vibration Durability Frequency 10 to 57Hz / Swing width : 0.075mm

Frequency 57 to 150Hz / Acceleration 9.8m/s2

XYZ directions Sweep time : 10 minutes Number of sweep : 10 times

Note1 Add an additional 0.3A inrush for Fieldbus Types.

Note2 In-rush current will flow for approximately 5msec after the power is turned on (at 40°C).

Note that the value of in-rush current differs depending on the impedance of the power supply line.

Note3 Add an additional 30g for CA/CB/CGB Fieldbus Type. Add an additional 10g for CFA/CFB/CGFB Fieldbus Type.

ACON, DCON List of Specifications

Description

Item ACON-CA/CB/CGB DCON-CA/CB/CGB

Number of controlled axes 1-axis

Power-supply Voltage 24V DC ±10%

Series Motor Type Rated Max. Power

Consumption MAX.(Note5) Rated MAX.

2W 0.8A 4.6A

5W 1.0A 6.4A

10W (RCL) 1.3A 6.4A

10W (RCA/ RCA2) 1.3A 2.5A 4.4A

20W 1.3A 2.5A 4.4A

20W (Model: 20S) 1.7A 3.4A 5.1A

RCA,

RCA2,

RCL

30W 1.3A 2.2A 4.0A

Load

Capacity

(It does

not

including

control

side

current

consump

tion)

(Note1)

RCD 3W 0.7A 1.5A

Power Supply for Electromagnetic

Brake (for actuator equipped with brake) 24V DC ±10% 0.15A (MAX.)

Heat Generation 8.4W 4W

Rush Current (Note2) 10A

Transient Power Cutoff Durability MAX. 500μs

<Identification for IAI use only>

* There is no identification in some cases.

<Type of Installation>

(Not Specified) : Screw Attachment Type

DN : DIN Rail Mounting Type

<Applicable to Simplified Absolute Unit>

(Not Specified): Incremental

/ Battery-less Absolute

AB : Simple Absolute Type

(With the Absolute Battery)

ABU : Simple Absolute Type

(With the Absolute Battery Unit

(SEP-ABU))

ABUN : Simple Absolute Type

(With no Absolute Battery)

<Power-supply Voltage>

0 : 24V DC

<I/O Cable Length>

0 : Equipped with no cable

2 : 2m (Standard)

3 : 3m

5 : 5m

Warning : Operation of this equipment requires detailed installation and operation instructions which are

provided on the DVD Manual included in the box this device was packaged in. It should be retained

with this device at all times.

A hardcopy of the Manual can be requested by contacting your nearest IAI Sales Office listed at

the back cove

of the Instruction Manual or on the First Step Guide.

Serial number

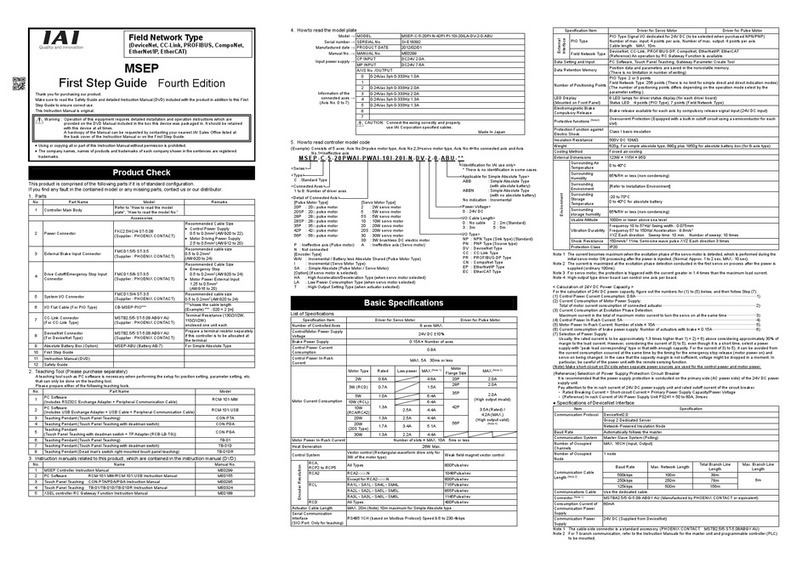

Model

Model

SER NO.

Input

Output

Actuator **

CAUTION: Connect the wiring correctly and

properly, use IAI specified cables

or min 60°C Cu wire.

IP20

*********

*********

DC24V A

0-24Vac,3ph,0-333Hz, A

*****

Applicable to Fieldbus

<Identification for IAI use only>

* There is no identification in some cases.

<Type of Installation>

(Not Specified) : Screw Attachment Type

DN : DIN Rail Mounting Type

<Applicable to Simplified Absolute Unit>

AB : Simple Absolute Type

(With the Absolute Battery)

ABU : Simple Absolute Type

(With the Absolute Battery Unit

(SEP-ABU))

ABUN : Simple Absolute Type

(With no Absolute Battery)

<Power-supply Voltage>

0 : 24V DC

<I/O Cable Length>

0 : Equipped with no cable

2 : 2m (Standard)

3 : 3m

5 : 5m

<Identification for IAI use only>

* There is no identification in some cases.

<Type of Installation>

(Not Specified) : Screw Attachment Type

DN : DIN Rail Mounting Type

<Power-supply Voltage>

0 : 24V DC

<I/O Cable Length>

0 : Equipped with no cable

2 : 2m (Standard)

3 : 3m

5 : 5m

<Series>

<Type>

CA/CB : Standard Type

CFA/CFB : High-Thrust Actuator

Connection Type

CGB

:

Sagety Categories Complied Type

CGFB

: High-Thrust Actuator

Connection Sagety Categories

Complied Type

<Detail of Connected Axis>

[Motor Type]

20P : 20□ pulse motor, 20SP : 20□ pulse motor

28P : 28□ pulse motor, 28SP : 28□ pulse motor

35P : 35□ pulse motor, 42P : 42□ pulse motor

42SP : 42□ pulse motor, 56P : 56□ pulse motor

56SP : 56□ pulse motor, 60P : 60□ pulse motor

86P : 86□ pulse motor

[Encoder Type]

WAI : Incremental / Battery-less Absolute Shared

SA : Simple Absolute

<I/O Type>

NP : NPN Type (Sync. Type) (Standard),

PN : PNP Type (Source Type),

PLN : Pulse Train Control NPN Type (Sync. Type),

PLP : Pulse Train Control PNP Type (Source Type),

DV : DeviceNet Connection Type, CC : CC-Link Connection Type

PR : PROFIBUS-DP Connection Type, CN : CompoNet Connection Type

PRT : PROFINET-IO Connection Type, EC : EtherCAT Connection Type

EP : EtherNet/IP Connection Type, ML : MECHATROLINK-Ⅰ/Ⅱ Connection Type

ML3 : MECHATROLINK-Ⅲ Connection Type (Except for PCON-CA/CFA)

CIE : CC-Link IE Type (PCON-CB/CFB/CGB/CGFB only)

<Series>

<Type>

CA/CB : Standard Type

CGB : Safety Categories Complied Type

<Detail of Connected Axis>

[Motor Type]

2 : 2W AC servo motor

5 : 5W AC servo motor

10 : 10W AC servo motor

20S : 20W AC servo motor

20 : 20W AC servo motor

30 : 30W AC servo motor

[Encoder Type]

WAI : Incremental / Battery-less Absolute

shared (CB only)

I : Incremental A : Serial Absolute

[Option]

HA : High Acceleration/Deceleration Type

LA : Low Power Consumption Type

No description : Standard Type

<I/O Type>

NP : NPN Type (Sync. Type) (Standard), PN : PNP Type (Source Type),

PLN : Pulse Train Control NPN Type (Sync. Type),

PLP : Pulse Train Control PNP Type (Source Type),

DV : DeviceNet Connection Type, CC : CC-Link Connection Type

PR : PROFIBUS-DP Connection Type, CN : CompoNet Connection Type

PRT : PROFINET-IO Connection Type, EC : EtherCAT Connection Type

EP : EtherNet/IP Connection Type, ML : MECHATROLINK-Ⅰ/Ⅱ Connection Type

ML3 : MECHATROLINK-Ⅲ Connection Type (Except for ACON-CA)

CIE : CC-Link IE Type (ACON-CB/CGB only)

<Series>

<Type>

CA/CB : Standard Type

<Detail of Connected Axis>

[Motor Type]

3 : 2.5W DC Brushless motor

[Encoder Type]

I : Incremental

<I/O Type>

NP : NPN Type (Sync. Type) (Standard), PN : PNP Type (Source Type),

PLN : Pulse Train Control NPN Type (Sync. Type),

PLP : Pulse Train Control PNP Type (Source Type),

DV : DeviceNet Connection Type, CC : CC-Link Connection Type

PR : PROFIBUS-DP Connection Type, CN : CompoNet Connection Type

PRT : PROFINET-IO Connection Type, EC : EtherCAT Connection Type

EP : EtherNet/IP Connection Type, ML : MECHATROLINK-Ⅰ/Ⅱ Connection Type

ML3 : MECHATROLINK-Ⅲ Connection Type (Except for DCON-CA)

CIE : CC-Link IE Type (DCON-CB only)