NOVACAT V10 ED Operational manual

Operator‘s manual

GB

+ INSTRUCTIONS FOR PRODUCT DELIVERY . . . Page 3

"Translation of the original Operating Manual" Nr. 99 3846.GB.80Q.1

• Disc mower

NOVACAT V10 ED/RC

(Type 3846 : + . . 01295)

1500_GB-PAGE 2

Product liability, information obligation

Product liability obliges manufacturers and dealers to issue operating instructions for the machine at the point of sale and to instruct

the customer on the operation, safety and maintenance regulations governing the machine.

A confirmation is required to verify that the machine and operating instructions have been handed over correctly.

For this purpose

- Document A is to be signed and returned to Pöttinger or via the internet to www.poettinger.at

- Document B remains with the specialist dealer handing over the machine.

- The customer receives document C.

For the purposes of product liability law, every farmer is an entrepreneur.

In the terms of product liability law, damage to property is any damage arising due to the machine, but not to the machine, and an

excess (500 euros) exists for this liability.

Corporate damage to property within the terms of the product liability law is excluded from this liability.

Be advised! The operating instructions must also be handed over with any subsequent machine sale or transfer and the transferee

must be instructed in the regulations stated.

Pöttinger - Trust creates AfÀnity - since 1871

"Quality pays for itself." Therefore we apply the highest quality standards to our products which are constantly monitored by our

in-house quality management and our management board. Because the safety, perfect function, highest quality and absolute

reliability of our machines in operation are the core competencies for which we stand.

There may be deviations between these instructions and the product as we are constantly developing our products. Therefore no

claims may be derived from the data, illustrations and descriptions. Please contact your Specialist Service Centre for any binding

information about specific features of your machine.

We would ask you to please understand that changes to the scope of supply with regard to form, equipment and technical

specifications are possible at any time.

Any form of reprint, translation or reproduction, including excerpts, requires the written approval of Pöttinger Landtechnik GmbH.

All rights according to copyright laws remain expressly reserved by Pöttinger Landtechnik GmbH.

© Pöttinger Landtechnik GmbH – 31st October 2012

Refer to PÖTPRO for additional information about your machine:

Are you looking for suitable accessories for your machine? No problem! All the information you require is here at your disposal.

Scan the QR code on the machine's type plate or look under www.poettinger.at/poetpro

And if we don't have what your looking for, then your Specialist Service Centre is there for you with help and advice.

Dokument D

GB-0600 Dokum D Anbaugeräte - 3 -

PÖTTINGER Landtechnik GmbH

Industriegelände 1

A-4710 Grieskirchen

Tel. 07248 / 600 -0

Telefax 07248 / 600-2511

TMachine checked according to delivery note. All attached parts removed. All safety equipment, drive shaft and operating

devices at hand.

TOperation and maintenance of machine and/or implement according to operating instructions explained to the customer.

TTyres checked re. correct pressure.

TWheel nuts checked re. tightness.

TDrive shaft cut to correct lenght.

TCorrect power-take-off speed indicated.

TFitting to tractor carried out: to three-point linkage

TTrial run carried out and no defects found.

TFunctions explained during trial run.

TPivoting in transporting and operating position explained.

TInformation given re. optional extras.

TAbsolute need to read the operating manual indicated.

Please check. X

According to the product liability please check the above mentioned items.

INSTRUCTIONS FOR

PRODUCT DELIVERY

GB

In order to prove that the machine and the operating manual have been properly delivered, a confirmation is necessary.

For this purpose please do the following:

- sign the document A and send it to the company Pöttinger or via the internet to www.poettinger.at

- document B stays with the specialist factory delivering the machine.

- document C stays with the customer.

- 4 -

TABLE OF CONTENTS

1601_GB-Inhalt_3846

GB

Attention!

Safety hints to

observe in

supplement!

Table of contents

WARNING SIGNS

CE sign ...................................................................... 5

Meaning of warning signs.......................................... 5

ATTACHING TO TRACTOR

Attaching machine to tractor..................................... 6

Attach connecting lines from the front mower. ......... 7

Establish an electrical connection to tractor ............ 7

Connect sensor cable from front mower................... 8

Detach cardan shaft ................................................. 8

Hydraulic connection................................................. 8

Note rotation direction of mower discs ..................... 9

TRANSPORT

Conversion from working position to transport

position.................................................................... 10

Raise to road transport position.............................. 10

Lower to field transport position.............................. 10

Driving on public roads............................................ 11

Transport position ................................................... 11

Parking position....................................................... 12

POWER CONTROL

Terminal performance features................................ 13

Initial start ................................................................ 13

Keys allocation ........................................................ 14

Menu tree................................................................. 15

Menus..................................................................... 16

Diagnosis function................................................... 27

ISOBUS TERMINAL

Operation structure - mower with ISObus solution. 30

Meaning of keys ...................................................... 31

Diagnosing function................................................. 35

Configuration menu ................................................. 36

Joystick - Mower configuration............................... 37

Setting the joystick .................................................. 37

OPERATION

Important notes prior to starting work..................... 38

Mowing.................................................................... 39

Reversing................................................................. 39

Anti-collision device................................................. 39

OPERATION

Working on slopes................................................... 40

ROLLER CONDITIONER

Safety advice ........................................................... 41

Operation mode....................................................... 41

Possible settings ..................................................... 42

Operation................................................................. 42

Maintenance ............................................................ 43

Roller conditioner for collector ................................ 46

Maintenance of the rotor tines:................................ 46

TINE CONDITIONER

Mowing with the conditioner ................................... 47

Rotor speed 700 rpm .............................................. 47

Correct V-belt tension ............................................. 47

Rotor tines: .............................................................. 47

Installing and removing the conditioner .................. 48

CONDITIONER

Mowing without Conditioner ................................... 51

SWATH DISCS

Swath Discs............................................................. 52

Flat cone conveyor (Optional extra)......................... 52

Safety advice ........................................................... 53

General maintenance information ........................... 53

Cleaning of machine parts....................................... 53

MAINTENANCE

Parking in the open.................................................. 53

Winter storage ......................................................... 53

Cardans ................................................................... 53

Hydraulic unit........................................................... 53

Cutter bar oil level check ....................................... 54

Oil change for cutter bar.......................................... 55

Maintaining the gearbox.......................................... 56

Maintenance of the mower articulated shafts ......... 57

Installing cutter blades ........................................... 58

Setting the field transport position (headlands FT).. 59

Checking wear on mowing blade holders ............... 60

Holder for a quick change of cutter blades............. 61

Checking the mowing blade suspension................. 61

Changing the Cutter Blades .................................... 61

ELECTRO-HYDRAULICS

Disruptions and remedies to power failure.............. 62

TECHNICAL DATA

Technical data ......................................................... 63

Necessary connections ........................................... 63

Position of Vehicle Identification Plate .................... 63

The defined use of the mower unit.......................... 64

SUPPLEMENT

Lubrication chart...................................................... 71

Lubricants................................................................ 73

SERVICE

Hydraulic plan.......................................................... 76

Electric circuit diagram............................................ 77

Electric circuit diagram (hydr. relief) ........................ 78

Processor ................................................................ 79

Signal socket connection cable............................... 80

Terminal (Power Control)......................................... 80

Repairs on the cutter bar......................................... 81

Combination of tractor and mounted implement .... 82

- 5 -

9700_GB-Warnbilder_361

GB

WARNING SIGNS

Stay clear of swinging area of implements

Close both side protective coverings before engaging

p.t.o..

Never reach into the crushing danger area as long as

parts may move.

CE sign

The CE sign, which is affixed by the manufacturer, indicates outwardly that this machine

conforms to the engineering guideline regulations and the other relevant EU guidelines.

EU Declaration of Conformity (see supplement)

By signing the EU Declaration of Conformity, the manufacturer declares that the machine being

brought into service complies with all relevant safety and health requirements.

Meaning of warning signs

Danger - flying objects; keep safe distance from the

machine as long as the engine is running.

Wait until all machine components have stopped

completely before touching them.

Stay clear of mower knife area as long as tractor engine

is running with PTO connected.

Shut off engine and remove key before performing

maintenance or repair work.

Recommendations

for work safety

All points referring

to satety in this

manual are

indicated by this

sign.

bsb 447 410

495.167

- 6 -

1500_GB-ATTACHING_3846

GB

ATTACHING TO TRACTOR

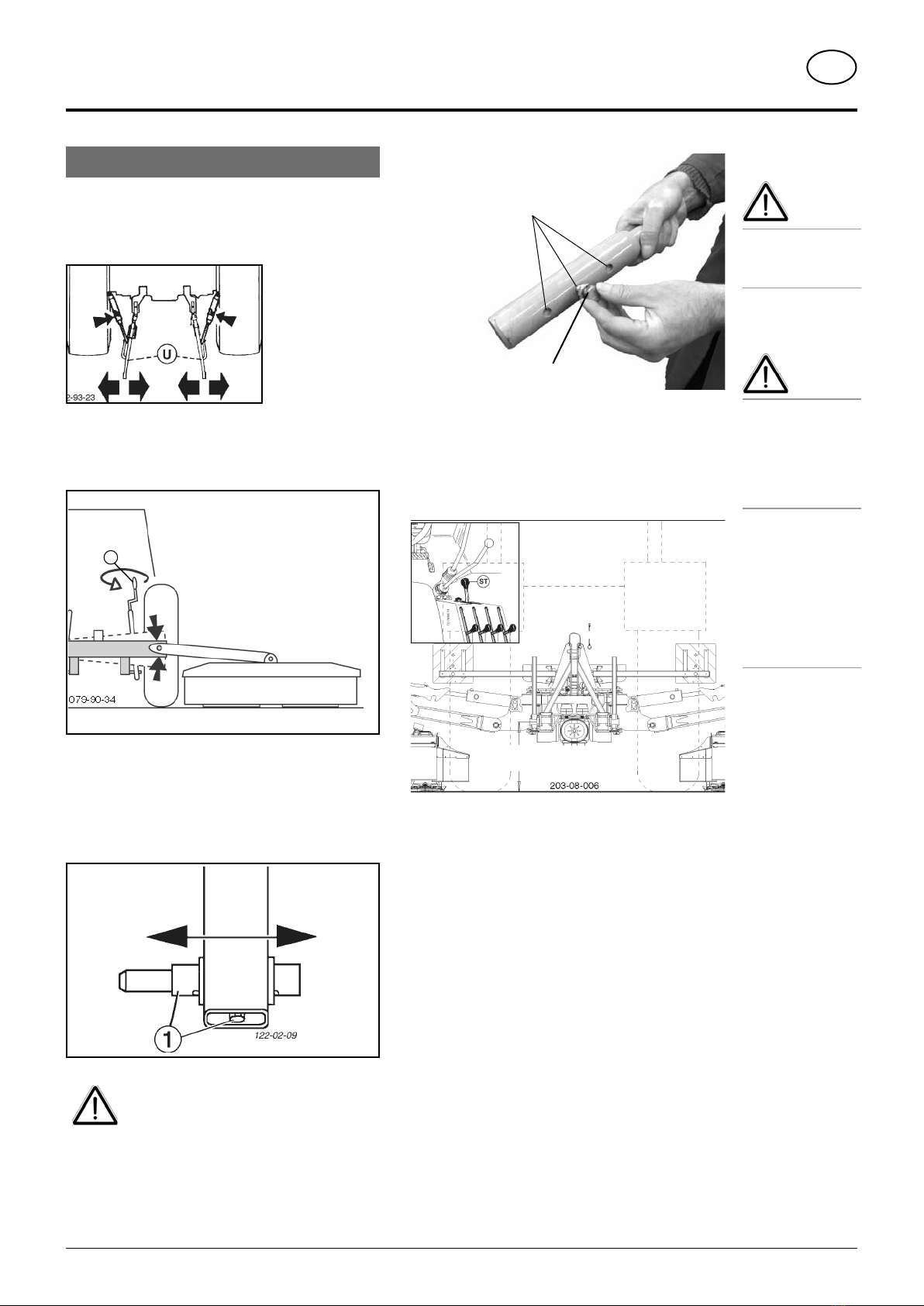

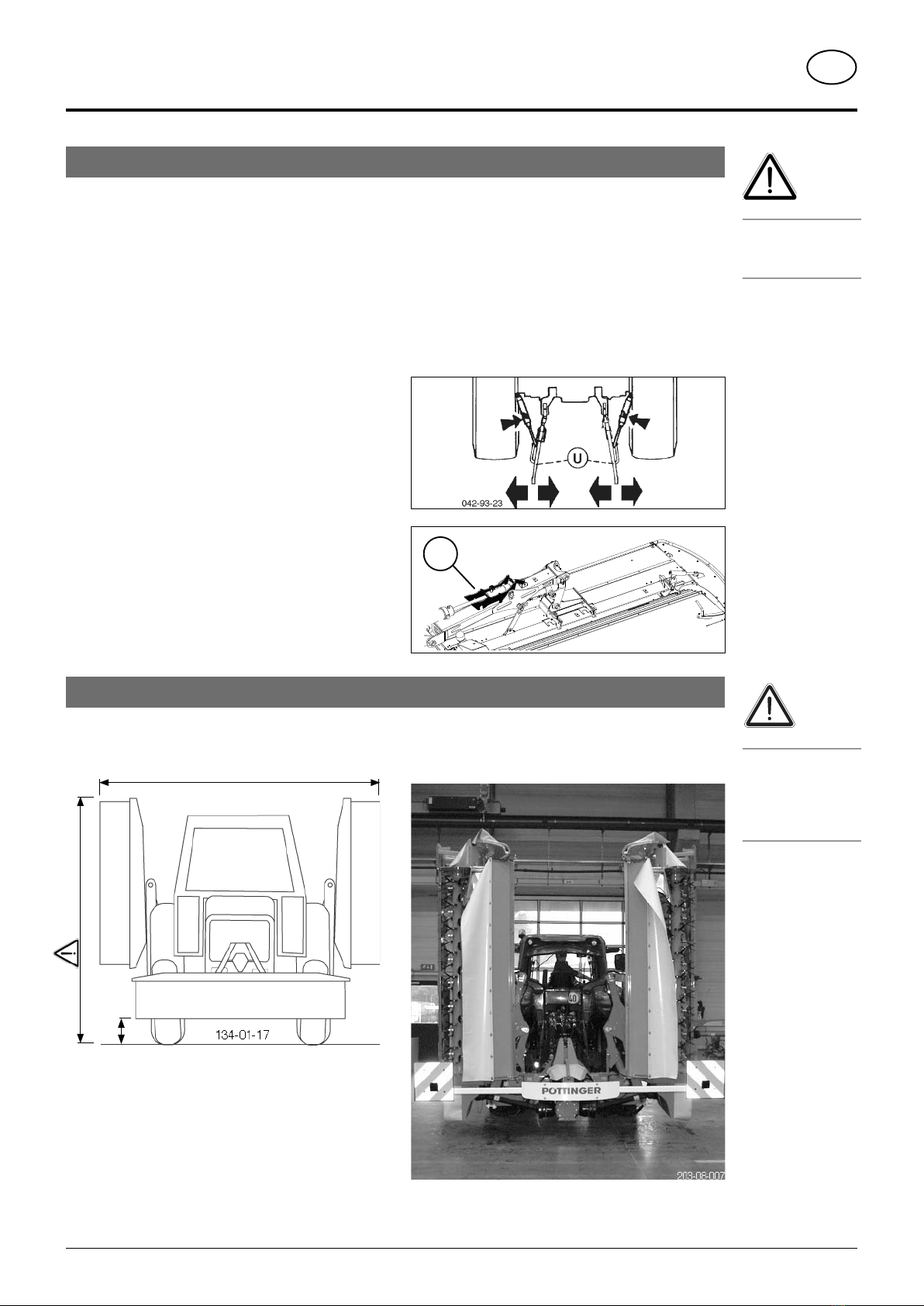

Attaching machine to tractor

Attach mower centrically to tractor

- Adjust lower link accordingly.

- Secure the lower link so that the machine cannot swing

out sideways.

Mounting frame horizontal

- Bringmounting frametohorizontal position by adjusting

lower link jackscrew (15).

15

Pin machine to three-point mount

- Adjust lower link bolts (1) on bearing frame according

to the three-point category, and adjust track width using

thefixing screw.Mowermustnottouchreartractortyres.

Ensure fixing screw is inserted in required

hole (see figure below) on the bolt!

Otherwise mower may come loose from

coupling, fall to the ground and cause

damage to property.

Safety

hints:

see Supple-

ment-A1, 7.), 8a.

- 8h.)

Caution

This machine

is designed for

operation with a

tractor (not for

self-drive work

machines).

The driver’s visual

range is limited

with self-drive

work machines

when both outer

mower bars are

raised in the

transport posi-

tion.

3 drilled holes

Fixing screw

Setting lower link height

- Set tractor hydraulics (ST) using the depth stop.

This height makes an optimum levelling of the uneven

ground possible and does not need to be altered when

swivelling the cutter bars up.

825

- 7 -

1500_GB-ATTACHING_3846

GB

ATTACHING TO TRACTOR

Adjust upper link spindle

- Turningupper link spindle(16) adjuststhe cutting height.

Ahydraulicupper linkis recommended

(double-acting control unit)

Attach connecting lines from the front

mower.

K

"Power Control" variant

With the “Power Control” variant, the possibility exists of

controlling the front mower's automatically folding side

protection along with the rear mower. (Optional extra)

Note:

The hydraulic hoses between front

mower and rear mower are pressurized.

These must be depressurized before

disconnecting.

Power Control Press key until

signal tone is heard (approx. 3 Sec)

ISOBus:Press key untilsignal

tone is heard (approx. 3 Sec)

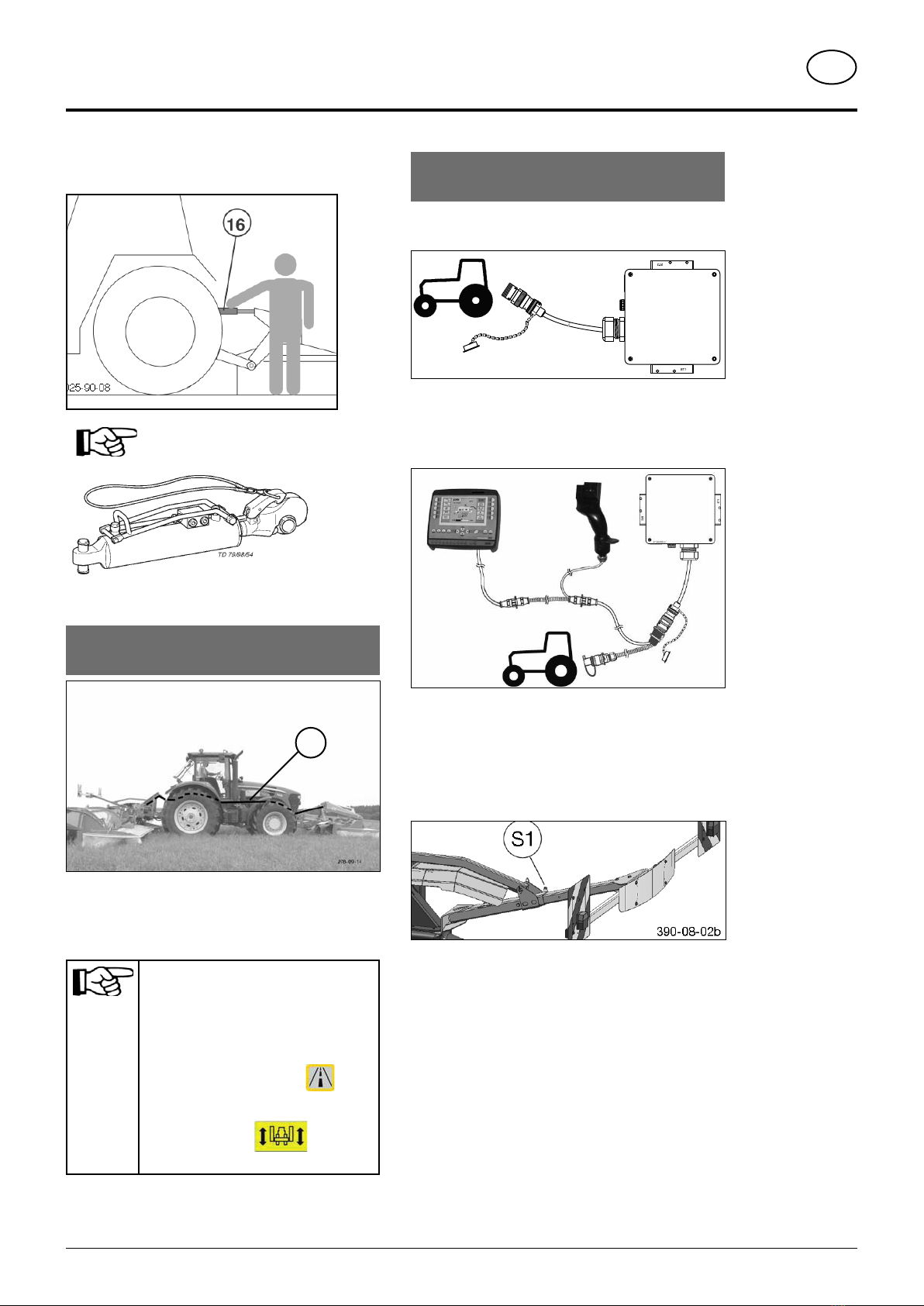

Establish an electrical connection to

tractor

Operating unit on tractor with ISO Bus control

- Connect 9-pin ISO plug to ISO-Bus socket on tractor

473A2000.0

Operating unit on tractor without ISO Bus control

- Attach connection cable between 9-pin ISO plug and

3-pin socket DIN 9680 on tractor or operating unit

Lighting:

- Connect 7-pin plug to tractor

- Adjust lighting carrier position (S1)

- Clean and check that lighting on mower functions

properly.

- 8 -

1500_GB-ATTACHING_3846

GB

ATTACHING TO TRACTOR

Important!

Check the vehicle

for roadworthi-

ness prior to

every operation

(lights, brakes,

protective panels,

…)!

Connect sensor cable from front mower

Electrical cable connection between front mower

and mower combination

- 3-pin cable for sensor attachment kit (1)

(Starting from the back, lay sensor cable to tractor so

that the cable cannot become damaged e.g. tyres,

exhaust, ...)

Detach cardan shaft

- Before initial operation, check the cardan shaft length

and adapt if necessary. See chapter "Drive Shaft" in

Supplement B also.

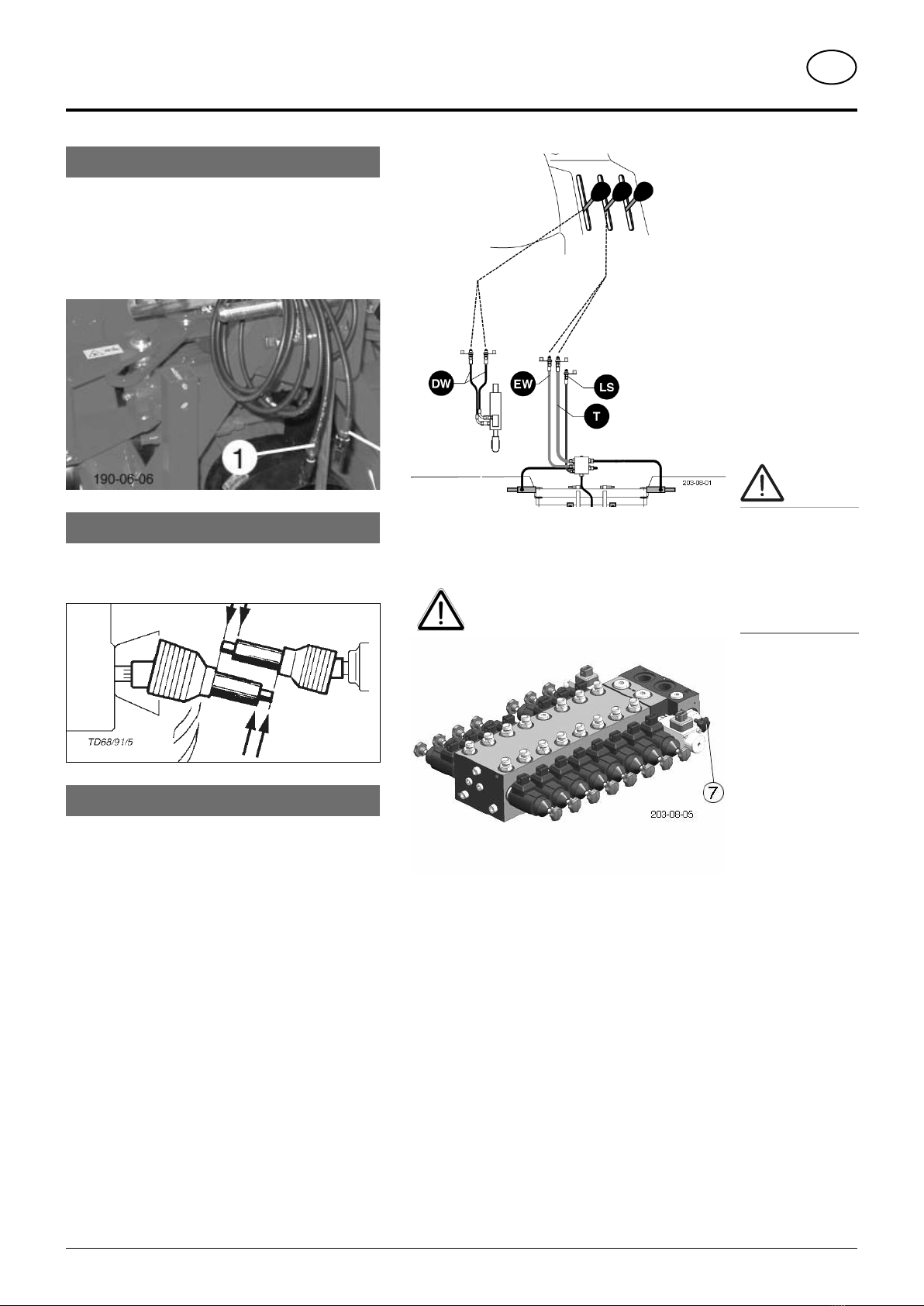

Hydraulic connection

Minimum hydraulic system:

1 single-acting hydraulic circuit (EW) with depressurized

return flow (T)

Optimum hydraulic system:

1 single-acting hydraulic circuit (EW) with depressurized

return flow (T)

1 dual-acting hydraulic circuit (DW) for hydraulic upper link

or

1x Load sensing hydraulic circuit (LS) (Optional extra)

consisting of:

- single-action hydraulic circuit (EW)

- pressureless return (T)

- load sensing line

1 dual-acting hydraulic circuit (DW) for hydraulic upper link

Settings

The screw (7) on the hydraulic block must also be adjusted.

Be advised!

Separate electrical connection

For tractors with "Load sensing"

- Screw in screw (7) completely on hydraulic block

For tractors with a closed hydraulic system

- Screw in screw (7) completely on hydraulic block

For tractors with an open hydraulic system

- Unscrew screw (7) completely on hydraulic block

- 9 -

1500_GB-ATTACHING_3846

GB

ATTACHING TO TRACTOR

Note rotation direction of mower discs

- Select appropriate rotation direction for the drive

- If the necessary p.t.o. direction of rotation cannot be

selected from the tractor, then turn the gearing (G1)

180° .

180°

Be advised!

Before gearing is refitted to the machine:

1. Swapventilationscrewand drain plug.

2. Correct position for ventilation screw

is on the top.

- 10 -

1400_GB-TRANSPORT_3846

GB

TRANSPORT

Raise to road transport position

This key's function can only be activated when all mower

units are in field transport position (headland FT)

- Switch off drive and wait for complete stop.

- Swivel all hoop guards on mower in

Variant with "Power Control"

Briefly press key

the function is activated

Press key

all mower units swivel to end position

Variant with "ISOBus-Terminal"

Press softkey to open Transport menu.

Briefly press softkey

the function is activated

Press softkey

all mower units swivel to end position

• Before swivelling cutter bar up, switch

off drive and wait for mower discs to

completely stop.

• Ensure that swivel range is clear and that

no-one is standing in the danger area.

Conversion from working position to transport position

Safety advice!

Carry out change

from working po-

sition to transport

position only on

even, firm ground.

• Move implement

only in transport

position!

Lower to field transport position

Variant with "Power Control"

Briefly press key

the function is activated

Press key

all mower units swivel to field transport position (FT)

Variant mit "ISOBUS-Terminal"

Press softkey to open Transport menu.

Briefly press softkey

the function is activated

Presssoftkey

all mower units swivel to field transport position (FT)

- Swivel all guard hoops on mower out

- 11 -

1400_GB-TRANSPORT_3846

GB

TRANSPORT

Transport position

Driving on public roads

- Observe the official regulations of your state/country.

• Travel on public roads only in the transport position.

• Safety devices must be in proper condition.

• Before travelling, bring swivelling parts to correct position and secure against dangerous position changes.

• Check that lighting functions before travelling.

• Important information is also available in the supplement to this operator's manual.

Hydraulic lower link

- Secure hydraulic lower link so that implement cannot

swing out sideways.

Transport safeguard (Ts)

- Check transport safeguard before travelling!

Check that both mower units are properly secured with

safety hooks!

max. 4000

200

3500

3000

Be advised!

Be aware of max.

permissible trans-

port height (4 m)!

Be advised!

Parking the

machine in the

transport position

is not permitted.

Danger of tipping!

161-09-04

Ts

- 12 -

1000_GB-ABSTELLPOS_3846

GB

PARKING POSITION

Parking position

Caution!

Only park the mower combination in the

working position (both mower units are

folded down). Maximum danger of tipping

over if the mower combination is parked

in the transport position.

278-09-16

Safety note:

Only park the disc

mower on firm,

level ground and

ensure a secure

position.

- 13 -

1400_GB-Power Control_3843

GB

POWER CONTROL

Terminal performance features

Connection to power

The power supply for the entire electronic system (job calculator and terminal) is conducted through a plug (compliant

with DIN 9680) from the tractor's 12V onboard electrical system. These three-pin plugs may also be two-pin versions as

only two main wires (+12 V, ground) are required.

Be advised!

Other plug and socket designs are not permitted otherwise functional reliability cannot be assured.

Technical data

Operating voltage: +10V / +15V

Operating temperature range: -20°C +60°C

Storage temperature: -30°C +70°C

Degree of protection: IP65

Fuse: 10A multifuse in an operating voltage plug

Function

All of the attached unit's functions can be directly controlled through the Power Control Terminal. In addition, the Power

Control Terminal has a large display to indicate the current operating condition, various menus and alarm reports. A

prerequisite is a single-acting hydraulic circuit with depressurised return or load sensing.

Operating with the Power Control Terminal

1. Position PowerControlTerminal in tractorcabin

where it can be clearly seen. (To secure the

terminal there is a holder on the reverse side.

2. Connect terminal to tractor cable with plug 1.

3. Run job calculator cable from implement to

tractor cabin and connect to tractor cable via

theISObusplug (2). (Makesurethatthecables

are properly arranged!)

4. Plug the tractor cable plug (3) in to the tractor's

12V power supply.

5. If hectare counting is required, connect cable

with plug (4) to socket in tractor (DIN 11786)

and job calculator's cable harness.

To activate terminal, press key "I/O" .

To deactivate terminal, press key "I/O" for

three seconds.

Note!

Do not leave the

control terminal

out in the weath-

er.

ISObus

plug 2

Tractor cable

with ISObus

Power

Control

Terminal

10 Amp fuse

ISObus-capable job

calculator

Plug 4

with

Tractor socket (DIN

11786)

Plug 3

Plug 1

Initial start

- 14 -

1400_GB-Power Control_3843

POWER CONTROL GB

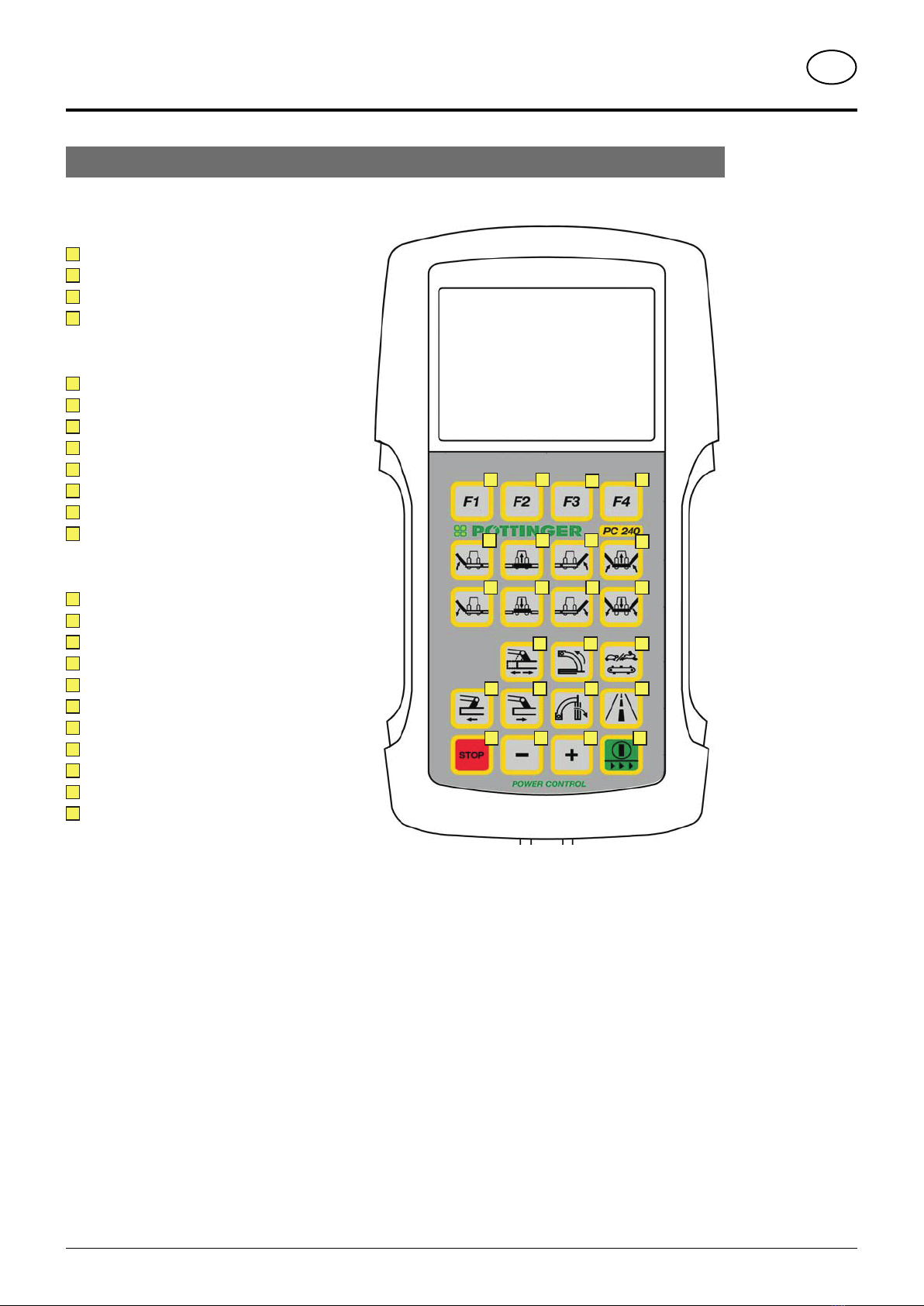

Keys allocation

a b d

fh

c

eg

i j k l

onm

qp r s

wvut

Function keys

aFunction key 1*

bFunction key 2*

cFunction key 3*

dFunction key 4*

Raising and lowering the mower unit

eRaise left mower unit

fRaise front mower unit

gRaise right mower unit

hRaise all mower units

iLower left mower unit

jLower front mower unit

kLower right mower unit

lLower all mower units

Side shift, cross conveyor, transport

mSlope travel preselection

nRaise cross conveyor

oChange cross conveyor belt speed

pDecrease working width

qIncrease working width

rLower cross conveyor

sRoad transport preselection

tStop - stops every required function

uDecrease value of a setting

vIncrease value of a setting

wOn/Off

Press [On/Off] key to switch on Power

Control Terminal. Press [On/Off] key to

open up System Menu.

Press and hold [On/Off] key longer to

switch off Power Control terminal.

* Function keys have different functions depending

on the menu.

- 15 -

1400_GB-Power Control_3843

POWER CONTROL GB

Menu tree

V10

V10

X8

X8

M1

M2 M3

M7

M6

M3

M4 M5

Press and hold for 10 seconds!

- 16 -

1400_GB-Power Control_3843

POWER CONTROL GB

Menus

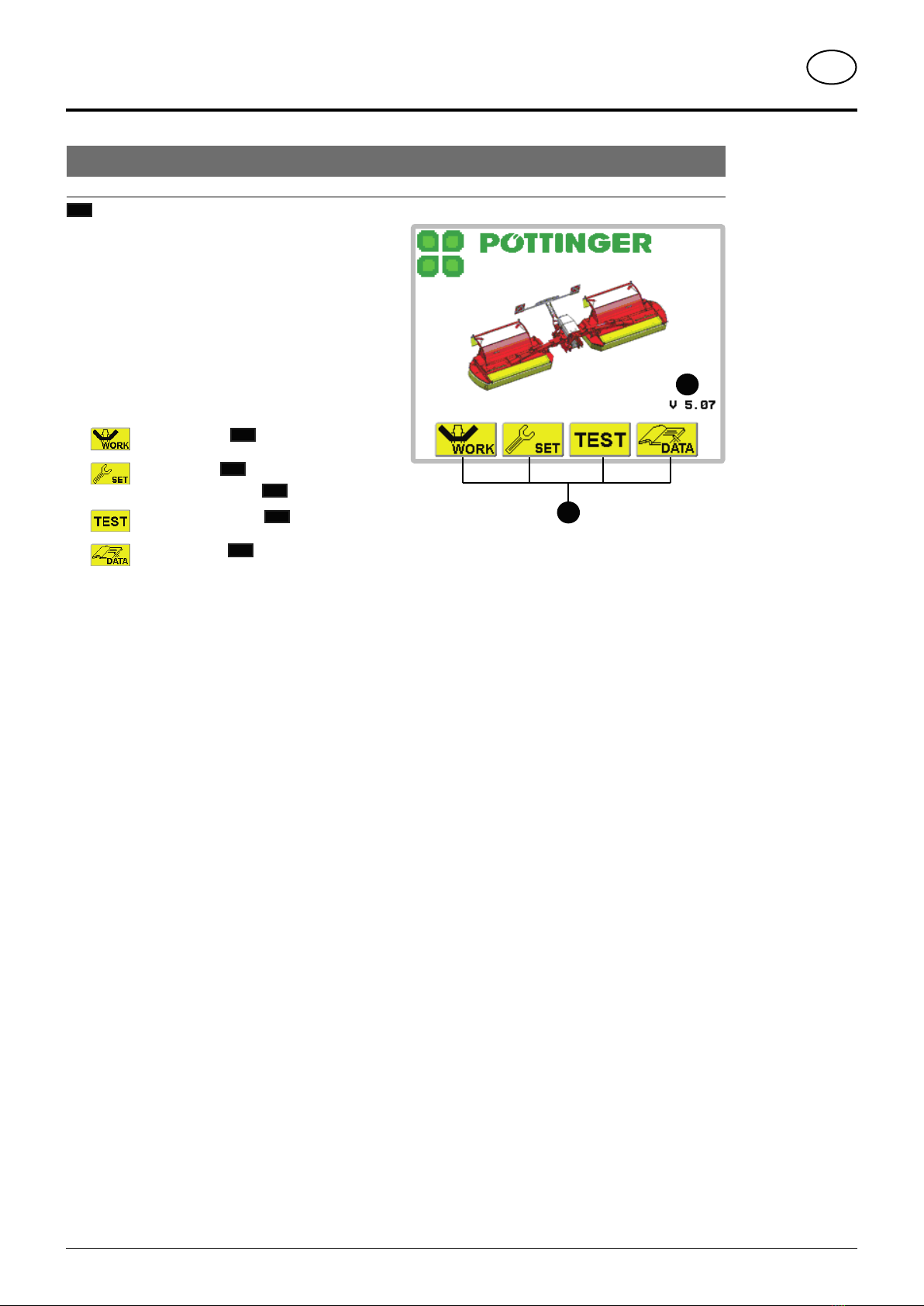

Start menu

M1

After activating the Power Control Terminal

the Start menu appears.

Display:

1…. Software version

2…. Function keys

Function keys:

... Work menu M2

... Set menu M3 / press longer:

Configuration menu M6

... Sensor test menu M4

... Data menu M5

1

2

- 17 -

1400_GB-Power Control_3843

POWER CONTROL GB

Work menu

M2

In Start menu, press function key to open up Work menu.

Press function key to return to Start menu.

13

12

11

12

4

3

1

1

5

6

8

7

2

Note!

To adjust the

relief pressure the

mower units must

be in the neutral

position.

Note!

It is not possible

to change to road

transport position

when, at least,

one cross con-

veyor is not in the

working position.

Display:

1…. Cross conveyor belt speed:

Fast (hare)/Slow(tortoise)(onlywithX8Collector)

2 ... Preselect to either raise or lower cross conveyor.

3 ... Operating condition of mower units:

Working (pic. 1), Field transport (pic. 2),

Road transport (pic. 3)

4 ... a cross conveyor is not in working position

5 ... Tractor speed:

can only be selected if in configuration menu

6 ... ha. per hr.:

only if tractor speed is selected in configuration menu.

7 ... Frontmoweravailable.Ifthissymbolisnotdisplayed,

there is either no front mower available or it

cannot be managed with this control.

8 ... Right rear mower unit relief pressure

9 ... Left rear mower unit relief pressure

10 ... Daily hectare counter only if tractor speed is

selected in configuration menu.

11 ... Slopetravel preselection (only withNovacatV10)

12 ... Side shift (only with Novacat V10)

both arrows point outward = max. width

both arrows point inward = min. width

both arrowspoint in the same direction

= slope travel

13 ... Road transport symbol

Only with the symbol displayed is raising and

lowering out of, or to, the road transport position

possible. If symbol begins to flash then press

[Road transport] key once again.

Function keys:

... Decrease relief pressure of rear

mower units*

... Increasereliefpressureof rearmower

units*

... Activate/deactivate front mower

... Go up one menu level (here: Start

menu)

Hard keys: Raising and lowering

*Momentary pressure differences could arise between left and right rear mower units. But these are

automatically balanced out after the filling process.

9

10

- 18 -

1400_GB-Power Control_3843

POWER CONTROL GB

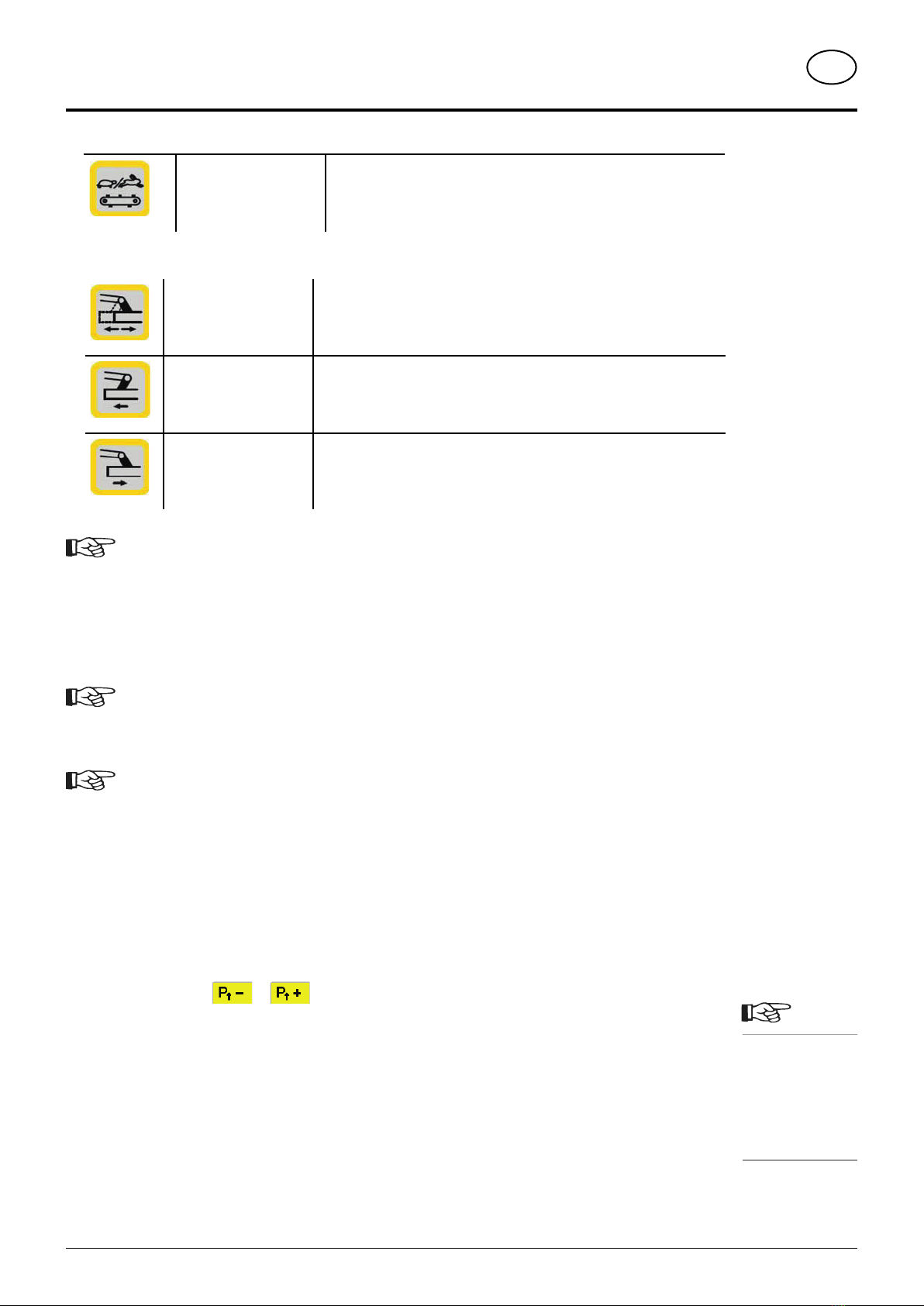

Lower left mower unit Lowers left mower unit from field transport to working position

Lower front mower Lowers front mower from field transport to working position

Lower right mower unit Lowers right mower unit from field transport to working position

Lower all mower units Lowers all mower units from field transport to working position

Raise left mower unit Raises left mower unit from working position to field transport position.

Raise front mower Raises front mower from working position to field transport position

Raise right mower unit Raises right mower unit from working position to field transport position

Raise all mower units Raises all mower units from working position to field transport position

Road transport

preselection

1. Press preselection key to make raising to and lowering from road

transport position possible.

2. Press either the [Raise] or [Lower] key to move the respective mower

units to, or out of, the road transport position.

Stop Stops any raising or lowering process.

Hard keys: Raising and lowering cross conveyor (only Novacat X8 Collector)

Raise cross conveyor Raises both or the preselected cross conveyor

Lower cross conveyor Lowers both or the preselected cross conveyor

Right cross conveyor

preselection

1. Pressthepreselectionkey tomakeraising or loweringanindividualcross

conveyor possible. The symbol "Right cross conveyor preselection"

2appears on the display.

2. Press the appropriate key, [Raise] or [Lower], to move the relevant

cross conveyor.

Left cross conveyor

preselection

1. Pressthepreselectionkey tomakeraising or loweringanindividualcross

conveyor possible. The symbol "Left cross conveyor preselection"

2appears on the display.

2. Press the appropriate key, [Raise] or [Lower], to move the relevant

cross conveyor.

Note!

Any menu can be

exited by pressing

the ESC key.

Note!

To be able to

activate the key

[Road transport

preselection],

both cross

conveyors must

be in the working

position.

Note!

To be able to

activate the key

[Road transport

preselection],

all mower units

must be in the

field transport

position.

Note!

To change to road

transport position

cardan shaft must

be idle. The [Road

transport] key

will not function

as long as the

cardan shaft is

turning.

Note!

Pressing the "Road

transport prese-

lection" key

will depressurize

the side protec-

tion hydraulic

hoses. (e.g. be-

fore uncoupling)

- 19 -

1400_GB-Power Control_3843

POWER CONTROL GB

Cross conveyor speed

levels

(Optional extra)

Press the key to change the speed level of the cross conveyor belts.

One of two levels can be selected which are represented by a "hare"

or a "tortoise"

Go to the Set menu to adjust the speed of the speed level.

Hard keys: Side shift (only Novacat V10)

Slope travel preselection 1. Press the preselection key to move both rear mower units in the same

direction, one after the other.

2. Press the appropriate key [side shift] to start the side shift in the relevant

direction. The mower units then move one after the other.

Decrease working width /

side shift left

Decreases working width of mower so that both mower units move inward

to end position.

In conjunction with [Slope travel preselection], both rear mower units

move to the left.

Increase working width /

side shift right

Increases working width of mower so that both mower units move outward

to end position.

In conjunction with [Slope travel preselection], both rear mower units

move to the right.

Note!

The keys "Decrease working width" and "Increase working width" are stayput keys (function activated

by briefly pressing the key).

The function is interrupted with the STOP key or by pressing the key for the opposite direction. If

function is interrupted with STOP key, no arrow appears in the display.

Note!

When mowing on slopes it is sensible to position both mower units uphill. Doing so will prevent

streaking.

Note!

Adjusting the working width is only possible in the working and field transport positions.

If both mowers are to be moved to the transport position and one of the mower units is in the field

transport position at max. working width, firstly bring both mower units to min. working width so as

not to exceed the 4 m transport height.

Set relief pressure for hydraulics

Adapt the relief pressure to the ground conditions.

1. Ensure that both mower units are in the neutral position. Otherwise the relief pressure cannot be adjusted.

2. Raise an outside rear unit. If this is even possible, this is equivalent to a relief pressure of approx. 70kg.

3. Press the function keys or to adapt the relief pressure to the ground conditions.

Note!

Raise an outside

rear unit. If this

is even possible,

this is equivalent

to a relief pres-

sure of approx.

70kg.

- 20 -

1400_GB-Power Control_3843

POWER CONTROL GB

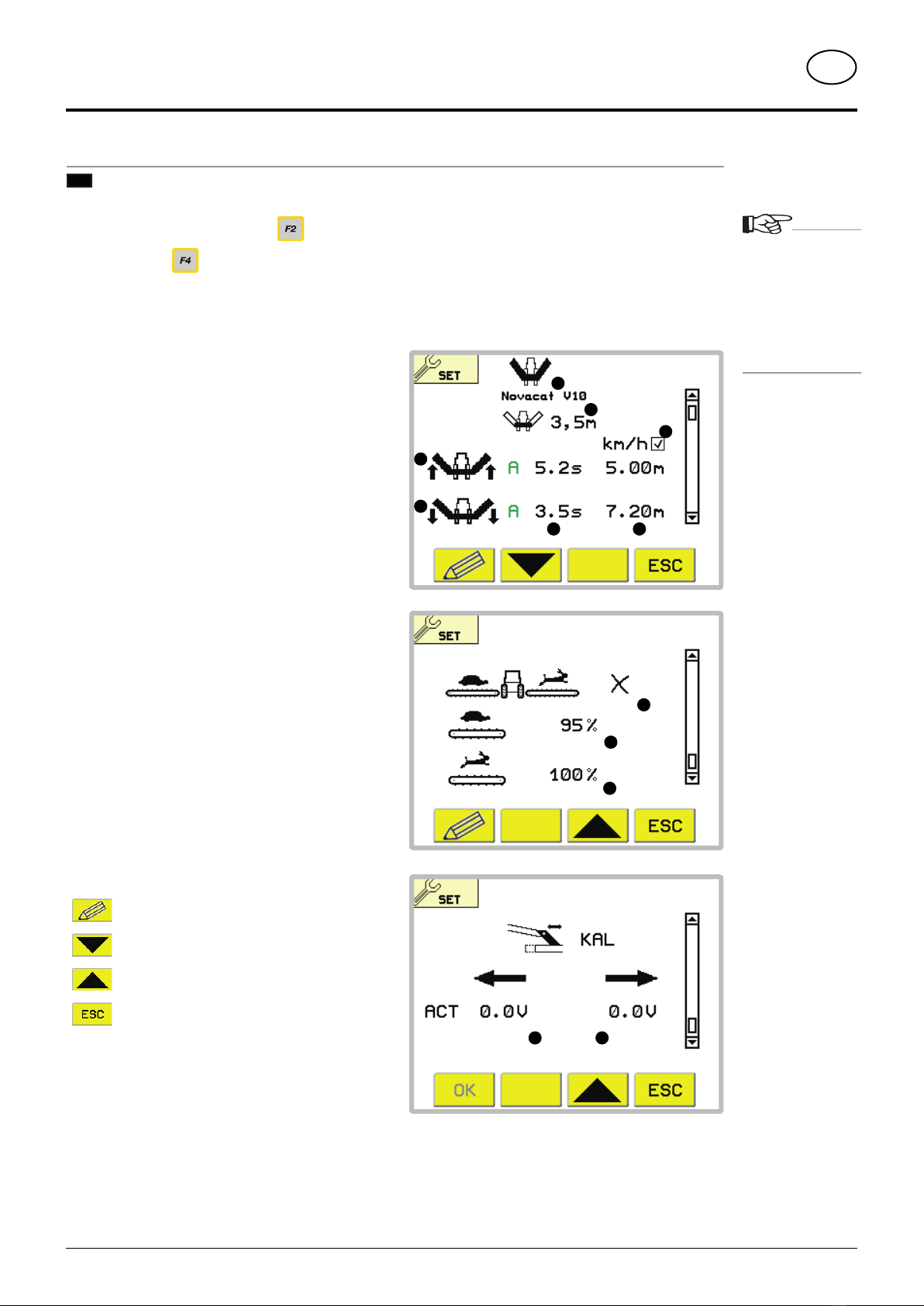

Set menu

M3

In the Start menu, press function key , to open the Set Menu.

Press function key , to return to the Start Menu.

Note:

The values

for the distance

controlled delay

will not appear if

the speed has not

been selected in

the configuration

menu.

1211

1

3

2

5 4

7

6

10

8

9

Display:

1…. Type of machine

2…. Front mower working width (only Novacat V10)

3 ... Time or distance controlled delay when

lowering the rear mower.

4 ... Column for the distance controlled delay

5 ... Column for the time controlled delay

6 ... Line for lowering the mower unit

7 ... Line for raising the mower unit

only Novacat X8 Collector:

8 ... Speed selection for cross conveyor belt:

Tick= Differingspeeds betweenthe left and right

cross conveyor belt (for mowing in contour lines)

Cross = Same speed for both cross conveyor

belts with the possibility of switching between

two speeds.

9 ... Speed regulator for speed 1

(Tortoise): same percentage =

same speed

10 ... Speed regulator for speed 2

(Hare):

only Novacat V10:

11 ... Voltage value for the left angle sensor

12 ... Voltage value for the right angle sensor

Function keys:

... Edit menu entry

... page down

... page up

... change to higher menu (here: Start

Menu)

This manual suits for next models

1

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions