Novalynx 200-WS-03D User manual

NOVALYNX CORPORATION

MODEL 200-WS-03D

WIND & TEMPERATURE SENSOR

INSTRUCTION MANUAL

ii

Receiving an Unpacking

Carefully unpack all components and compare to packing list. Notify NovaLynx

Corporation immediately concerning any discrepancy. Inspect equipment to detect any

damage that may have occurred during shipment. In the event of damage, any claim for

loss must be filed immediately with the carrier by the consignee. amages to equipment

sent via Parcel Post or UPS require the consignee to contact NovaLynx Corporation for

instructions.

Returns

If equipment is to be returned to the factory for any reason, call NovaLynx between 8:00

A.M. and 4:00 P.M. Pacific Time and request a Return Authorization Number (RA#).

Include with the returned equipment, a description of the problem and the name, address,

and daytime phone number of the sender. Carefully pack the equipment to prevent

damage or additional damage in the return shipment. Call NovaLynx for packing

instructions in the case of delicate or sensitive items. If packing facilities are not available

take the equipment to the nearest Parcel Post, UPS, or freight service and obtain

assistance with the packaging. Write the RA# on the outside of the box.

Warranty

NovaLynx Corporation warrants that its products are free from defects in material and

workmanship under normal use and service for a period of one year from the date of

shipment from the factory. NovaLynx Corporation's obligations under this warranty are

limited to, at NovaLynx's option: (i) replacing; or (ii) repairing; any product determined to

be defective. In no case shall NovaLynx Corporation's liability exceed product's original

purchase price. This warranty does not apply to any equipment that has been repaired or

altered, except by NovaLynx Corporation, or that has been subjected to misuse,

negligence, or accident. It is expressly agreed that this warranty will be in lieu of all

warranties of fitness and in lieu of the warranty of merchantability.

A ress

NovaLynx Corporation

4055 Grass Valley Highway, Suite 102

Auburn, CA 95602

(530) 823-7185

FAX (530) 823-8997

Copyright © , 1997 by NovaLynx Corp.

1

MODEL 200-WS-03D

WIND & TEMPERATURE SENSOR

1.0 INTRODUCTION

This manual contains information to aid in the design of custom interface circuits for use

with the NovaLynx Model 200-WS-03 combination Wind and Temperature Sensor. This

information is supplied to systems integrators with the express understanding that

NovaLynx Corporation assumes no responsibility or liability for the operation of the sensor

as a part of any equipment that has been designed or furnished by any organization other

than NovaLynx.

The Model 200-WS-03 Wind and Temperature Sensor assembly consists of three major

parts: an anemometer for measuring wind speed; a wind vane for measuring horizontal

wind direction; a thermistor temperature sensor. The complete sensor assembly has been

designed with the wind vane mounted on top of the anemometer for stability and ease of

signal transmission. A small white shield protects the thermistor from direct solar heating

and is located on the side of the sensor where the thermistor passes through the sensor

housing. Output signal transmission is accomplished through a forty-foot length of six-

conductor, twenty-six gauge, flat cable. The cable has been terminated by a six-pin RJ-11

connector. Monitoring equipment supplied by NovaLynx will be equipped with a matching

connector receptacle.

1.1 ANEMOMETER

The anemometer uses a three-cup hub and cup assembly to sense wind velocity. As the

wind blows past the cups, the pressure of the wind against the insides of the cups causes

them to rotate. There are three permanent magnets embedded in the hub that holds the

cups. Each magnet, as it rotates past a fixed point on the sensor base, activates a

magnetic reed switch mounted in the base. Three closures of the reed switch will be

produced for each revolution of the cup assembly. The contacts of the magnetic reed

switch capsule are normally open; the contact will close each time a magnet passes over

it. The ratio of closed-to-open time is nominally 1/10 of the total period for a revolution of

the wind cups. This duty cycle may change slightly as the sensor ages and with exposure

to temperature extremes.

The anemometer is rated for wind speeds up to 125 miles per hour and has a starting

threshold of approximately 1 mile per hour. The magnetic reed switch capsule is rated to

carry a maximum current of 10.0 milliamperes with an applied voltage of no more than 50

volts AC or C. The approximate speed constant for the anemometer is 1.25 mph/Hz.

2

1.2 WIND VANE

The wind vane is coupled to a 20K ohm, ±20%, single turn potentiometer. The linearity of

the potentiometer is ±1%. Maximum power dissipation should be limited to 1/4 watt.

Resolution is infinite over potentiometer's 355 degree arc. There is a gap ("dead band")

of approximately 5 degrees between the ends of the resistive media. As the wind blows

past the vane, the design of the counter-weight and the tail fin align the point of the

counter-weight into the wind. Fluctuations in the wind direction are measured by the

sensor as the aerodynamics of the counter-weight and the tail try to keep aligned to the

path of the wind. The motion of the wind vane is translated to the potentiometer shaft

causing a change in the potentiometer's resistance. Connecting the potentiometer wires

to a voltage source allows easy measurement of the wind direction as a change in voltage.

1.3 TEMPERATURE

The ambient air temperature is measured by using a thermistor that is mounted inside the

protective shield located on the side of the sensor base. The thermistor exhibits rapid

changes in its resistance in response to temperature changes. The resistance change is

inversely proportional to the temperature. By using precision scaling and linearization

resistors in a bridge circuit, the resistance changes of the thermistor can be converted into

a voltage that can be easily calibrated and monitored. The thermistor's resistance vs.

temperature data can be found in Table 1.

2.0 SPECIFICATIONS

Anemometer:

Turning Radius: 3" to center of cup

Speed Threshold: 1.2 mph

Transducer Type: Reed Switch, Magnet Activated

Speed Constant: 1.25 mph = 1 Hz

Measurement Range: 0-100 mph

Accuracy: 1 mph or ±3%

3

Win Vane:

Azimuth Accuracy: ±3°

Bearing Type: Bushing

Potentiometer Gap: 5° Approximately

istance Constant: 1.5'

amping Ratio: 0.4

Vane Threshold: 1.2 mph

Measurement Range: 0-360 egrees Azimuth

Turning Radius: 10 1/2"

TEMPERATURE:

Accuracy: ±0.4F (0.2° C)

issipation: 2.5mW

issipation Factor: 7mW/°C

Operating Temperature: -40° to +150°F

(-40 to +60° C)

Thermal Time Constant: 11 seconds in still air ( approx )

COMPLETE SENSOR:

Total Size: 12" H x 17" W

Cable: 40' - 6 Cond 26 AWG

Connector: 6-Pin RJ-11

Mounting: 1-1/16"O. . pipe (standard 3/4" pipe)

Total Weight/Shipping: 2 lb / 4 lbs

4

3.0 INSTALLATION

3.1 LOCATION

Choose a mounting location for the wind sensor assembly that is free of obstructions.

Nearby objects can create eddy currents that will seriously affect the wind measurements.

Try to locate the wind sensors so that the nearest object is 10 x T away from the wind

sensor mast. T is the height of the object. If the sensors are located on top of a building,

the sensor height should be 1.5 x H, where H is the height of the building. Avoid overhead

power lines whenever possible. If there are overhead power lines, use extreme care to

prevent contact with the power lines while installing the equipment. Roof mounted sensors

should be placed on the upwind side of the building and away from all exhaust vents. In

all cases, if the wind sensor data is to be correlated to National Weather Service data or

World Meteorological Organization data, then the standard exposure is 33 feet (10 meters)

above the ground.

WARNING: Use extreme caution to avoid contacting overhead electrical power lines

during the anemometer installation. NovaLynx recommends using only

experienced equipment installers to avoid injury and serious problems.

3.2 Mounting

Typically, the Model 200-WS-03 sensor is mounted onto a pipe or a mast. A mast size

of 1" to 1-1/16" outside diameter works best. If the pole is metal it should be properly

grounded to minimize lightning damage. It may be necessary in some locations to contact

a local contractor to ensure that local electrical codes have been met by the installer. The

mast should be easy to reach for servicing the sensor and should be properly anchored

and grounded. Position the sensor onto the end of the mast. Secure the sensor to the

mast using the set screws provided in the sensor base. At this point leave the base set

screws loose until after the sensor has been aligned to North. o not use excessive force

when tightening the screws. Simply tighten the screws until the sensor base can no longer

be manually rotated.

3.3 SENSOR ALIGNMENT TO NORTH

The Wind Vane requires alignment of the "dead band" or potentiometer gap to North,

either magnetic or True North, to obtain valid measurements. Alignment can be done at

ground level allowing easier installation of the sensor, but it must be checked again after

the sensor has been fully installed. The Wind Sensor base is used to orient the wind vane

to North. Normally, wind direction sensors are aligned to True North, rather than Magnetic

North. True North is usually found by reading a magnetic compass and applying the

correction for magnetic declination, where magnetic declination is the number of degrees

between True North and Magnetic North.

5

Wind Vane alignment can be performed using a compass. Alignment involves creating an

imaginary line running through the wind sensor from North to South. When this line has

been established, the mounting base of the sensor is rotated until the screw head in the

base and the screw hole that is just above it in the sensor body both point toward North.

Rotate the sensor housing until the two screw holes point toward the North. Rotate the

vane tail until the counter-weight nose also points to North and is in line with the two screw

holes. Check the output signal of the direction sensor. If the alignment is correct, the

output signal should indicate North ( 355.0 or 0.00 egrees ). Correct the sensor base

rotation to bring the reading into agreement with the compass. When the alignment

appears to be good, secure the sensor base set screws to the mast.

3.4 SIGNAL CABLE INSTALLATION

The sensor signal cable is routed down the mast and to the monitoring equipment in the

most direct manner. Fasten the cable to the mast to protect the cable from damage during

high velocity winds. For best results, use plastic cable ties that are resistant to ultra-violet

radiation and place them at two foot intervals. Along areas where there is no mast or there

is some other type of support structure, use the most appropriate method available to

fasten the cable to the support. Use care when installing the cable to avoid sharp bends,

excessive twisting, scrapes and nicks. Additional cable protection can be provided by

using plastic or metal conduit.

4.0 SENSOR CALIBRATION

Calibration of the Wind & Temperature Sensor is limited to checking of the three sensors'

performance. Contact NovaLynx for assistance whenever a sensor appears to be out of

its specified calibrated range.

4.1 ANEMOMETER CALIBRATION

Spin the cups by hand and monitor the output signal wires using an ohmmeter. There

should be three switch closures for each revolution of the cups. The ohmmeter should

show transitions from infinite resistance to zero resistance during each switch closure. If

the ohmmeter is equipped with an audible cable test function, use the cable test mode and

count the beeps per revolution.

Anemometer calibration can be checked by comparing the anemometer's output signal to

that of an anemometer that has recently been calibrated or used as a testing standard. An

anemometer can also be checked by placing it into a wind tunnel and comparing the wind

tunnel velocity against the anemometer's output signal. A non-contacting tachometer can

also be used to verify anemometer performance.

6

4.2 WIND VANE CALIBRATION

Wind Vane calibration involves checking the potentiometer output and verification of the

sensor alignment to North.

NovaLynx recommends that the sensor alignment be verified before attempting the sensor

calibration testing. Use the procedure described in step 3.3 to verify sensor alignment to

North. After doing the alignment check and making any necessary adjustments, test the

sensor potentiometer. The potentiometer test may be done with the sensor installed on

the mast or with the sensor removed.

To test the Wind Vane potentiometer, monitor the sensor output wires using an ohmmeter,

or use the data logging equipment to record the sensor output during the test. If the

ohmmeter is used, disconnect the sensor signal wires from the monitoring or data logging

equipment. Starting at the North point, slowly rotate the sensor in a clockwise direction as

viewed from above the sensor. Looking at the potentiometer with an ohmmeter, the

readings should start at or near zero resistance and increase to 20,000 ohms as the sensor

is rotated. The resistance changes should be smooth and gradual without any

discontinuities. The sensor output should be approximately 56 ohms per degree of

horizontal wind. The maximum resistance reading should appear at 355 degrees azimuth.

After 355 degrees, the potentiometer's dead band is entered by the wiper and the

ohmmeter reading should float and not read any specific resistance. After 5 degrees of

motion, the readings should begin at zero again.

Correction of the wind direction potentiometer setting involves disassembly of the sensor

and rotation of the potentiometer shaft from inside the sensor housing. o not attempt to

make this adjustment unless the correct tools and test equipment are available. Please

contact NovaLynx for assistance before attempting to adjust the sensor.

To adjust the potentiometer gap position setting, first remove the vane tail and hub

assembly from the sensor by removing the small set screw located on one side of the hub.

With the screw removed, slide the hub up and off the potentiometer shaft. Note that the

potentiometer body is bonded to the sensor body and should not move. Using an

ohmmeter to monitor the potentiometer output, turn the potentiometer shaft until the center

of the gap is obtained. At this point, carefully lower the hub back onto the potentiometer

shaft. Try to avoid moving the shaft. With the hub in place reinstall the set screw. o not

over tighten the set screw. Check the sensor calibration after the hub has been reseated.

One recommended method of calibrating and checking the calibration is to point the nose

to South and measure 180° (approx. 10000 ohms). This method may be more accurate

and easier to do for some technicians since there is a more stable reading available at

180° than there is when the potentiometer wiper is in the dead band. Several attempts

may be necessary to get the exact results needed. Remember to check the calibration

setting again after the hub has been reinstalled. Use care to avoid putting the hub on

backwards.

7

4.3 TEMPERATURE SENSOR CALIBRATION

Calibration of the temperature sensor is limited to checking the operating range of the

sensor. There are no user adjustments available for the temperature sensor.

Check the thermistor operation by comparing the signal at the monitoring equipment

against the temperature readings of a precision thermometer. This procedure assumes

that the monitoring equipment has already been properly calibrated and is working

perfectly.

Ambient temperature readings should be taken by placing a precision thermometer next

to the thermistor shield. Leave the thermometer next to the thermistor long enough for a

stable reading to be made.

If ambient temperature readings are difficult to make right at the thermistor, place the

thermometer at a point that is as close to the thermistor as possible. Try to shield the

thermometer from direct solar heating during the readings. For readings made in this

manner, an agreement of 1 to 2 degrees Fahrenheit would be acceptable.

Increased testing accuracy requires taking the sensor assembly down from its mast and

placing the entire sensor into a chamber with a stable temperature. The chamber should

be equipped with a precision temperature sensor or a thermometer must also be placed

into the chamber next to the thermistor. Again, compare the temperature reading of the

thermistor to that of the precision thermometer. Agreement between the two temperatures

should be close to if not better than the specified accuracy of the thermistor (±0.4° F).

Any thermistor that appears to be out of calibration or that is inoperative must be replaced

by NovaLynx. Contact NovaLynx to arrange for repair of the sensor.

Remember that when the Wind & Temperature Sensor assembly is reinstalled onto its

mast that it should be re-aligned to North.

5.0 SENSOR MAINTENANCE

Maintenance of the Wind & Temperature Sensor assembly is limited. Periodic but regular

inspections of the equipment is necessary to prevent damage due to loose or missing

hardware. Tower and mast mounted sensors experience many vibrations due to high

velocity winds blowing through the tower and mast support structure. These vibrations can

cause mounting hardware to become loose and to fall out. Tighten any loose hardware

and replace any missing hardware.

8

Inspect the sensor cable as well to detect any damage due to wind whipping. Replace any

damaged cables immediately, especially if there are exposed wires. Cracked and

weathered cable jackets are not usually a problem as long as the cable is securely

fastened by wire ties. Check wire ties and replace any that have become loose or that are

missing.

Check for damage to the anemometer cups and the vane tail. Replace any cup assembly

that has been damaged.

Apply several drops of light weight ( 3 IN 1 ) machine oil or lightly spray W 40 onto the

anemometer bearing located just below the cups.

Remove all dust, dirt, mud, bird droppings, etc. that may have been deposited onto the

cups and vane tail. Repair or replace bent tails. Check the counterweight of the wind

direction sensor. Repair the vane shaft if the counterweight is loose. The counterweight

is held in place by epoxy.

Remove any debris that may become lodged inside the temperature shield. Rinse off the

thermistor bead with clean water.

Always look at the Wind Vane alignment to North. If the alignment is critical, do the check

with a compass. Make corrections to the alignment as needed. Always check the

alignment after a severe storm with high velocity winds.

Check the equipment that the sensor assembly is connected into. Make sure that there

are signals coming from the sensors. Test the signals to be certain that the measurements

are accurate.

For critical measurements, a second sensor should be stored nearby for immediate

replacement should the primary sensor become damaged or disabled.

Contact NovaLynx for assistance with sensor testing or for help with replacement sensors

and spare parts.

9

TEMPERATURE VS. RESISTANCE DATA FOR THERMISTOR

TABLE 1

TEMPERATURE

egrees C

RESISTANCE

Kohm

-40 328.4

-35 237.7

-30 173.9

-25 128.5

-20 95.89

-15 72.23

-10 54.89

-5 42.07

0 32.51

5 25.31

10 19.86

15 15.69

20 12.49

25 10.00

30 8.060

35 6.536

40 5.331

45 4.373

50 3.606

55 2.989

60 2.490

65 2.085

70 1.753

Table of contents

Other Novalynx Accessories manuals

Novalynx

Novalynx 200-WS-02 Series User manual

Novalynx

Novalynx 200-WS-01B User manual

Novalynx

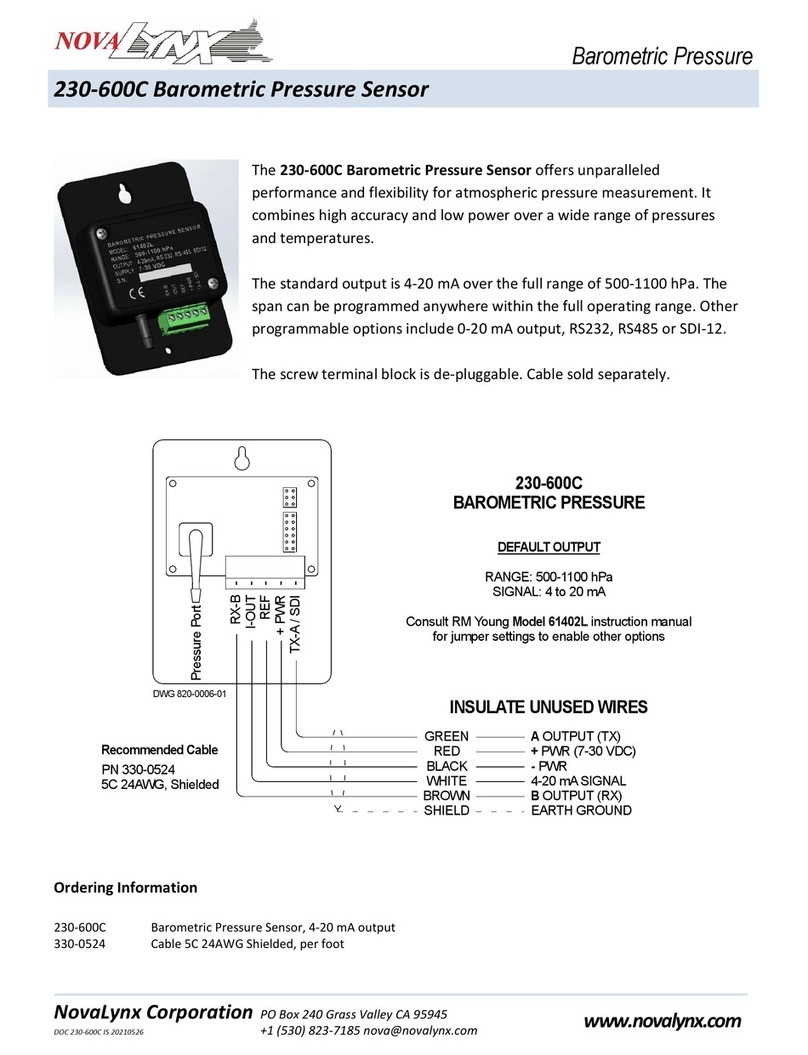

Novalynx 230-600C User manual

Novalynx

Novalynx 200-WS-02E User manual

Novalynx

Novalynx 200-WS-22 User manual

Novalynx

Novalynx 255-100 User manual

Novalynx

Novalynx 200-WS-01B User manual

Novalynx

Novalynx 225-WS-32THA User manual

Novalynx

Novalynx 200-WS-23 User manual

Novalynx

Novalynx 225-HMP60A User manual