Novalynx 200-WS-02 Series User manual

DOC 200-WS-02 UM 20210413

200-WS-02x

User Manual

WeatherPort

Wind Speed and Direction Sensors

200-WS-02E, 200-WS-02F

Phone (530) 823-7185

Email nova@novalynx.com Website www.novalynx.com

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 2 April 2021

Receiving and Unpacking

Carefully unpack all components and compare to the packing list. Notify NovaLynx Corporation

immediately concerning any discrepancy. Inspect equipment to detect any damage that may have

occurred during shipment. In the event of damage, any claim for loss must be filed immediately with

the carrier by the consignee. Damages to equipment sent via Parcel Post or UPS require the consignee

to contact NovaLynx Corporation for instructions.

Returns

If equipment is to be returned to the factory for any reason, call NovaLynx between 8:00 a.m. and 4:00

p.m. Pacific Time to request a Return Authorization Number (RA#). Include with the returned

equipment a description of the problem and the name, address, and daytime phone number of the

sender. Carefully pack the equipment to prevent damage or additional damage during the return

shipment. Call NovaLynx for packing instructions in the case of delicate or sensitive items. If packing

facilities are not available take the equipment to the nearest Post Office, UPS, or other freight service

and obtain assistance with the packaging. Please write the RA# on the outside of the box.

Warranty

NovaLynx Corporation warrants that its products are free from defects in material and workmanship

under normal use and service for a period of one year from the date of shipment from the factory.

NovaLynx Corporation's obligations under this warranty are limited to, at NovaLynx's option: (i)

replacing; or (ii) repairing; any product determined to be defective. In no case shall NovaLynx

Corporation's liability exceed product's original purchase price. This warranty does not apply to any

equipment that has been repaired or altered, except by NovaLynx Corporation, or that has been

subjected to misuse, negligence, or accident. It is expressly agreed that this warranty will be in lieu of

all warranties of fitness and in lieu of the warranty of merchantability.

Address

NovaLynx Corporation

431 Crown Point Circle, Suite 120

Grass Valley, CA 95945-9531 USA

Phone: (530) 823-7185

Email: nova@novalynx.com

Website: www.novalynx.com

Copyright © 1988-2021 by NovaLynx Corporation

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 3 April 2021

CONTENTS

1 FORWARD ....................................................................................................................................................................... 4

2 INTRODUCTION ............................................................................................................................................................... 4

3 PRECAUTIONS ................................................................................................................................................................. 5

4 SPECIFICATIONS .............................................................................................................................................................. 5

5 SITE SELECTION ............................................................................................................................................................... 6

6 TAIL ASSEMBLY ................................................................................................................................................................ 6

7 MOUNTING OPTIONS ...................................................................................................................................................... 7

8 INSTALLATION ................................................................................................................................................................. 8

9 WIRING DIAGRAMS ......................................................................................................................................................... 9

10 MAINTENANCE .......................................................................................................................................................... 10

10.1 General Inspection ................................................................................................................................................ 10

10.2 Lubrication and Adjustment ................................................................................................................................. 10

11 FUNCTIONAL TESTS ................................................................................................................................................... 11

11.1 Anemometer Electrical Test .................................................................................................................................. 11

11.2 Potentiometer Electrical Test ............................................................................................................................... 12

12 SENSOR REPAIR ......................................................................................................................................................... 12

APPENDIX A Tripod Dimensions ............................................................................................................................................ 13

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 4 April 2021

1 FORWARD

Thank you for purchasing NovaLynx products. NovaLynx has been designing and manufacturing

weather instruments since 1988. NovaLynx represents several well-known brands of quality

manufacturers, including Gill Instruments, RM Young, Kipp & Zonen, and Vaisala. It is our hope that our

products will meet all your monitoring requirements.

2 INTRODUCTION

WeatherPort 200-WS-02 Wind Sensors are moderately priced anemometers designed for general

applications up to 125 mph (56 m/s). The sensors are easy to install and maintain. They are

constructed of injection molded thermoplastic, anodized aluminum, and stainless steel for reliable

operation in adverse environments.

The base of the sensor is designed to mount on a vertical 1.07" (27 mm) diameter mast. If the sensor

cannot be mounted at the top of the mast, an optional side-mount boom (NovaLynx 200-153) is

available. Each sensor includes 40-feet (12 m) of cable.

The 200-WS-02 consists of two major parts: a rotating cup style anemometer for measuring wind

speed and a wind vane for measuring horizontal wind direction.

Wind Speed Measurement

Air movement (wind) causes the cup and hub assembly to rotate, moving the permanent magnets

embedded in the hub over a magnetic reed switch fixed in the base. Three closures of the reed

switch will be produced for each revolution of the cup assembly. The ratio of closed-to-open time is

nominally 1/10 of the total period for a revolution of the wind cups. This duty cycle may change

slightly as the sensor ages and with exposure to temperature extremes.

Wind Direction Measurement

The wind vane is mounted directly above the wind speed sensor. Fluctuations in the wind direction

are measured by the sensor as the aerodynamics of the counterweight and the tail try to keep

aligned to the path of the wind. The wind vane is coupled to a 20K ohm single turn potentiometer.

When connected to a well-regulated voltage source the output voltage of the sensor is

proportional to the wind direction and can be read by a single-ended analog input channel.

The potentiometer has a “dead band” of approximately 5 degrees between the ends of the

resistive media in the potentiometer. This gap is aligned to the NORTH label on the body of the

sensor.

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 5 April 2021

3 PRECAUTIONS

Handle the sensor carefully to avoid undue stress on the potentiometer which supports the wind vane

assembly. Do not lay the sensor on its side which would place strain on the cup assembly.

The shield wire in the sensor cable is electrically connected to the shaft holding the vane assembly. The

purpose is to bleed off static that would otherwise affect the sensor output. Therefore it is important

to earth ground the shield wire for best results.

Installations where nearby lightning strikes are likely should include a properly grounded lightning rod

above the level of the sensor, preferably on a separate tower.

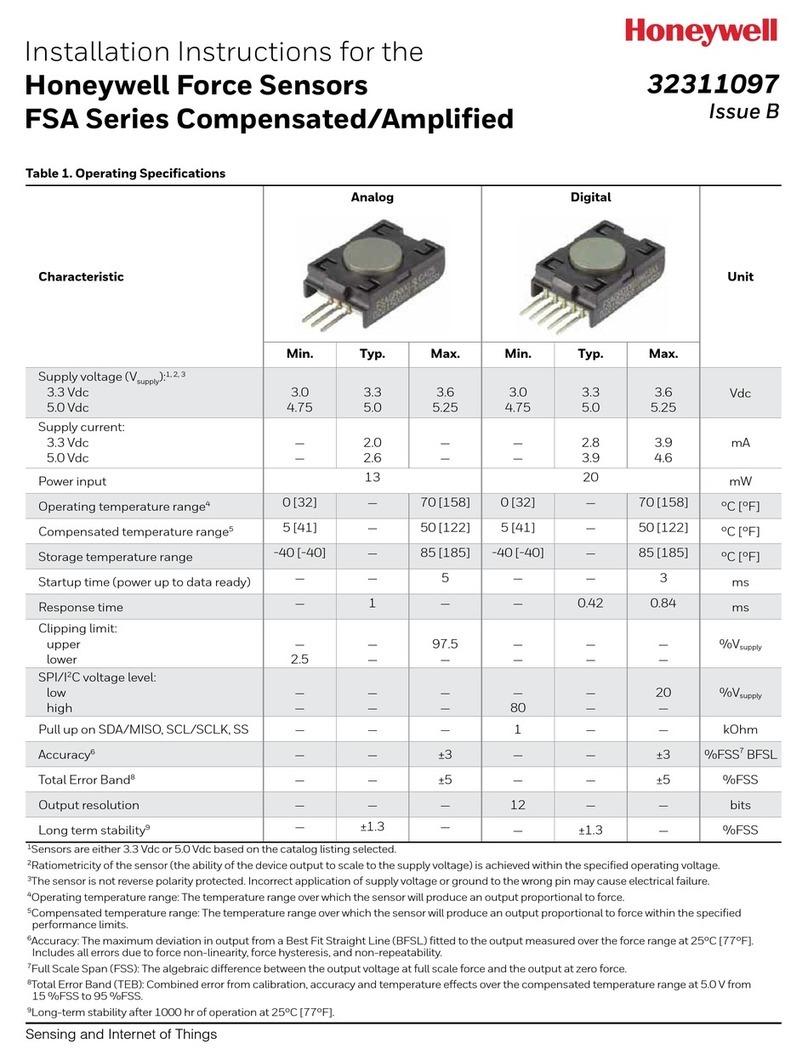

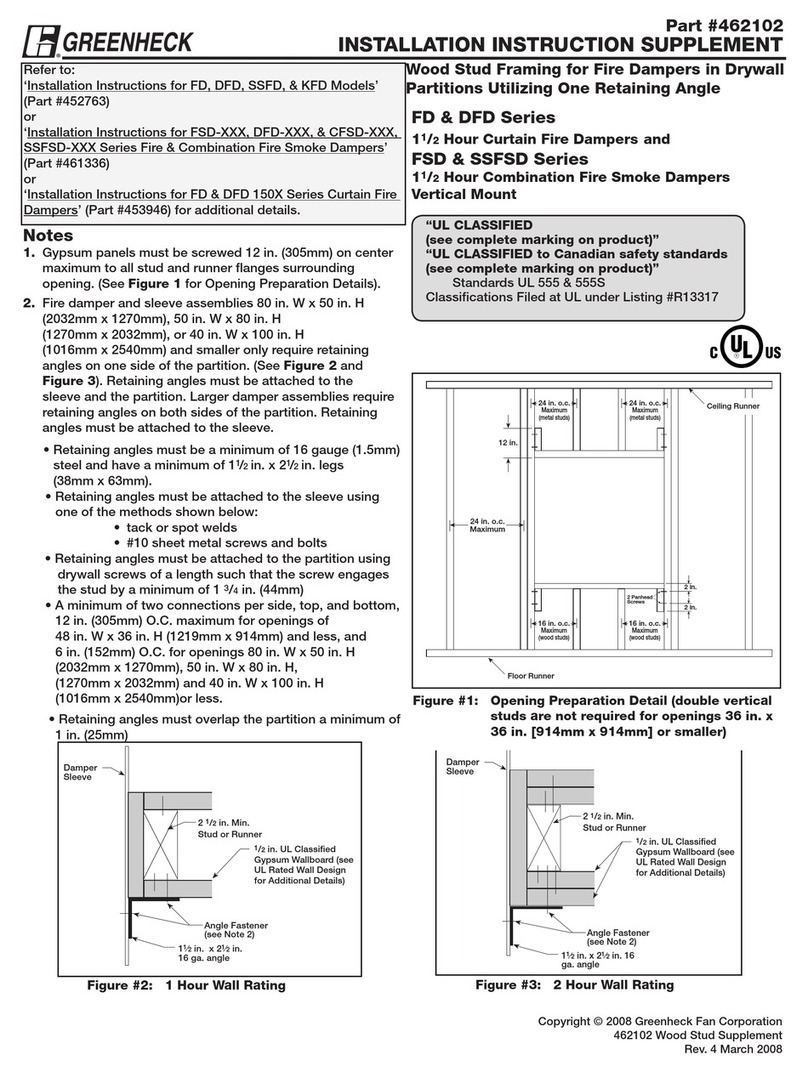

4 SPECIFICATIONS

Measurement Range 125 mph max (56 m/s max)

Speed Threshold 1.2 mph (0.54 m/s)

Speed Constant 1.25 mph = 1 Hz (0.5588 m/s = 1 Hz)

Accuracy 1 mph (0.4470 m/s) or ±3%

Transducer Type Reed switch, magnet activated

Maximum Rating 10 mA @ 50 V (ac or dc)

Turning Radius 4 inch (10.16 cm)

Measurement Range 0-360 degree azimuth

Potentiometer Gap 5 degree (approximate)

Accuracy ±3 degrees

Vane Threshold 1.2 mph (0.5364 m/s)

Distance Constant 1.5 feet (45.72 cm)

Time Constant 2 seconds

Damping Ratio 0.4

Transducer Type 20k ohm, 20% tolerance, 1% linearity, bushing type bearing

Maximum Rating 1/4 watt

Turning Radius 10.5 inch (26.67 cm)

Cable, 200-WS-02E 40 feet (12 m), 4 conductor, 24 AWG, shielded, tinned leads

Cable, 200-WS-02F 40 feet (12 m), 5 conductor, 24 AWG, shielded, tinned leads

Mounting 1.07 inch diameter by 0.82 inch socket (27 mm dia x 21 mm)

Assembled Dimensions 12.0" H x 15.2" W x 8.2" D (31 x 39 x 21 cm)

Shipping Dimensions 10.5 x 6.75 x 6.25 inches (27 x 17 x 16 cm)

Weight / Shipping 1.95 lbs (0.88 kg) / 3 lbs (1.4 kg)

Anemometer Specification

Wind Vane Specification

Overall Specification

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 6 April 2021

5 SITE SELECTION

WARNING: Avoid overhead power lines whenever possible. If there are overhead power lines, use

extreme care to prevent contact with the power lines while installing the equipment.

Choose a mounting location for the wind sensor that is free of obstructions since nearby objects can

create eddy currents that will affect the wind measurements. Try to locate the wind sensor so that the

nearest object is 10 x T away from the wind sensor mast, where T is the height of the object.

Roof mounted sensors should be placed on the upwind side of the building and away from all exhaust

vents. If the sensor is located on top of a building the sensor height should be 1.5 x H, where H is the

height of the building.

In all cases when the wind sensor data is to be correlated to National Weather Service data or World

Meteorological Organization data, the standard exposure is 33 feet (10 meters) above the ground.

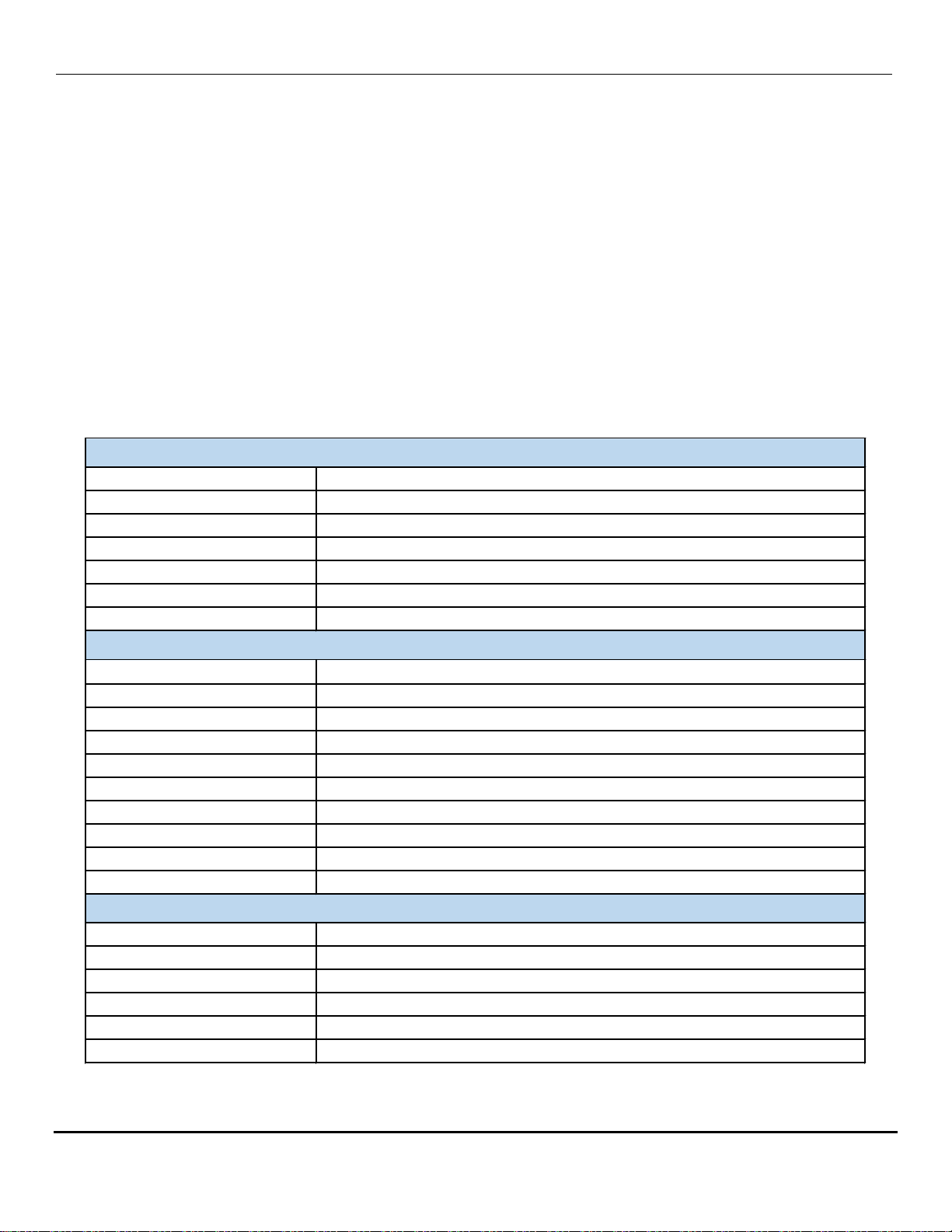

6 TAIL ASSEMBLY

The tail piece must be assembled to the vane shaft before installing the sensor.* Locate the tail piece

(packed with this manual). Remove the blue tape from the shaft and save the two screws stored there.

Slide the tail piece into the slot in the shaft and align the screw holes. Secure the tail with two screws

using a #1 Phillips screwdriver.

4-40 x 1/4 PAN PH SS

TAIL ASSEMBLY

Counterweight Hub Shaft

Tail

Vane setscrew

Potentiometer setscrew

(on opposite side)

DWG 890-0015-02

Figure 1

*Pre-assembled in some cases.

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 7 April 2021

7 MOUNTING OPTIONS

CAUTION: Be careful when working on equipment that is mounted above you. Do not allow others to

stand below when equipment is being installed as falling objects can be hazardous.

The support for the sensor must be rigid or supplemented with guy wires. A mast can be assembled

from pipe, using larger pipe at the base and ending in ¾" IPS pipe at the top. The mast should be easy

to reach for servicing the sensor and should be properly anchored and grounded. A tilt-down

arrangement can eliminate the need for lifts or ladders during installation and service.

NovaLynx tripods are a convenient alternative for temporary and permanent installations. The tripods

are available in three sizes: 3', 5' and 10' tall (Appendix A). Masts are available in various lengths.

Swaged mast segments can be fitted together to obtain the overall height needed. The swaged end is

the correct diameter for mounting 200-WS-02 sensors.

1.07" 1.25"

SWAGED ALUMINUM MAST

3.75"

Note: The base of the 200-WS-02 sensor accepts 1.07" (27 mm) diameter pipe.

If the wind speed sensor cannot be mounted at the top

of the mast, the NovaLynx 200-153 Mounting Arm (sold

separately) can be mounted to the mast or tower leg at

the desired height.

200-153 Mounting Arm

The supporting mast or tripod should be properly grounded. In areas where lightning is likely, install a

lightning rod to minimize lightning damage. NovaLynx 190-Series Lightning and Surge Protection

products are available to accommodate most applications.

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 8 April 2021

8 INSTALLATION

NOTE: Wind direction sensors are usually aligned to true north, rather than magnetic north. True north

is usually found by reading a magnetic compass and applying the correction for magnetic declination.

On-line calculators are available to enter your location and obtain the correction factor. One such

website is: https://www.ngdc.noaa.gov/geomag-web/#declination

1. Loosen the two mounting screws on the base of the sensor.

2. Place the sensor on the top of the mast or mounting stub.

3. Align the NORTH label to geographic (true) north.

4. Tighten the mounting screws using moderate torque.

The PVC jacket of the cable will last for many years outdoors under normal circumstances. In harsh

environments it may be necessary to protect the cable with conduit.

Route the sensor cable down the mast and to the monitoring equipment in the most direct manner.

Fasten the cable to the mast with cable ties to prevent whipping during high velocity winds. For best

results, use plastic cable ties that are resistant to ultra-violet radiation and place them at two foot

intervals. Leave a "drip loop" of cable below the entry point to the equipment enclosure to help keep

moisture out.

Birds of all sizes find the shaft of the wind vane a desirable place to land. The weight of a large bird can

easily damage the potentiometer by breaking it loose from the body of the sensor. The best way to

reduce this hazard is to provide an alternate landing site nearby that would be more attractive to the

weary bird.

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 9 April 2021

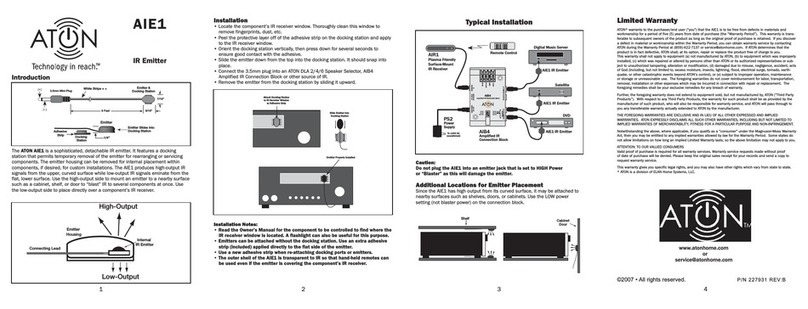

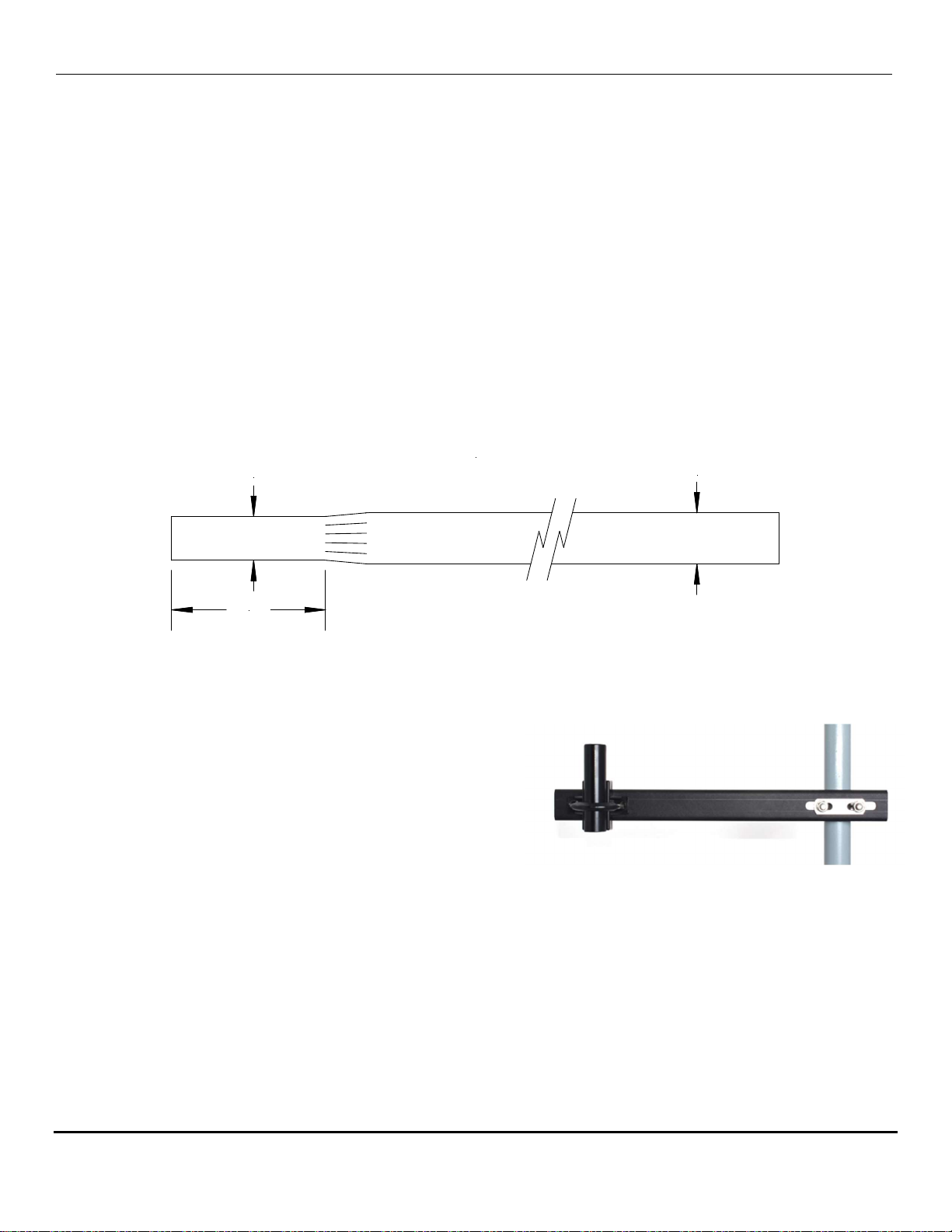

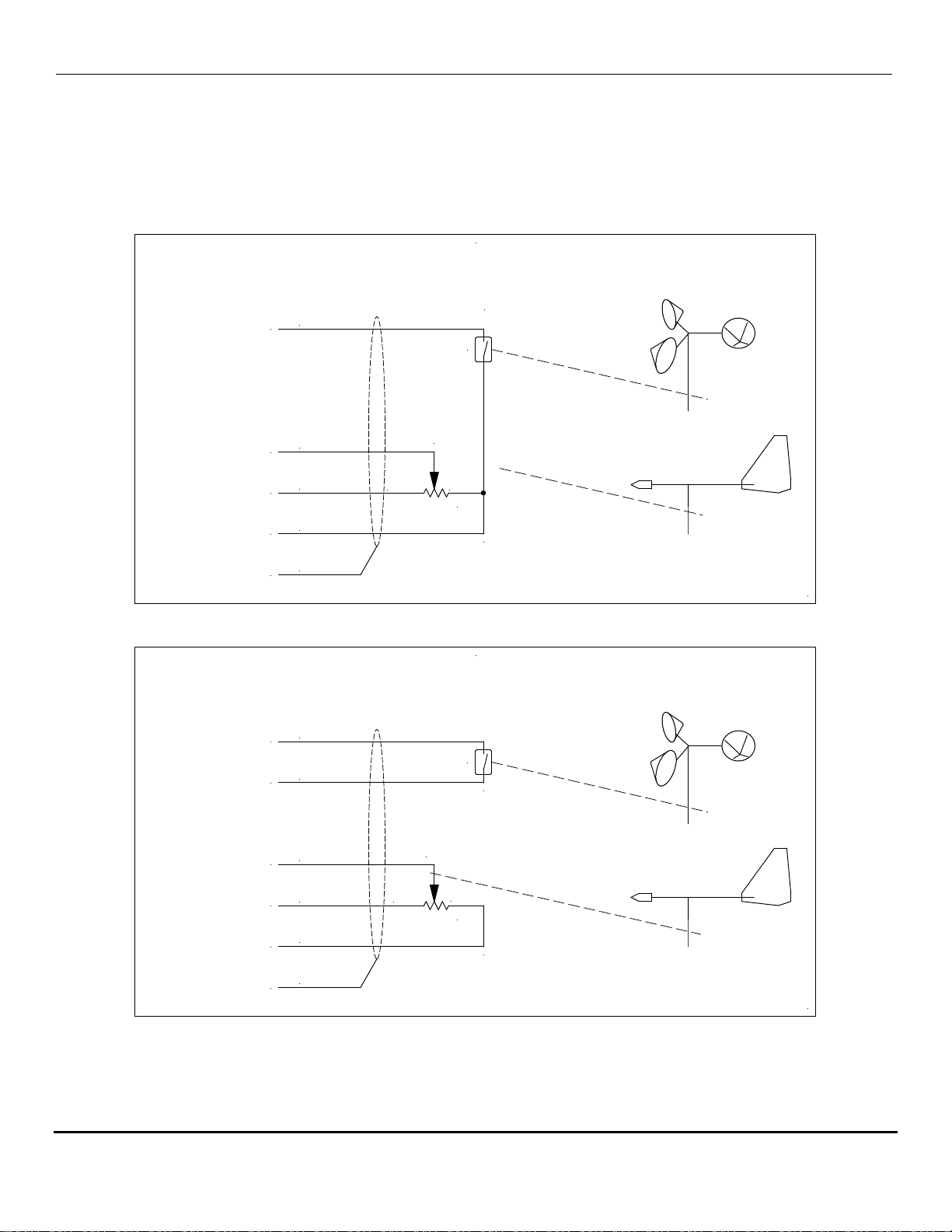

9 WIRING DIAGRAMS

CAUTION: Turn off power to the logger or other monitoring device before connecting the sensor.

CCW CW

S

355° ELECTRICAL ANGLE

3 PER REV

Earth Ground Clear

Black

Red

Green

White

Reed Switch

20k ohms

Signal Ground

Vref

Direction Signal

Speed Signal

DWG 890-0023-04

200-WS-02E

Wind Speed and Direction Sensor

200-WS-02F

Wind Speed and Direction Sensor

Speed Signal

Speed Ground

Direction Signal

Vref

Direction Ground

20k ohms

Reed Switch

White

Brown

Green

Red

Black

Clear

Earth Ground

3 PER REV

355° ELECTRICAL ANGLE

S

CW CCW

DWG 890-0016-04

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 10 April 2021

10 MAINTENANCE

Wind sensors experience vibration due to high velocity wind. The vibration can loosen the mounting

screws or the support structure. Regular inspection of the mounting hardware is required to prevent

damage to the sensor.

10.1 General Inspection

CAUTION: On occasion a sensor may be damaged by high wind or by a large bird landing on the wind

vane. Before approaching the weather station, check whether the wind vane is in position on the top

of the sensor. If it appears to be out of position, exercise extreme caution when working near the

station because the vane could detach and fall.

1. Tighten the mounting screws at the base of the sensor if necessary (do not over-tighten).

2. Spin the anemometer cup assembly. It should turn freely.

3. Rotate the wind vane gently. It should turn freely with no "rough" spots.

4. Inspect the counterweight to ensure it is firmly cemented to the vane. Repair if necessary.

5. Inspect the wind vane to ensure the tail is vertical and the screws holding it to the vane are snug.

6. Inspect the cable and secure it to the mast to prevent damage due to wind whipping.

10.2 Lubrication and Adjustment

The bearings in the 200-WS-02 sensor may eventually require lubrication to restore free movement of

the anemometer cup assembly or the wind vane. Some disassembly is required to access the bearings,

so it is best to dismount the sensor before servicing. Use a light machine oil (such as fishing reel oil) for

lubrication. Do not use WD-40 or similar products, as they wear off quickly, leaving the bearing dry and

susceptible to rust.

Disassembly

1. Remove the sensor from the weather station and take it to a

clean workbench.

2. Loosen the set screw that holds the vane to the

potentiometer shaft. The set screw requires a 1/16" Allen

wrench.

3. Lift the tail assembly straight up carefully. The shaft of the

potentiometer will be exposed, and the top of the bearing in

the cup assembly will be visible.

4. Wipe off any dust that has accumulated.

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 11 April 2021

Lubrication

1. Apply a tiny drop of light machine oil (e.g. fishing reel oil) to

the shaft of the potentiometer where it enters the bearing.

Turn the potentiometer shaft to work the oil into the bearing.

Do not apply too much oil as it could spread inside the

potentiometer and contaminate the resistance material.

2. Apply a few drops of light machine oil to the top of the ball

bearing that supports the cup assembly. Spin the cup

assembly to work the oil into the bearing.

3. Wipe excess oil off of the bearing and potentiometer shaft.

Test and Balance

1. Perform the Anemometer Electrical Test (Section 11.1). The test will confirm that the reed switch

responds to the magnets when the cup assembly rotates.

2. Perform the Potentiometer Electrical Test (Section 11.2). This test will ensure the electrical output

of the direction sensor is working. The procedure includes information on how to align the vane

with the potentiometer. Install the vane according to the instructions.

3. The final step is to balance the wind vane. Hold the base of the sensor and turn it sideways so that

the sensor is horizontal to the ground. If the vane is balanced it should show no tendency to rotate.

If it is not balanced either the counterweight or tail will rotate downwards. If the vane is out of

balance, loosen the vane set screw (Figure 1) and slide the vane either forwards or backwards to

balance the vane. Don’t forget to align the tail with the vertical axis while you tighten the set screw.

11 FUNCTIONAL TESTS

The following checks can be done with an ohm-meter after the sensor has been removed from the

tower or tripod. These tests can help determine whether the sensor needs repair or adjustment.

11.1 Anemometer Electrical Test

Set the ohm-meter to a low resistance range and touch its leads together to check for zero ohms. If it is

an analog meter adjust the dial to read zero ohms. Connect the meter to the wind speed output signal

wire and ground wire.

Rotate the cup assembly slowly until you notice the meter reading drop to less than 10 ohms. Continue

to rotate until the switch opens (high resistance). Do this for each of the 3 magnets in the cup

assembly. If the meter always reads a low resistance then the reed switch is not opening (the contacts

may have welded together) or there may be a short circuit in the cable. If the switch never closes then

NovaLynx Corporation________________________________________________________________________________

200-WS-02 Page 12 April 2021

there may be a break in the cable or the magnets are not near enough to activate the switch. Check

the distance between the cup assembly and the base. The gap should be about 1/16" (1.6 mm).

11.2 Potentiometer Electrical Test

Wind vane calibration involves checking the potentiometer output and verification of the sensor

alignment to north.

Set the ohm-meter to the 20k range (or greater range if needed). Connect the black meter lead to the

black sensor wire, and the red meter lead to the red sensor wire. The reading on the meter should be a

stable output of about 20,000 ohms (+/-20%). Rotate the vane once around while watching the meter

to ensure the reading does not change.

Connect the red meter lead to the green wire. Observe that the meter reading changes as you rotate

the vane. Check the "dead band" where the meter goes to "infinite" and verify that the counterweight

is pointing the same direction as the NORTH label on the base of the sensor. Now rotate the vane

slowly clockwise and observe that the resistance changes smoothly from near zero to the maximum

just before hitting the "dead band" again as you approach north.

If the "dead band" does not align with the NORTH label then the position of the vane can be changed

to correct the alignment:

1. Using a 1/16" Allen wrench, loosen the potentiometer set screw located on one side of the hub.

2. Lift upwards to remove the vane assembly from the sensor. Note that the potentiometer body is

bonded to the sensor body and should not move.

3. Using an ohmmeter to monitor the potentiometer output, turn the potentiometer shaft until the

center of the gap is located. You may wish to make a mark on the shaft aligned to the NORTH label.

4. Aim the counterweight in the same direction as the NORTH label and carefully lower the hub onto

the potentiometer shaft. Tighten the set screw. Note: There must be a small gap between the hub

and the cup assembly below, to allow the cups to turn freely.

5. Check your work by observing the meter as you swing the vane across north.

12 SENSOR REPAIR

The working elements of the sensor (potentiometer, anemometer cup assembly and shaft) can be

replaced as a unit. Order NovaLynx 200-WS-02E-ASSY or 200-WS-02F-ASSY depending on the type of

sensor you wish to repair. The kit includes 40 feet of cable. Save the wind vane and base from your

current sensor to complete the repair.

NovaLynx Corporation

200-WS-02 Page 13 April 2021

APPENDIX A TRIPOD DIMENSIONS

Other manuals for 200-WS-02 Series

1

This manual suits for next models

2

Table of contents

Other Novalynx Accessories manuals

Novalynx

Novalynx 200-WS-01B User manual

Novalynx

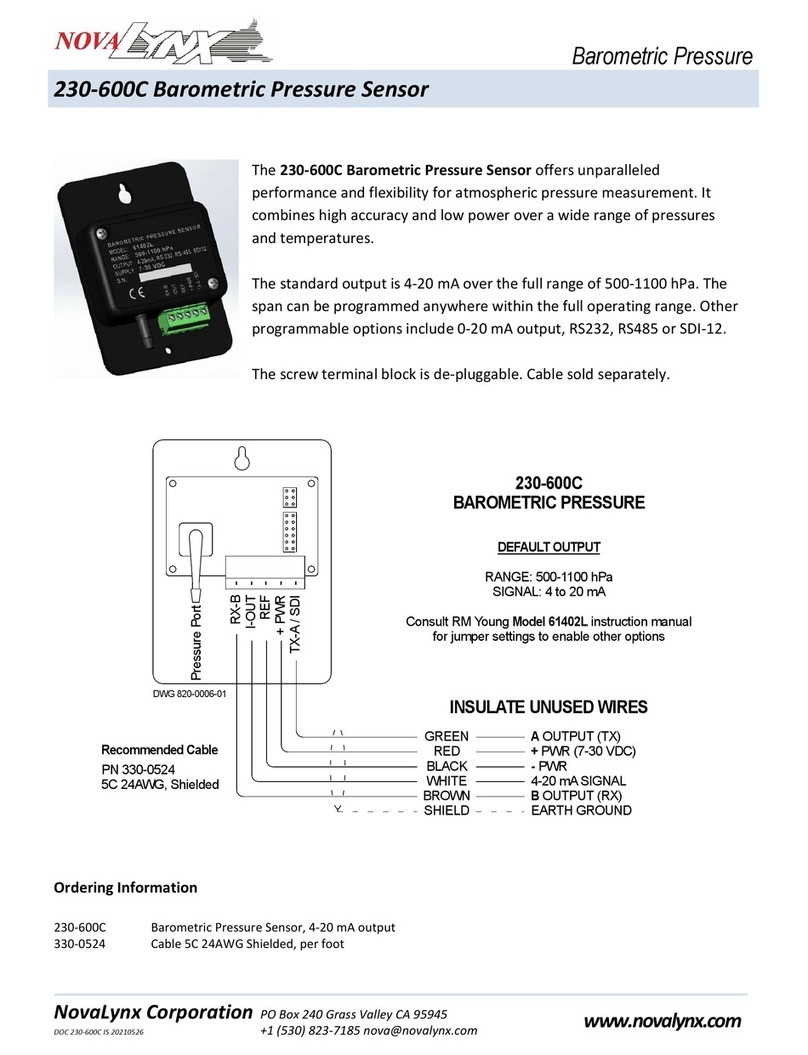

Novalynx 230-600C User manual

Novalynx

Novalynx 225-HMP60A User manual

Novalynx

Novalynx 200-WS-22 User manual

Novalynx

Novalynx 200-WS-01B User manual

Novalynx

Novalynx 200-WS-02 Series User manual

Novalynx

Novalynx 200-WS-23 User manual

Novalynx

Novalynx 200-WS-04 User manual

Novalynx

Novalynx 200-WS-02E User manual

Novalynx

Novalynx 260-2520 User manual