Novatech ST-400A Manual

The ST-400A is

designed to assist with

locating and recovering

equipment at sea. The

is not designed

for personnel rescue or

safety and must not be

used for those

applications.

ST-400A

NOVATECH DESIGNS LTD.

271 Brownlow Ave.

Dartmouth, N.S., Canada,B3B 1W6

Tel. (902)468-7275;Fax (902)3481-5538

e-mail: sales@novatechdesigns.com

Web Page: www.novatechdesigns.com

ST-400A XENON FLASHER

OPERATION & MAINTENANCE MANUAL

Revised: June 2000

Copyright © 1997–2000 Novatech Designs Ltd. All rights reserved.

Pressure

Switch

with Manual

ON/OFF

Control

Innovative

design

combines

pressure

switch

and manual

on/off switch

INTRODUCTION

The ST-400A is a self-contained submersible Xenon Flasher designed to

assist in the location and recovery of underwater oceanographic equipment.

It may be submerged for long periods in ocean depths to 7300 meters

(24,000 feet). The activation of the ST-400A is completely automatic,

when submerged below 10 meters it is OFF and at the surface it is ON at

night only.

At the surface, the ST-400A “double burst” flashes for approximately

7 days at night only and visual range is up to 3 miles at factory settings.

UNPACKING

Be sure to check shipping container for any signs of damage that might

have damaged the contents. Report any such damage to the carrier.

OPERATOR WARNINGS

PRESSURE CASE

As with any sealed pressure case, the contents could be under pressure due

to battery or seal failure. This could expel the batteries when the Pressure

Switch is removed. To be safe, always point the open end away from you

and always remove the Pressure Switch first. The Pressure Switch is designed

to vent any internal pressure when it is being removed. If a battery is trapped

in the case take extreme care, there could be a pressure buildup behind it

and the battery could be expelled at any time.

QUICK START

1. The ST-400A is shipped with batteries installed

2. Check that the Pressure Switch is secure, clockwise finger tight

3. Turn Pressure Switch knob to ON position

4. Cover lens for darkness and verify “double burst” flash

5. The ST-400A is ready to be deployed

2ST-400A

SPECIFICATIONS

Flash Tube: ............... Replaceable — rated for 20 x 106

flashes

Flash Rate: ............... adjustable 14/minute to 60/minute ±5%

over 3 to 6 volt battery life (factory set

at 20/minute)

Visible Range: .............. adjustable 2 to 4 nautical mile range

(0.2 to 0.6 watt-seconds) ±5% over 3 to

6 volt battery life (factory set at 3 nm

range)

Effective Intensity: ............ 6 to 35 candelas

(factory set at 20 candelas)

Operating Temperature Range: ...... -40°C TO + 60°C

Ocean Depth Rating: ........... Approx. 7,300 metres (24,000 feet)

Pressure Switch:............. Pressure activated switch turns ST-400

ON at the surface, OFF at depths below

approx. 10 metres . Manual override,

ON/OFF control knob.

Batteries: ................ 4 alkaline “C” cells

Battery Life at 4°C: Approx. 7 days, ON at night, OFF during

day at factory settings

Pressure Case Material: ......... 6061-T6 Aluminum, Hard Anodized to

Mil Spec A8625 Type 3

Weight With Batteries: .......... In water 2.2 lb. (2.2 kg)

In air 3.7 lb. (1.7 kg)

Pressure Case Dimensions: ....... 18.5" long (470 mm), 1.7” diameter

(43 mm)

11

ST-400A

CUSTOMER SERVICE

If you have any questions or problems, please contact the factory. We are

available to provide assistance Monday to Friday 8:00 a.m. to 5:00 p.m.

Telephone: (902)468-7275

Fax: (902)481-5538

E-mail: [email protected]

WARRANTY

Novatech Designs Ltd. guarantees this product to be free from defective

materials and workmanship and agrees to remedy any such defects for a

period of 1 year commencing from the date of purchase. The Pressure

Switch is guaranteed for 2 years, excluding corrosion damage.

This warranty does not apply if the equipment has been subject to misuse,

neglect, accident or improper installation, or altered outside our factory, or

to damage caused by defective batteries. Novatech Designs Ltd. neither

assumes nor authorizes any person to assume for it any other obligation or

liability in connection with this product, including damage resulting from

design or equipment failure.

10 ST-400A

INSTALLATION

PRESSURE CASE

When mounting the pressure case take care to prevent any side loading on

the Pressure Switch or the top end Delrin bulkhead cap. Over time, side

loading on those parts can cause a leak. Never attach anything to the 2

mounting screws on the Pressure Switch Zinc anode.

To minimize corrosion never mount the pressure case directly to metal. Isolate

the pressure case by wrapping it with vinyl tape at the contact points.

OPERATING INSTRUCTIONS

BATTERIES

The ST-400A uses 4 Alkaline “C” cells for approximately 7 days of night-

time flashing. Install fresh batteries with the positive terminal towards the

bulkhead connector. The circuit is reverse polarity protected. Rechargeable

batteries are not recommended. Always remove and discard batteries when

the ST-400A is not in use.

TURN ON & OFF

A manual ON/OFF switch is incorporated in the Pressure Switch. To turn

ST-400A ON or OFF rotate the knob as shown in Figure 1.

Figure 1. PS-200 Label

3

ST-400A

PRESSURE SWITCH PS-200

MAX. DEPTH 7300 M

PATENT PENDING

ON

OFF

Turn ON before deployment

(ON at surface, “AUTO OFF” below 10 m.

Turn OFF when not in use.

TEST OPERATION

The following quick test verifies the ST-400A is functioning properly.

1. Turn Pressure Switch knob to ON

2. Cover the lens for darkness

3. Verify a “double burst” flashing

4. Expose lens to light, Flasher stops flashing

5. Turn Pressure Switch knob to OFF, flasher stays off in the dark

6. ST-400A is ready to be deployed.

ADJUSTMENTS

To gain access to the electronic board, remove the top cap (bulkhead

connector end) on the pressure case by rotating the black Delrin cap

counterclockwise by hand. Only hand tight when reinstalling.

CAUTION: The ST-400A generates high voltage so do not operate it

without the protective sleeve around the electronic board.

SINGLE FLASH (disable “double burst”)

Remove black jumper on lower end of PC Board (end opposite the flash

tube). Battery life will increase by approximately 30%.

ADJUST FLASH RATE

Flash rate control location is marked on the yellow label — use a small flat

screwdriver to prevent damage to the control. Higher flash rate will de-

crease battery life (see graph, figure 2).

ADJUST INTENSITY (VISIBLE RANGE)

Intensity control location is marked on the yellow label. Increasing inten-

sity will decrease battery life (see graph, figure 2).

The measurement of light and the units used can be confusing and mislead-

ing. The standard in the marine industry is Effective Intensity measured in

Candelas. Tests were performed in clear nighttime conditions at sea. From

the resulting data, the following table was prepared.

Note: As conditions are highly variable, your actual range may be less than

the estimates in Table 1.

4ST-400A

4. Test the operation by pressing the Cup Seal with your finger and listen

for the micro switch clicking as you press down firmly

5. Thoroughly lubricate the outer portion of the Cup Seal

6. Make sure the Delrin Knob carrier is clean and lubricated

7. Install the Delrin carrier

8. Lubricate the two socket head cap screws

9. Install Zinc Anode and secure with the two socket head cap screws. It

will be necessary to rotate the Delrin knob carrier to line up the

threaded holes in the aluminum body

Testing

1. Install the PS-200 on your equipment

2. Make sure the Unit is ON when the PS-200 ON/OFF knob is in the

ON position

3. Make sure the Unit is OFF when the PS-200 ON/OFF knob is in the

OFF position

CORROSION PREVENTION

Corrosion is a problem common to all metals used in the ocean. To help

minimize corrosion damage, the ST-400A is made with 6061-T6 aluminum

and is hard anodized; it is also fitted with a Zinc Anode. If the Zinc is more

than 50% wasted, replace it with part no. ZN-100. If the anodized surface

is damaged, pitted or gouged, protect it against further corrosion by apply-

ing tape, paint, or fast cure epoxy.

Several precautions can be taken prior to deployment to further minimize

corrosion:

•Do not mount the flasher against metal.

•Wrap the entire flasher with vinyl tape. Take care not to cover the hole in

the bottom of the Pressure Switch or the Zinc Anode.

•Prevent the anodized surface from being scratched or damaged. Damage to

the anodized surface can cause pitting.

9

ST-400A

“O” RING MAINTENANCE

Novatech strongly recommends that “O” rings be serviced on a regular basis

to ensure a reliable seal. Remove and lubricate at least once a year or

sooner and replace every two years or sooner. With regular maintenance,

“O” rings will be very reliable and trouble free. It has been, however, our

observation that most “O” rings are neglected for years and expected to

perform at the extremes of their design limits.

There are two “O” rings and a Cup Seal to service. The “O” rings are at the

top end of the Pressure Case and on the Pressure Switch, the Cup Seal is on

the Pressure Switch. Replace the two “O” rings with Parker #218 or

equivalent available from Novatech or your local “O” ring supplier. Lubri-

cate lightly with a silicone grease, we recommend Parker Super O Lube.

Instructions for the lubricating or replacing the Cup Seal are below.

PRESSURE SWITCH CUP SEAL

The Cup Seal must not be overlooked when lubricating the “O” rings. The

Cup Seal should be lubricated every year and replaced every two years or

sooner. Lightly lubricate the Cup Seal by performing the following procedure:

Disassembly

1. Remove the two socket head cap screws on the Zinc Anode.

2. Withdraw the Zinc Anode and the black “Delrin” Knob Carrier.

3. Make sure the PS-200 Pressure Switch is in the upright position

(Cup Seal up, spring down); this will make sure a small internal pin

will not fall out. Do not lose that pin.

4. Carefully pry off the rubber Cup Seal, do not scratch the Cup Seal or

the mating “O” ring surface.

5. Observe the S.S. Flat Spring and note how it is installed.

Lubrication

1. Clean all surfaces and the Cup Seal.

2. Lubricate (very lightly) the “O” ring shaped portion of the Cup Seal

and the mating aluminum surface with silicone grease (Parker Super O

Lube). Do not spread the silicone grease anywhere else. Excess

silicone grease can cause the Pressure Switch to fail.

Reassembly

1. Be sure the small pin is in place

2. Place the Stainless Steel Flat Spring back in its correct position

3. Install the Cup Seal and rotate the Cup Seal ¼ turn to make sure it is

seated correctly

8ST-400A

INTENSITY SETTING EFFECTIVE INTENSITY

(Candelas)

RANGE

nautical miles

MINIMUM 6 2.0

FACTORY SETTINGS 20 3.0

MAXIMUM 35 4.0

Table 1. Effective Intensity measured in Candelas (estimated)

BATTERY LIFE

The following graph (Figure 2) may be used to estimate the approximate

battery life for different flash rate and intensity settings. Your actual results

may vary since we have assumed 1 day is 12 hours daylight, 12 hours

night. (ST-400A operates 12 hours per 24-hour period). Your actual day to

night ratio will depend on the season and your location.

5

ST-400A

Figure 2. ST-400A — Battery Life Estimates “Double Burst Flash”

6ST-400A

12

9

6

3

2.0 2.5 3.0 3.5 4.0

Range in Nautical Miles

Battery Life

(Days)

(ON at night

OFF during

daylight)

For single

burst

setting,

increase

battery life

by approx.

30%

MAINTENANCE

There are no user repairable parts in the ST-400A, return to the factory for

repairs.

REGULAR MAINTENANCE

•Rinse thoroughly with fresh water after every use

•Always remove batteries when not in use

•Always use fresh batteries

•Protect “O” ring surface from damage

•Replace worn or damaged “O” rings

•Keep batteries and electronics dry

“O” RING FACTS

“O” rings don’t last forever; two to five years is a conservative estimate.

The main problem with “O” rings is that over time they can take a “set”.

They lose their original round shape and they become slightly flattened

resulting in less squish. Reduced squish can lead to a water leak near the

surface. The best way to prevent a problem is to service the “O” rings

before every deployment.

Some of the main factors that can cause a “set” are:

•High storage temperature (exceeding 40ºC) over time will cause the rubber

to harden

•Exposure to sunlight and ozone will cause the “O” ring to deteriorate and

stiffen

•Temperature does not have to be that cold for an “O” ring to lose a great

deal of its flexibility. At 4ºC, an “O” ring has stiffened significantly.

•“O” rings must be lightly lubricated with silicone- based grease. We rec-

ommend “Parker Super O Lube”

•A typical seal failure results in a very small amount of water, not a flooded

case. Most seal failures occur near the surface

•The “O” ring becomes less flexible as the rubber ages

•If you are operating or storing at low temperature, it makes it even more im-

portant to service the “O” ring regularly

7

ST-400A

Table of contents

Popular Marine Equipment manuals by other brands

Maxwell

Maxwell HWVC3500 Series manual

auto maskin

auto maskin Marine Pro 200 Series Quick installation guide

Webasto

Webasto AirTop 2000 S installation instructions

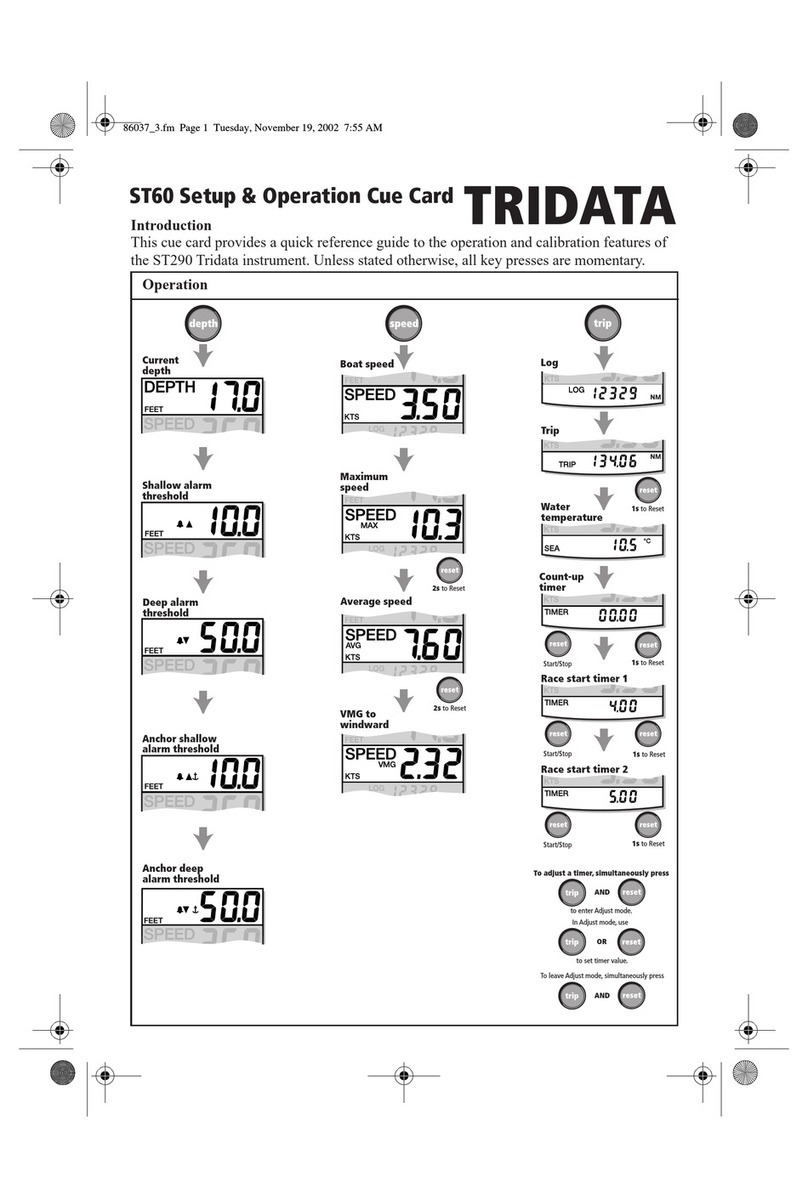

Raymarine

Raymarine ST60 Tridata quick start guide

Bennett Marine

Bennett Marine AutoTrimPro Installation & user guide

Plastimo

Plastimo PILOT 150N owner's manual