1 Description

AlphaRiverTrackPilot is a track control system for inland vessels. It is designed to assist in navigation by steering the

ship along pre-defined guiding lines. The track control system computes the steering commands such that the center of

gravity of the ship follows the guiding line with a small cross track error. The steering commands are sent to the autopilot

system as values for desired rate of turn (ROT). The autopilot system controls the rudder angle so that the ship turns

as required by the track control system. The position, orientation and motion of the ship are measured using a GPS

compass together with a ROT sensor (gyro).

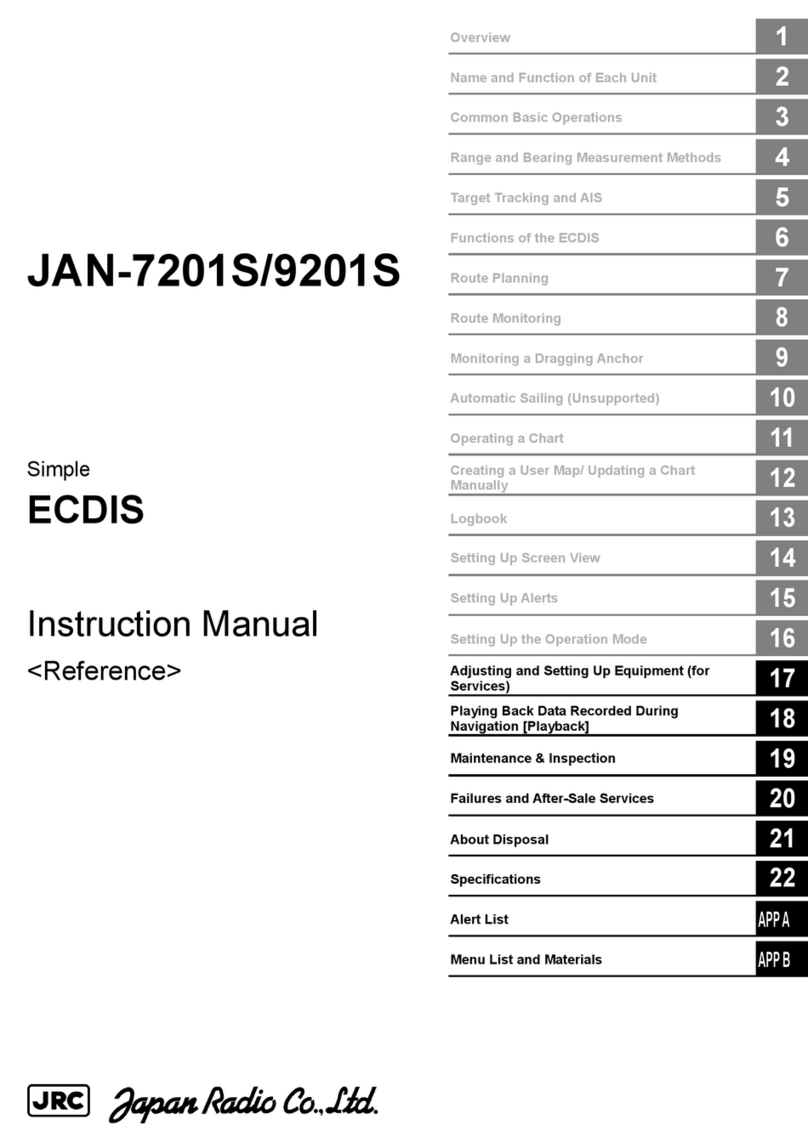

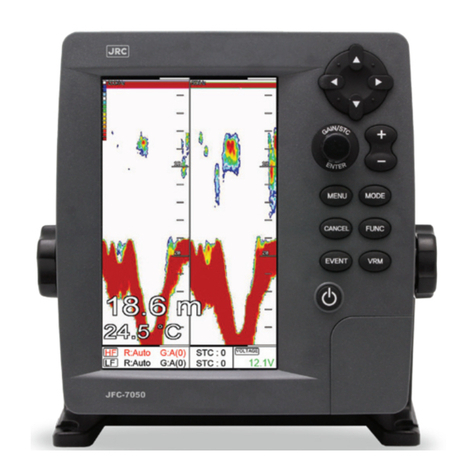

Figure 1: Overview navigation

The track control system features a network interface for inland ECDIS chart displays. At first, the chart display shows

the selected guiding line. Later, using the chart system, it is possible to select other guiding lines or create new guiding

lines according to personal experience and send them to the track control system.

For passing and encounter of other vessels there is an adjustable offset to the guiding line. The offset is changed using

the joystick on the control panel, a button on the touchscreen serves to reset the offset to zero. When an offset has been

set, a new parallel guiding line is computed by the track control system and displayed, in red, in the chart system.

The track control system is delivered together with a touchscreen that displays the most important data of the control

system. It is possible to select different configurations and control parameters i.e. for different loading conditions. The

touchscreen also displays alarms and warnings.

The track control system can be delivered with an optional LTE modem for remote monitoring and maintenance.

1.1 Limitations

The track control system performs an extensive analysis of the sensor data to be able to detect errors of the GPS

receiver and the ROT sensor. The detection of errors is subject to the technical possibilities. Detected errors are

displayed on the touchscreen. Severe errors will trigger an additional acoustic alarm. In case of such a severe error, it is

required to switch to manual steering.

Since there is only one single sensor for the measurement of the position and attitude of the ship, there is no guarantee

that every possible error of the sensor is detected. If there is an undetected failure of the sensor there may be large

deviations from the selected track. Especially beneath bridges and close to large buildings, reception of GPS signals is

deteriorated and thus the track control system must be monitored carefully. Someone must monitor the operation of the

track control system at any time and switch back to manual control in case of an error. The track control system is not an

autonomous system that reacts to the surrounding traffic.

The skipper is fully responsible to comply with the laws and regulations of inland navigation.

5 | Description