2

Installation Instructions

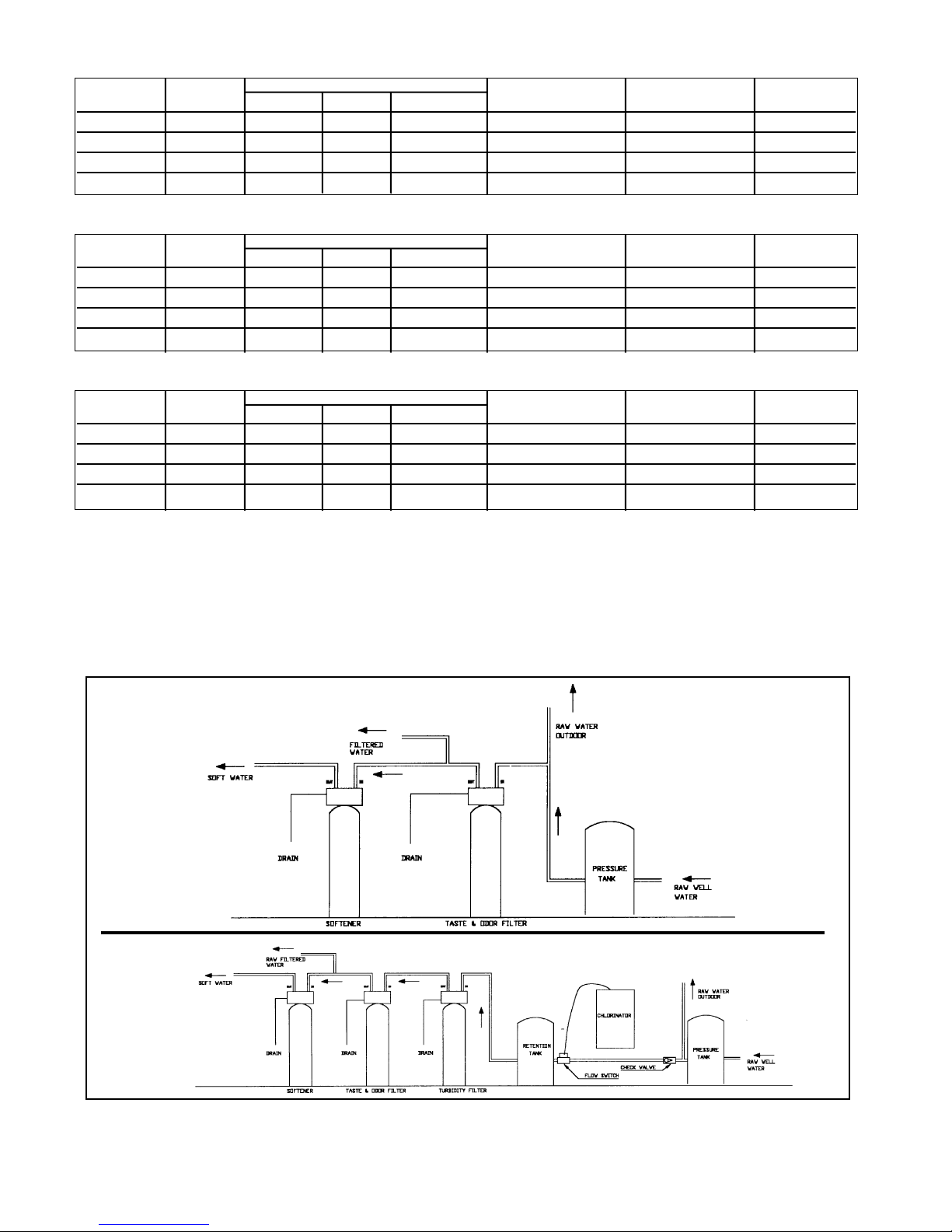

CAUTION:

If the g ound f om the elect ical panel o b eake

box to the wate mete o unde g ound coppe

pipe is tied to the coppe wate lines and these

lines a e cut du ing installation of the No yl

bypass valve and/o poly pipe, an app oved

g ounding st ap must be used between the two

lines that have been cut in o de to maintain

continuity. The length of the g ounding st ap will

depend upon the numbe of units being installed

and/o the amount of coppe pipe being eplaced

with poly. See Figu e 1.

In all cases whe e metal pipe was o iginally used

and is late inte upted by poly pipe o the No yl

bypass valve, as in Figu e 1 o by physical

sepa ation as in Figu e 2, to maintain p ope

metallic pipe bonding, an app oved g ound clamp

c/w not less than #6 coppe conducto must be

used fo continuity.

Check you local elect ical code fo the co ect

clamp and cable size.

NOTE: This time ’s p og ams will be out of sync if

you tu n the knob too fa o do not allow the d ive

moto to stop completely befo e continuing to the

next step. If this happens while doing any

p ocedu e, otate the knob clockwise until the

white dot lines up with the time of day a ow and

the unit will etu n to the se vice position. You can

then sta t again.

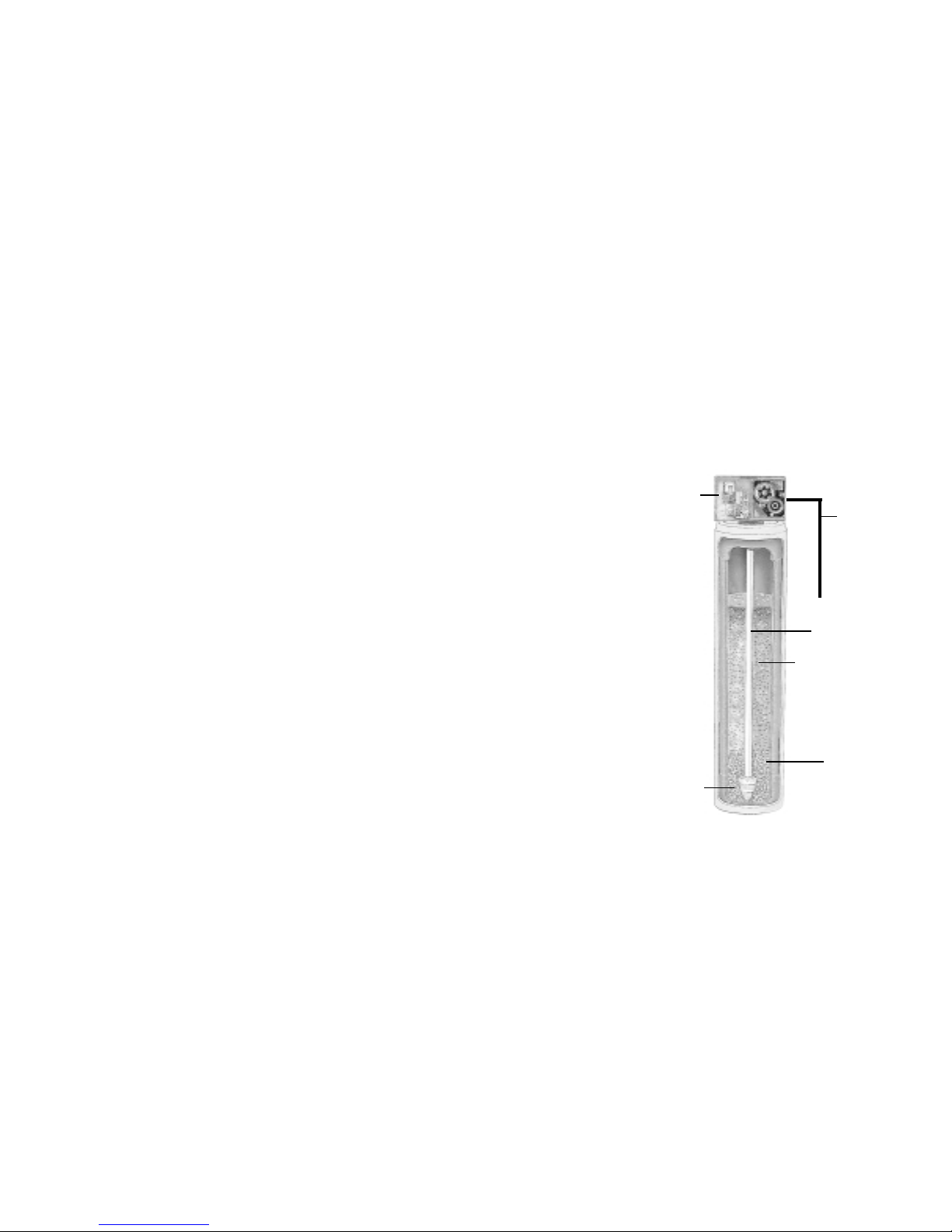

1. Place filte on a flat su face in desi ed location, nea a d ain and 115 volt AC outlet. Subjecting you filte to f eezing o to

wate tempe atu es above 120°F (49°C) will void the wa anty. Remove the valve f om the ca ton. Be su e the dist ibuto

tube is in place. Ca efully position the valve ove it and tu n secu ely on to the fibe glass tank.

Note: All multi media and some la ge units a e supplied with the media sepa ate. Please efe to page 5 Installations &

Replacement of Filte Media Pak.

2. Attach the installation kit o bypass to the cont ol valve. Make inlet and outlet wate connections to meet applicable

plumbing codes. A 3/4” inlet line is ecommended. When sweat fittings a e used, solde the adapte s fo the inlet and outlet

to the coppe pipe fi st. This p ocedu e is necessa y because the cont ols must not be subjected to tempe atu es above

160°F (71°C). Then, using teflon tape, sc ew the adapte s fo the inlet, outlet and d ain into the valve. CAUTION: do not

use pipe th ead compound as it may attack the mate ials in the valve body.

3. On the d ain, use 1/2” hose ba b supplied and full 1/2” hose (not supplied) fo the d ain line and make the sho test un to a

suitable d ain. The d ain line must be secu ed in position at the end which discha ges into the d ain so it cannot be

inadve tently moved f om the d ain.

4. Loosen the two sc ews on the time cove to emove it f om the time .

5. Automatic wate filte s a e supplied f om the facto y in the backwash position, eady fo sta t up. Tu n on the wate supply

to the unit. Open the supply line slowly and allow the ai to escape f om the filte befo e tu ning the supply wate on all the

way. Allow the unit to backwash until all the ai and media fines a e no longe showing at the d ain. This may take up to 15

minutes so you need to unplug the time until you a e eady to continue.

6. Plug the time in, set the time and f equency of egene ation following inst uction on page 4. Allow the unit to complete the

cycle on its own f om this point.

7. Make su e the bypass valve is in the se vice position.

Installation and Start-up Procedure

ALL GOVERN ENT CODES GOVERNING INSTALLATIONS OF THESE DEVICES UST BE OBSERVED.

Elect ical Panel

G ound St ap

Poly Pipe

G ound F om Panel Poly Pipe

Filte

c/w Plastic Bypass

Coppe Pipe

Wate Mete

Outside Wate Line Fo Outside & 3 d Tap Comes F om Mete

Filte ed Wate Line in Home

Unfilte ed Wate Bypass

Loop Cut & Capped G ound St ap Requi ed Because

of B eak in Continuity

Figu e 2

Figu e 1