Novatron XSITE PRO SPI 14.2 User manual

XSITE PRO SPI 14.2

USER MANUAL

Version 1.14.2.46

October 2018

TA LE OF CONTENTS

1 INTRODUCTION 1

1.1 Safety instructions....................................................................................................................4

1.2 Product overview......................................................................................................................8

1.3 Handling of the system.............................................................................................................9

1.4 Transportation and storage.......................................................................................................9

1.5 Support and maintenance........................................................................................................9

2 GETTING STARTED 10

2.1 Connecting the display........................................................................................................... 10

2.2 Turning on the system............................................................................................................11

2.3 Installing or changing a SIM card............................................................................................11

2.4 Display unit, US ports and buttons.......................................................................................12

2.5 Turning off the system............................................................................................................ 12

3 USING THE 2D SOFTWARE 13

3.1 Getting started........................................................................................................................ 13

3.2 Measurement / work view.......................................................................................................13

3.2.1 Symbols (icons) on the display while working...............................................................14

3.2.2 asic operations / buttons on the display......................................................................15

3.3 Settings..................................................................................................................................16

3.4 Excavation using a reference height (stake)...........................................................................17

3.5 Distance measurement while working....................................................................................18

3.6 Relocating the excavator by using the memory function.........................................................19

3.7 Creating an advanced or simple slope using the system........................................................21

3.8 Working with a Laser reference (with or without the stake).....................................................22

3.8.1 Automatic height update to a laser reference while working..........................................24

3.9 Special settings......................................................................................................................25

3.9.1 Alert limits and XD2 LED display...................................................................................25

3.9.2 Warning limits for boom movements.............................................................................26

3.10 Worn or new ucket calibration............................................................................................27

3.10.1 Checking the bucket calibration..................................................................................28

3.10.2 Tilt bucket calibration (tilt sensor is optional)...............................................................29

4 WORKING USING POSITIONING (3D / LANDNOVA) 31

4.1 License key and access rights for optional modules...............................................................32

4.2 Opening a project...................................................................................................................32

4.3 Object selector (object selection method)...............................................................................33

4.4 User interface......................................................................................................................... 34

4.4.1 How to change view or change active layer / line..........................................................36

4.4.2 Additional views, profile and cross-section....................................................................40

4.4.2.1 Additional profile views detailed........................................................................41

4.4.3 Information bar..............................................................................................................42

4.4.3.1 Terrain...............................................................................................................43

4.4.3.2 Point..................................................................................................................44

4.4.3.3 Line...................................................................................................................45

4.4.3.4 DTM + Line.......................................................................................................47

4.4.3.5 GPS.................................................................................................................. 47

4.4.3.6 Log....................................................................................................................48

5 MENU 50

5.1 Menu structure....................................................................................................................... 50

5.2 Options menu.........................................................................................................................51

5.3 Settings..................................................................................................................................52

5.3.1 User interface................................................................................................................53

5.4 Operations.............................................................................................................................. 53

5.4.1 Create reference line.....................................................................................................54

5.4.2 Drilling plan creator.......................................................................................................55

5.4.3 Importing project data to the system.............................................................................56

5.4.4 Importing the project from FTP......................................................................................57

5.4.5 Importing the project from US memory stick...............................................................57

5.5 Example projects....................................................................................................................58

5.5.1 Digital terrain models....................................................................................................58

5.5.1.1 ackground maps in projects............................................................................59

5.5.1.2 Line model........................................................................................................ 60

5.5.1.3 2D / 3D object proximity alarm..........................................................................61

5.5.2 Additional files for digital terrain models and line models..............................................62

5.5.2.1 Point files..........................................................................................................62

6 ACCURAC TEST 63

6.1 Depth and distance accuracy test 1........................................................................................63

6.2 Depth and distance accuracy test 2........................................................................................63

6.3 Tilting bucket accuracy test.....................................................................................................64

6.4 Quality of positioning..............................................................................................................65

6.5 GNSS positioning, RTK correction and localisation................................................................67

6.6 Coordinate systems and transformations...............................................................................68

6.7 Geoid Model...........................................................................................................................69

6.8 GNSS accuracy test...............................................................................................................69

7 NETWORK OPERATION 70

7.1 Remote support......................................................................................................................70

8 TECHNICAL SPECIFICATIONS 71

APPENDICES

EC Declaration of Conformity

EC Declaration of Conformity

FCC Declaration of Conformity

FCC Declaration of Conformity

1 INTRODUCTION

This document is user manual for XSite PRO machine control system (“Product”). Read this

manual carefully before any use of the product and especially observe the safety instructions.

Make sure that you understand the information contained in this manual before any use of the

product. Keep manual available for later use.

System software version

This manual applies to software version SPI 14.2

Manufacturer's contact information

Novatron Oy

Jasperintie 312

33960 Pirkkala, Finland

Tel: +358 (0)3-357 26 00

Web: www.novatron.fi

Conformity to FCC rules (North America)

This product complies with part 15 of the FCC rules.

Disclaimer

The manufacturer does not accept any liability for damages caused by:

Inappropriate assembly and/or installation

Non-observance of the User Manual

Non-intended and improper use

Use beyond operation limits

Use by insufficiently qualified and trained personnel

Use of unauthorized spare parts and accessories

Deconstructing and/or rebuilding of the product

Conformity to directives and regulations

This product is in conformity with EU's EMC (2004/108/EC), RED (2014/53/EU), RoHS

(2002/95/EC), and WEEE (2002/96/EC) directives and REACH (2006/1907/EC) regulation.

This product may not be disposed of together with unsorted household waste, it must be collected

separately.

The product contains radio modem manufactured by Sierra Wireless.

•Sierra Wireless MC7710 or MC7304 modem (European Union)

•Sierra Wireless MC7330 modem (Eastern Asia)

Modem is used for communicating in the following networks: GSM, GPRS, EDGE, WCDMA,

HSPA, HSUPA.

EU declaration of conformity for the radio modem is available at:

Sierra Wireless (UK), Limited

Lakeside House

1 Furzeground Way, Stockley Park East

Uxbridge, Middlesex

U 11 1 D

England

User Manual. Xsite PRO SPI 14.2 Page 1 / 77

Disclaimer

The manufacturer does not accept any liability and makes no warranty and representation (either

implied or express) of the accuracy or completeness of the information contained in this document.

The manufacturer is not liable in any circumstances for any possible loss of profit or revenue or

other financial loss, including but not limited to any special, incidental, indirect or other damages.

Furthermore, the manufacturer reserves the right to correct and change the contents of this

document from time to time, without any obligation to inform any person of such corrections and

changes.

The product shall be only used for the purpose determined in this document, and only together with

such devices and parts that the manufacturer has accepted or which it recommends. The

manufacturer does not warrant fitness for any particular purpose. Correct and reliable functioning

of the machine requires appropriate transport, storage and installation, as well as cautious use and

repair.

The manufacturer does not accept any liability for any damages caused by:

•Inappropriate assembly and/or installation

•Non-observance of the User Manual

•Non-intended and improper use

•Use beyond operation limits

•Use by insufficiently qualified and trained personnel

•Use of unauthorized spare parts and accessories

•Deconstructing and/or rebuilding of the product, or

•any other similar matters for which the operator is responsible for

User Manual

The Manual contains basic information to be considered when using and maintaining the product.

Observing all security instructions and guidelines given here is important for safe operation.

Therefore this operator Manual must be read prior to any use of the product and applied without

fail by any person assigned with working processes at the machine, such as operation, diagnostics

and maintenance.

The Manual is a part of the product and must be passed on to third persons or later owners as

required. It must be permanently kept at the usage site and be available for operating and

maintenance personnel. All local accident prevention regulations, general safety regulations and

the manufacturer’s safety regulations must be observed by the operator.

The product is available with various sensor combinations. If your system is not equipped with all

sensors or other components, their description and instructions do not apply. Due to multiple

possible applications, the functions of the product in this manual will be explained by an excavator

installation manual.

It is the intention of the manufacturer that the Manual remains correct and up-to-date. To ensure

that we keep our technological advantage it may be necessary to undertake modifications of the

product and its operation without prior notice; in such cases the information in this manual may be

superseded by further revisions, and your local dealer will provide you with a new manual upon

your request. The manufacturer and its representatives do not accept liability for any disturbances,

failures or resulting damages.

We will not be held liable for possible errors or consequences arising from this manual. Should you

wish to make suggestions regarding this manual or point out possible errors, please contact your

local dealer. We will gladly take your ideas and suggestions into consideration.

User Manual. Xsite PRO SPI 14.2 Page 2 / 77

Explanation of the symbols

Notices are marked with symbols in the Manual. Observe these notices at all times and proceed

carefully to prevent accidents, personal injury, and material damage.

Indicates a hazardous situation. If not avoided, could result in death, serious injury, or

material damages.

Note! Emphasizes useful tips and recommendations as well as information referring

efficient and failure-free operation.

User Manual. Xsite PRO SPI 14.2 Page 3 / 77

1.1 Safety instructions

This chapter outlines important safety matters concerning the operating procedures necessary for

ensuring optimal personnel safety. It is important that these instructions are followed because they

enable users to recognize and prevent potential operating risks before they occur. All users must

understand and observe these instructions prior to any use of the product.

When operating machine the operator must not solely trust the operation of the

product. Operating machine solely based on the product is forbidden. The operator

must observe the usage site in order to avoid risks.

Conventional use

The product has been exclusively designed and constructed for conventional use as described

here:

•Positioning the tool of a construction machine

•Indicating the position of a measuring point to the operator

•Comparing the position of a measuring point with reference informationn

Any other use not listed here, as well as any application not complying with the technical data, is

not considered conventional use. The manufacturer is not liable for any damages or consequences

caused by any improper or unauthorised use of the product.

Improper use

The following situations, without any limitations, are considered improper use of the product

•Non-conventional use

•Exceeding the limit values given in the manual

•Use of the product without instructions

•Use of the product beyond the limits of use

•Using the product with safety equipment disabled

•Removal of labels on the product (for example, warning labels)

•Opening, taking apart, rebuilding or making alterations to the product

•Using the product in spite of obvious defects or damage

•Using the product with unauthorised accessories, devices or services from other

manufacturers

•Using the product at insufficiently secured construction sites

Alteration and rebuilding of the product

To prevent risks and ensure optimal performance, rebuilding or making any alterations to the

product may not be carried out without the manufacturer’s explicit prior permission. The

manufacturer's explicit permission is also required before adding any attachments or notices to the

product.

The operator’s responsibility

The product is used in the industrial sector. Therefore, the operator of the product is liable to the

legal responsibilities for operational safety. esides the operational safety instructions in this

manual, the safety, accident prevention, and environmental protection regulations valid for the

operational area of the product have to be observed by the operator

User Manual. Xsite PRO SPI 14.2 Page 4 / 77

•The operator has to inform himself about the current operational safety regulations and, in a

risk assessment, detect additional risks that are caused by the special working conditions at

the usage site of the product. The operator must then implement these in the form of

directives. These directives have to be kept near to the product and permanently be

available for the persons working with it.

Particularly applying for the operator, without any limitations:

•The operator has to clearly define the personnel’s responsibilities referring the appliance.

•The operator has to ensure that the operator Manual’s content is fully understood by the

operating personnel prior to any use of the product. The operating personnel must adhere

to User Manual at all times when using the product.

•The statements of the User Manual have to be observed thoroughly and unrestrictedly.

•The operator has to ensure that all maintenance, inspection and assembling processes are

carried out by qualified specialized personnel, which have informed themselves sufficiently

by closely studying and understanding the manuals for the product’s operation.

•The operator informs the manufacturer or the authorized dealer without any delay if any

safety defects occur at the product or during operation.

Special risks

Epilepsy warning

Some people are susceptible to epileptic seizures or loss of consciousness when

exposed to certain flashing lights or light patterns. Immediately discontinue use and

consult your doctor if any of the following symptoms occur while using the product:

dizziness, blurred vision, eye or muscle twitches, loss of consciousness, disorientation

or any involuntary movement or convulsion.

Risks caused by electric current

When working close to electric systems (, for example, overhead powerlines), there is

danger to life due to electric shock. Keep sufficient safety distance to electric systems.

Moving components

Keep persons away from the machine’s and the tool’s working range. Remove objects

from the machine’s and the tool’s working range. Do not interfere with the moving

components during operation.

Overlapping machine parts

Subsequently assembled system components (, for example, GNSS masts) can

overlap the typical machine dimensions. This can lead to injuries and material

damages.

User Manual. Xsite PRO SPI 14.2 Page 5 / 77

Risk of injury caused by malfunction

Uncontrolled machine actions caused by the malfunction of a system component can

lead to severe personal injuries in the machine’s working range or cause material

damage. Ensure that the machine is operated, controlled and inspected by a qualified

and experienced operator, who has to be able to induce emergency measures, for

example, an emergency stop.

Lacking instruction

Lacking or insufficient instruction can lead to operating errors or incorrect use. This can

lead to severe personal injuries as well as severe material and environmental

damages. Observe the manufacturer’s safety instructions and the operator’s directives.

Risk of injury caused by insufficient safeguarding

Insufficient safeguarding of the construction site and the component’s location, for

example, of the laser emitter, can lead to hazardous situations in traffic and at the

construction site. Ensure sufficient safeguarding of the construction site. Ensure

sufficient safeguarding of the single components’ locations. Observe the country-

specific safety and accident prevention regulations as well as the current road traffic

regulations.

Risks caused by faulty measurement results

Faulty measurement results due to use of a dropped product, another illegitimate

demand or an alteration can lead to severe material damages. Do not use obviously

damaged products. efore reusing a dropped component, carry out a check

measurement.

Risk of injury caused by unreadable signs

In the course of time, labels and symbols on the product can get dirty or get

unrecognizable due to other events. Due to immoderate mechanical effects labels and

symbols can be detached. Always keep safety, warning and operation instructions in a

well readable state. Regularly check the adhesiveness of the labels and symbols on the

product. Do not remove labels and symbols from the product.

Risk of injury caused by inappropriate disposal of the product

When burning plastic parts, toxic gases that can cause illnesses emerge. Dispose the

product properly according to the current national country-specific disposal regulations.

Careless disposal might also enable unauthorized persons to improperly use the

product. In doing so these persons and/or third persons can be severely injured and

also pollute the environment. At all times, protect the product against the access of

unauthorized persons.

User Manual. Xsite PRO SPI 14.2 Page 6 / 77

Accidents and Emergencies

Preventive measures

•Always be prepared for possible accidents or fire

•Keep a first aid kit within reach

•Familiarise all personnel with the location and use of first-aid equipment, accident

notification procedures and procedures for alerting the emergency services

•Keep access routes clear for emergency vehicles

In the event of an accident, proceed appropriately:

•Shut down the equipment immediately by switching the power off

•egin first aid measures

•Move persons out of the hazard zone

•Inform the manager of the job site

•Alert medical assistance and/or the fire brigade

•Ensure that access routes are clear for emergency vehicles

User Manual. Xsite PRO SPI 14.2 Page 7 / 77

1.2 Product overview

Xsite PRO is a machine control system for construction machines. Xsite PRO indicates the position

of the measuring point (for example, measuring point of the bucket’s blade) compared to a

reference level. The system can be used as a 2D (Vision) or 3D system (LandNova).

The system can be used in the following construction machines:

•Excavator

•Wheel loader (Machine model is different and bucket calibration is horizontal not vertical

plumbline calibration)

The system contains the following components by default:

•Computer unit (MCC15)

•Display unit (Xsite PRO display)

•Gravitation sensors (G2 sensors)

•Number of sensors depends on type and model of the machine

•Excavator system contains at least bucket, stick, boom, and frame sensors

•Wheel loader contains at least bucket, boom and frame sensors

The system can be expanded by the following optional accessories:

•Tilt bucket sensor

•Dual block boom sensor

•Laser receiver (EL2 not used with wheel loader)

•XD2 LED display

•GNSS equipment

•Radio modem

Fig. 1. System diagram

User Manual. Xsite PRO SPI 14.2 Page 8 / 77

1.3 Handling of the system

The display cable must not be connected or disconnected when the system power is

on. The cable must be connected properly before switching on the system. Incorrect

use of the display cable may cause damage to the display or to the computer. See

section 2.1 “Connecting the display” for more information.

The display unit is not waterproof. If the display or other components are taken away from the

construction machine for any reason, a carrying case should be used. Make sure that the

components are clean and dry before placing them in the carrying case. Also make sure that the

carrying case is clean and dry.

Fingerprints and other dirt can be removed from the display with a soft, lint-free cloth. A cleaning

liquid can also be used with the cloth. Dampen the cloth with isopropyl alcohol, water or a mixture

of alcohol and water and clean the display. Do not spray the cleaning liquid directly on the screen.

Do not use any corrosive chemicals on the screen.

3D features of the system require a license key which is connected to the system. The operator of

the system is responsible for storing the license key.

Note! If the 3D license key is lost, a new one must be purchased from the local dealer.

License key is located inside of the MCC 15 computer unit.

1.4 Transportation and storage

When transporting the equipment to the usage site or carrying it in the field, always ensure that the

product is transported in suitable, secure containers. Never transport the product loosely in a

vehicle; knocks and bumps can severely harm the functioning of the product. In case of

transportation by railway, plane or ship, always use the original packaging, transport containers

and transport boxes. The packaging protects the product from bumps and vibration.

Store the product in a well-ventilated dry place. During storage, protect it against moisture. Use the

original packaging whenever possible. Avoid extensive temperature changes during storage.

Water condensation can form gradually and may harm the functioning of the product.

1.5 Support and maintenance

Maintenance services are provided by the manufacturer or the authorised dealer. The installation

and servicing of the product should only be carried out by trained and qualified personnel.

All settings are stored onto the internal memory device, which is backed up by the fitter after the

installation. If any problems occur with the installation settings, a recovery can be made.

Only representatives of the manufacturer are allowed to open the product housings.

Remote support provides instant help desk services for machine operators (see section 7 ”Network

operation”).

User Manual. Xsite PRO SPI 14.2 Page 9 / 77

2 GETTING STARTED

This section provides information about the system hardware and the user interface.

2.1 Connecting the display

Don’t strain or kink the cable while connecting or disconnecting the cable. Avoiding sharp bends in

the cable will keep your cable working longer. The display cable must be connected before

switching on the power to the construction machine. The display cable is connected to the

connector on the back of the display (Fig. 2). The cable is connected by pushing the connector and

is disconnected by pulling from the connector housing.

e sure to visually check that the cable is properly connected. An improper connection may cause

damage to the display unit or to the computer. The cable must not be connected or disconnected

while the system power is on because it may cause hardware damage (Fig. 3).

Fig. 2. ack of the display unit

(1) Display cable with connector

(2) RAM mount

Fig. 3. Improper (left) and proper (right) connections

Make sure that the system is powered off when you connect or disconnect the cable.

Make sure that the cable is properly connected before turning on the system.

When the cable is connected, the display can be mounted with the RAM mount bracket to a

suitable viewing angle. Mount the display so it blocks the view as little as possible.

User Manual. Xsite PRO SPI 14.2 Page 10 / 77

2.2 Turning on the system

To help protect system memory and prevent possible data loss when first starting the

machine, it is recommended to start the machine first and then turn the system on. It

is not necessary to turn the system off before restarting a warm machine. This

situation may occur, for example, when restarting from an auto idle shutdown

condition.

The system is turned on by pressing the power button on the display (Fig. 6). After one

second, the red back lights of the buttons will turn on. When the red lights have been on

for approximately 15 seconds the light will turn yellow. It takes approximately one minute

for the operating system to start up.

Sensors are equipped with an internal heating system. When a machine is used below 0°C (32F)

temperatures, it will take time for the sensors to warm up and provide accurate results. The

recommended amount of time needed between turning the system ON and starting work is shown

in Table 1 below. Users should allow for the proper warm-up time in order to ensure accurate

measurement results.

Table 1. Recommended warm-up time.

Temperature Warm up time

-20°C Approx. 20 min

-10°C Approx. 10 min

-5°C Approx. 5 min

2.3 Installing or changing a SIM card

For network services and getting RTK correction a SIM card is needed. SIM card is installed to

MCC15 computer unit, see Fig. 4.

To insert or change a SIM card:

1. Make sure that the system is powered off

2. Open plastic dust lid labelled as “SIM”

3. Press yellow tab to get tray out

4. Place SIM card to the tray

5. Close the tray. Card installation is now completed

Fig. 4. Inserting a SIM card in to the MCC15 computer unit.

User Manual. Xsite PRO SPI 14.2 Page 11 / 77

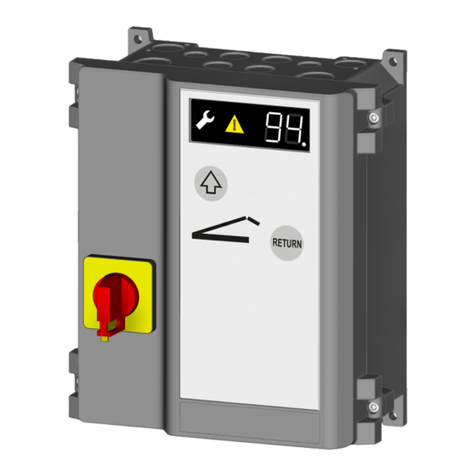

2.4 Display unit, US ports and buttons

The system works via touch screen (Fig. 6). In addition to touch screen, there are separate buttons

for brightness adjustment and a mute.

Connectors: There are two US connectors (Fig 5) at the bottom of the display unit that can be

used.

Fig. 6. Display unit

Touch screen (display)

Reduce brightness

Increase brightness

Power on/off

Mute

2.5 Turning off the system

Press shortly power button and select “Shutdown”.

The system can be turned off by pressing from start window.

If you need to continue working with 2D application the LandNova can be closed by selecting

“Project” → “ ack to 2D or Exit”.

If a shut down cannot be carried out, for example, the system does not turn off after the ”Shut

down” button on the touch screen has been pressed, forced shut down can be accomplished by

pressing and holding the ”Power” button down for 30 seconds.

Avoid forced shutdown, it may damage the internal storage media and cause data

loss. Contact local service personnel before use forced shutdown.

User Manual. Xsite PRO SPI 14.2 Page 12 / 77

Fig 5. US connectors bottom of the display unit

3 USING THE 2D SOFTWARE

The 2D application is named as “Vision”. When using the 2D system the height reference can be

taken from laser reference (optional laser received is needed) or a stake (any physical height

reference can be used). System can measure height and distance. Height reference have to be

taken again when machine is relocated.

3.1 Getting started

When the Vision is started the Main menu is shown as in Fig. 8 below. To starting work with 2D,

press “Start” button 1.

Selections from the Main menu of the Vision (fig 8):

(1) Start opens “2D work view” as seen in the fig. 7

◦“Measurement / work view”

(2) Language opens language selection

◦Language of 2D software user interface can be changed.

(3) Settings opens 2D software settings

◦For example, bucket calibration (measurements and plumbline calibration)

3.2 Measurement / work view

The fig. 7 displays software's measurement / work view. It can be used, for example, to measure

depth, distance and slope. Operator can see measurements results and change view angles.

To begin work select Main menu → “Start”

User Manual. Xsite PRO SPI 14.2 Page 13 / 77

Fig. 8. Main menu of Vision Fig. 7. Measurement / work view

3.2.1 Symbols (icons) on the display while working

At “work view” the symbols are seen on top of the display (Fig. 7).

Height. See section 3.4

When height icon is pressed, the height readout is zeroed or set to a predefined value

Distance. See section 3.5

When distance icon is pressed, the distance readout is zeroed or set to a predefined

value

Slope Slope: Edit slope by clicking Slope See section 3.7

B1..B10 Identifier of the chosen bucket ( 1, 2 ...) Change bucket by clicking B1..B10

Side view of the bucket:

•The view from the side of the bucket

•Zoom in / out by using the + and - icons

Front view of the bucket:

•The view from the front of the bucket

•Zoom in / out by using the + and - icons

Free view

•A freely adjustable view

•Zoom in / out by using the + and - icons

•Rotate by moving a finger on the screen

Change measuring point of a bucket

•Left

•Middle

•Right

•Automatic (Measuring from the lowest point of the buckets blade)

Orient machine with model (Used only with slopes)

•+Y (270 deg)

•-Y (90 deg)

•+X (0 deg)

•-Y (180 deg)

Start LandNova (The 3D application)

Zoom view in

Zoom view out

User Manual. Xsite PRO SPI 14.2 Page 14 / 77

3.2.2 asic operations / buttons on the display

In work/measurement mode an operator can perform basic operations using buttons from the lower

part of the display (Fig 7).

Button Action

Start depth

and

distance

Reset depth and distance readouts (Zero or set to both readings to predefined

values).

More information:

“Depth settings”: section 3.4

“Distance settings”. section 3.5

Start slope

Slope (Simple in fig. 10 / Advanced in fig. 9)

•Sets the depth reading and bucket tip to the start of the slope.

•Slope and depth values have to be defined before starting work.

•Profile is visualized on display (See fig 11, red line)

More information in 3.7

Memory

Memory function

It is used for keeping height reference when relocating the excavator.

For more information in 3.6

Menu Various settings (set slope, cut depth, alerts).

See “Settings” 3.3

Return to the Main menu, see Fig 8.

Fig. 11. “Start slope” is selected, view “Side view” is selected (green circle.)

User Manual. Xsite PRO SPI 14.2 Page 15 / 77

Fig. 9. Advanced slope settings

Fig 10 Simple slope

3.3 Settings

Enter to the settings:

Start screen → “Start” → “Menu”

(1) GPS (opens menu where you can

start or stop LandNova 3D software)

Depth and distance settings

(2) Set cut depth / set start depth / Use

laser as reference

See section “Depth settings” 3.4

(3) Laser ON / OFF

Set laser receiver on or off

(4) Set distance / Set start distance

Set start distance. See section

“Distance settings” 3.5

Slope settings

(5) Set slopes

See section “Slope measurement”

Movement limits

(6) Set limits

Warning levels can be set. The system will alert the operator if the bucket or boom crosses the

warning levels. See section “Restriction of movements” 3.9.2.

Alert limits

(7) Tone and led settings

See section “Alert limits” 3.9.1

(8) Reset

Reset all settings to factory defaults.

(9) Volume

Increase / decrease the volume of the system.

User Manual. Xsite PRO SPI 14.2 Page 16 / 77

3.4 Excavation using a reference height (stake)

To excavate using a reference height (for example, a stake), select:

“Main menu” → “Start” → “Menu” → “Set cut depth / Set start depth”

Note that “Use laser as reference” should not be checked when the stake is used as reference.

Example: Reference (stake) is at 30.0 metres and target depth is 28.2 m (1.8 m will be removed).

(1) Set target (cut) depth to 28.2 and press OK (see the below fig 13 and 12)

(2) Set laser/start depth to 30 and press OK

(3) Return to the “working / measuring mode” press ←

(4) ring bucket to the reference and press icon to set start depth (Fig 14).

•Pressing “Start depth and distance” (yellow circle fig 14) will reset both depth and

distance to predefined values.

(5) Verify that start depth is 30 meter (reading inside the green circle at the (Fig 14)

(6) Start and continue excavating until bucket is level with horizontal red (or green) line (Fig 15)

(7) Target depth is reached at 28.2m (30m - 1.8m)

Readout (big green circle in Fig. 14) indicates the height of the bucket. The red (or green)

horizontal line shows target level (depth). Here the target is 1.8 metres below start depth.

When height icon is pressed, only depth reading is set to predefined “laser/start depth”

value.

User Manual. Xsite PRO SPI 14.2 Page 17 / 77

Fig. 12. Depth settings (predefined levels) Fig. 13. Start and cut depth in a jobsite

Fig. 16. Target depth reached at 28.2m.

Fig. 15 Target depth is reached at 28.2 metres

Fig. 14. Readout at stake after reference is set

Table of contents

Other Novatron Control System manuals

Popular Control System manuals by other brands

Inovance

Inovance Monarch NICE Series user guide

Sensaphone

Sensaphone Sentinel Pro User manual addendum

Moore Industries

Moore Industries HIT manual

XYZ Machine Tools

XYZ Machine Tools ProtoTRAK KMX CNC Safety and Quick Start guide

Toro

Toro Lynx Smart Satellite Sensor Kit Installation and user guide

potenza

potenza Aura 8 user guide

Alltech

Alltech Manual Barrier quick start guide

American Standard

American Standard AccuLink Platinum 1040 Installation & user guide

Siemens

Siemens tiastar MCC installation instructions

Canon

Canon BU 45 user manual

Harman

Harman AMX VPX-1401 user manual

Pentair Pool Products

Pentair Pool Products Pool/Spa Control System CP-100 Installation and owner's manual