NOVO NovoSoft 165 Series User manual

Canada West

855 Park St., Unit 1

Regina, SK S4N 6M1

Canada East

490 Pinebush Rd., Unit 1

Cambridge, ON N1T 0A5

U.S.A.

56 Lightcap Rd.

Pottstown, PA 19464

9760 Mayower Park Drive,

Suite 110

Carmel, IN 46032

4655 McDowell Rd. W

Phoenix, AZ 85035

Owners Manual

165 Series

Water Softener

1. Page 21 of this manual contains important maintenance procedures for the continued proper

operation of your unit. These MUST be performed regularly for your warranty to remain valid.

2. Read all instructions carefully before operation.

3. Avoid pinched o-rings during installation by applying NSF certied lubricant to all seals (provided with install kit).

4. This system is not intended for treating water that is microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

IAPMO R & T Certified

against NSF/ANSI 44

IAPMO R & T Certified

against CSA B483.1

Table of Contents

READ THIS PAGE FIRST

BEFORE STARTING INSTALLATION 3

EFFICIENCY STATEMENT 4

HOW YOUR WATER CONDITIONER WORKS 5

SPECIFICATIONS

SPECIFICATION / SYSTEM DIMENSIONS 6

BRINE TANK DIMENSIONS 7

INSTALLATION

UNPACKING / INSPECTION OF TWIN TANK MODEL 9

UNPACKING / INSPECTION OF CABINET MODEL 11

BEFORE INSTALLATION 13

PREPARATIONS 14

PREPARATIONS / INSTALLATION STEPS 15

INSTALLING BRINE TANK 16

WATER SOFTENER INSTALLATION 17

CABINET WATER SOFTENER INSTALLATION 18

OPERATION

STARTUP INSTRUCTIONS 19

MAINTENANCE INSTRUCTIONS 21

RES-UP® FEEDER INSTALLATION INSTRUCTIONS 23

SERVICING 165 VALVE 25

REPLACEMENT

TIMER REPLACEMENT 26

REPLACING THE BYPASS AND METER CABLE 27

CLEAN INJECTOR ASSEMBLY / PISTON AND/OR BRINE VALVE ASSEMBLY REPLACEMENT 28

REPLACE METER ASSEMBLY / REPLACE MOTOR 29

REPLACE DRAIN LINE FLOW CONTROL / REPLACING PCBS 30

PARTS BREAKDOWN 31

PARTS

POWERHEAD 32

VALVE BODY 33

BYPASS 34

CABINET 35

MASTER PROGRAMMING 36

3

READ THIS PAGE FIRST

BEFORE STARTING INSTALLATION

Read this manual thoroughly to become familiar with the

appliance and its capabilities before installing or operating

the new appliance. Failure to follow instructions in this

manual could result in personal injury or property damage.

This manual will also help you to get the most out of

your new appliance.

Installation must comply with all State, provincial or local

regulations. Check with your local public works department

for plumbing and sanitation codes. In the event the codes

conflict with any content in this manual the local codes

should be followed. Consult your licensed plumber for

installation of this system.

WARNING!: Do not use water that is microbiologically unsafe

without adequate disinfection before or after this system.

Do not install this appliance where it may be exposed to wet

weather, direct sunlight, or temperatures outside of the

range specified above.

This appliance is designed to operate on pressures of 30

psi to 125 psi. If the water pressure is higher than the

maximum use a pressure reducing valve in the water supply

line to the device.

This appliance is capable of operating at temperatures

between 40°F and 110°F (4°C - 43°C). Do not use this

appliance on hot water supplies.

Avoid pinched o-rings during installation by applying

(provided with install kit) IAPMO certified lubricant to all

seals.

It is not uncommon for sediment, precipitated iron or

hardness to be present in water supplies. Precipitated

minerals or sediments can cause damage to the seals and

piston. This is considered a harsh environment and the seals

and piston would not be covered by warranty stated or

otherwise.

It is recommended to regularly inspect and service the

control valve on an annual basis. Cleaning and or replacement

of piston, seals, and or spacers may be necessary depending

on how harsh the conditions are. An Annual Maintenance kit

is available for this purpose

This publication is based on information available when

approved for printing. Continuing design refinement could

cause changes that may not be included in this publication.

The manufacturer reserves the right to change the

specifications referred to in this literature at any time,

without prior notice.

INSTALL NOTES &

SAFETY MESSAGES

Watch for the following

messages in this manual:

NOTE

Do not remove or destroy

the serial number. It must be

referenced on request

for warranty repair or

replacement

CAUTION!

Disassembly while

under pressure can

result in flooding.

WARNING!

ELECTRICAL SHOCK

HAZARD! UNPLUG THE UNIT

BEFORE REMOVING THE

COVER OR ACCESSING ANY

INTERNAL CONTROL PARTS

NOTE: used to emphasize

installation, operation or

maintenance information

which is important but does

not present a hazard.

CAUTION: used when

failure to follow directions

could result in damage to

equipment or property.

WARNING: used to

indicate a hazard which

could cause injury or death if

ignored.

4

IAPMO R & T Certified

against CSA B483.1

PERFORMANCE DATA SHEET

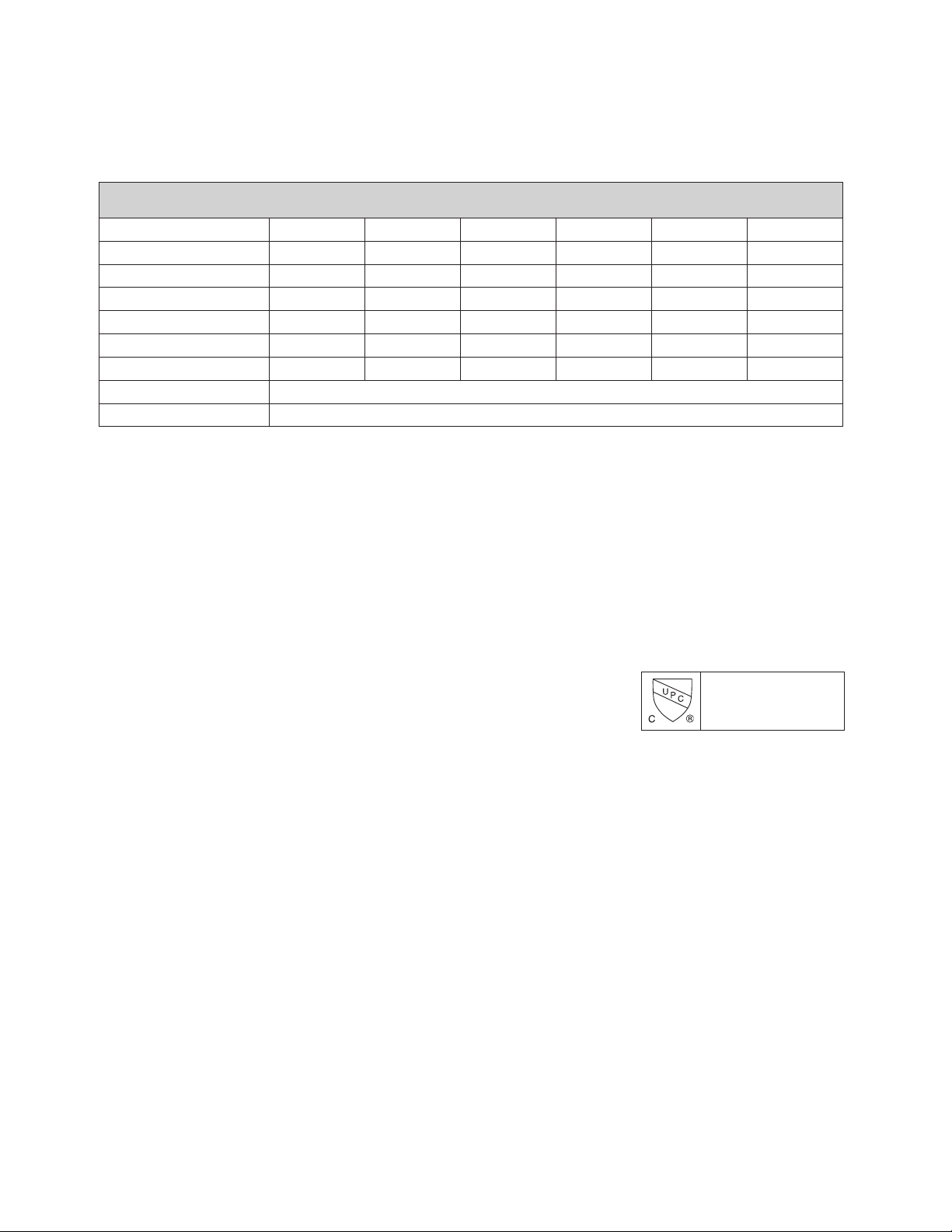

MODEL NUMBER 165-75 165-IOO 165- 150 165-200 165-250 165-300

Qty High Capacity Resin 0.75 ft3 1.0 ft3 1.5 ft3 2.0 ft3 2.5 ft3 3.0 ft3

Rated Service Flow (gpm) 7.5 11.0 11.2 12.4 12.6 12.9

Pressure Drop at Rated Service Flow (psi) 7.0 15.0 15.0 15.0 15.0 15.0

Rated Softening Capacity (grains) 9,609 @ 2.25lbs 13,269 @ 3lbs 20,443 @ 4.5lbs 27,258 @ 6lbs 32,559 @ 9lbs 40,887 @ 9lbs

Eciency (grains/lb salt) 4,271 4,543 4,543 4,543 4,543 4,543

Max. Flow Rate to Drain (gpm) 2.0 2.0 2.4 3.5 4.0 5.0

Working Pressure Min.20 • Max. 125 psi

Operating Temperature Min 39 - Max. 100 degrees Fahrenheit

EFFICIENCY STATEMENT

This product is efficiency rated according to NSF/ANSI 44.The stated efficiencies are valid only at the specified salt dosages and maximum service flow rate.

These softeners conform to NSF/ANSI 44 for the specific performance claims as verified and substantiated by test data.These models are efficiency rated.The efficiency rating is

valid only at the stated salt dose and maximum service flow rate. They have a demand initiated regeneration (D.I.R.) feature that complies with specific performance specifica-

tions intended to minimize the amount of regenerant brine and water used in their operation.These softeners have a rated softener efficiency of not less than 3350 grains of

total hardness exchange per pound of salt (based on sodium chloride) and shall not deliver more salt than their listed ratings.The rated salt efficiency is measured by

laboratory tests described in NSF/ANSI Standard 44.These tests represent the maximum possible efficiency that the systems can achieve. Operational efficiency is the actual

efficiency after the system has been installed. It is typically less than the efficiency due to individual application factors including water hardness, water usage, and other

contaminants that reduce the softener’s capacity. These systems are not intended for use with water that is microbiologically unsafe or of unknown quality without adequate

disinfection before or after the system. For best results, use plain, white block salt. Refer to Installation/operation manual and warranty for further details on installation, parts

and service, maintenance and further restrictions or limitations to the use of the product.

4 5

HOW YOUR WATER CONDITIONER WORKS

Why Water Gets Hard And How It Is Softened

All of the fresh water in the world originally falls as rain, snow, or sleet. Surface water is drawn upward by the sun, forming clouds.Then, nearly pure and soft as it starts to fall,

it begins to collect impurities as it passes through smog and dust-laden atmosphere. And as it seeps through soil and rocks it gathers hardness, rust, acid, unpleasant tastes and

odors.

Water hardness is caused primarily by limestone dissolved from the earth by rainwater. Because of this, in earlier times people who wanted soft water collected rainwater from

roofs in rain barrels and cisterns before it picked up hardness from the earth.

Some localities have corrosive water. A softener cannot correct this problem and so its printed warranty disclaims liability for corrosion of plumbing lines, fixtures or appliances.

Iron is a common water problem. The chemical/physical nature of iron found in natural water supplies is exhibited in four general types:

1. Dissolved Iron—Also called ferrous or“clear water”iron. This type of iron can be removed from the water by the same ion exchange principle that removes the

hardness elements, calcium and magnesium. Dissolved iron is soluble in water and is detected by taking a sample of the water to be treated in a clear glass.The

water in the glass is initially clear, but on standing exposed to the air, it may gradually turn cloudy or colored as it oxidizes.

2. Particulate Iron—Also called ferric or colloidal iron.This type of iron is an undissolved particle of iron. A softener will remove larger particles, but they may not be

washed out in regeneration effectively and will eventually foul the ion exchange resin. A filtering treatment will be required to remove this type of iron.

3. Organic Bound Iron—This type of iron is strongly attached to an organic compound in the water. The ion exchange process alone cannot break this attachment

and the softener will not remove this type of iron.

4. Bacterial Iron—This type of iron is protected inside a bacteria cell. Like the organic bound iron, it is not removed bya water softener.

Water softeners remove hardness in the water by exchanging particles in the water, or ions. They remove hard ions such as calcium and magnesium in the water by trading it

for sodium ions producing soft water. Unlike the calcium and magnesium, sodium stays dissolved in water and does not form a scale. Sodium also does not interfere with the

cleaning action of soaps. The sodium is released by a charged resin contained in the softener, this resin also traps the calcium and magnesium ions. Eventually this resin releases

all of its sodium and has filled up with other ions, so it then must be regenerated. Regeneration is accomplished by washing the resin with a salt saturated brine solution that

removes the calcium and magnesium while replenishing the sodium. This is why the softener requires a brine tank and salt. The water softener can run for days before running

out of sodium, and when it does, the sodium is replenished in only a matter of a few hours

When using a softener to remove both hardness and dissolved iron it is important that it regenerates more frequently than ordinarily would be calculated for hardness removal

alone. Although many factors and formulas have been used to determine this frequency, it is recommended that the softener be regenerated when it has reached 50–75% of the

calculated hardness alone capacity. This will minimize the potential for bed fouling.

If you are operating a water softener on clear water iron, regular resin bed cleaning is needed to keep the bed from coating with iron. Even when operating a softener on water

with less than the maximum of dissolved iron, regular cleanings should be performed. Clean every six months or more often if iron appears in your conditioned water supply. Use

resin bed cleaning compounds carefully following the directions on the container.

CAUTION!

Do not use where the

water is microbiologically

unsafe or with water of

unknown quality without

adequate disinfection be-

fore or after the unit.

Other manuals for NovoSoft 165 Series

1

This manual suits for next models

6

Table of contents

Other NOVO Water Dispenser manuals

Popular Water Dispenser manuals by other brands

IBC Water

IBC Water AST0715MP-960 Installation & operating instructions

Lancaster Water Treatment

Lancaster Water Treatment X FACTOR LX15 Series Installation, operating and service manual

Elkay

Elkay EMABF8 Series Installation & use manual

Oasis

Oasis Osmosis Home installation manual

Monarch Water

Monarch Water ULTIMATE MINI AQUA HE install guide

Haier

Haier HLM-109B instruction manual