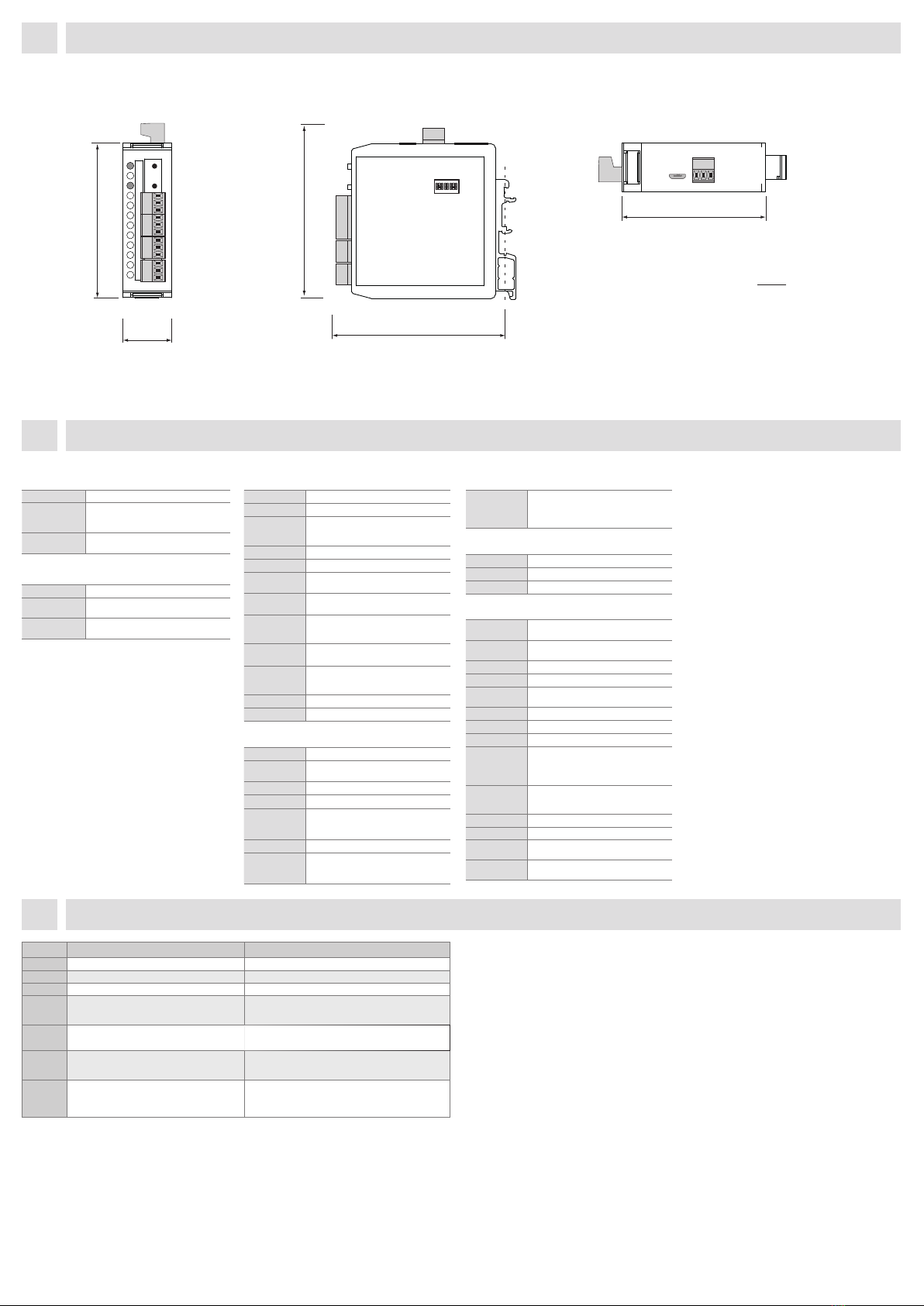

INPUT

No. of inputs 1

Setting 24-bit ΔΣADC with PGA

The range is selectable either by DIP

switch or by OM Link free SW from PC

Power 2.5 VDC/5 mA,

potentiometer resistance > 500 Ω

EXTERNAL INPUT

No. of inputs 2

Function EXT 1 KEYLCK Device buttons blocked

(see ch. 3 Device setting)

Function EXT 2 not used

INSTRUMENT SPECIFICATION

TC 15 ppm/°C

Accuracy ±0.01 % of FS

Rate 100…7 200 measurements/s

speed of 400 meas./s is with FFT

signal ltering

Latency < 580 µs

Overload 10x (t < 30 ms), 2x

Functions Teach-in, Tare, Math. functions,

Simulation (only via OMNI Link)

Digital lters exponentia l / oatin g / arithmetic aver-

age, rouding (only via OMNI Link)

Math functions polynomial/ inverse polynomial/loga-

rithm /exponential / power / root (only

via OMNI Link)

Linearization linear interpolation in 100 points

(only via OMNI Link)

OMNI Link On request: company communica-

tion interface for operation, setting and

update of instrument (microUSB).

Watch-dog reset after 500 ms

Calibration at 25°C and 40 % r.h.

ANALOG OUTPUT

No. of outputs 1

Type isolated, adjustable with 16-bit DAC,

output type and range is selectable

TC 15 ppm/°C

Non-linearity 0.024 % of FS

Accuracy ±0.02 % of FS

±0.03 % of FS 0…5 V

±0.05 % of FS 0…2 V / 0…5 mA

Rate response to change of value < 160 µs

Output signals 0…2/5/10 V, ±10 V, resistive load ≥ 1 kΩ

0…5/20 mA/4…20 mA, comp. < 500 Ω/12 V

Indication of error message (output < 3.2 mA)

POWER SUPPLY

Power 10…30 VDC/24 VAC, ±10 %, 2.5 VA,

PF ≥ 0.4,

ISTP< 40 A/1 ms, isolated

Fuse inside (T500 mA)

MECHANIC PROPERTIES

Material PA66, incombustible UL 94 V-0, green

Dimensions 25 x 79 x 90.5 mm (w x h x d)

Installation to DIN rail 35 mm wide

OPERATING CONDITIONS

Connection connector terminal blocks,

section < 1.5 mm2

Stabilization

period

within 5 minutes after switch-on

Working temp. -20°…60°C

Storage temp. -20°…8 5°C

Working

humidity

< 95 % r.h., non condensing

Protection IP20

Construction safety class I

El. safety EN 61010-1, A2

Dielectric

strength

2.5 kVAC for 1 min. between power

supply and signal input

2.5 kVAC for 1 min. between signal

input and outputs

Insulation

resistance*

for pollution degree II, measurement cat. III

power supply > 300 V (PI), 255 V (DI)

Input/outputs > 300 V (PI)

EMC EN 61326-1 (Industrial area)

RoHS EN IEC 63000 : 2018

Seismic

qualication

IEC/IEEE 60980-344 Edition 1.0, 2020, par. 6, 9

Mechanical

resistance

EN 60068-2-6 ed. 2:2008

* PI - Primary insulation, DI - Double insulation

5Technical data

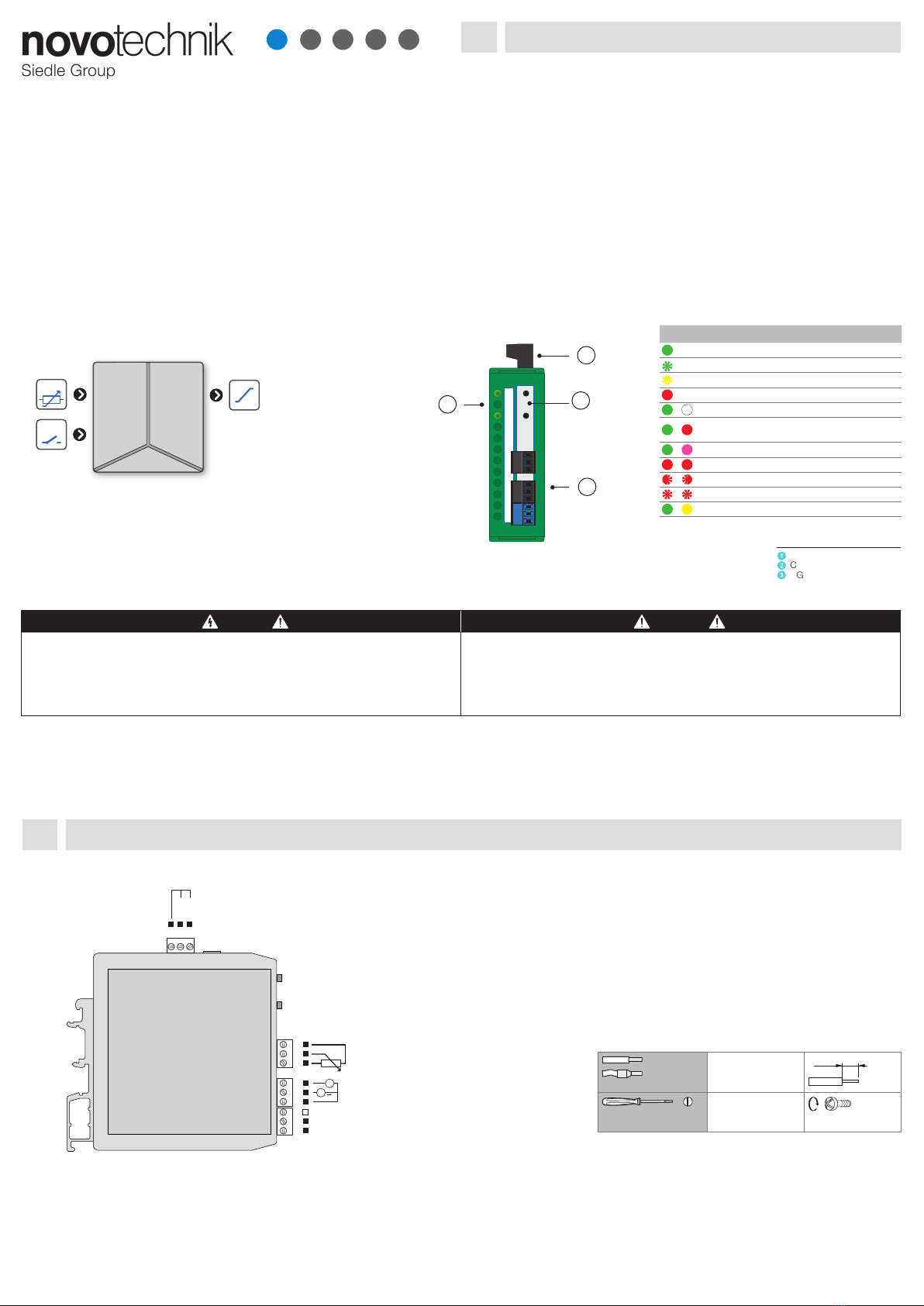

4 Instrument dimensions and installation

mm

inch

25

3.11

3.54

3.56

Lo

Hi

2

90,5

90

1 2 3 4 5 6 7 8

ON

Installation to DIN rail of 35 mm width

2.91

74

6Error Messages

Error Error description Solution

ERR 1 Input range exceeded by ±10% or more. Change input signal value or input setting (range).

ERR 3 Potentiometer wire broken. Check sensor cable and connection.

ERR 10 Output current loop broken. Check cable and current loop connection.

ERR 34 User conguration could not be loaded from

EEPROM.

Default conguration automatically applied.

Repeat device conguration.

If message is shown repeatedly, send the device for repair.

ERR 35 Factory calibration has been lost. Converter’s

accuracy is compromised up to ±5%

When this error occurs, send the device for

re-calibration or upload factory calibration data.

ERR 36 User calibration could not be loaded from

EEPROM. Factory calibration automatically

applied.

Repeat the user calibration.

If message is shown repeatedly, send the device for repair.

ERR 50 Serious device error - damaged EEPROM.

The device operates in an emergency mode, i.e.

settings cannot be changed. Measurement error

can be up to 5%

Send the device for repair.

MINI-TECHDOK - MUP-410_AO - 2023.1.7 - en

4 / 4www.novotechnik.de