novotechnik MUP-410 User manual

2 Connection

1 Description

12 1413

EXT. 1

EXT. 2

+

-

-

+

3 4 5

1 2

+

Power supply

V

Analog

output

mA

79

8

OMNI

,…,mm

3 0…1 2 A W G

8

0.32

Ø , mm

Ø 0.14 in

, Nm

13.2 lb-in

MINI-TECHDOK - MUP-410_AO - 2023.1.0 - en

www.novotechnik.de 1 / 4

fr it

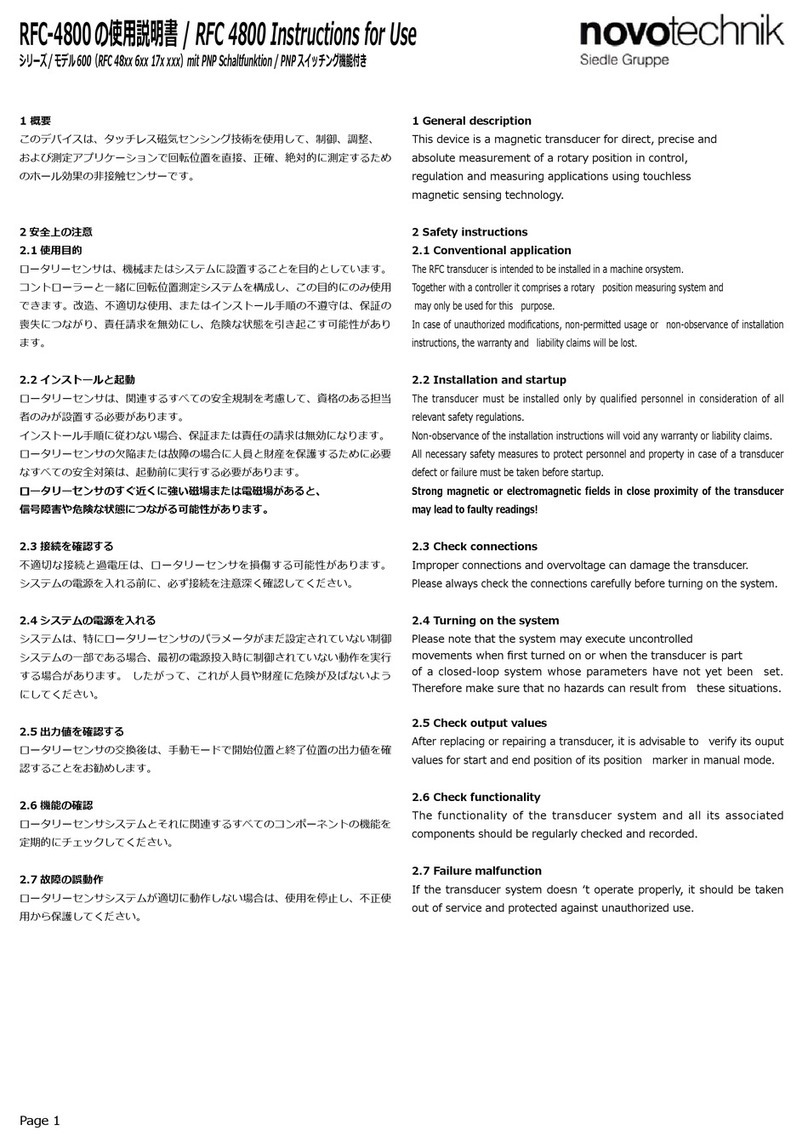

Digital DIN rail mounted signal

convertor

INPUT FOR POTENTIOMETERS

• Input for potentiometers

• Analog output

• Up to 7 200 measurements/s

• Quick configuration by DIP switch

• PC configurable via USB port

• Galvanic isolation 2.5 kVAC

• Simple instalation to DIN rail

de csesen fr

MUP-410

Lo

Hi

1

2

4

3

1

USB

micro

1 2 3 4 5 7 8 9

Power

IN 1 OUT 1

Input

Pot.

mA

V

OMNI

LED Indication

Hi Lo Status

Device is running

Device functionality is limited, powered via USB

This device has a Delayed Start option

Error: device is out of order

Tare function is activated

Error: of input (> ±% of range) or of sensor

[ERR.]

Error: AO loop open [ERR.]

Error: setting /calibration [ERR.-]

Serious error (Safe mode) [ERR.]

Button function is blocked

Simulation mode is activated

Legend

① Connectors

② Control button

③ RGB Status LED

④ microUSB port for PC connection

Note

Contactors, high power electric motors, frequency drives and other power devices

should not be in a close proximity of the meter. Input signal leads (measured value)

should be seperated from all power lines and power devices. Even though the

device has been designed and tested according to standards for industrial environ-

ment, we strongly advise to adhere to the above presented rules.

DANGER WARNING

HAZARD OF ELECTRICAL SHOCK

- Disconnect all power and other supply lines before servicing equipment

EQUIPMENT OPERATION HAZARD

- Do not use this product in safety critical system

- Do not disassemble, repair or modify this product

- Do not operate beyond the recommended operating environment

Failure to follow this instruction may result in death or serious injury. Failure to follow these instructions may result in death, serious injury, or equipment damage.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Novotechnik Messwertaufnehmer OHG for any consequences arising out of the use of this device.

OMNI

LINK

3

Device setting

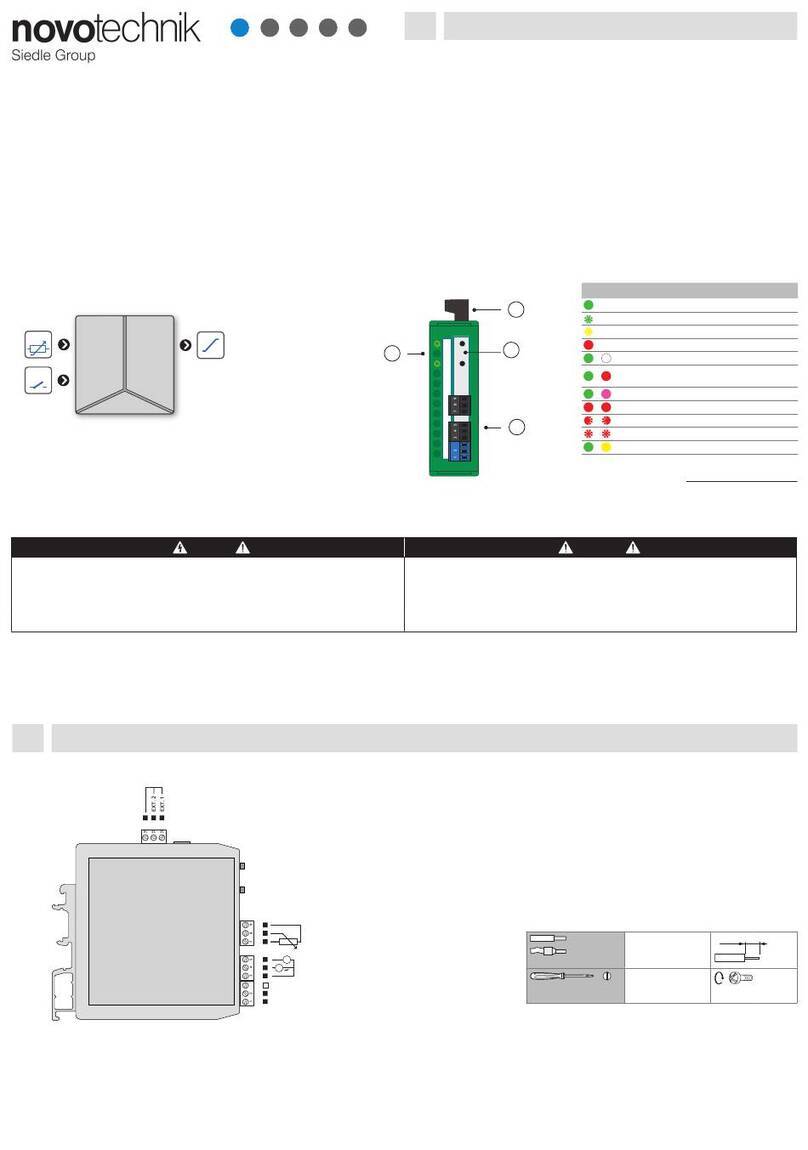

Input wiring diagram

Analog output

… / mA

… mA

3 - 4

… // V

± V

3 - 5

Input - Potentiometers

iControl of external inputs is via

contact (voltage-free)

Analog current output [mA]

Lo

Hi

1 2 3 4 5 7 8 9

Lo

Hi

1 2 3 4 5

mA

7 8 9

+−

Analog Voltage Output [V]

Lo

Hi

1 2 3 4 5

V

7 8 9

+−

Input - External inputs

12 13 14

Ext. 1

Ext. 2

Output wiring diagram

Analog input range setting, TEACH-IN

1. by a short press of the Lo button enter the configuration mode - LED Hi yellow and LED Lo turquoise

2. connect the signal of the desired value for the minimum of the range RNG.MIN (for example 5 mA)

3. by a long press (>2s) of the Lo button this value is se - LED Hi yellow, LED Lo purple

4. connect the signal of the desired value for the maximum of the range RNG.MAX. (for example 19,5 mA)

5. by a long press (>2s) of the Lo button this value is set - LED Hi yellow, LED Lo green

6. by a short press of the Lo button return to the standard working mode - LED Hi green

DIP switch

For a quick set up you can use the DIP switch

Tare settings

1. by a short press of the Hi button enter configuration of Tare - LED Hi white and LED Lo turquoise

2. by a long press (>2s) of the Hi button set the current value of Tare - LED Hi white, LED Lo green

3. by a short press of the Hi button return to the standard working mode with active Tare - LED Hi green, LED Lo white

i A short press at any time during the calibration

will end the calibration without saving.After one

minute of inactivity, the calibration is terminated

without saving and both LEDs return to the basic

state

i Setting of Analogue input TEACH-IN is active only

when DIP switches No. 1-2 are in the “0” position,

i.o. Setting via OMNI Link

Minimum range of Analog output for U/I inputs

signals is pre-set as unipolar,

i.e. "0 V/mA" or "4 mA".

If required, it is also possible to enter a negative

value of the maximum in the minimum, i.e. zero

will be in the middle of the selected range.

i

MINI-TECHDOK - MUP-410_AO - 2023.1.0 - en

www.novotechnik.de 2 / 4

1 2 Input

Setting via OMNI Link

•Potentiometer (default)

3 4 5 Rate [measurements/s]

50

•300

•400

• • 400 - FFT

•1200

• • 2400

• • 4800

••• 7200 (default)

6 7 8 Output - range

0…2 V

•0…5 V

•0…10 V

• • ±10 V

•0…5 mA

• • 0…20 mA

• • 4…20 mA (default)

• • • Er. 4…20 mA

Selection of input for analogue output

Selection of range for analogue output

Assigning the value of the input to the lower end of the range of AO

Assigning the value of the input to the upper end of the range of AO with error indication (< 3.2 mA)

Password to connect the device to PC. If it is set to "0", access is not blocked

Setting the time [sec.] - when the measurement is not performed aer powering the device on

Saves the current device settings

Loads the user settings into the device

Loads the original factory settings, restores the initial settings (BLUE TEXTS)

Clears user calibration, restores factory calibrations (aer user calibration via OMNI Link SW had been performed)

Disables the push button(s) on the front panel of the device

Errors that will be signalled on the selected output

Setting of the start of the range for simulation

Setting of the end of the range for simulation

Setting of increment/step value

Setting the increment/step duration time [sec.]

Start of simulation

Stop of simulation

Tare resetting

Measuring rate selection

Measuring range selection Device measures the value of the Lo signal

Setting of fixed tare Lo signal connection confirmed

For the minimum of the selected input range Device measures the value of the Hi signal

For the maximum of the selected input range Hi signal connection confirmed

Setting the input range in the Teach-in mode Manual entry of Lo input signal for MIN

M Setting the input range in the Manual mode Entry of signal value (example: 4.02 Ω)

Filters for math. adjust. of the input signal Manual entry of Hi input signal for MAX

Setting the constant for the filter Entry of signal value (example: 997.2 Ω)

Selection of functions controlled by external input 1

Selection of functions controlled by external input 2

Analog output

4

Configuration from PC using OMNI Link SW

0…99

OFF AVERAG. FL. AVG. EXPON. ROUND.

Inputs

Setting of password

Delayed Start

Save user settings

Load user settings

Factory reset

Erase user calibration

Key lock

Error selection for signalling

Simulation of input signal

Service

0…100…999.9

MIN ›-99999…0…99999

-99999…0…99999

-99999…100…99999

Reset of Tare

Sampling rate

Measuring range

Preset tare

Setting of converted value

Input setting Expert

Digital filters

Filter constant

External input

0-100%

0…9999

ER.4-20

›

›

›

›

›

›

›

›

›

›

›

›

›

›

›

›

-99999…0…999999

-99999…100…999999

MAN. LO MAN. HI

T-IN.LO T-IN.HI

›

›

›

›

›

›

›

›

›

›

›

›

›

›

YES

YES

YES

ON OFF

YES

CL.TAR.

INPUT FILTER. LIN.TAB.MAT.FNC.

YES

START ›

50 100 400 1200 2400 4800 7200

0-5 mA 0-20 mA 4-20 mA ER.4-200-2 V 0-5 V 0-10 V ±10 V

CLEAR

READ. S.

M.RANGE

P. TARE

RNG.MIN.

RNG.MAX.

TEACH-IN

MANUAL

F.MODE

F.CONST.

EXT.IN.1

EXT.IN.2

INP. A.O.

A.O.TYPE

A.O. MIN.

A.O. MAX.

PASSW.

DLY.STR.

SAV.SET.

LOA.SET.

FACT.ST.

CLR.CAL.

KEY.LCK.

SIG.ERR.

SIM.MIN.

SIM.MAX.

STEP

TIME

START

STOP

T-IN.LO

ANO

ANO

T-IN.HI

MAN. LO

4.02

MAN. HI

997.2

Input selection for the math function Polynomial

Inv. polynomial

Setting constants for mathematical functions Logarithmic

Input selection for the linearization table Exponential

Number of points in the table Power

Values of X/Y Square root

OFF INPUT FILTER.

POLYN. IN. POL. LOGAR. EXPON. POWER SQ.ROOT

INP. M.F.

TYPE.M.F.

CONST. A … F

INP. L.T.

N.OF.PTS.

VALUES

Function

0…99

POLYN.

OFF INPUT FILTER.

IN. POL.

POWER

SQ.ROOT

EXPON.

LOGAR.

-9999…99999

5…100

›

›

›

›

›

›

Mathematical function

Linearization table

FExDxCxBxAx +++++ 2345

F

x

E

x

D

x

C

x

B

x

A

5+++++ 234

F

EDx

CBx

A+

+

+

´ln

FeA

EDx

CBx

+×

+

+

(

)

(

)

FCBxA EDx ++× +

F

EDx

CBx

A

+

+

+

×

-99999…1…999999

OFF HOLDTARE CL.TAR. KEY.LCK.HLD.MMHLD.MAXHLD.MINSAMPLE

Output

0…9999

OFF HOLDTARE CL.TAR. KEY.LCK.HLD.MMHLD.MAXHLD.MINSAMPLE

YES

STOP ›

MAX ›-99999…100…99999

0…9999

The USB connector is galvanically connected to the

input! USB-to-USB Isolator must be used when input

signal is connected to the device.

DANGER OF COMPUTER DAMAGE

ERR 1 ERR 2 ERR 4 ERR 10 …

MINI-TECHDOK - MUP-410_AO - 2023.1.0 - en

www.novotechnik.de 3 / 4

!

Error messages

Error Error description Solution

ERR 1 Input range exceeded by ±10% or more. Change input signal value or input setting (range).

ERR 2 AD converter overflow / underflow. Change input signal value or input setting (range).

ERR 4 Potentiometer wire broken. Check sensor cable and connection.

ERR 10 Output current loop broken. Check cable and current loop connection.

ERR 20 Math function error. Change math function settings.

ERR 21 Linearization table error. Change/complete the settings of the linearization

table.

ERR 30 Powered only by USB, analog circuits inactive. Connect power supply to the device (clamp 1,2).

ERR 34 Default configuration not successfully set. Repeat device configuration.

If message is shown repeatedly, send the device

for repair.

ERR 35 Factory default calibration not successfully set. When this error occurs, send the device for

re-calibration or upload factory calibration data.

ERR 36 Default user calibration not successfully set. Repeat the user calibration.

If message is shown repeatedly, send the device

for repair.

ERR 50 Serious device error - damaged EEPROM.

The device operates in an emergency mode, i.e.

settings cannot be changed. Measurement error can

be up to 5%

Send the device for repair.

Errors ERR 34-50 are displayed permanently, until they are corrected.

INPUT

No. of inputs 1

Setting 24-bit ΔΣ ADC with PGA

The range is selectable either by DIP switch or by

OM Link free SW from PC

DU Power 1.65 VDC/3 mA,

potentiometer resistance > 500 Ω

EXTERNAL INPUT

No. of inputs 2, on contact

Function OFF No function assigned

TARE Activation of Tare

CL.TAR. Reset of Tare

HOLD Measurement paused

SAMPLE Take a one-o measurement

HLD.MIN Value of minimum *

HLD.MAX Value of maximum *

HLD.M-M Value of MAX-MIN*

KEY.LCK. Device buttons blocked

*The value is calculated from the period starting with the previous external input activation.

INSTRUMENT SPECIFICATION

TC 15 ppm/°C

Accuracy ±0.01 % of FS

Rate 100…7 200 measurements/s

speed of 400 meas./s is with FFT signal filtering

Latency < 580 µs

Overload 10x (t < 30 ms), 2x

Functions Teach-in, Tare, Math. functions, Simulation

Digital filters exponential / floating / arit hmet ic average,

rouding

Math functions polynomial/inverse polynomial/logarithm /

exponential/power/root

Linearization linear interpolation in 100 points

(only via OM Link)

OM Link company communication interface for operation,

setting and update of instruments. (microUSB)

Watch-dog reset aer 500 ms

Calibration at 25°C and 40 % r.h.

ANALOG OUTPUT

No. of outputs 1

Type isolated, adjustable with 16-bit DAC,

output type and range is selectable

TC 15 ppm/°C

Non-linearity 0.024 % of FS

Accuracy ±0.02 % of FS

±0.03% of FS 0…5 V

±0.05% of FS 0…2 V / 0…5 mA

Rate response to change of value < 160 µs

Output singals 0…2 /5/ 10 V, ±10 V, resistive load ≥ 1 kΩ

0…5 /20 mA/4…20 mA, comp. < 500 Ω/12 V

Indication of broken current loop

Indication of error message (output < 3.2 mA)

POWER SUPPLY

Power 10…30 VDC/24 VAC, ±10 %, 2.5 VA, PF≥ 0.4,

ISTP< 40 A/1 ms, isolated

Fuse inside (T500mA)

MECHANIC PROPERTIES

Material PA66, incombustible UL 94 V-0, green

Dimensions 25 x 79 x 90.5 mm (w x h x d)

Installation to DIN rail 35 mm wide

OPERATING CONDITIONS

Connection connector terminal blocks, section < 1.5 mm2

Stabilization

period

within 5 minutes aer switch-on

Working temp. -20°…60°C

Storage temp. -20°…85°C

Working humidity < 95 % r.h., non condensing

Protection IP20

Construction safety class I

El. safety EN 61010-1, A2

Dielectric

strength

2.5 kVAC for 1 min. between power supply and

signal input

2.5 kVAC for 1 min. between signal input and

outputs

Insulation

resistance*

for pollution degree II, measurement cat. III

power supply > 300 V (PI), 255 V (DI)

Input/outputs > 300 V (PI)

EMC EN 61326-1 (Industrial area)

RoHS EN IEC 63000 : 2018

Seismic

qualification

IEC/IEEE 60980-344 Edition 1.0, 2020, par. 6, 9

Mechanical

resistance

EN 60068-2-6 ed. 2:2008

* PI - Primary insulation, DI - Double insulation

6 Technical data

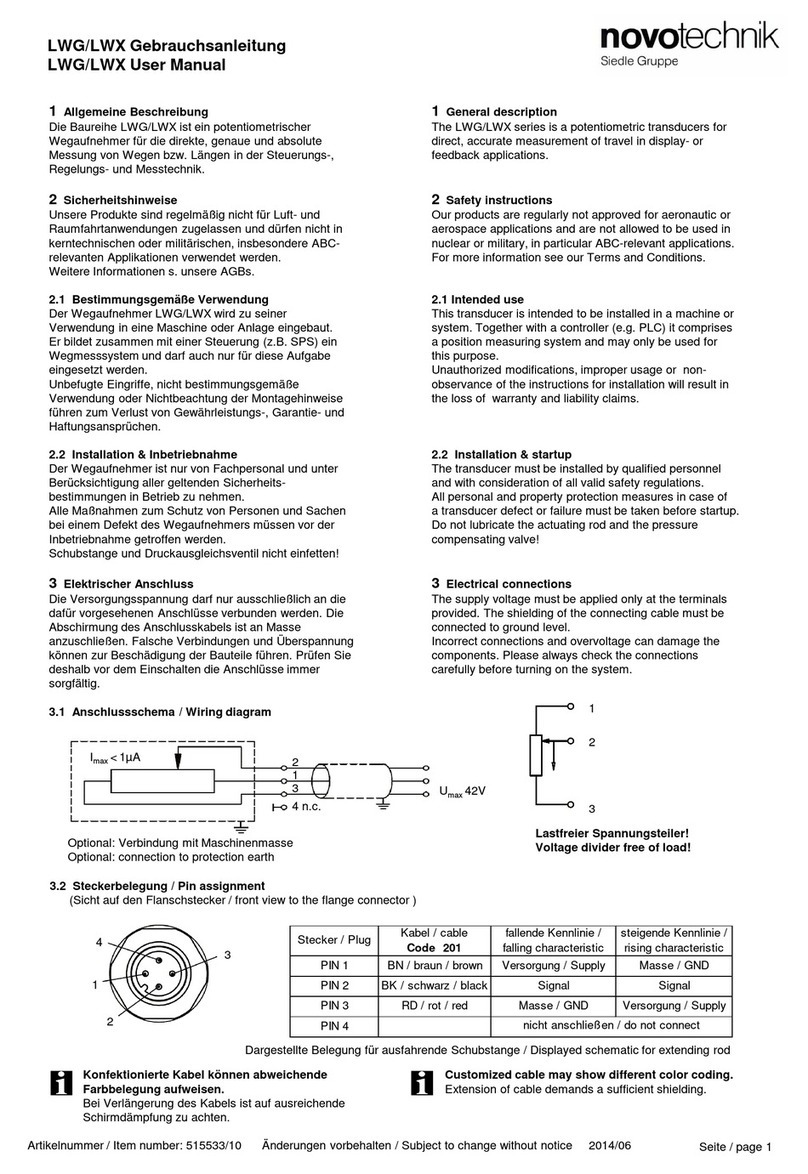

5 Instrument dimensions and installation

Measuring instruments of the MUP-410 series conform to the European regulation 2014/30/EU, 2014/35/EU and 2011/65/EU, 2015/863/EU.

This product must be installed, connected and used in compliance with prevailing standards and/or installation regulations.

As standards, specifications and designs develop from time to time, always ask for confirmation of the information given in this publication.

Side view

mm

inch

Front view

25

0.98

3.11

Top view

3.54

3.56

79

Lo

Hi

2

90,5

90

1 2 3 4 5 6 7 8

ON

Installation to DIN rail of 35 mm width

2.91

74

Novotechnik Messwertaufnehmer OHG

Horbstrasse 12, 73760 Ostfildern,

Germany

+49 711 4489-250 support@novotechnik.de

MINI-TECHDOK - MUP-410_AO - 2023.1.0 - en

4 / 4www.novotechnik.de

Other novotechnik Media Converter manuals

Popular Media Converter manuals by other brands

H&B

H&B TX-100 Installation and instruction manual

Bolin Technology

Bolin Technology D Series user manual

IFM Electronic

IFM Electronic Efector 400 RN30 Series Device manual

GRASS VALLEY

GRASS VALLEY KUDOSPRO ULC2000 user manual

Linear Technology

Linear Technology DC1523A Demo Manual

Lika

Lika ROTAPULS I28 Series quick start guide

Weidmuller

Weidmuller IE-MC-VL Series Hardware installation guide

Optical Systems Design

Optical Systems Design OSD2139 Series Operator's manual

Tema Telecomunicazioni

Tema Telecomunicazioni AD615/S product manual

KTI Networks

KTI Networks KGC-352 Series installation guide

Gira

Gira 0588 Series operating instructions

Lika

Lika SFA-5000-FD user guide