i

Table of Contents

Table of Contents

Safety Information

Important Safety Information .............................................................................iv

Section 1: General Information

Contacting Noyes Customer Service .................................................................1

Unpacking and Inspection .................................................................................1

Feature Overview ..............................................................................................2

Recommended Accessories ...............................................................................2

Section 2: Functional Description

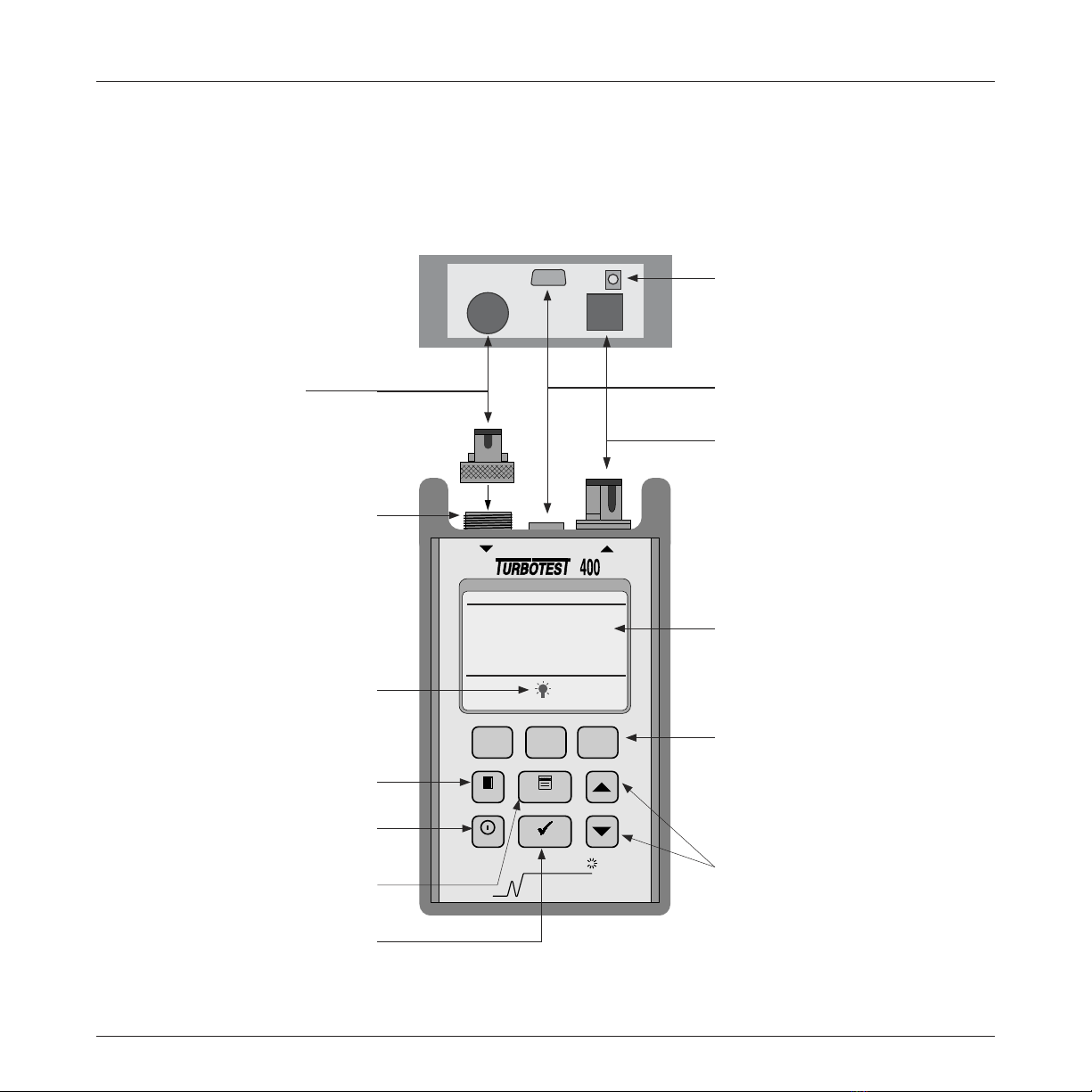

Main Unit .........................................................................................................3

Remote Unit .....................................................................................................4

Section 3: Setup and Operation

Setting an AutoTest Reference ...........................................................................5

Saving Test Results ...........................................................................................6

to create a new file ........................................................................................6

to open an existing file ...................................................................................6

to create a fiber name ...................................................................................6

to specify starting fiber numbers ....................................................................7

to review test results .....................................................................................8

to delete selected files or all files ....................................................................8

to display file and fiber storage statistics ........................................................8

Selecting AutoTest Rules ...................................................................................8

to choose an AutoTest rule .............................................................................9

Selecting AutoTest Direction (one-way or two-way) .............................................9

Setting the Index of Refraction ...........................................................................9

General Setup Options .....................................................................................9

Connecting to a PC ...........................................................................................10

Using the Main Unit as a Power Meter ................................................................10

power meter referencing ................................................................................11

power meter setup ........................................................................................11

Using the Remote Unit as a Light Source ............................................................11

About the T410 or T420 Units ............................................................................11

Section 4: AutoTest Procedures

Conducting an AutoTest .....................................................................................13

Conducting a Loop-Back AutoTest .....................................................................14