PDES-02DX-LA User Manual

___________________________________________________________________________

___________________________________________________________________________

version 1.3 page 4

2. PDES-2DX System

2.1. System Description

Pressure ejection is a convenient method for applying both ionic and non-ionic solutions from

micropipettes. This method is popular for two reasons. First, it can apply to almost all

solutions. Second, the amount of solution ejected can be monitored by viewing the tip of the

micropipette under a microscope.

The PDES-2DX is designed for pressure ejection of drugs in physiological and

pharmacological studies. PDES systems are equipped with high pressure outputs (Pmax = 2 bar

/ 29 psi or 4 bar / 58 psi) for drug application with fine-tipped micropipettes, but can also be

operated in low-range pressure for controlled droplet application from large-tipped pipettes.

Digital timers and a remote control unit facilitate the use of these instruments.

In order to speed up drug ejection, PDES-2DX systems are available with the microJect

option. These systems are equipped with a micro valve located in an injection holder. The

micro valve has a switch time of less than 1 ms and a very small volume that has to be

controlled, resulting in application times in the ms range.

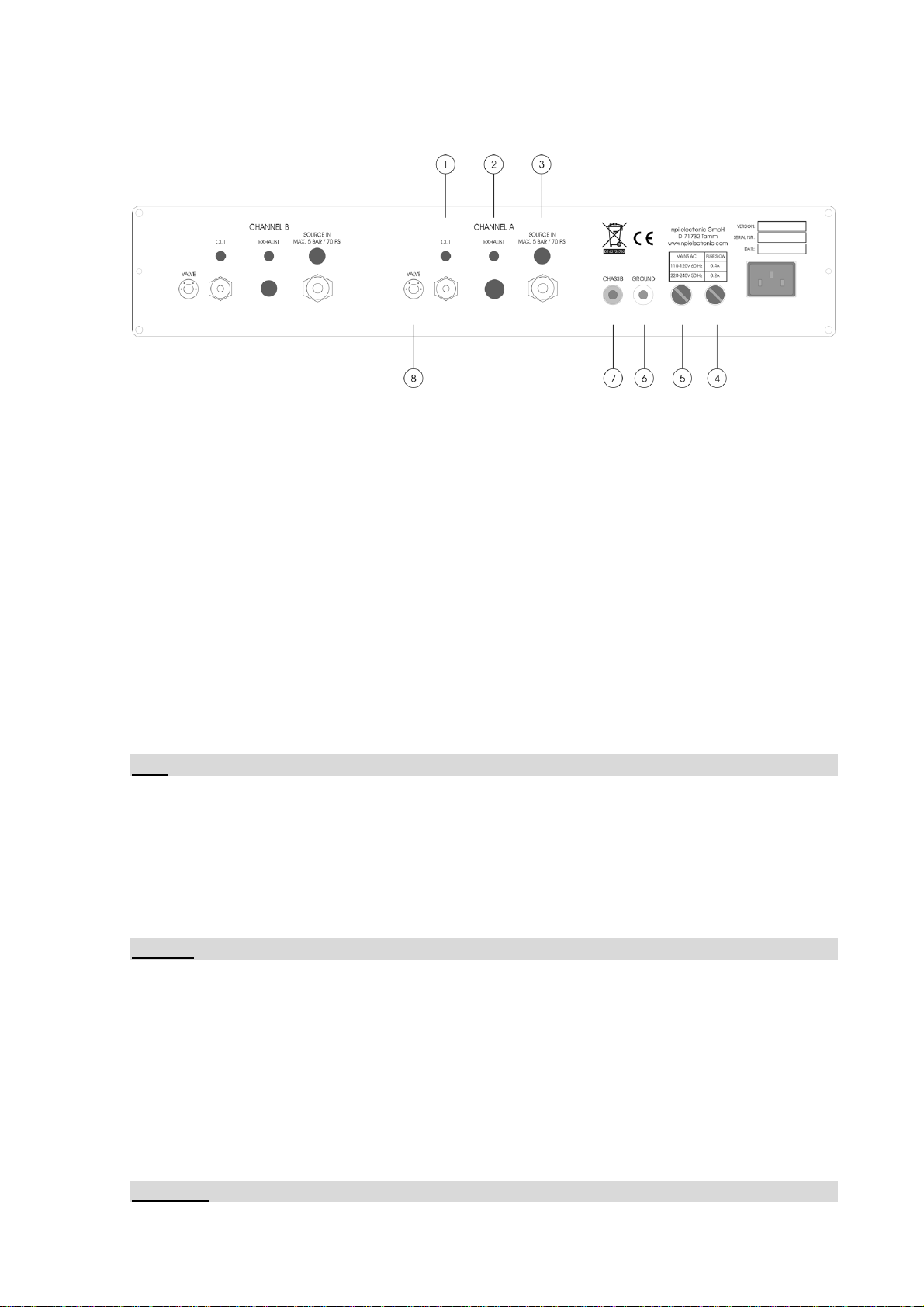

The PDES-2DX is housed in a 19" cabinet that can be mounted in a rack. It comprises of two

channels. Two systems can be combined to form a 4 channel system. Each channel consists of

a precision pressure regulator, a digital pressure display, electronically controlled valves,

control electronics and a regulated power supply. Ejection of drugs can be activated manually

or via a TTL input. The operational status is indicated by a red/green LED. The pressure

output is monitored at a BNC output (1V / bar) and additionally the signal for pressure control

is available via TTL OUT BNC connector. Optionally, each channel can be equipped with an

"EXHAUST" coupling whereby a low "retain" pressure can be applied (analogous to the

"retaining" current used in iontophoretic systems).

Mode of operation and timing is selected by controls at the front panel. If the internal timers

are used, the eject time is preset by a control. Each channel can be turned off by using a

switch that is combined with the timing control. The operational status is indicated by a

red/green LED. Red means that the channel has been turned on and the valve is closed, green

indicates that the valve is open and injection takes place.

The remote control unit (option) is housed in a small box. For each channel it has a red LED

that indicates if the respective channel is turned on and a toggle switch with a temporary and a

fix position for starting drug application.

The pressure connectors (quick connect type) are located at the rear panel of the instrument.

Each channel is equipped with an INPUT coupling where the pressure source is connected, an

OUTPUT coupling where the injection pipette is connected, and optionally, an EXHAUST

coupling where a low "hold" pressure can be applied in order to avoid capillary effects at the

tip of the injection pipette or to apply a "retain" negative pressure (analogous to the

"retaining" current used in iontophoretic systems). The "retain" pressure must be generated by

an additional pneumatic device. Please contact npi electronic for details.

The injection pressure is preset by a precision pressure regulator. The pressure is displayed on

a digital manometer. Additional pneumatic devices (tubes, fittings connectors, filters etc.) are

available. Please contact npi electronic for details.

A calibration procedure allowing quantitative drug application is described by Hofmeier and

Lux (1981) (see chapter 3).