NSK Bruel & Kjaer Vibro VC-8000 Installation guide

UNRESTRICTED DOCUMENT

Instruction

VC-8000 for Hydro

and Low Speed Machines

Including Machine-State Alarming

Operation and Maintenance

Trademarks and Copyrights

All trademarks, service marks, and/or registered trademarks used in this document belong to BK Vibro America

Inc., except as noted below:

Copyright © 2021 Brüel & Kjær Vibro GmbH

All rights to this technical documentation remain reserved.

Any corporeal or incorporeal reproduction or dissemination of this technical documentation or making this

document available to the public without prior written approval from Brüel & Kjær Vibro GmbH shall be

prohibited. This also applies to parts of this technical documentation.

Instruction VC-8000 for Hydro and Low Speed Machines, S000024.002 / V01, en, date of issue:

10.11.2021

Brüel & Kjær Vibro GmbH

Leydheckerstrasse 10

64293 Darmstadt

Germany

Phone: +49 6151 428 0

Fax: +49 6151 428 1000

Brüel & Kjær Vibro A/S

Lyngby Hovedgade 94, 5 sal

2800 Lyngby

Denmark

Phone: +45 69 89 03 00

Fax: +45 69 89 03 01

BK Vibro America Inc

1100 Mark Circle

Gardnerville NV 89410

USA

Phone: +1 (775) 552 3110

Homepage

www.bkvibro.com

© Brüel & Kjær Vibro ● S000024.002 / V01 ●Page 3 of 54

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VC-8000 for Hydro and Low Speed Machines

Table of Contents

EN

UNRESTRICTED DOCUMENT

Table of Contents

1Overview...................................................................................................................6

1.1 Vertical Machines..................................................................................................................................6

1.1.1 Sensor Orientation & Direction of Rotation.............................................................................................................6

2Hydro Radial Vibration............................................................................................7

2.1 Configure Hydro Radial Vibration.......................................................................................................7

2.1.1 Rack Layout ...........................................................................................................................................................7

2.2 Verify Hydro Radial Vibration..............................................................................................................8

3Hydro Velocity..........................................................................................................9

3.1 Configure Hydro Velocity.....................................................................................................................9

3.1.1 Rack Layout ...........................................................................................................................................................9

3.2 Verify Hydro Velocity..........................................................................................................................10

3.2.1 Test Setup............................................................................................................................................................10

3.2.2 Simulate Signals (Standard - in/s)........................................................................................................................11

3.2.3 Simulate Signals (Standard - mm/s).....................................................................................................................12

3.2.4 Simulate Signals (Integrated –mils pp)................................................................................................................13

3.2.5 Simulate Signals (Integrated –µm pp).................................................................................................................13

4Low F Velocity........................................................................................................14

4.1 Configure Low F Velocity...................................................................................................................14

4.1.1 Rack Layout .........................................................................................................................................................14

4.2 Verify Low F Velocity..........................................................................................................................14

5Low F Acceleration................................................................................................15

5.1 Configure Low F Acceleration...........................................................................................................16

5.1.1 Setting the Low Pass Filter...................................................................................................................................16

5.1.2 Rack Layout .........................................................................................................................................................16

5.2 Verify Low F Acceleration..................................................................................................................17

5.2.1 Test Setup............................................................................................................................................................17

5.2.2 Simulate Signals (Standard).................................................................................................................................17

5.2.3 Simulate Signals (Integrated –in/s)......................................................................................................................18

5.2.4 Simulate Signals (Integrated –mm/s) ..................................................................................................................19

Page 4 of 54 © Brüel & Kjær Vibro ● S000024.002 / V01

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

6Selecting a Seismic Sensor..................................................................................20

6.1 Machine Speed....................................................................................................................................20

6.2 Hydro Measurements .........................................................................................................................20

6.3 Environment (Noise)...........................................................................................................................21

6.4 System Specifications........................................................................................................................22

6.4.1 Channel Type Selection .......................................................................................................................................22

6.4.2 Sensor Specifications...........................................................................................................................................24

6.4.3 SETPOINT CMS Plots and Measurement Units...................................................................................................25

6.5 Cost......................................................................................................................................................25

7Hydro Air Gap Channel.........................................................................................26

7.1 Options for Extending Hydro functionality......................................................................................26

7.2 Background.........................................................................................................................................27

7.2.1 AG Sensor Operation Principles...........................................................................................................................27

7.2.2 How Many Sensors to Install................................................................................................................................28

7.3 Configure Hydro Air Gap ...................................................................................................................29

7.3.1 Rack Layout .........................................................................................................................................................29

7.3.2 Hydro View...........................................................................................................................................................29

7.3.3 Phase Trigger.......................................................................................................................................................31

7.3.4 Waveform Sample Rates......................................................................................................................................32

7.3.5 Waveform Collection ............................................................................................................................................32

7.4 Compatible Sensors...........................................................................................................................33

7.4.1 Sensor Power.......................................................................................................................................................33

7.4.2 Setting Ok Limits..................................................................................................................................................34

7.4.3 Pole Detection......................................................................................................................................................34

7.5 Verify Air Gap Alarms.........................................................................................................................35

7.6 SETPOINT CMS Air Gap Plots...........................................................................................................37

7.6.1 Creating Multiple Air Gap Plots ............................................................................................................................38

7.6.2 Differences from Compass Software....................................................................................................................38

7.6.3 Verify the Air Gap Plot in SETPOINT CMS ..........................................................................................................38

7.6.4 Troubleshooting the Air Gap Plot .........................................................................................................................42

© Brüel & Kjær Vibro ● S000024.002 / V01 ●Page 5 of 54

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VC-8000 for Hydro and Low Speed Machines

Table of Contents

EN

UNRESTRICTED DOCUMENT

8Machine-State Alarming........................................................................................ 43

8.1 Configure VC-8000 Channels ............................................................................................................43

8.1.1 Phase Trigger (Speed) Channel...........................................................................................................................43

8.1.2 Discrete Input Channel.........................................................................................................................................43

8.1.3 Define Machine (Asset) Groups ...........................................................................................................................44

8.1.4 Temperature Channels (TMM).............................................................................................................................45

8.1.5 Modbus and Machine-State Alarms .....................................................................................................................45

8.2 Configure Machine-States .................................................................................................................46

8.2.1 Add a Machine .....................................................................................................................................................46

8.2.2 Add Inputs............................................................................................................................................................47

8.2.3 Add States............................................................................................................................................................48

8.2.4 Set Machine-State Definitions..............................................................................................................................49

8.3 Configure Machine-State Alarms ......................................................................................................50

8.4 Validate Machine-State Alarming......................................................................................................51

8.4.1 Documentation.....................................................................................................................................................52

8.4.2 Trip Multiply Vs. Machine-State Alarming.............................................................................................................52

8.4.3 Alarm Delays (Timers) and Hysteresis.................................................................................................................53

8.5 Viewing States in SETPOINT CMS software ....................................................................................53

8.6 Troubleshooting States......................................................................................................................53

Page 6 of 54 © Brüel & Kjær Vibro ● S000024.002 / V01

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

1 Overview

This application note is an addendum to the VC-8000 Operation & Maintenance Manual (S1079330),

and the SETPOINT Condition Monitoring System Operation Manual (S1176125). Please refer to

these manuals for basic operating instructions.

This application note provides information specific for hydro turbine generators, other low speed

machines, and machines using Machine-State alarming. This includes the following channel types:

Channel Type

Application

Air Gap

Air gap measurements on the generator.

Hydro Radial Vibration

Machines up to 720 rpm using proximity probes.

Hydro Velocity

Machines up to 720 rpm using velocity sensors.

Low F Acceleration

Fans or other low speed machinery.

Low F Velocity

Fans or other low speed machinery

(any)

Machine-State alarming

1.1 Vertical Machines

Please consider the following when configuring channels on vertical machines.

1.1.1 Sensor Orientation & Direction of Rotation

Sensor Orientation and Direction of Rotation are measured as follows: The observer is looking from

the top of the generator down towards the turbine. The reference location (0 degrees) is decided at

the customer site (typically 0 degrees = upstream).

© Brüel & Kjær Vibro ● S000024.002 / V01 ●Page 7 of 54

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VC-8000 for Hydro and Low Speed Machines

Hydro Radial Vibration

EN

UNRESTRICTED DOCUMENT

2 Hydro Radial Vibration

The Hydro Radial Vibration channel is optimized for low speed (< 720 RPM) and provides a selection

of tracking filters and bandpass filters.

Table 2-1 Hydro Radial Vibration

Measurement

Description

Direct

Overall dynamic amplitude bandpass filtered measurement.

High Pass = 0.3 Hz minimum (14 pole)

Low Pass = 200 Hz maximum (12 pole)

Gap

Gap voltage for diagnostics.

1X Amplitude,

1X Phase

Amplitude and phase measurements. This measurement defaults to 1X, but

can be changed if desired (i.e. 0.5 X).

2X Amplitude,

2X Phase

Amplitude and phase measurements. This measurement defaults to 2X, but

can be changed if desired (i.e. 0.5 X).

Bandpass 1

Bandpass 2

Peak-Peak bandpass filtered measurements that can be added (if desired).

See MPS Manual S1079330. Search for “Adding Measurements”.

High Pass = 0.3 Hz min (14 pole)

Low Pass = 200 Hz max (12 pole)

2.1 Configure Hydro Radial Vibration

There are no special configuration settings for the Hydro Radial Vibration channel. Please see the

main VC-8000 Operation & Maintenance Manual (S1079330) for general information on channel

configuration.

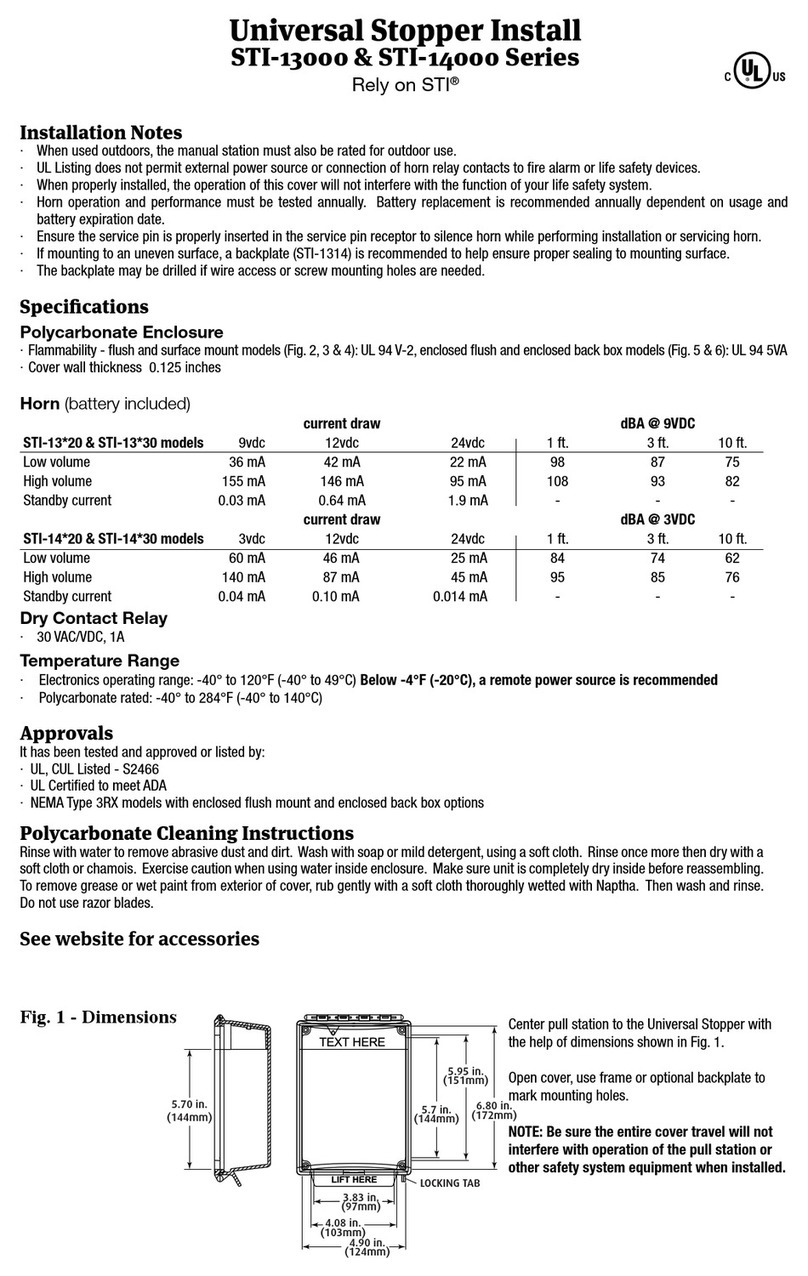

2.1.1 Rack Layout

Hydro Radial Vibration channels (XY pairs) must be in the same UMM using Ch 1 & 2 (or Ch 3 & 4).

Hydro Radial Vibration channels (XY pairs) must have the same CMS Navigation path. This “groups”

the two channels together and allows the software to show Orbit plots etc.

Page 8 of 54 © Brüel & Kjær Vibro ● S000024.002 / V01

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

2.2 Verify Hydro Radial Vibration

Set up the test equipment as shown. Set the power supply to the transducer Gap voltage.

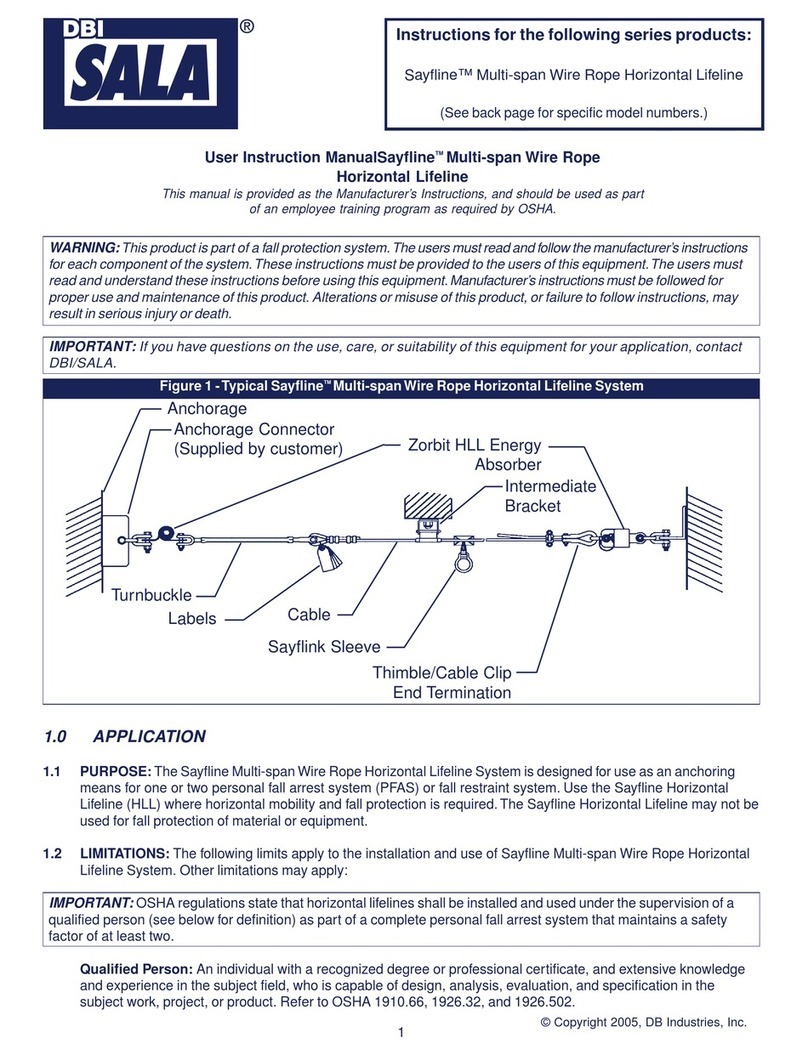

Figure 2-1) Test Setup for Hydro Radial Vibration

Set the function generator to a frequency inside your band-pass filtered region (i.e. 10 Hz) so the filter

does not attenuate the signal. Set the amplitude as follows (units are shown in mils):

Equation 2.1 Input (Vrms)

Where:

•Input (Vrms) = Simulation voltage from function generator

•Vibration (mils, or µm) = Direct vibration reading that is desired (i.e. 5 mils pp, 125 µm pp)

•Scale Factor (mV/mil or µm) = Configured transducer scale factor (i.e. 200 mV/mil, 7.87

mV/µm)

•1000 = conversion factor from mV to V

•

= conversion factor from Vpp to Vrms

Example 1: To simulate a 75 µm pp signal with a 7.87 mV/µm transducer.

© Brüel & Kjær Vibro ● S000024.002 / V01 ●Page 9 of 54

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VC-8000 for Hydro and Low Speed Machines

Hydro Velocity

EN

UNRESTRICTED DOCUMENT

3 Hydro Velocity

The Hydro Velocity channel is specifically designed for Hydro machines. It provides a good selection

of tracking filters (1X, 2X) and bandpass filters to be used depending on the installed location of the

sensor.

The Hydro Velocity channel also has a very steep High Pass filter (14 pole). This allows the channel

to return a strong signal at the lowest frequencies and still eliminate noise from the channel.

Table 3-1 Hydro Velocity Measurements

Measurement

Description

Direct

Overall dynamic amplitude measurement.

High Pass = 0.7 Hz minimum (14 pole)

Low Pass = 200 Hz maximum (12 pole)

Bias

Bias voltage for diagnostics.

1X Amplitude

1X Phase

Amplitude and phase measurements. This measurement defaults to 1X, but

can be changed if desired (i.e. 0.5 X).

2X Amplitude

2X Phase

Amplitude and phase measurements. This measurement defaults to 2X, but

can be changed if desired (i.e. 0.5 X).

Bandpass 1

Peak-Peak bandpass filtered measurement (can be added)

High Pass = 0.7 Hz minimum (14 pole)

Low Pass = 200 Hz maximum (12 pole)

Low F

Bandpass 2

Peak-Peak bandpass filtered measurement (can be added)

High Pass = 0.2 Hz minimum (14 pole)

Low Pass = 25 Hz maximum (12 pole)

The Hydro Velocity channel has excellent filter options for a low speed machine. The Low Pass and

High Pass corner filters are configurable in the VC-8000 Setup Software (Measurements tab, All

view). The filters are specific to the Direct, and Bandpass measurements. The Asynchronous and

Synchronous waveforms are not bandpass filtered.

3.1 Configure Hydro Velocity

There are no special configuration settings for the Hydro Velocity channel. Please see the main VC-

8000 Operation & Maintenance Manual (S1079330) for general information on channel configuration.

3.1.1 Rack Layout

To view casing orbit plots in SETPOINT CMS software, the Hydro Velocity channels must be in Ch 1

& 2, or Ch 3 & 4 and the two channels must be paired. Otherwise, the Hydro Velocity channel can be

in any location.

Page 10 of 54 © Brüel & Kjær Vibro ● S000024.002 / V01

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

3.2 Verify Hydro Velocity

3.2.1 Test Setup

Simulate the Hydro Velocity channel depending on the sensor selected.

3.2.1.1 Constant Current Velocity Sensor

Use a 3.3 kΩ resistor to set the bias voltage (+10 Vdc). The 940 µF (or larger) capacitor is used to

force the current through the resistor. A large test capacitor is needed because of the low frequency

characteristics of the input signal.

Figure 3-1) Constant Current Sensor

3.2.1.2 Velocity (Moving Coil) Sensor

Simulate a velocity (moving coil) sensor as shown here.

Figure 3-2) Velocity (Moving Coil) sensor

© Brüel & Kjær Vibro ● S000024.002 / V01 ●Page 11 of 54

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VC-8000 for Hydro and Low Speed Machines

Hydro Velocity

EN

UNRESTRICTED DOCUMENT

3.2.2 Simulate Signals (Standard - in/s)

Use a test frequency compatible with the Hydro Velocity Channel (i.e. 25 Hz). Use the following

equations to calculate the velocity input value:

Equation 3.1 (in/s pk)

Equation 3.2 (in/s rms)

Where:

•Input = Simulation voltage from function generator (Vrms)

•Vibration = Desired vibration reading (i.e. 0.5 in/s pk, 10 mm/s pk, etc.)

•Scale Factor = Configured transducer scale factor (i.e. 20 mV/mm/s, 508 mV/in/s)

•1000 = conversion factor from mV to V

•1/√2 = conversion factor from pk to rms

Example 1: To simulate a 0.5 in/s pk signal with a 508 mV/in/s transducer.

Example 2: To simulate a 0.5 in/s rms signal with a 508 mV/in/s transducer.

TIP

A multimeter may have trouble measuring the test signal at low frequencies.

Temporarily increase the signal frequency (i.e. 60 Hz) to verify the amplitude.

Page 12 of 54 © Brüel & Kjær Vibro ● S000024.002 / V01

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

3.2.3 Simulate Signals (Standard - mm/s)

Use a test frequency compatible with the Hydro Velocity Channel (i.e. 25 Hz). Use the following

equations to calculate the velocity input value:

Equation 3.3 (mm/s pk)

Equation 3.4 (mm/s rms)

Where:

•Input = Simulation voltage from function generator (Vrms)

•Vibration = Desired vibration reading (i.e. 10 mm/s pk, etc.)

•Scale Factor = Configured transducer scale factor (i.e. 20 mV/mm/s)

•1000 = conversion factor from mV to V

•1/√2 = conversion factor from pk to RMS

Example 2: To simulate a 10 mm/s pk signal with a 20 mV/mm/s transducer.

Example 1: To simulate a 10 mm/s rms signal with a 20 mV/mm/s transducer.

© Brüel & Kjær Vibro ● S000024.002 / V01 ●Page 13 of 54

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VC-8000 for Hydro and Low Speed Machines

Hydro Velocity

EN

UNRESTRICTED DOCUMENT

3.2.4 Simulate Signals (Integrated –mils pp)

Use a test frequency compatible with the Hydro Velocity Channel (i.e. 25 Hz). Use the following

equations to calculate the velocity input value:

Equation 3.5 (mils pp)

Where:

•Velocity = Velocity at the given displacement and frequency

•mils pp = desired displacement value

•Frequency = Input Frequency

•318.3 = conversion factor

Example 1: To simulate a 10 mils pp integrated signal, where the signal frequency is 25 Hz and the

scale factor is 508 mV/in/s, first use Equation 3.5 and then input the result into Equation 3.1

3.2.5 Simulate Signals (Integrated –µm pp)

Use a test frequency compatible with the Hydro Velocity Channel (i.e. 25 Hz). Use the following

equations to calculate the velocity input value:

Equation 3.6 (µm pp)

Where:

•Velocity = Velocity at the given displacement and frequency

•µm pp = desired displacement value

•Frequency = Input Frequency

•318.3 = conversion factor

Example 2: To simulate a 250 µm pp integrated signal, where the signal frequency is 25 Hz and the

scale factor is 20 mV/mm/s, first use Equation 3.6 and then input the result into Equation 3.3

Page 14 of 54 © Brüel & Kjær Vibro ● S000024.002 / V01

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

4 Low F Velocity

The Low F Velocity was not designed for Hydro monitoring. It is a modification of the Standard

Velocity channel with some improvements for lower frequency measurements.

The band-pass frequency of the channel is very wide. The integration of a signal (with low frequency

and a wide band-pass) requires extra processor power; some measurements were removed to allow

for this option.

Table 4-1 Low F Velocity Measurements

Measurement

Description

Direct

Overall dynamic amplitude measurement.

Bias

Bias voltage for diagnostics.

1X Amplitude

1X Phase

Amplitude and phase measurements. This measurement defaults to 1X, but

can be changed if desired (i.e. 0.5 X).

Table 4-2 Low F Velocity Band-pass

Measurement

High Pass Min (LP1)

Low Pass Max (HP1)

Direct

0.2 Hz (1000 Hz) (4 pole)

5000 Hz (1 Hz) (4 pole)

Direct (Integrated)

0.7 Hz (3500 Hz) (4 pole)

5000 Hz (1 Hz) (4 pole)

1. The High Pass (HP) and Low Pass (LP) filters must be within 5000x. For example, if I select a High Pass filter

of 0.2 Hz, my Low Pass filter must be less than 1000 Hz.

4.1 Configure Low F Velocity

There are no special configuration settings for the Hydro Velocity channel. Please see the main VC-

8000 Operation & Maintenance Manual (S1079330) for general information on channel configuration.

4.1.1 Rack Layout

If the customer is viewing casing orbit plots in SETPOINT software, the Low F Velocity channels must

be in Ch 1 & 2, or Ch 3 & 4. Also, the two channels must be paired.

If the sensor is not providing casing orbit plots in CMS, the channel can be in any location in the rack

and is not required to be part of an XY pair.

4.2 Verify Low F Velocity

The instructions to verify a Low F Velocity channel are the same as for the Hydro Velocity channel.

Please see Section 3.2.

© Brüel & Kjær Vibro ● S000024.002 / V01 ●Page 15 of 54

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VC-8000 for Hydro and Low Speed Machines

Low F Acceleration

EN

UNRESTRICTED DOCUMENT

5 Low F Acceleration

The Low F Acceleration channel can be used for Hydro monitoring, but it was not specifically

designed for Hydro monitoring. It is a modification of the Standard Acceleration channel with some

improvements for lower frequency signal components.

The band-pass frequency of the channel is very wide. The integration of a signal (with low frequency

and a wide band-pass) requires extra processor power; some measurements were removed to allow

for this option.

Table 5-1 Low F Acceleration Measurements

Measurement

Description

Direct

Overall dynamic amplitude measurement.

Bias

DC sensor bias voltage for diagnostics.

1X Amplitude

1X Phase

Amplitude and phase measurements. This measurement defaults to 1X, but

can be changed if desired (i.e. 0.5 X).

Bandpass

Bandpass filtered measurement that can be added (if desired).

Table 5-2 Low F Acceleration Bandpass

Measurements

High Pass Min (LP1)

(HP1) Low Pass Max

Direct

0.2 Hz (- 1000 Hz) (4 pole)

(1 Hz -) 5000 Hz (4 pole)

Direct (Integrated) pk

0.7 Hz (- 3500 Hz) (4 pole)

(1 Hz -) 5000 Hz (4 pole)

Direct (Integrated) rms

0.2 Hz (- 1000 Hz) (4 pole)

(1 Hz -) 5000 Hz (4 pole)

Bandpass 1

2.0 Hz (- 10,000 Hz) (4 pole)

(2.0 Hz -) 10,000 Hz (4 pole)

Band-pass 1 (Integrated) pk

10 Hz (- 10,000 Hz) (4 pole)

(10 Hz -) 10,000 Hz (4 pole)

Band-pass 1 (Integrated) rms

2.0 Hz (- 10,000 Hz) (4 pole)

(2.0 Hz -) 10,000 Hz (4 pole)

1. The High Pass (HP) and Low Pass (LP) filters must be within 5000x. For example, if I select a High Pass filter

of 0.2 Hz, my Low Pass filter must be less than 1000 Hz.

TIP

The High Pass and Low Pass filter settings only affect the measurement specified (i.e.

Direct, Bandpass). These settings do not affect 1X measurement, or the waveforms

used to create the time-base and spectrum plots in SETPOINT CMS software.

The Low F Accel channel has a Direct measurement, and a Bandpass measurement. If the sensor is

installed (for example) on the draft tube of the Hydro machine, you can set the Direct measurement

with a bandpass of 0.5 to 25 Hz to measure flow turbulence, and then set the Bandpass

measurement for 25 Hz to 5000 Hz to measure cavitation.

Page 16 of 54 © Brüel & Kjær Vibro ● S000024.002 / V01

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

5.1 Configure Low F Acceleration

If you are using this channel for a Hydro machine, you a will probably need to modify a few of the

default channel settings. These are explained below.

5.1.1 Setting the Low Pass Filter

To set the Low Pass filter correctly, you need to know what you are measuring. The default Low Pass

filter is 200 Hz. That may seem low for an accelerometer, but for a Hydro machine that is equivalent

to 12,000 RPM (very high). If you are using this for 1X and 2X vibration you will want to modify the

Low Pass filter to 25 Hz or lower.

The following example highlights how the filter settings will affect this measurement.

The AS-477 Accelerometer has a scale factor of 500 mV/g with a low frequency range down to 30

CPM (0.5 Hz) (-3 dB). A machine running at 166 RPM (2.7 Hz) with 5.0 mm/sec RMS (0.20 in/sec

RMS) of 1X vibration, is equivalent to 0.012 g’s pk which is a signal of only 6 mV.

In comparison, higher frequency components with smaller signal amplitudes will be larger than the 1X

signal component. For example, a 0.5 mm/sec amplitude vibration at 200 Hz = 0.09 g’s pk = 45 mV.

The vibration is 10 times smaller, but the signal component is 8 times larger.

This example, again, highlights why it is better to use a velocity sensor, over an accelerometer, if you

are using it to primarily measure low frequencies.

5.1.2 Rack Layout

If the customer is viewing casing orbit plots (this is rare) in SETPOINT software, the channels must

be in Ch 1 & 2, or Ch 3 & 4. The two channels must be paired.

If the customer is not using casing orbits in CMS software the channels can be in any location in the

rack and they are not required to be in XY pairs.

© Brüel & Kjær Vibro ● S000024.002 / V01 ●Page 17 of 54

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VC-8000 for Hydro and Low Speed Machines

Low F Acceleration

EN

UNRESTRICTED DOCUMENT

5.2 Verify Low F Acceleration

5.2.1 Test Setup

Use a 3.3 kΩ resistor to set the bias voltage (+10 Vdc). The 940 µF (or larger) capacitor is used to

force the current through the resistor. A large test capacitor is needed because of the (expected) low

frequency characteristics of the input signal.

Figure 5-1) Constant Current Sensor

5.2.2 Simulate Signals (Standard)

Use a test frequency compatible with the configuration of the channel (i.e. 25 Hz). Set the function

generator amplitude as follows:

Equation 5.1 (Units g pk)

Equation 5.2 (Units g rms)

Where:

•Input = Simulation voltage from function generator (Vrms)

•Vibration = Desired vibration reading (i.e. 0.5 g pk)

•Scale Factor = Configured transducer scale factor (i.e. 100 mV/g, 500 mV/g)

•1000 = conversion factor from mV to V

•√2 = conversion factor to Vrms

Example 1: To simulate a 0.5 g pk signal with a 100 mV/g transducer.

TIP

A multimeter may have trouble measuring the test signal at low frequencies.

Temporarily increase the frequency (i.e. 60 Hz) to verify the signal amplitude.

Page 18 of 54 © Brüel & Kjær Vibro ● S000024.002 / V01

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

5.2.3 Simulate Signals (Integrated –in/s)

Use a test frequency compatible with the configuration of the channel (i.e. 25 Hz). Use the following

equations to calculate the acceleration input value:

Equation 5.3 (in/s pk)

Equation 5.4 (in/s rms)

Where:

•Acceleration (g pk) = Acceleration value for input signal

•Velocity in/s pk (or mm/s pk) = desired velocity value

•Frequency = Input signal frequency

•61.45 = conversion factor

Example 1: To simulate a 1.0 in/s pk integrated signal, where frequency is 25 Hz and the scale factor

of the sensor is 100 mV/g, first use Equation 5.3 , and then input the result into Equation 5.1.

To see 1.0 in/s pk (integrated) I need to

input a signal equivalent to 0.41 g pk.

0.41 g pk is 28.7 mVrms (multimeter).

Example 2: To simulate a 1.0 in/s rms integrated signal, where frequency is 25 Hz and the scale

factor of the sensor is 100 mV/g, first use, Equation 5.4 and then input the result into Equation 5.2.

To see 1.0 in/s rms (integrated) input a

signal equivalent to 0.41 g rms.

0.41 g rms is 41 mVrms (multimeter).

© Brüel & Kjær Vibro ● S000024.002 / V01 ●Page 19 of 54

Technical alterations reserved!

Brüel & Kjær Vibro │Instruction VC-8000 for Hydro and Low Speed Machines

Low F Acceleration

EN

UNRESTRICTED DOCUMENT

5.2.4 Simulate Signals (Integrated –mm/s)

Use a test frequency compatible with the configuration of the channel (i.e. 25 Hz). Use the following

equations to calculate the acceleration input value:

Equation 5.5 (mm/s pk)

Equation 5.6 (mm/s rms)

Where:

•Acceleration (g pk) = Acceleration value for input signal

•Velocity in/s pk (or mm/s pk) = desired velocity value

•Frequency = Input signal frequency

•1560 = conversion factor

Example1: To simulate a 25 mm/s pk integrated signal, where frequency is 25 Hz and the scale factor

of the sensor is 100 mV/g, first use Equation 5.5 and then input the result into Equation 5.1.

To see 25 mm/s pk (integrated) I need to

input a signal equivalent to 0.40 g pk.

0.40 g pk is 28.3 mVrms (multimeter).

Example 2: To simulate a 25 mm/s rms integrated signal, where frequency is 25 Hz and the scale

factor of the sensor is 100 mV/g, first use, Equation 5.6 and then input the result into Equation 5.2.

To see 25 mm/s rms (integrated) input a

signal equivalent to 0.40 g rms.

0.40 g rms is 40 mVrms (multimeter).

Page 20 of 54 © Brüel & Kjær Vibro ● S000024.002 / V01

Technical alterations reserved!

EN

UNRESTRICTED DOCUMENT

6 Selecting a Seismic Sensor

There are several things to consider before selecting a sensor.

1.

What is the speed of the machine?

2.

What am I trying to measure?

3.

What is the environment?

4.

What are the specifications for the system (Sensor, VC-8000, CMS)

5.

What is the cost of the sensor?

These topics are addressed in the following sections.

6.1 Machine Speed

All Hydro machines are low speed. But this makes sensor selection more difficult, rather than easier.

At 300 RPM (or above) your 1X vibration will be at 5 Hz (or above) and there is a wider array of

sensors available. Many of these sensors are general purpose and are not designed specifically for

low frequency applications.

Below 300 RPM you will probably need a sensor specifically targeting low speed machines. For

example, at 166 RPM your 1X vibration will be at 2.7 Hz. If you are interested in vibration related to

flow turbulence (or vortex) you will want to see 0.4X (1.1 Hz).

6.2 Hydro Measurements

There can be a lot of regional differentiation in what is measured and how it is measured. The

following guidelines may help when selecting a sensor.

Draft Tube - Flow Turbulence (Vortex)

Vortex typically causes a vibration around 0.4X to 0.5X of the running speed of the machine. Since

this vibration is very slow an accelerometer will not provide enough signal amplitude to measure this.

A velocity sensor should be used.

Draft Tube - Cavitation (High Frequency)

Use an accelerometer. Cavitation is typically around 5000 Hz.

Stator Vibration

The frequencies of interest for Stator Vibration will typically be 1X and an accelerometer could be

used.

Radial Bearing Housing (XY)

The frequencies of interest for bearing housing vibration will typically be 0.4X and 1X. Also, when

measuring vibration at the bearing housing it is common to integrate to displacement units; therefore,

a velocity sensor should be used.

Turbine Cover (Blade Pass)

The frequencies of interest for Turbine Cover (Blade Pass) vibration will typically be 1X and greater,

and an accelerometer could be used.

Table of contents

Popular Protection Device manuals by other brands

Valex

Valex C170 Instruction manual and safety instructions

Maxair

Maxair CA-DLC-CAPR-36 User instructions

Delta-Opti

Delta-Opti KN-04C-BR user manual

Arcteq

Arcteq AQ-M257 instruction manual

DBI SALA

DBI SALA Sayfline Multi-span Wire Rope Horizontal... User instruction manual

Hirschmann

Hirschmann BAT-ANT Protector M-F Mounting instruction