A Ground Fault Circuit Interrupter (GFCI) is an electrical

safety device that under normal use is intended to mitigate

electric shock hazard. Use this product only within the

specified operating parameters. (Failure to do so may result

in bodily injury.) Consult a licensed electrician for assistance

on installation and repairs. Do not use this GFCI if it fails to

function as instructed. Never attempt to tamper with this

device. This GFCI must never be used as a switch to

connect or disconnect power. (Power should be

disconnected at main power feed or by secondary switch

located at the primary feed of GFCI.) This GFCI is not an

over-current protection device. (An appropriate fuse or

circuit breaker must be used in series at primary power

feed.) This GFCI does not provide protection against shocks

caused by holding both circuit conductors. This GFCI does

not provide protection against electrical shocks generated

by the conductors supplying power to the device. Note:

primary feed to GFCI is live even when GFCI is tripped.

(Power should be disconnected at main service panel

before servicing load side of GFCI.)

Do not use this device to feed power to life support

apparatus.

To minimize nuisance tripping:

Do not use on swimming pool equipment

installed before 1965 NEC code.

Do not use on electric clothes dryers or electric

ranges with frames grounded by neutral

conductor.

Installation must comply with local and national

electrical codes (NEC).

During installation, turn power off at the service panel to

prevent serious injuries.

What is a GFCI?

A GFCI is a device designed to interrupt power when a

ground fault (a current that takes a path to ground) exceeds

a predetermined value. This power interruption is quickly

accomplished to prevent serious injuries.

Why do we need a GFCI?

The human body is conductive to electricity, and electric

shocks can be fatal. Any electrical tool or appliance is a

potential shock hazard, especially when used near wet

locations; and this is where a GFCI is needed the most.

This is why most electrical codes require GFCI protection in

kitchens, bathrooms, garages, outdoor outlets, laundry

rooms, workshops, etc.

North Shore Safety’s GFCI, LineGard®, will offer such

protection. Its safety scope surpasses its peers to include

open supply protection (most receptacle type GFCIs do not

sense open neutral condition) as well as dual indication of

operating modes, with fault indication or power status.

How does a GFCI operate?

The GFCI constantly monitors the current-balance of the

conductors supplying power to the load. When a ground

fault occurs - by a leakage or by shock - the imbalance of

current is sensed and the GFCI trips when the ground fault

exceeds 5 mA +/- 1 mA. The tripping action must be within

a fraction of a second to prevent serious injuries.

What a GFCI cannot do:

Will not protect the circuit’s line side.

Will not protect you when touching two current carrying

conductors of opposite polarity (the GFCI sees this as a

load).

Will not protect you when touching a line of another

circuit.

Will not detect over-current.

North Shore Safety

7335 Production Drive

Mentor, Ohio 44060

Phone: 440.205.9188

Fax: 440.205.9187

Toll-free: 877.472.3348

Web: www.nssltd.com

Email: sales@nssltd.com

North Shore Safety warrants to the consumer its Line-Gard Ground Fault Circuit Interrupter (GFCI) to be free from defects in

materials and workmanship, under normal use and service, for a period of two years from date of purchase. North Shore

Safety, at its option, will repair or replace the defective GFCI without charge within 2-years of the date of the product’s

purchase provided that the defect occurred during normal use. The defective unit must be returned freight prepaid, with a RGA

(Returned Goods Authorization) including a description of the problem, and a proof of purchase date to the Quality Assurance

Dept. North Shore Safety, Ltd. 7335 Production Drive, Mentor, OH 44060.

North Shore Safety will not be liable, directly or indirectly, for installation or removal of this device, or for any personal injury, or

property damages, or incidental, indirect, or consequential damages of any kind, as a result of a defective device. The

exclusive remedy, under this warranty, is the repair or replacement of the defective device. In no case shall North Shore

Safety’s liability exceed the purchase price. This warranty is void or not covered if this device is found to be: not properly

installed, tampered with, not used according to label instructions and ratings, enclosure breached (button cover label, conduit

hubs, vent, or lid fasteners), surged, short circuited, or abused.

IMPORTANT!

THIS DEVICE MUST BE INSTALLED BY A QUALIFIED

PERSON WHO UNDERSTANDS ELECTRICAL

CIRCUITS.

Please read all the information on this sheet.

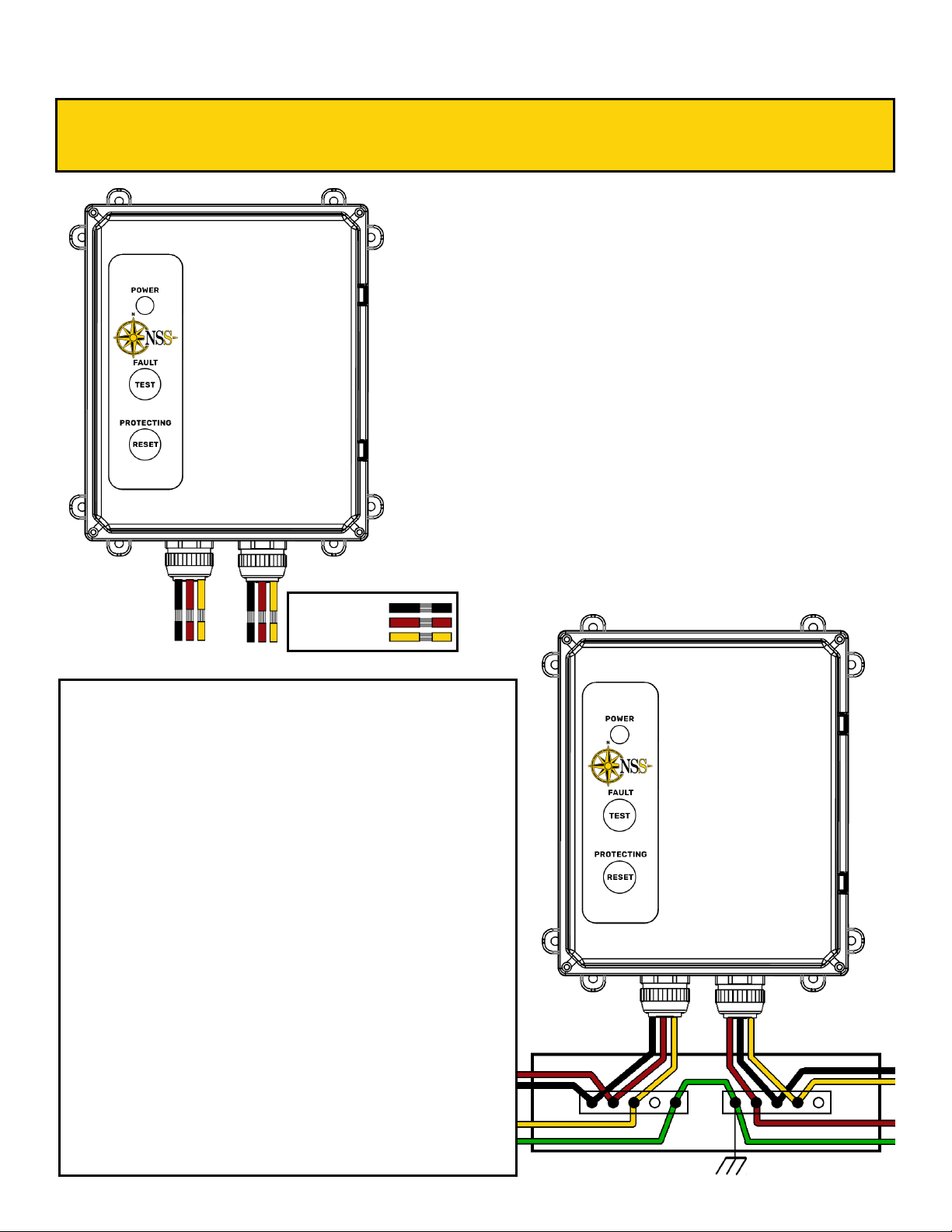

INSTALLATION AND TESTING

PROCEDURE

WARNING

North Shore Safety TWO YEAR LIMITED MANUFACTURER’S WARRANTY

192211A