Chapter 1. Basic information

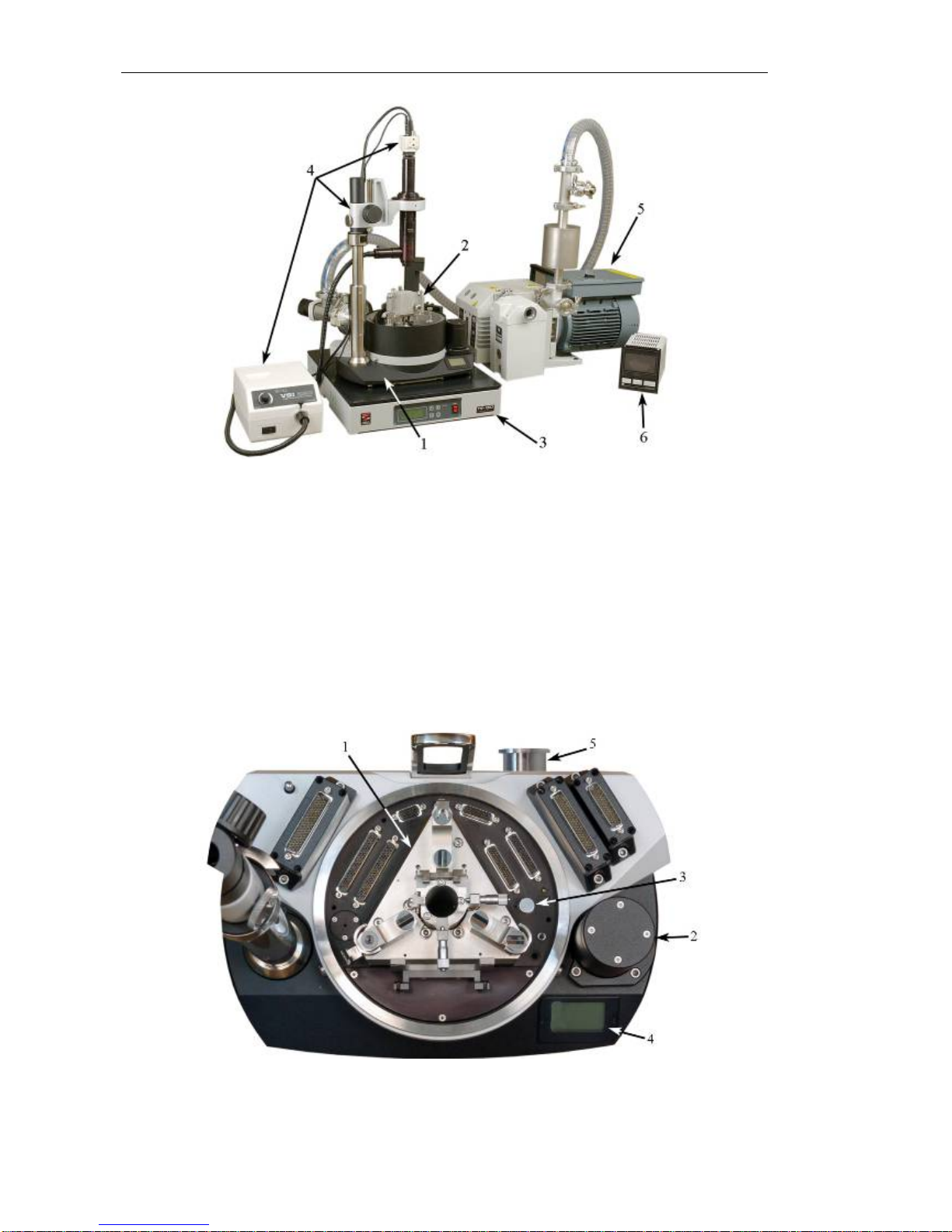

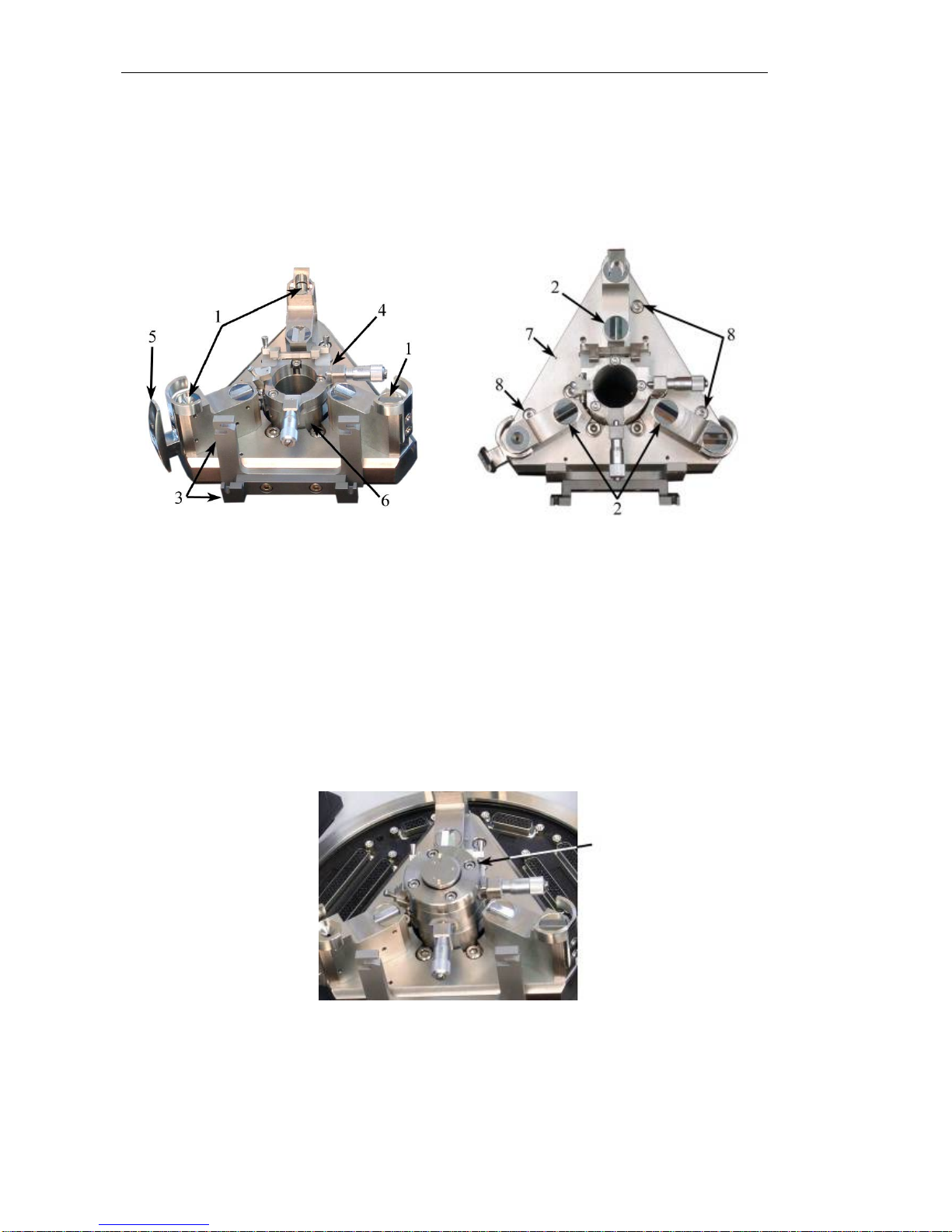

The base module accommodates the stepper motor 2, which provides the approach of the

sample to the probe. There is no function of manual approach of the sample in the vacuum

measurement configuration. Therefore control of the stepper motor is provided only

through the control program Nova.

The LC-display 4 contains information about temperature and humidity inside the vacuum

hood, which is measured by sensor 3.

Fig. 1-3 provides a diagram of connectors located in the base unit of the instrument.

Fig. 1-3. Diagram of connectors located in the base unit

There are the following female connectors for connecting devices mounted on the

base unit:

HEAD – for connecting measuring heads.

SCANNER – for connecting scanners. It is used for connecting either

exchangeable scanners or the measuring head scanner.

SCAN+SENSOR – for connecting scanners with built-in sensors. It is used for

connecting either exchangeable scanners or the measuring head

scanner.

Т°– for connecting the heater. It is used to connect heating stages, fluid

cells with heaters etc.

SM – for connecting the stepper motor.

AFAM – for connecting the sample holder to perform the AFAM technique.

BV – bias voltage feed line.

There are the following male connectors for connecting the base unit to the

controllers of the control system:

CONTROLLER 1 – for connecting the PNL controller;

CONTROLLER 2 - for connecting the PNL controller;

CONTROLLER T - for connecting the thermocontroller.

7