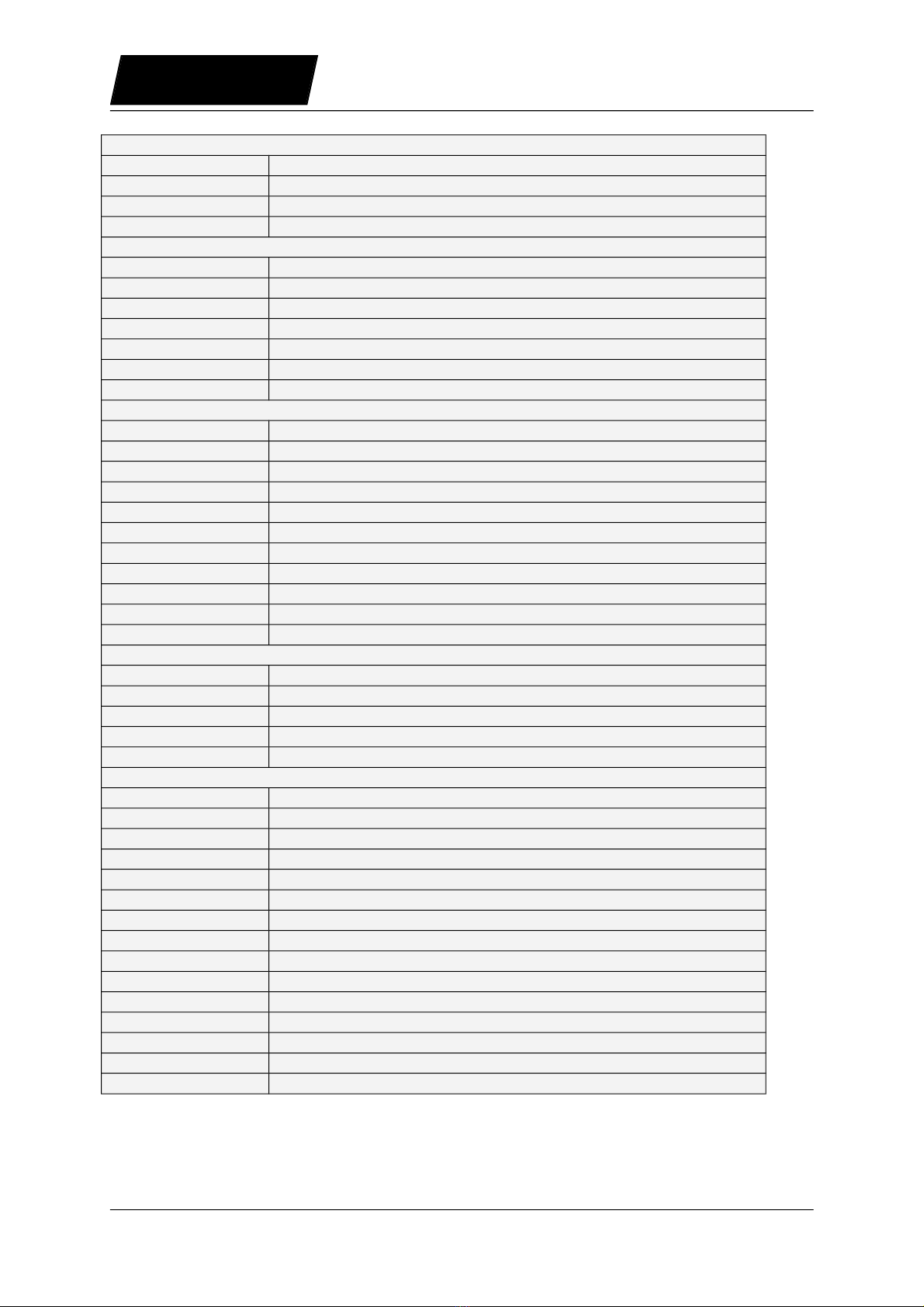

PROFIBNET Interface

Parameter (UPID) List

20 Start Getting UPID List

21 Get next UPID List item

22 Start Getting Modified UPID List

23 Get next Modified UPID List item

Stop / Start / Default

30 Restart drive

31 Set parameter ROM values to default (OS SW)

32 Set parameter ROM values to default (MC SW )

33 Set parameter ROM values to default (Interface SW)

34 Set parameter ROM values to default (Application SW)

35 Stop MC and Application Software (for Flas access)

36 Start MC and Application Software

Curve Service

40 Save all Curves from RAM to Flas

41 Delete all Curves (RAM)

50 Start Adding Curve (RAM)

51 Add Curve Info Block (RAM)

52 Add Curve Data (RAM)

53 Start Modifying Curve (RAM)

54 Modify Curve Info Block (RAM)

55 Modify Curve Data (RAM)

60 Start Getting Curve (RAM)

61 Get Curve Info Block (RAM)

62 Get Curve Data (RAM)

Error Log

70 Get Error Log Entry Counter

71 Get Error Log Entry Error Code

72 Get Error Log Entry Time low

73 Get Error Log Entry Time ig

74 Get Error Code Text Stringlet

Command Table

80 Command Table: Save to Flas

81 Command Table: Delete All Entries (RAM)

82 Command Table: Delete Entry

83 Command Table: Write Entry

84 Command Table: Write Entry Data

85 Command Table: Get Entry

86 Command Table: Get Entry Data

87 Get Presence List of Entries 0..31 from RAM

88 Get Presence List of Entries 32..63 from RAM

89 Get Presence List of Entries 64..95 from RAM

8A Get Presence List of Entries 96..127 from RAM

8B Get Presence List of Entries 128..159 from RAM

8C Get Presence List of Entries 160..191 from RAM

8D Get Presence List of Entries 192..223 from RAM

8E Get Presence List of Entries 224..255 from RAM

Page 10/24 User Manual PROFINET Interface / 09/09/2015 NTI AG / LinMot