NTI Sentry 2100 Quick start guide

Installation & Operational

Instructions

Never make electrical connects on or around Sentry 2100 while power is on, electrical

arching can damage unit, voiding warranty.

Caution: All Sentry inputs are DC voltage. DO NOT ground, or provide any AC voltage to the Sensors or

thermostat inputs, this will result in serious damage to the Sentry 2100 voiding the warranty.

For terminals A C T use dry contacts only to switch signal.

Verify that there is NO EXTERNAL VOLTAGE between these wires prior to connection.

Verify that there is NO EXTERNAL VOLTAGE to ground and these wires prior to

connection.

Sentry 2100 Microprocessor

Boiler Controller

Software Version C2.0 ONLY

For L or T versions, consult Trinity or Legacy manual

Control Input Voltage (L1L2) = 120 VAC. Contact Output FLA B1= 3 Amps, C1& AP= 3 Amps.

Provide 15 Amp, time delay Fuse protection. Contact Output FLA F1 = 3 Amps, (optional contact).

Maximum Ambient Condition = 150°F. Install ONLY as specified by NY Thermal.

Caution: All Sentry inputs are DC voltage. DO NOT ground, or provide any AC voltage to the Sensors or

thermostat inputs, this will result in serious damage to the Sentry 2100 voiding the warranty.

For terminals A C T use dry contacts only to switch signal.

Verify that there is NO EXTERNAL VOLTAGE between these wires prior to connection.

Verify that there is NO EXTERNAL VOLTAGE to ground and these wires prior to connection.

The Sentry 2100 microprocessor boiler controller is designed to give superior control of boiler

operations while ensuring a high degree of safety and reliability. The sentry 2100 Controller a

proprietary designs of NY Thermal and is intended only for use in specified NY Thermal boilers.

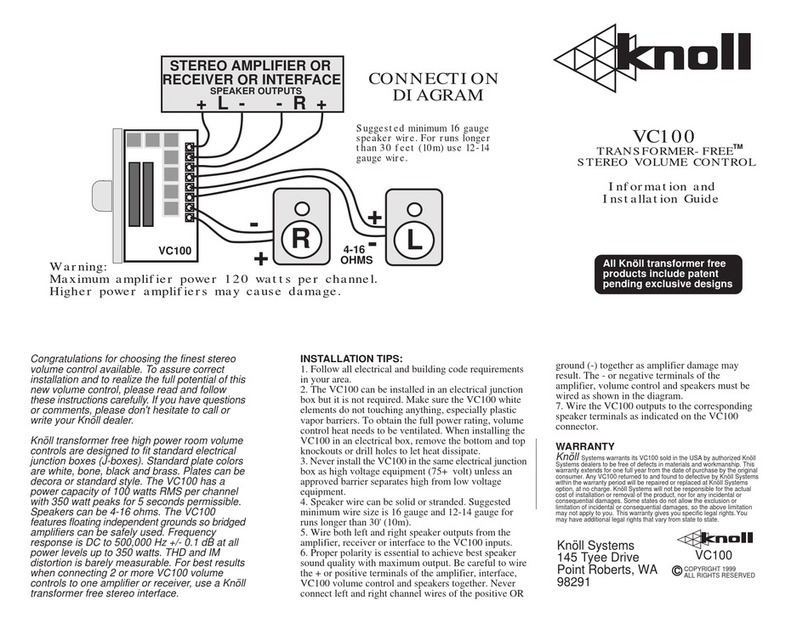

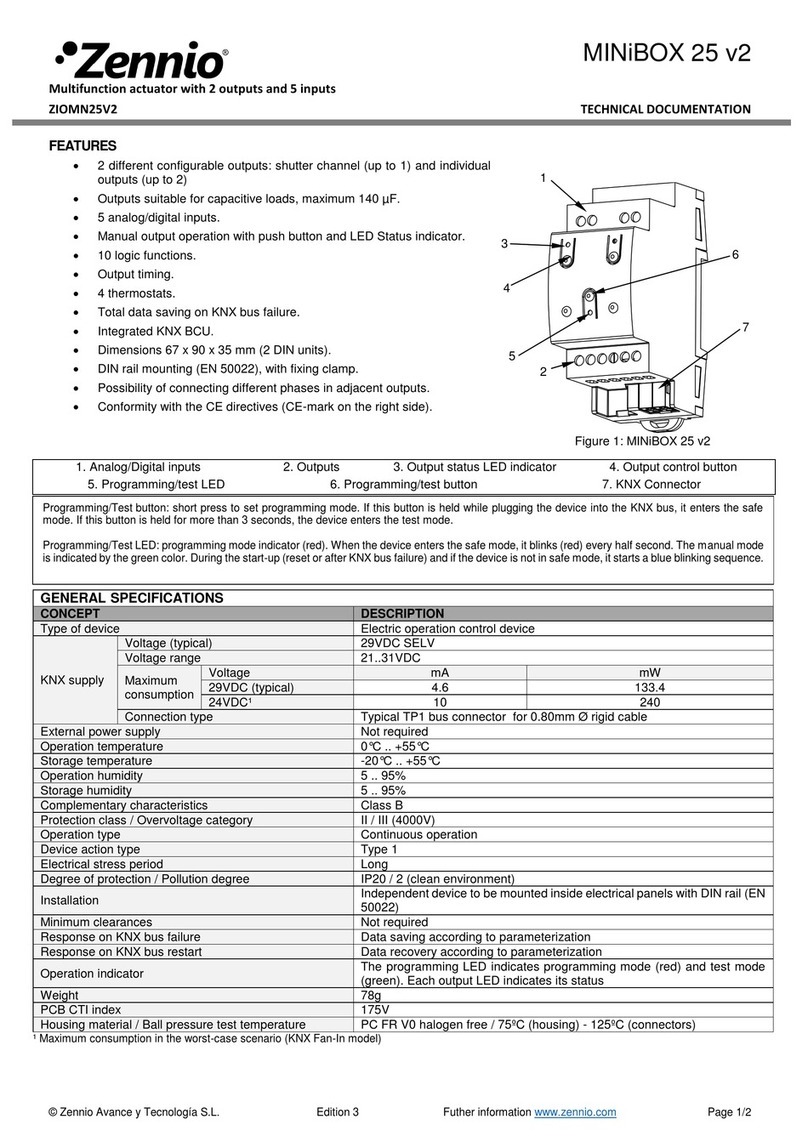

120 V Power Out to

Heating Pump

120 Volt Line

Power In (

+

)

120 V Power Out

To Burner

120 Volt Neutral

Power In (-)

120 V Power Out

To Indirect Pump

Not used

Connect

to Air

Sensor

Connect

to Water

Probe

Thermostat Input

(use dry contact only) Control Setting Buttons

(

See section on settin

g

control

)

Aux. Circulator Input

(use dry contact

Indicates

Device

Activated

NYT

Indicates item

Displayed in LED area

A

Com T

L1B1Ap F1 L2C1

Function

Air Water

Probe Probe

Sentry 2100 Microprocessor

Boiler Controller

FEATURES

• Control is fully enclosed in impact resistant enclosure.

• Multi-functional LED display system.

• Digital set point for unmatched accuracy.

• Provides all safety and operational functions.

• Operates Burner, Heating pump, and Auxiliary indirect

pump or valve.

• Provided with outdoor sensor for automatic burner

temperature reset.

• All connections are quick socket connections

• Automatically detect presence of additional sensors.

• Optional stack sensor provides continuous

combustion efficiency display.

• Pump exerciser routine, activates pump for 5 second,

every 72 hours preventing seizing.

• Optional fan modulation output.

• Records burner run time, for energy utilization

calculations.

• Internal diagnostic system, continuous monitors for errors.

• Designed to withstand power dips and spikes.

DISPLAY

Burner/Brûleur – indicates that the burner has been activated.

Circ. – Indicates the heating circulator has been activated

Circ. Aux. – Indicates that the A-Com input has been closed, and the contact for the Auxiliary or Indirect circulating pump

or valve has been activated.

Thermostat Demand- Indicates that the T-Com input has been closed, and that a “Call for Heat” has been requested.

Water/Eau – When this light is activated, the LED panel is displaying the Water temperature inside the boiler.

Air – This function works only when the outdoor probe is being used, and has been detected by the controller. When this

light is activated, the LED panel is displaying the Outdoor Air temperature.

Gas Input Value or Run Time/en marche – When this light is activated, the LED panel displays the accumulated hours

that the burner has been energized. This value can be reset to zero. See the section of Control Programming.

.

Control Programming

Setting control

Programming is accomplished by a series of three push buttons located on the bottom side of the control. (Function

↑

and

↓

). To enter the programming mode, press the function key once. To scroll through the various menu options depress

↑

until the menu is displayed. To alter the value press Function once, and the current value will be displayed, then use the

↑

for up, and

↓

for down, until the desire value is obtained. To enter the selected value press Function, which will return to

the menus. When all desired values are inputted, scroll to the RUN menu, and press Function, which exits the Programming

Mode and initiates normal operation. A safety feature has been added to ensure that the control is not left in the Program

Mode, the unit will flash all lights and display “OFF”, which means the unit was left in the program mode for more the 10

seconds without receiving an input. Press Function once to continue programming.

MENU

RUN HI LO DIF SCA RST RES ICS

To start the control operation, you must return to RUN on the menu, and press

Function. Normal operation will begin.

Stores Values & initiates

normal O

p

eration

Hi & LO Differential

1-40°F

(

1-22°C

)

Min. Water temperatur

e

40-205°F

(

4-96°C

)

Max. Water temperatur

e

120-205°F

(

49-96°C

)

Degree Type

FAR = Fahrenheit

CEL

=

Celsius

Resets Run

Time to Zero

Adjusts Outdoor Reset

Curve.

(

70-205

)

Indirect Cold Start Mode

OFF = Not activated

ON

=

Activated

Operation

The control function to three different modes of operation based upon the number of sensors used, or by the mode selected.

The following is a brief explanation of the various modes:

Conventional Mode – Standard configuration (Outdoor Sensor not Detected) – This operation is very similar to a

conventional Triple Aquastat. Upon a call for heat (T-C Jumpered) the boiler maintains the Hi setpoint less the differential

setting. The circulator activates at the low temperature, and deactivates if the water temperature falls 10°F below the Lo

Setting (This establishes a priority for domestic hot water). When there is no call for heat (T-C Open) the burner maintains

the Lo Setting cycling between 10°F below the Lo setting and the diF setting. If the Dif setting is higher than 10°the burner

turns off at (( Lo +(Dif –10)).

Reset Mode – Standard configuration (Outdoor Sensor Detected) – This operation is very similar to Conventional Mode

Except that the control automatically reduces the Hi setpoint based upon the outdoor Air temperature. Upon a call for heat

(T-C Jumpered) the boiler maintains the calculated theoretical Hi setpoint less the differential setting. If the theoretical Hi

setpoint is lower than the Lo setpoint, then the controller will ignore the theoretical Hi setpoint and the burner will operate to

the Lo setting. The circulator activates at the Lo setting, and deactivates if the water temperature falls 10°F below the Lo

Setting (This establishes a priority for domestic hot water). When there is no call for heat (T-C Open) the burner maintains

the Lo Setting cycling between 10°F below the Lo setting and the Dif setting. If the Dif setting is higher than 10°the burner

turns off at (( Lo +(Dif –10)).

ICS Mode – Indirect Cold Start (Caution: This feature is for selected “cold start” boilers only).

Activated by Menu option ICS, select ON to activate. - This operation is very similar to Conventional Mode or Reset mode

depending upon the use of the outdoor sensor. The major difference for ICS Mode is that the burner only fires, when there is

a call for heat or a call for domestic (via an indirect water heater). Upon a call for heat (T-C Jumpered) the circulator

immediately activates, and the burner maintains the theoretical Hi setpoint less the differential setting. Upon a call for

domestic (A-C Jumpered) 120V is switched to Apwire to activate an indirect circulator or valve. The burner maintains the

Lo Setting, cycling between 10°F below the Lo setting and the (Lo + Dif setting). If the water is or falls 10°F below the Lo

Setting the heating pump deactivates, establishing a priority for the domestic hot water.

Example to change LO Default from 180°F to 140°F

Step Press Button Display Shows

1 Normal Cycling

2 Function Run

3 ↓Hi

4 ↓LO

5 Function 180

6 ↓40 times 140

7 Function LO

8 ↓4 times RUN

9 Function Normal Cycling

Important Note:

FLASHING OFF – Indicates that the control was left unattended in

program mode. Pressing Function, ↑, or ↓will resume

programming.

ICS – Not all NY Thermal boiler are compatible with this operation,

ensure unit is rated for Cold Start.

AIR – The AIR temperature will only be displayed if the outdoor air

sensor is installed, and is detected by the controller.

Input State

T-C Open T-C Closed

Condition Domestic Standby Heating

Burner On LO-10 HI-Dif

Burner Off LO+(Dif-10) HI

Heat Circ. ON - LO

Heat Circ. Off - LO-10

Closing A-C terminals, activates Aux. Circ. and provides 120V

out to AP.

Input State

T-C Open T-C Closed

Condition Domestic Standby Heating

Burner On LO-10 HI

Calc. -Dif

Burner Off LO+(Dif-10) HI

Calc.

Heat Circ. ON - LO

Heat Circ. Off - LO-10

Closing A-C terminals activates Aux. Circ. and provides 120V

out to AP.

** Note: If the calculated HI Setting is less than the LO setting,

the LO will be used in place of the HI setting.

Determining Reset Temperature HICalc

Once the control identifies the presence of a good outside

sensor, the control will automatically reduce the HI setting,

based upon the outdoor temperature. The calculated HI

setpoint (HICalc ) is calculated as follows:

Example: Hi=205, Air Temperature=32

RESET RATIO

= (High Setting - 70)/70

= (205 - 70) /70

= 1.92

RESET TEMPERATURE HICalc

=[(70-Outdoor Air) x Reset Ratio] + 70

=[(70-32) x 2.00] + 70

=[73] + 70

=143.00°F

Wiring

• Provide dedicated 120-volt power from house service to Sentry 2100 controller, utilizing a minimum of 14-gauge

wiring.

• Provide adequate overload protection. A 15 Amp time-delay fuse, or 15-amp breaker is required.

• A service switch between the boiler and the room exit should be provided.

• Disconnect all power prior to working on the controller, burner thermostats, & pumps.

• During wiring discharge yourself of static electricity, by touching the boiler casing with your hand or screwdriver

prior to touching the control.

Warning!!! A bad installation could ruin the Sentry Board and void your warranty.

- Prior to connecting to A C T terminals, operate the thermostat system, and using a

Multimeter, verify that these wires don’t go to ground and have any voltage across the

wires, or from the wires to ground.

- The A T C terminals are low voltage DC inputs. Do not provide any external power supply to these inputs.

- Thermostat and indirect contacts must be “A DRY CONTACT ONLY”.

- DO NOT run thermostat or indirect wiring within conduits or around wiring containing AC power supplies.

- If the control doesn’t operate properly, Contact NY Thermal immediately (before replacing it). If not your

warranty could be voided.

ICS Mode

T-C & A-C Open T-C Closed & A-C Open T-C Closed & A-C Close T-C Open & A-C Closed

Condition Standby Heating Only Heating & Domestic Domestic Only

Burner On - HI

Calc. -Dif **(HI Calc.–Dif) Or L0-10 LO-10

Burner Off - HI

Calc. **(HI Calc.) Or L0+(Dif-10) L0+(Dif-10)

Heat Circ. ON - T-C Close LO -

Heat Circ. Off - T-C Open LO-10 -

Aux Circ. On - - A-C Close A-C Close

Aux. Circ. Off - - A-C Open A-C Open

** Note: Burner c

y

cles to the hi

g

hest calculated tem

p

erature of either formula.

QUICK INSTALL STEPS

1.Ensure controller has dedicated fused

power supply from the house service.

2.Ensure that there is a Disconnect switch

for the controller within the boiler room.

3.Install the water probe into the ¼” NPT

fitting provided.

4.Run wiring from outdoor sensor (if

used), and splice to the connector

provided.

5.Marrett the main 6 wire plug to the

appropriate devices (as in the diagram).

6.Insert the water probe plug into the slot

provided (barbed end up).

7.Complete wiring system to thermostat

and indirect. Prior to connecting to A-C-

T terminals, verify that there is no

voltage on the lines while cycling the

thermostats.

8.Turn power on, and immediately set the

controls to the desired settings.

9.Verify that the display is scrolling,

Water temp. - Air temp. (if connected) -

Run Time.

10.Complete at least one complete burner

cycle to ensure safe operation.

SAFETY LIMIT SENSOR

(Not used on Odyssey boilers)

For added protection the Sentry 2100 comes with an

additional Hi limit sensor, which is connected, to the

supply nipple using the gear clamp configuration. Install

the safety limit on the supply nipple approximately 1”

from the base of the boiler. This is a manual reset

control. If this safety switch has to be reset, reduce the

Hi setting by 5ºF. If it persists, contact NY Thermal.

DO NOT OVER TIGHTEN THE GEAR CLAMP. Apply only enough pressure to secure the sensor in place.

TROUBLE SHOOTING

This section is intended to assist the service technician in detecting and correcting common errors. The Sentry 2100 is

equipped with an internal diagnostic system that verifies control operation. The following series of error codes has been

developed to aid in diagnosing control problems:

Problem Detected Problem Remedy

ER1 On Display

(Water probe) The Safety High Limit of 230°F, has been

reached Reduce limit setting, (and/or) ensure that there

is proper water circulation in the system.

ER2 On Display

(Water probe) The water probe is transmitting an invalid

signal. Closed circuit. Check to determine is display temperature

seems accurate. Check wiring

ER3 On Display

The water probe is not connected. Open

circuit. Check wiring

Board Resets Infrequent resets are normal. Frequent

resets are signs of poor voltage supply, or

power going to ground.

Remove wire harness form Sentry, and check

for grounding. Ensure the voltage supply is

120 volts at all times. Voltage dips below 105

volts will prevent operation.

Run time not

accumulating If the unit resets before the accumulation

of one-hour run time is reached, the

reading will reset the counting.

Not serious, however continuous resets can

damage the board. See “Board Resets”

Run time has

Reset to 0 If the unit was subject to a serious voltage

situation (short circuit, or lightning strike,

or power surge).

Unit is not damaged, however setting may be

altered. Check setting to ensure desired

operation.

Burner light on but

no power to the

ignition module

This unit is provided with an additional re-

settable safety limit connected to the

supply pipe on the inside of the casing.

Press the red reset button. Reduce setting

slightly to avoid nuisance tripping.

Table of contents

Other NTI Controllers manuals

Popular Controllers manuals by other brands

D+H

D+H GE 650 Set Original instructions

Dell

Dell PowerConnect W-6000 installation guide

rotork

rotork IQ3 Range Instructions for Safe Use, Installation, Basic Setup and Maintenance

Autonics

Autonics TM-XGT Solution guide

Koso

Koso REXA Electraulic Xpac Installation and operation manual

Coemar

Coemar 12 plus user manual