NTI E-H2 User manual

E-H2

Hydrogen Gas Detector

Installation and Operation Manual

MAN236 Rev. 5/16/22

ENVIROMUX®Series

3

GENERAL SAFETY INFORMATION

INTENDED USE

The E-H2 Hydrogen Gas Detector is a low voltage (12-24VAC or VDC) electronic detector of hydrogen

gas. The detector is designed for connection to alarm control panels. Alarm control panels that work on 12 or 24

VDC can provide battery backup to the detector. This gas detector is NOT designed to detect smoke, fire or

carbon monoxide.

LIST OF WARNINGS AND CAUTIONS

Each person using this equipment must read and understand the information in these User Instructions before use.

Use of this equipment by untrained or unqualified persons, or use that is not in accordance with these User

Instructions, may adversely affect product performance and result in sickness or death.

Use only for monitoring the gas which the sensor and detector are designed to monitor. Failure to do so may result

in exposures to gases not detectable and cause sickness or death. For proper use, see supervisor or User

Instructions, or call Macurco Technical Service.

Detector may not function effectively below 32 F or above 120F. Using the detector outside of this temperature

range may adversely affect product performance and result in sickness or death.

This detector helps monitor for the presence and concentration level of certain specified airborne gases. Misuse

may produce an inaccurate reading, which means that higher levels of the gas being monitored may be present and

could result in overexposure and cause sickness or death.

The detector is not designed to measure compliance with Occupational Safety and Health Administration (OSHA)

commercial or industrial standards.

When the unit is powered up it performs a self-test during which the green LED light will blink for a period of one and

one half to two minutes. Afterward, the green LED light will turn on continuously to indicate the unit is in normal

operation (ARMED). If the self-test fails or the green LED light does not turn on continuously do not use. Failure to

do so may adversely affect product performance and result in sickness or death.

Immediately exit the environment if there is an alarm condition on the detector. Failure to do so may result in

sickness or death.

This detector will only indicate the presence of combustible gas at the sensor. Combustible gas may be present in

other areas. Accommodation spaces should be well ventilated when household cleaning supplies or similar

contaminants are used.

Do not cover or obstruct visual alarm LED. Doing so may adversely affect product performance and result in

sickness or death.

Do not disassemble unit or attempt to repair or modify any component of this detector. This detector contains no

user serviceable parts, and substitution of components may adversely affect product performance and result in

sickness or death.

CAUTION

Avoid the use of harsh cleaning materials, abrasives and other organic solvents. Such materials may

permanently scratch the surfaces, damage the sensor, labels, or instrument housing.

If you have any doubts about the applicability of the equipment to your job situation, consult an

industrial hygienist.

! WARNING

5

INSTALLATION AND OPERATING INSTRUCTIONS

The following instructions are intended to serve as a guideline for the use of the E-H2 Hydrogen Gas

Detector.

It is not to be considered all-inclusive, nor is it intended to replace the policy and procedures for each

facility.

This detector helps monitor for the presence and concentration level of certain specified airborne gases.

Misuse may produce an inaccurate reading, which means the higher levels of the gas being monitored

may be present and could result in overexposure and cause sickness or death. For proper use, see

supervisor or User Instructions.

LOCATION

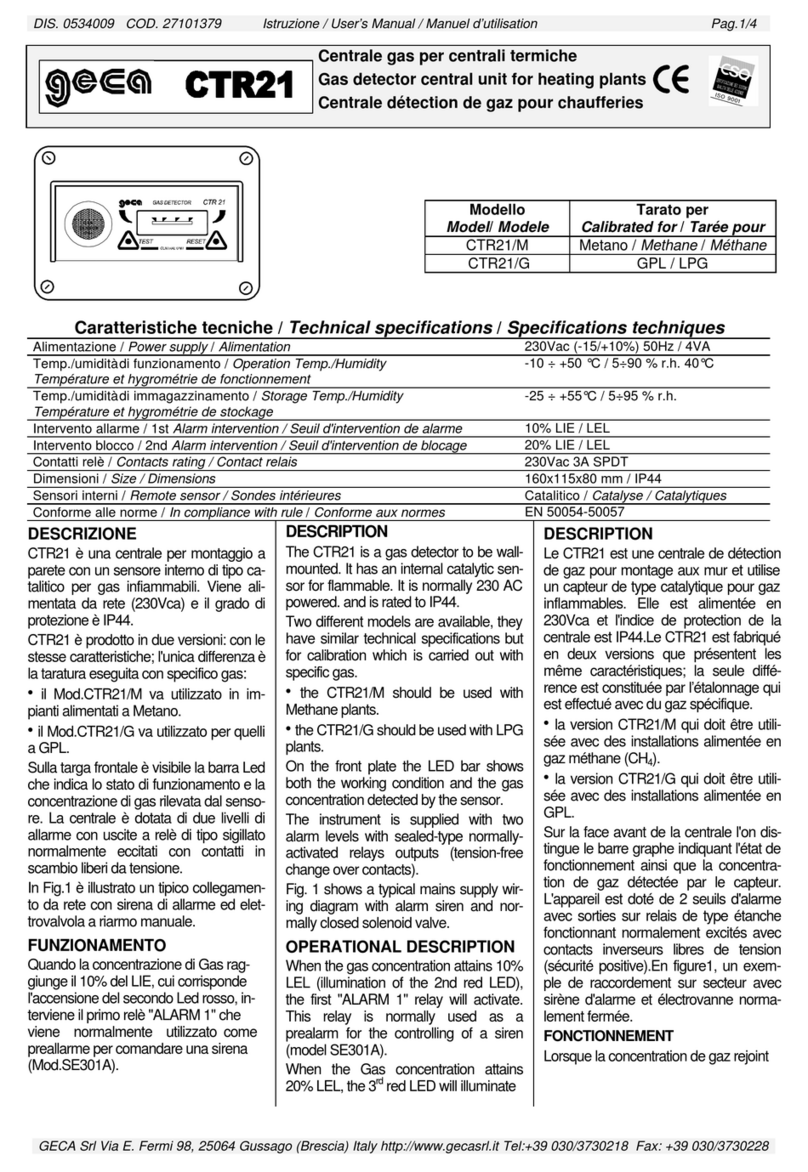

The E-H2 is NOT intended for use in industrial applications such as refineries, chemical plants, etc. The

unit can cover approximately 900 sq. ft. The coverage depends on air movement in the room or facility.

Locate the unit high in the room where storage batteries are being charged, or where there may be other

hydrogen sources. Extra detectors may be needed near any areas where people work or the air is

stagnant.

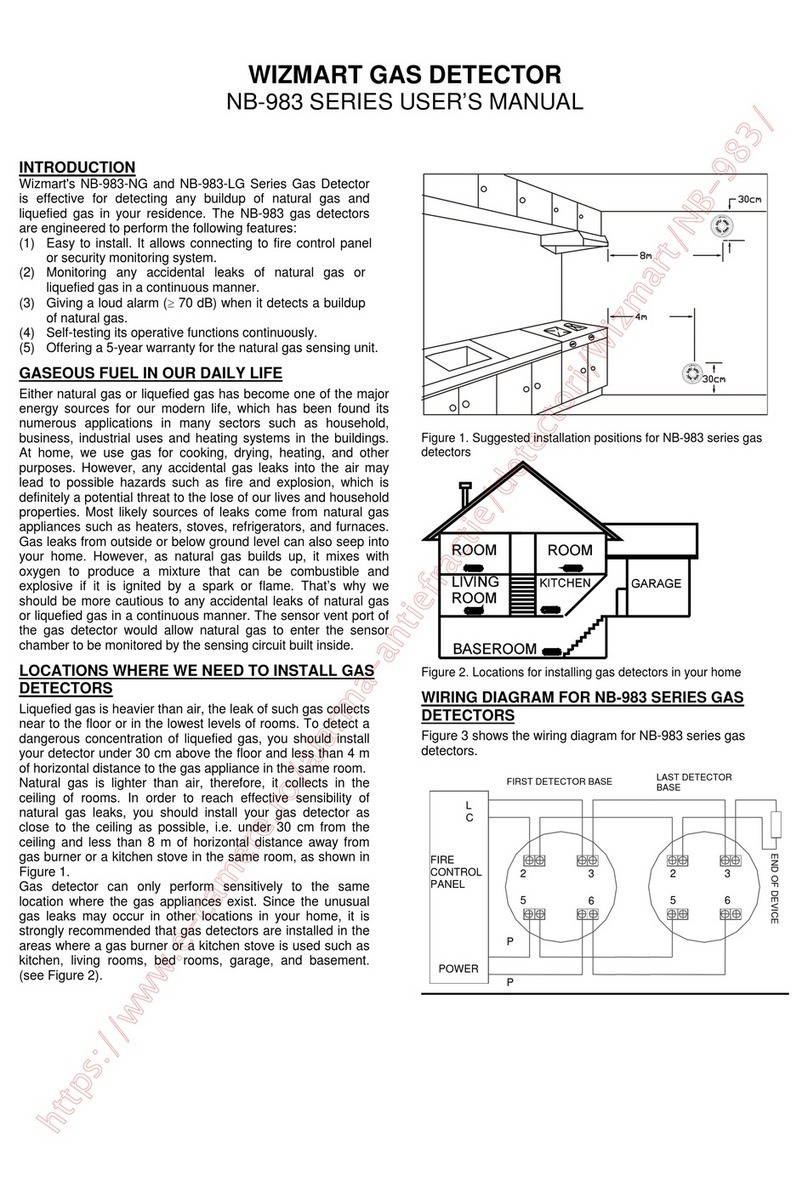

Hydrogen gas is lighter than air, so it will tend to rise and accumulate in high places. We recommend

placing one sensor in each corner of the ceiling in high-risk environments where hydrogen may

accumulate.

This product is intended for use in ordinary indoor locations of family living units and office workspaces.

The detector is not designed to measure compliance with Occupational Safety and Health Administration

(OSHA) commercial or industrial standards.

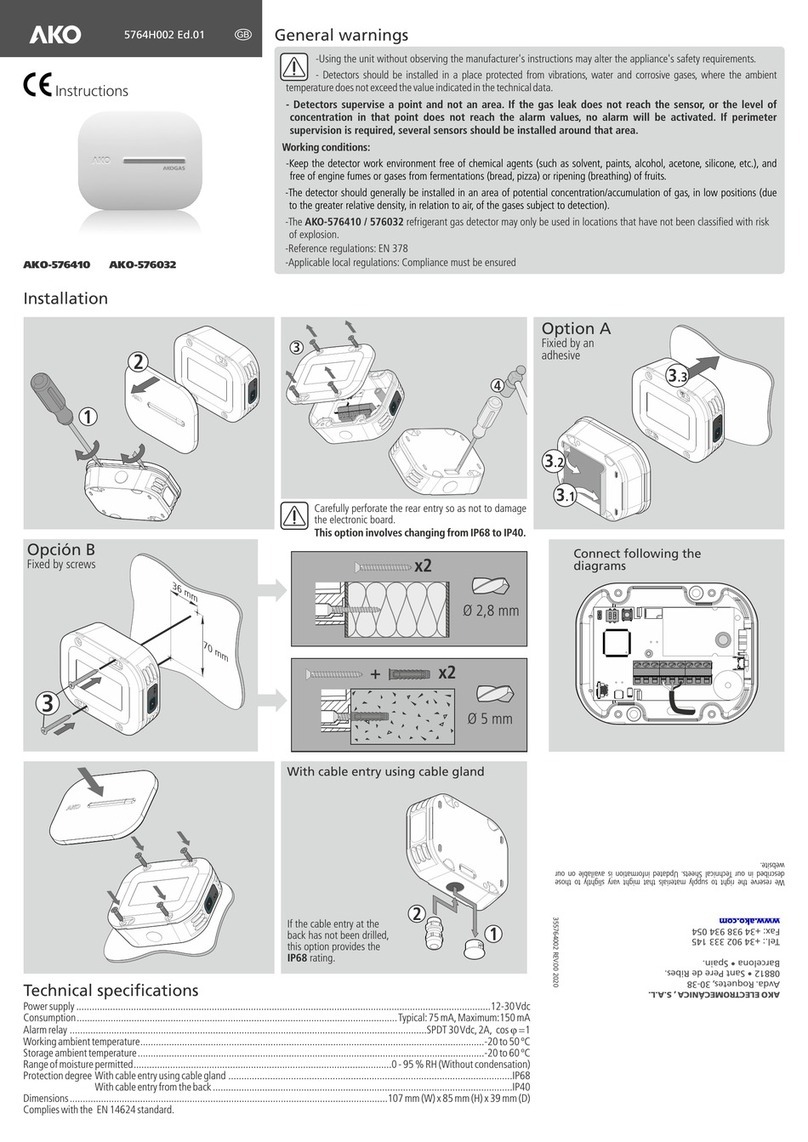

INSTALLATION

1. Mount the detector high on a wall within one foot of the ceiling, or on the ceiling. Use the same

spacing as for smoke detectors- 30-foot centers, 900 square feet per detector.

2. The three part plastic case allows the detector to be either surface mounted or installed over a four-

inch square or double gang electrical box, providing a near flush mount. The detector snap on front cover

will need to be removed before installation. To remove it, lightly pry the front cover off of the mounting

plate (middles section) with a coin or flat screwdriver inserted into the vent at the bottom (see below).

The cover will snap off exposing the electronics and mounting plate.

6

3. For flush mount, remove the 2 screws and rear cover from the mounting plate and use the appropriate

hole-pattern for installation. The four holes toward the center of the mounting plate match the hole-pattern

of a double gang electrical box. The four holes near the corners match the pattern of a four-inch square

box. When wall-mounting the detector, mount the detector so the “TOP” marked side of the mounting

plate is at the highest side. Snap the front cover back on when finished, making sure that the lights line up

with the access holes.

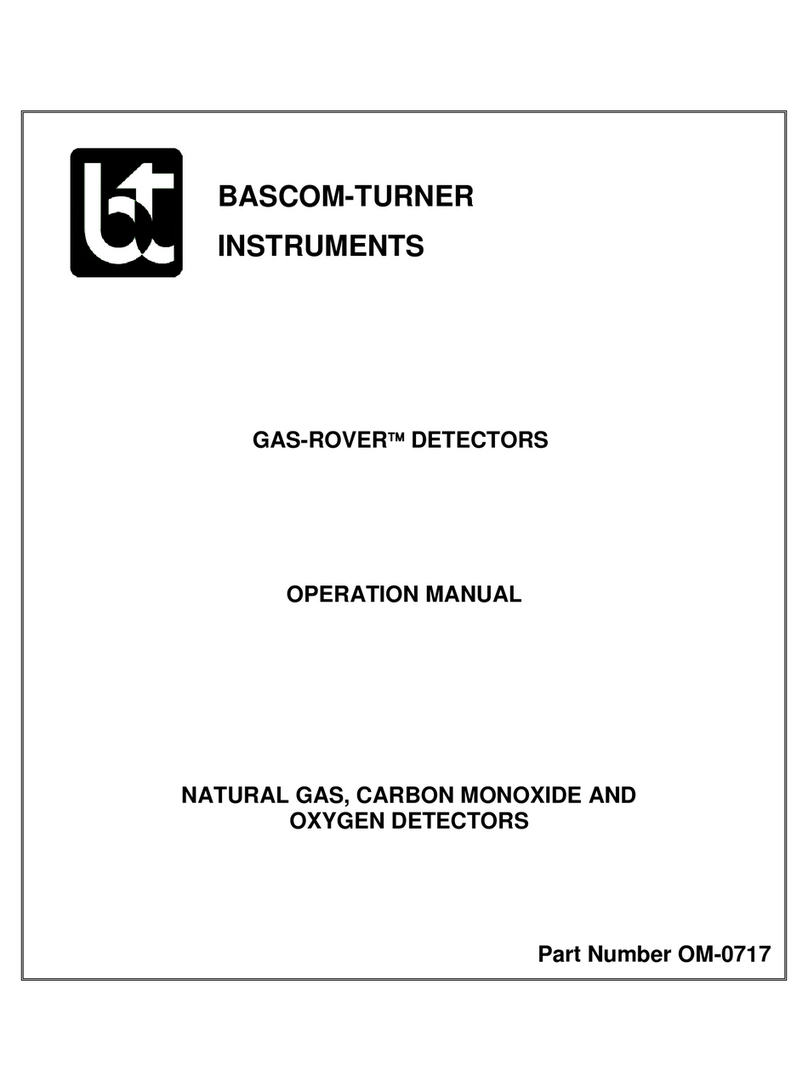

4. When using the detector with normally-closed initiating circuits, use the Com. and N.C. alarm relay

connections.

5. See wiring diagram (below) and on page 9 for connections of the E-H2.

6. The E-H2 uses a full wave bridge rectifier at its power input, so that it is independent of the polarity of

the input power. It can operate on DC or AC voltages between 12 and 24 volts.

7. A switching regulator is used to efficiently match the wide input voltage range to the fixed, internal

power system. As a result the power consumption is fairly constant at about 0.75 watts in normal

operation, and 1.0 watt in alarm.

8. The alarm control panel zone inputs must be terminated with end of line resistors (E.O.L.R.), which are

provided with the panel. The detector does not have an internal audible sounder and must be connected

to an audible device that provides at least 85dB sound output.

SPECIFICATIONS

DIMENSIONS- WxDxH: 4.5x5x1.63 In. (114x127x41 mm)

SHIPPING WEIGHT: 0.54 pound

VOLTAGE: 12 to 24 VAC or VDC

CURRENT (non-alarm): 45 mA @ 12VDC, 22 mA @ 24VDC, 65mA @ 12VAC, 45 mA @ 24VAC

CURRENT (alarm): 70 mA @ 12VDC, 35 mA @ 24VDC, 100mA @ 12VAC, 65 mA @ 24VAC

COLOR: White

SENSOR MAINTENANCE: Not required

ALARM RELAY RATING: 0.125 Amps, 40V, 3VA

TROUBLE RELAY: 0.25 Amps, 40V, 10VA

OPERATING TEMPERATURE RANGE: 32⁰to 120⁰F

ALARM SET POINT: 10% LEL Hydrogen gas

10

This manual suits for next models

1

Table of contents