NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK NUTEK

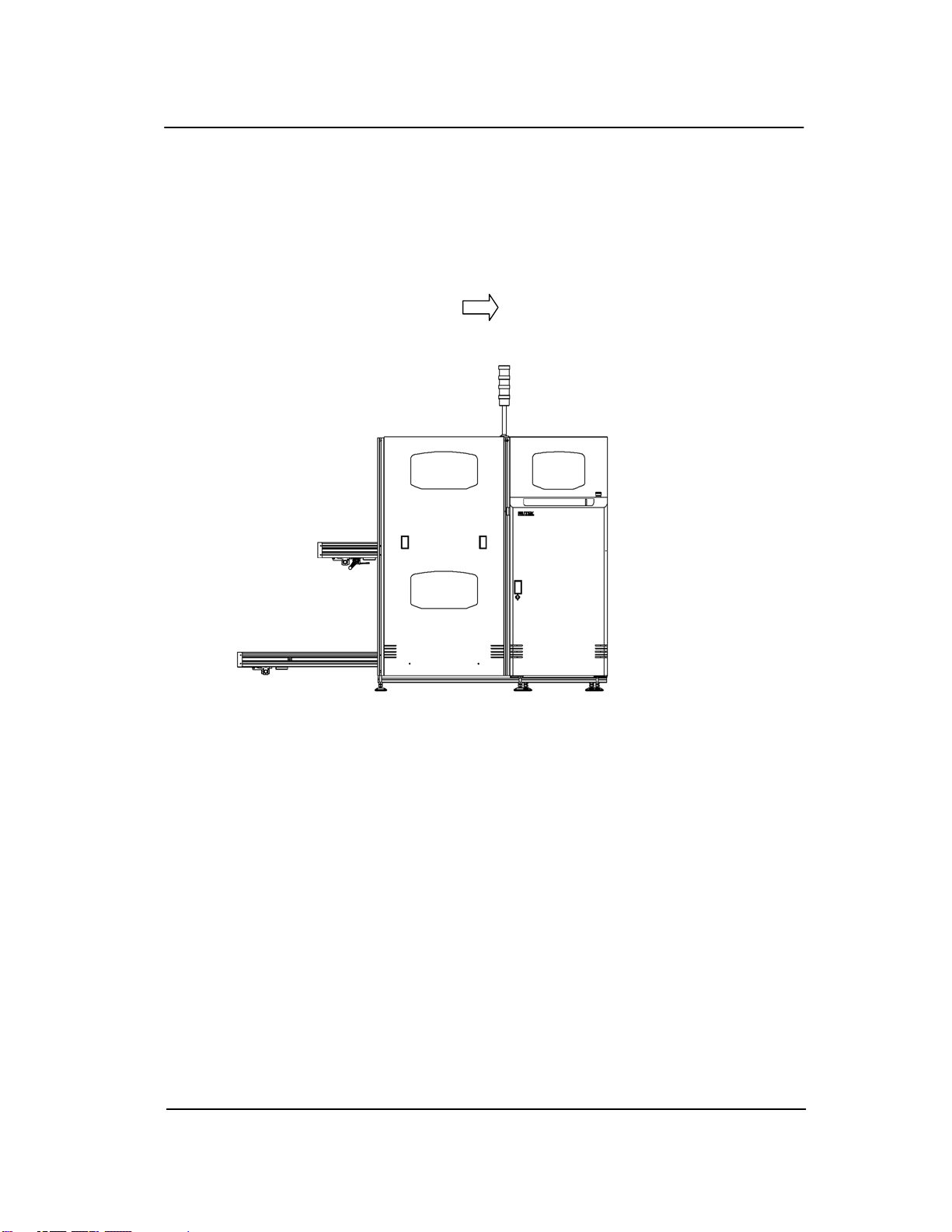

MULTI

MAGAZINE

LINE

LOADER

NTM110LL-HW