- 4 -

2. Specific Product Precautions

Warning

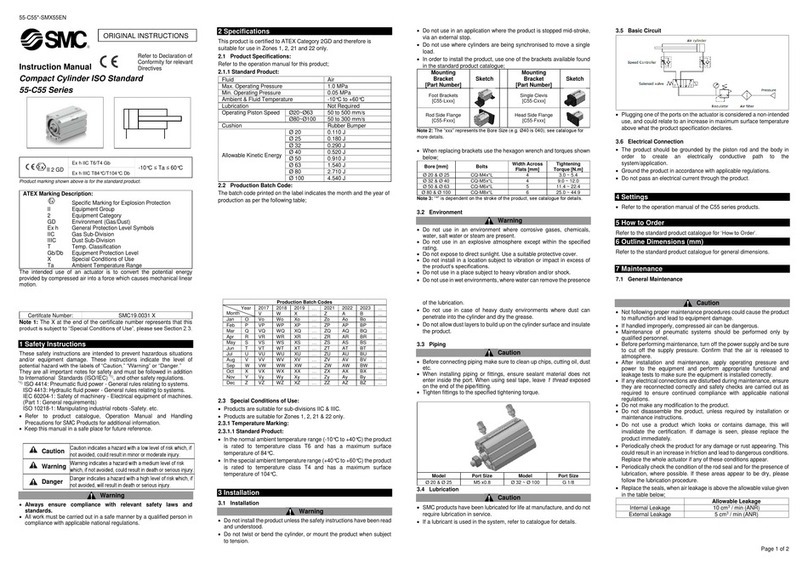

(1) Confirm the specifications.

The products are designed to be used in

compressed air systems (including vacuum) only.

Do not operate at pressures, temperatures, etc.,

beyond the range of specifications, as this can cause

damage or malfunction. (Refer to the specifications.)

Please contact SMC when using a fluid other than

compressed air (including vacuum).

We do not guarantee against any damage if the

product is used outside of the specifications range.

(2) Products mentioned in this catalog are not

designed for use as stop valves with zero air

leakage.

A certain amount of leakage is allowed in the

products specifications.

Tightening the needle forcibly to achieve zero air

leakage through main valve may result in damage of

internal parts and the product may stop functioning

properly. Please do not tighten the needle forcibly.

(3) Do not disassemble the product or make any

modifications, including additional machining.

Doing so may cause human injury and/or an

accident.

(4) The flow rate characteristics for each product

are representative values.

The flow rate characteristics are characteristics of

each individual product. Actual values may differ

depending on the piping, circuitry, pressure

conditions, etc.

The flow rate may not be recognized from the fully

closed position until around the first turn. This is due

to the product design and not a malfunction.

Also, depending on product specifications, there

may be variations in the zero needle rotations

position.

(5) Sonic conductance and critical pressure ratio

values for products are representative values.

For controlled flow direction values the needle is fully

open. For free flow direction values the needle fully

closed.

(6) Check if PTFE can be used in application.

PTFE powder (Polytetrafluoroethylene resin) is

included in the seal material of the male thread type

piping taper thread. Confirm that the use of it will not

cause any adverse effect on the system. Please

contact SMC if the Safety Data Sheet (SDS) is

required.

(7) Speed controllers are designed to control the

speed of the actuator.

Warning

(1) Operation Manual

Install the products and operate it only after reading

the operation Manual carefully and understanding its

contents. Also, keep the Manual where it can be

referred to as necessary.

(2) Ensure sufficient space for maintenance

activities.

When installing the products, allow access for

maintenance.

(3) Tighten threads with the proper tightening

torque.

When installing the products, follow the listed proper

torque.

(4) Use R external threads with Rc internal threads

and NPT external threads with NPT internal

threads G external threads with G internal

threads.

(5) Confirm that the lock nut is securely tightened.

Confirm that the lock nut is securely tightened and

the needle is locked after adjusting the cylinder

speed.

When the product is used with a loose lock nut, the

set flow rate may change unknowingly and the

actuator speed may change, which leads to

dangerous situations.

Forcibly tightening the lock nut exceeding the

locked state may result in breakage. Follow the

proper tightening torque when tightening.

(6) Check the degree of rotation of the needle valve.

As the needle valve has a stopper mechanism for

maximum opening, it is not possible to rotate

beyond the given limit.

Excessive rotation will cause damage to the

product. Please check the specified number of

rotations before using the product.

(7) Do not use tools such as pliers to rotate the

knob.

It can cause idle rotation of the knob or damage.

Design/Selection Mounting