nVent.com/CADDY |4

1. Wire Rope Support Overview

C. SLK Features

The locking device is the piece of hardware that holds the wire loop in place. The Speed Link SLK locking device is designed to be the

safest, most aesthetical, and easiest locking device on the market. The guide below shows several of the product’s innovative features

and the overall goal of each one.

EASE OF USE FEATURES

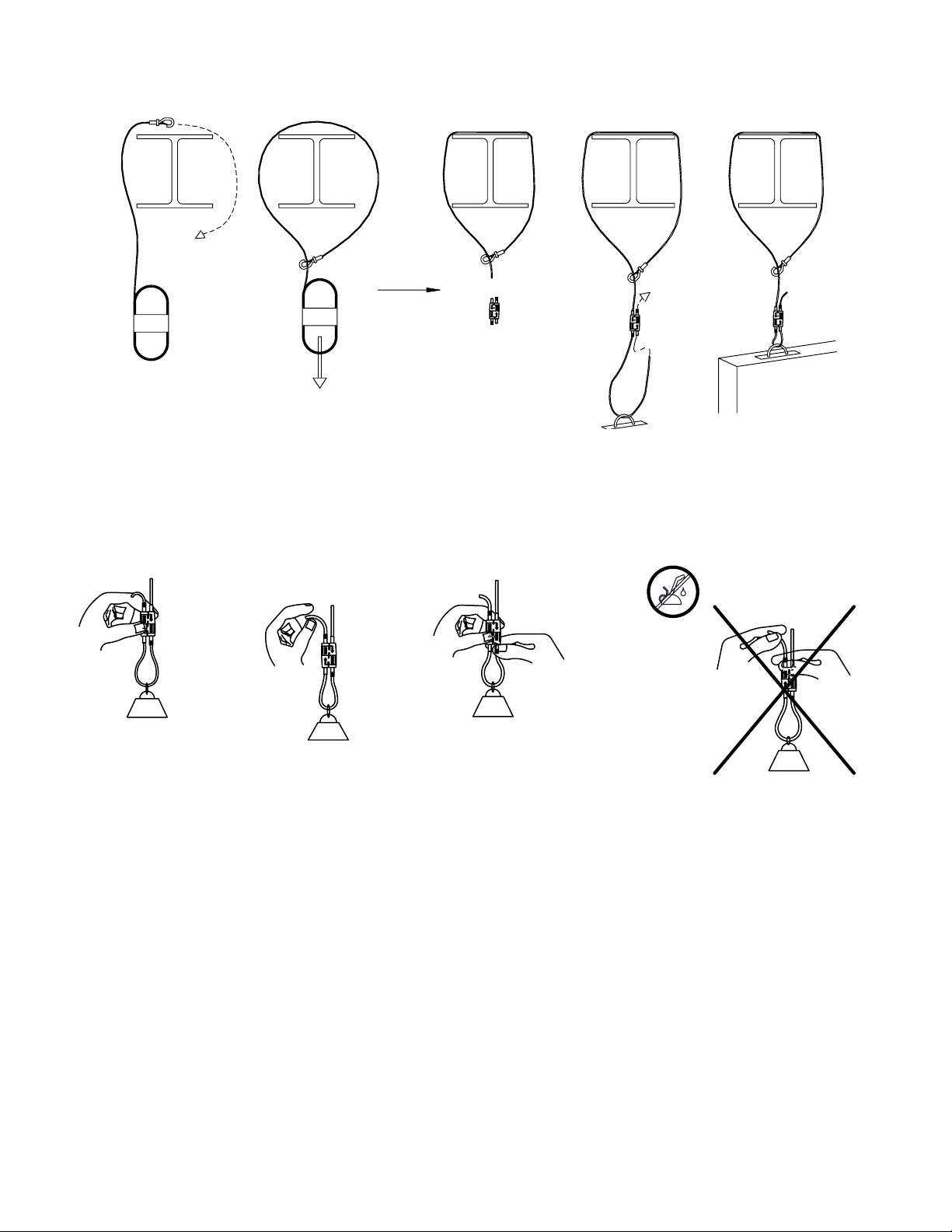

Arrows on the device clearly

demonstrate the correct direction

to push the wire

Speed Link is lighter, faster

to install, easier to transport

and generates less waste than

alternative hanging methods

Available in pre-cut lengths with

11 end-fittings or in bulk with

spools of wire to adapt to the

end-users’ needs and applications

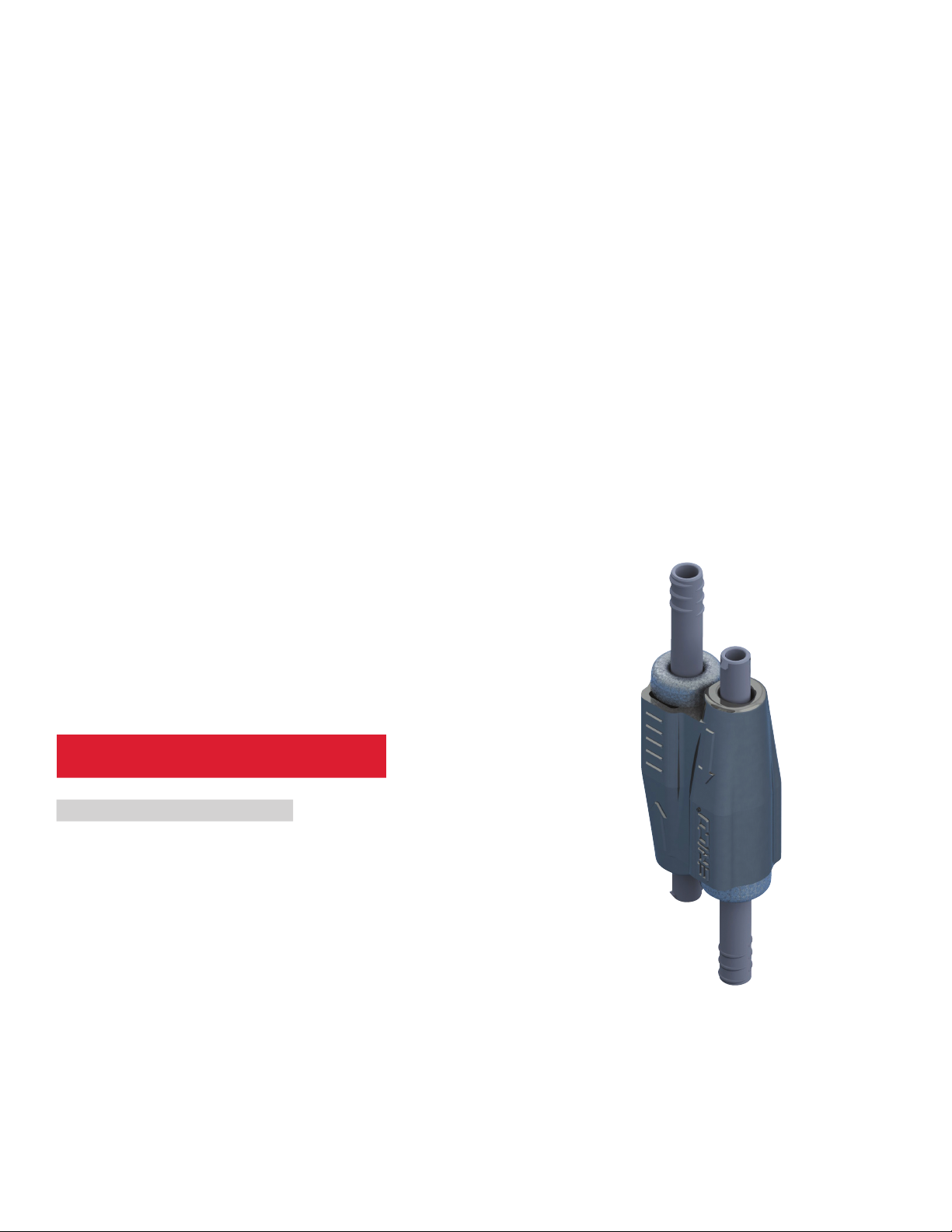

Two tool-free locking devices are

available for three wire sizes

• SLK2 compatible with 1.5mm

and 2mm wire

• SLK3 compatible with 3mm wire

SAFETY FEATURES

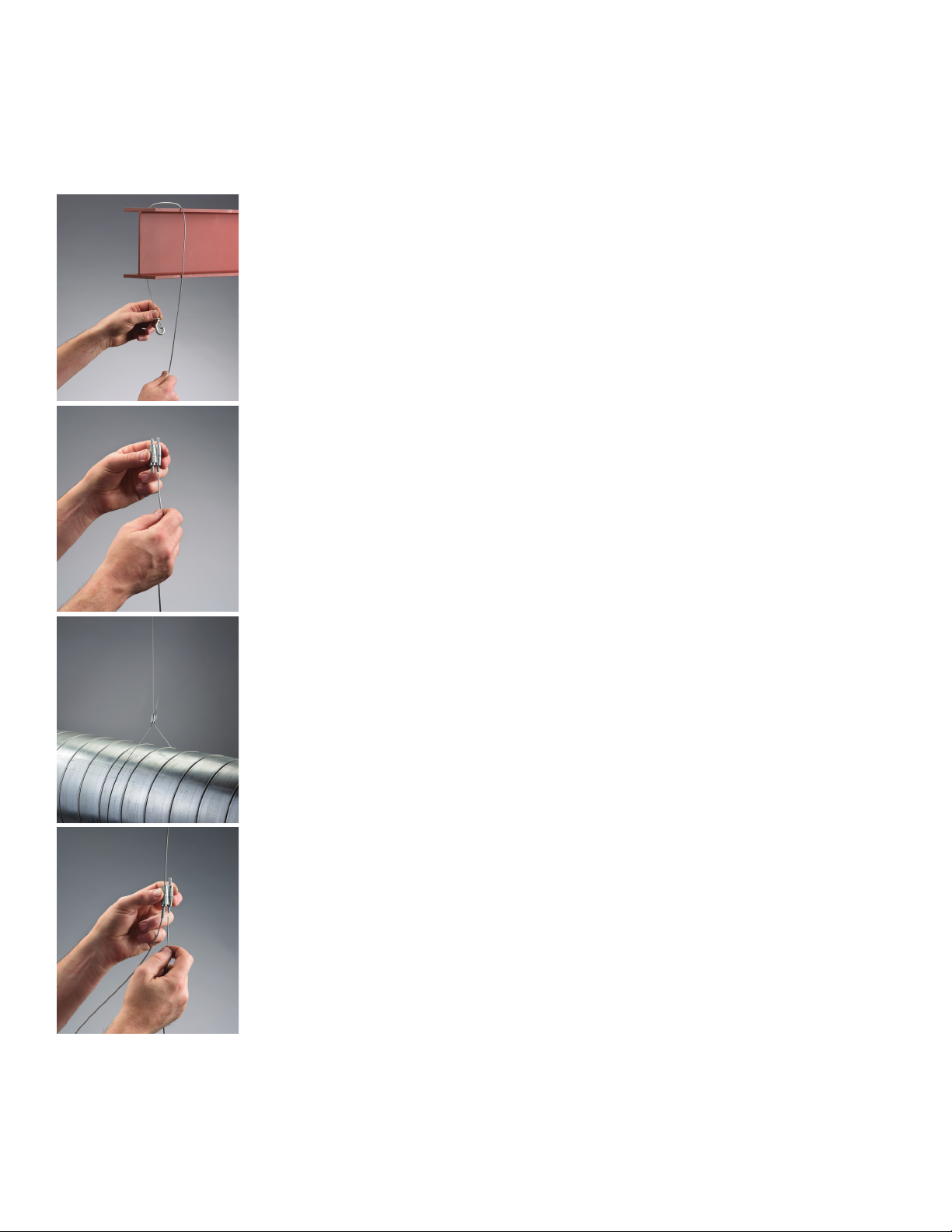

Keyless release tubes are

designed to allow safe and easy

adjustment, even while wearing

bulky gloves

Two jaws grip the wire inside

the device, holding the wire

more securely than single-cam

devices common among most

competitors. This rare gripping

mechanism allows it to be used

in unique applications such as

splicing / joining 2 wires, infinite

loop etc.

UL Listing on all 11 end-fittings

for pre-cut lengths, SMACNA

approved for Hook and Loop

end-fittings. Intertek Load Test

report available upon request.

AESTHETICAL FEATURES

Low-profile locking device

provides a positive aesthetic

to a finished project

The locking device can

accommodate wire rope at

up to 90 degrees, allowing

it to be positioned closer to

the load than other locking

devices on the market, hiding

it from view and creating

a much more aesthetically

pleasing installation.

The color of the line

corresponds to the larger

goal of each feature:

SAFETY FEATURES

AESTHETICAL FEATURES

EASE OF USE FEATURES