7

23. 11. 21. Document Number 672010

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

MR-ECO-COOL-V

Installation Manual

8.0 CONTROLS / DESCRIPTION OF OPERATION

•MVHR will run continuously at Background/Whole dwelling duty

(Speed 1) unless it receives a 230v signal to Switched-Live input

connections SL1 or SL2.

•Cooling module will be enabled to run and MVHR enabled to

speed 3 by a 230v Switched live from wall mounted thermostat

CM-THERM-CONTROL (supplied).

•The wall mounted thermostat will control the cooling module and

MVHR unit. On reaching the set point (user defined) the Cooling

Module will operate and the MVHR will increase to speed 3. The

wall mounted thermostat also features a ECO mode which is pre-

set to 23°C (not adjustable) and can be set to operate between 1

and 24 hours by the user.

•It is recommended that, if possible, the cooling unit be interlocked

with the heating system to prevent triggering when heat is being

called for. Figure 8 shows connection to a heating system which is

normally closed via a link. This can be replaced by a suitable VOLT

FREE connection to the heating device. Contact Nuaire for further

information and to check compatibility.

•Supplied with a Summer/Winter switch. When set to summer

mode the MVHR will target a temperature under 20°C within the

apartment.

•Summer mode can be selected year round to attempt to mitigate

overheating caused by solar gains but must be selected when

cooling is expected to run (summer months).

•Winter mode ensures the MVHR will recover heat at all times.

•For further details, see MRXBOXAB-ECO5-AESC installation

manual (671861).

9.0 COMMISSIONING

To ensure the cooling module operates correctly and prevent

the thermal overload protection from tripping, there must be a

minimum airflow of 180 m3/h (50 l/s).

It is recommended the ventilation unit is set to speed 3 on supply

and extract, adjusters are set to maximum (fully clockwise).

To commission the MVHR unit providing the air flow through the

cooling module, please refer to MRXBOXAB-ECO5-AESC installation

manual (Document number 671861).

10.0 MAINTENANCE

Isolate before commencing work, make sure that the unit, switched

live and Nuaire control are electrically isolated from the mains

supply and switched live supply.

It is important that maintenance checks are recorded and that the

schedule is always adhered to, in all cases, the previous report should

be referred to.

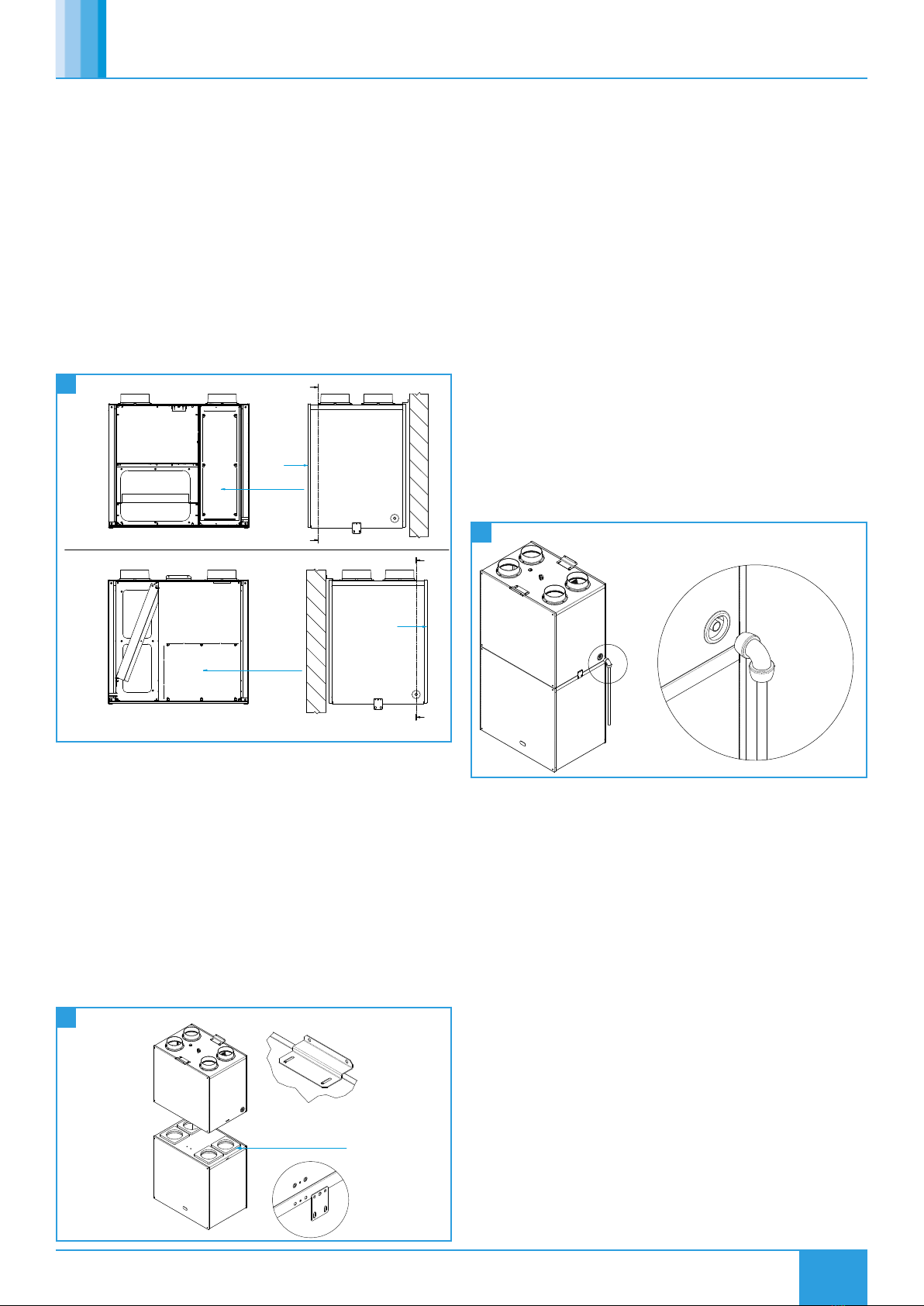

10.1 Access

Access to both Coils for maintenance can be gained by removing

the front cover of the outer case and the inner covers of the Cooling

Module.

Depending on the orientation of the unit (standard or opposite hand)

access will be given to one of the two coils. To access the second coil an

internal access panels must be removed.

Opposite hand installation do not have access to the compressor.

The compressor is sealed-for-life and requires no maintenance.

10.2 Annual Maintenance - Evaporator and Condenser

•Inspect all heat exchangers for signs of damage or dirt. Loose dirt

may be removed by using a soft brush, taking care not to brush

the dirt into the coil, blocking the fins. Damaged fins should be

combed out using a coil comb.

•If the coil is excessively dirty check that MVHR filters are still in

place.

•Filters are to be inspected every 6 months and replaced every 12

months (or sooner if required).

•If the coil is excessively dirty, use a proprietary cleaning agent, e.g.

HYDRO-COIL or MULTISOLVE.

•Inspect the condensate drain tray and clean as required.

•Check all electrical connections for tightness.

•Switch on the power to the unit. Check the operation of the

mechanical cooling system.

•Check that all the panels are in place and that the unit is in a clean

condition.

•In the event the cooling module is not operating initially inspect

the MCB in the controls.

10.2.1 Refrigeration Circuit Components

All repair and replacement work on refrigeration components must

be carried out by a fully qualified refrigeration engineer, trained

in maintenance and refrigeration recovery, and with a sound

knowledge of all relevant safety regulations pertaining to the job.

All refrigerant in the unit must be reclaimed and disposed of safely.