5

08. 04. 21. Document Number 671971

Nuaire | Western Industrial Estate | Caerphilly | CF83 1NA | nuaire.co.uk

HTS / HTEInstallation Manual

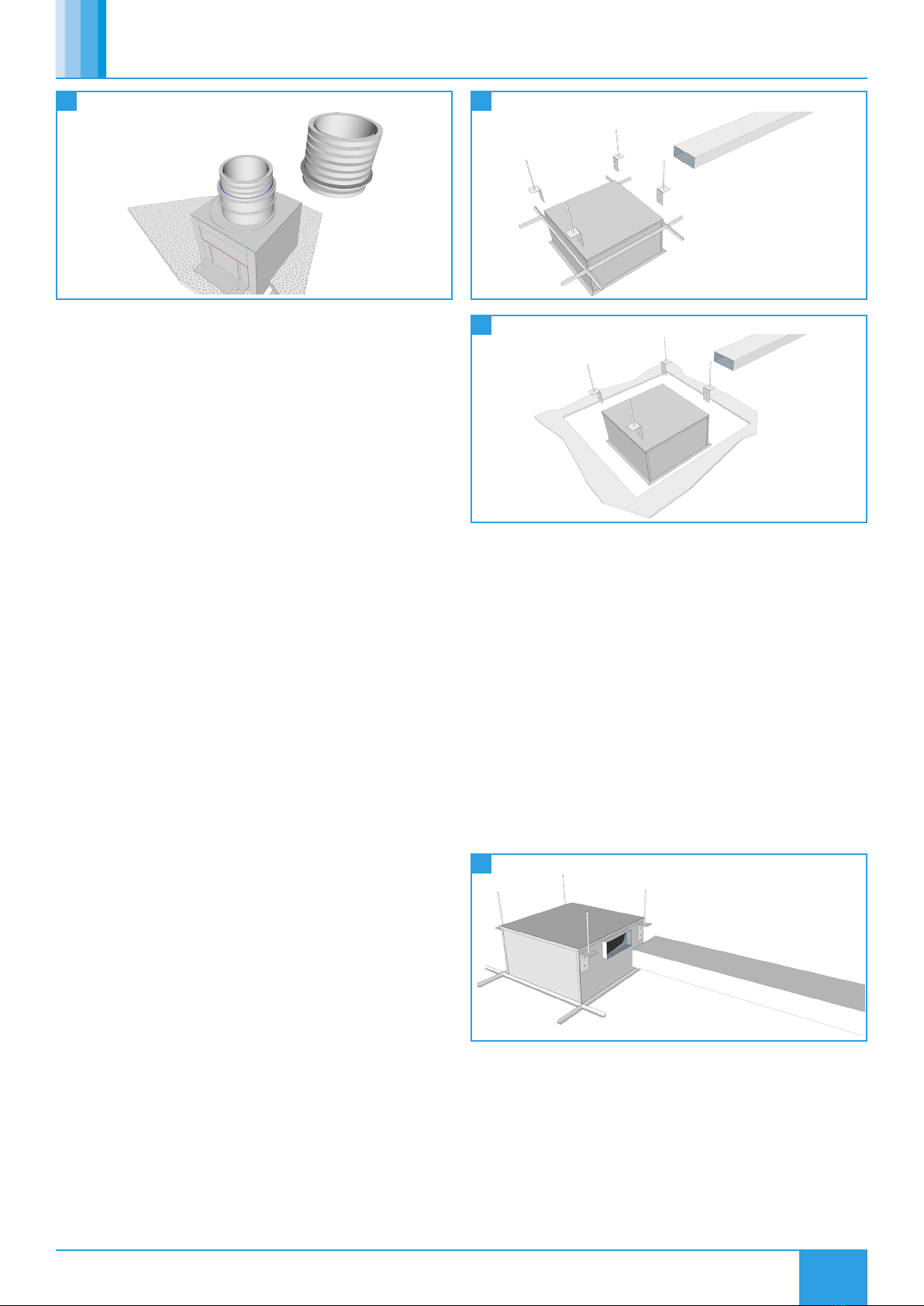

15 HTE(1/2/3) Extract Terminal Duct Connections

The transition piece should be secured to a suitably rigid structure in

the ceiling void.

The gap between the vertical duct and ceiling cut-out should be fully

sealed with a proprietary low modulus, neutral cure mastic.

The transition piece is supplied with blanking plates. To remove these,

pull out and retain the wire fixing clip and remove plate from the port.

Ensure that unused ports have blanking plates with sealing rings fitted

and wire fixing clip in place.

The semi-rigid ducting is installed by first locating the sealing ring

provided into the second complete groove in the duct outer surface.

Mark the semi-rigid duct at 35mm from the cut end, and push evenly

into the port aperture. When secure, insert the port’s wire fixing clip

to retain the duct. No further sealing of the connection is required or

should be applied.

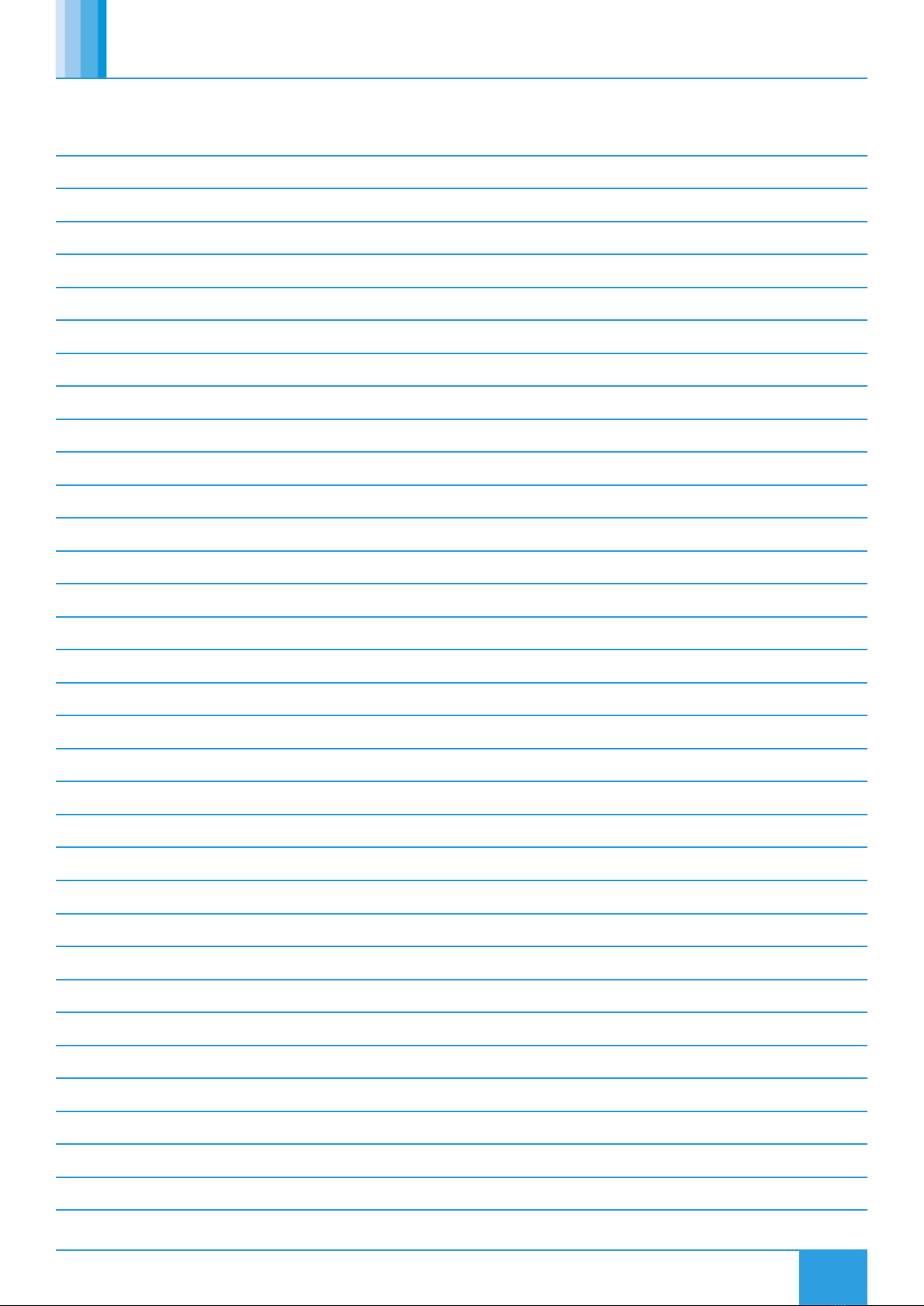

This duct type is largely self- supporting, and may be readily cut with

a hacksaw and manually formed into swept bends with a minimum

internal radius of approx. 150mm. Compact 90° bend components are

also available from Nuaire with similar sealed port design (product

code NRDD75-90).

For extended lengths of duct, supports with a maximum spacing of 1m

must be provided.

The duct must not be used to support the weight of the transition

housing or other components. If the duct becomes kinked or crushed,

the affected section must be discarded and replaced.

Once the installation is complete, the facia plate may be attached to

the lower surface of the housing to obscure the cut edges of the ceiling

hole using screw caps provided and screws / plugs appropriate to the

ceiling type.

If required, the facia plate may be carefully trimmed to shape with

metal shears.

4.0 MAINTENANCE

It is important that maintenance checks are recorded and that the

schedule is always adhered to, in all cases, the previous report should

be referred to.

Note and ensure that the position of adjustable louvres is

maintained during the maintenance operation.

4.1 HTS1, HTE1, HTE2 & HTE3 Maintenance

The single supply terminal (HTS1) and extract terminals (HTE1/2/3)

require cleaning only when necessary – vacuum and wipe over with a

clean damp cloth – do not use cleaning agents on these products.

Check for damage and visible obstructions to louvre / grille and rectify /

remove as necessary.

4.2 HTS4, HTS9 & HTS12 Maintenance

As required, clean the visible surface of the terminal - vacuum and wipe

over with a clean damp cloth – do not use cleaning agents on these

products.

Check for damage and visible obstructions to louvres and rectify /

remove as necessary.

4.3 Filter Maintenance

Where a filter has been fitted to a Haven terminal, it will have been

selected for its particular properties and must only be replaced

with a new filter with the same properties.

Failure to observe this requirement will result in compromising the

intended level of Indoor air quality in the occupied space, and may

be detrimental to the health and well-being of occupants.

Filter changing should be carried out in accordance with the system

design requirements, but an annual filter change is the minimum

requirement. Failure to do so may impair the performance and

energy efficiency of this unit.

The filter is accessed through the hinged lower panel of the terminal.

The panel is hinged at the side opposite to the retaining latches.

Undoing the latches will free the panel and a weight of up to 4kg will be

released.

Whilst manually supporting the panel centrally between the latches,

release them in turn by rotating through 90°.

Gently lower the hinged panel down to its greatest extent.

The filters are 525 x 460 x 80mm and weigh up to 4kg (ePM1 type) and

5kg (E11 type).

Remove the old filter, place in a suitable bag and seal.

Remove the new filter from its packaging and refit in housing.

Lift the hinged panel to its original position and re-secure the latches

(full 90 degree rotation).

16 Filter Replacement 1