Il presente documento è sottoposto a gestione controllata e non può essere riprodotto senza autorizzazione di NUOVA FIMA s.r.l.

This document is issued as controlled copy and it can not be reproduced without NUOVA FIMA licence.

Data di emissione 18.05.2018 Edizione C0

Industrial Instrumentation for Pressure and Temperature

Via C.Battisti 59 - 28045 INVORIO (NO) -Italy

Tel. +39 0322 253200 - Fax +39 0322 253232

www.nuovafima.com – info@nuovafima.com

DICHIARAZIONE UE DI CONFORMITÀ

EU DECLARATION OF CONFORMITY

NUOVA FIMA s.r.l. dichiara sotto la propria responsabilità che i seguenti strumenti

NUOVA FIMA s.r.l. declares on its sole responsibility that the followings instruments

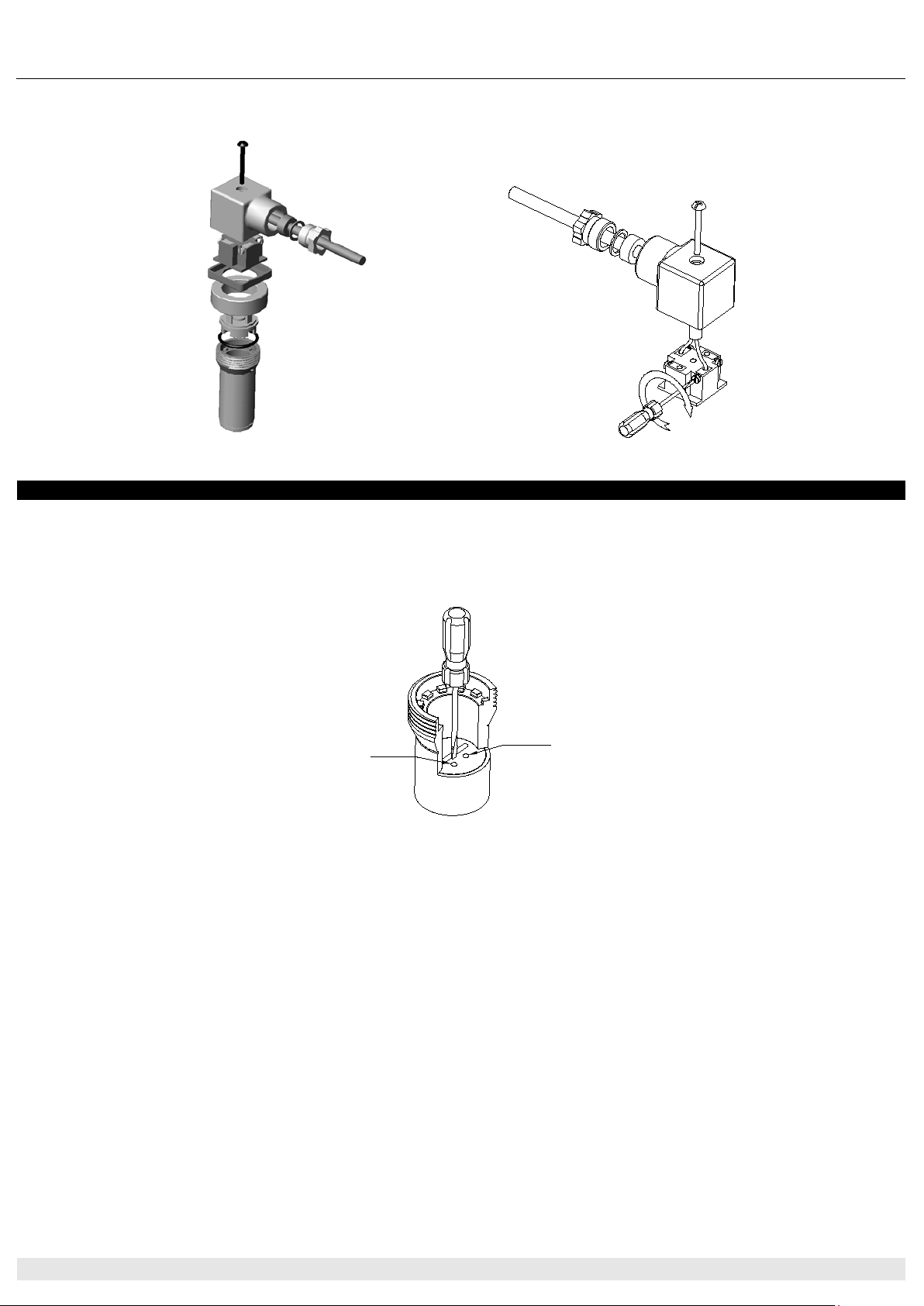

Trasmettitori di Pressione serie SX

Pressure Transmitters SX series

Sono conformi ai requisiti delle Direttive e sono marcati - Fulfill the requirements of

the Directives and they are marked.

2014/68/UE (PED)(1)

2014/34/UE (ATEX)(2)

2014/30/UE (EMC)(3)

2011/65/CE (RoHS)

(1) Gli strumenti con sovrappressione applicabile ≤200 bar (massima pressione ammissibile - PS) sono progettati

e fabbricati secondo criteri di buona prassi costruttiva, in accordo con l’articolo 4, par.3 della direttiva.

Gli strumenti con sovrappressione applicabile >200 bar (massima pressione ammissibile - PS) in aggiunta,

sono classificati in CATEGORIA I e sottoposti a valutazione della conformità secondo il Modulo A – Controllo di

fabbricazione interno.

Instruments with allowable overpressure value

≤

200 bar (maximum allowable pressure – PS) are designed

and manufactured in accordance with sound engineering practice, according to article 4, par. 3 of the

directive.

Instruments with allowable overpressure value >200 bar (maximum allowable pressure – PS) are additionally

classified with CATEGORY I and subjected to the conformity assessment procedure according to Module A -

Internal production control.

(2) Gli strumenti sono marcati -Instruments are marked

II 1GD Ex ia IIC T6/T5/T4 Ex ia IIIC T85/T100/T135°C

II 1/2GD Ex ia IIC T6/T5/T4 Ex ia IIIC T85/T100/T135°C

e sono conformi alle norme – and they comply with the standards

•EN 60079-0:2012/A11:2013

•EN 60079-11:2012

•EN 60079-26:2015

Hanno la certificazione di tipo 0425 ATEX 2635 relativa al Fascicolo Tecnico TF 4 rev.2, e la sorveglianza

sulla produzione ha la certificazione N° 1591 rilasciate dall’Organismo Notificato ICIM S.p.A. N° 0425.

They have a type certification 0425 ATEX 2635 referred to the Technical File TF 4 rev.2, and the surveillance

for production has the certification N° 1591 issued from the Notified Body ICIM S.p.A. N° 0425.

(3) Gli strumenti sono conformi alla norma – Instruments comply with the standard

•EN 61326-1:2013

Il controllo della fabbricazione interna degli strumenti è assicurato dal Sistema Qualità secondo ISO 9001

operante in azienda e certificato da ICIM SpA.

The control of internal manufacturing of the instruments is assured by the Quality System according to ISO

9001 of the factory, certified by ICIM SpA.

Responsabile ATEX-ATEX Responsible

Invorio, 18.05.2018 F.Zaveri