nVent.com |9

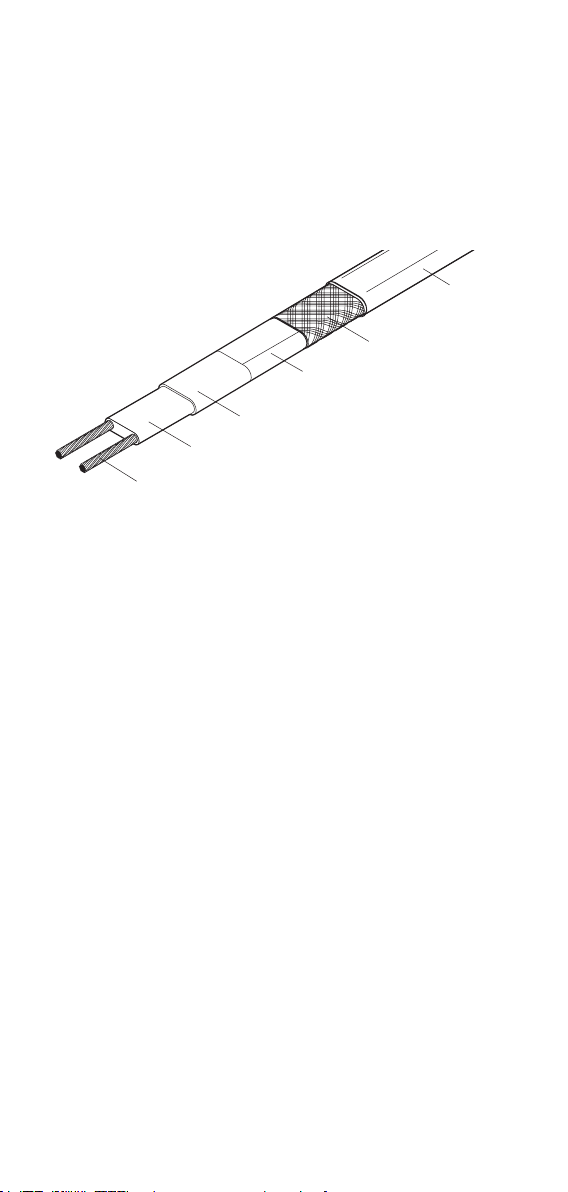

3 HEAT-TRACING CABLE INSTALLATION

3.1 Heat-tracing cable storage

• Store the heat-tracing cable in a clean, dry

location. Temperature range: –40°C to 60°C

• Protect the heat-tracing cable from mechanical

damage and moisture.

3.2 Pre-installation testing

Check materials received:

• Review the HWAT cable design and compare the

list of materials to the catalogue numbers of the

heat-tracing cables and connection kits received

to confirm that the proper materials are on site.

The HWAT cable type is printed on its jacket.

• The HWAT System is limited to 230 V service

when using the HWAT-ECO control unit. Ensure

that the service voltage available is correct.

• Inspect the heat-tracing cable and connection kits

to ensure there is no in-transit damage.

• Make sure that the inner jacket of the heat-tracing

cables is not damaged. Carry out an insulation

resistance check on every reel for this (see

section9). Do not power the heat-tracing cable

when it is on thereel.

Check the pipe:

• Make sure that all mechanical pipe tests (i.e.

hydraulic pressure test/rinsing) have been carried

out completely and the pipe fittings are finally

tightened.

• Walk the system and plan the routing of the heat-

tracing cable on the pipe.

• Inspect the piping and remove any burrs, rough

surfaces or sharp edges.

3.3 Installation

• Reel off the heat-tracing cable. Pull it loosely

along the pipe. Make sure that the heat-tracing

cable always runs along next to the pipe when

there are obstructions.

• Install the cable in straight runs along the pipe.

Spiralling the heat-tracing cable is not necessary.

• When installing the heat-tracing cable, the cable

must not be compressed or pinched between

two objects. Wall and floor penetrations and pipe

straps are particular areas of concern.