800-633-0032

2215 Dunwin Dr., Mississauga, Ont. L5L 1X1

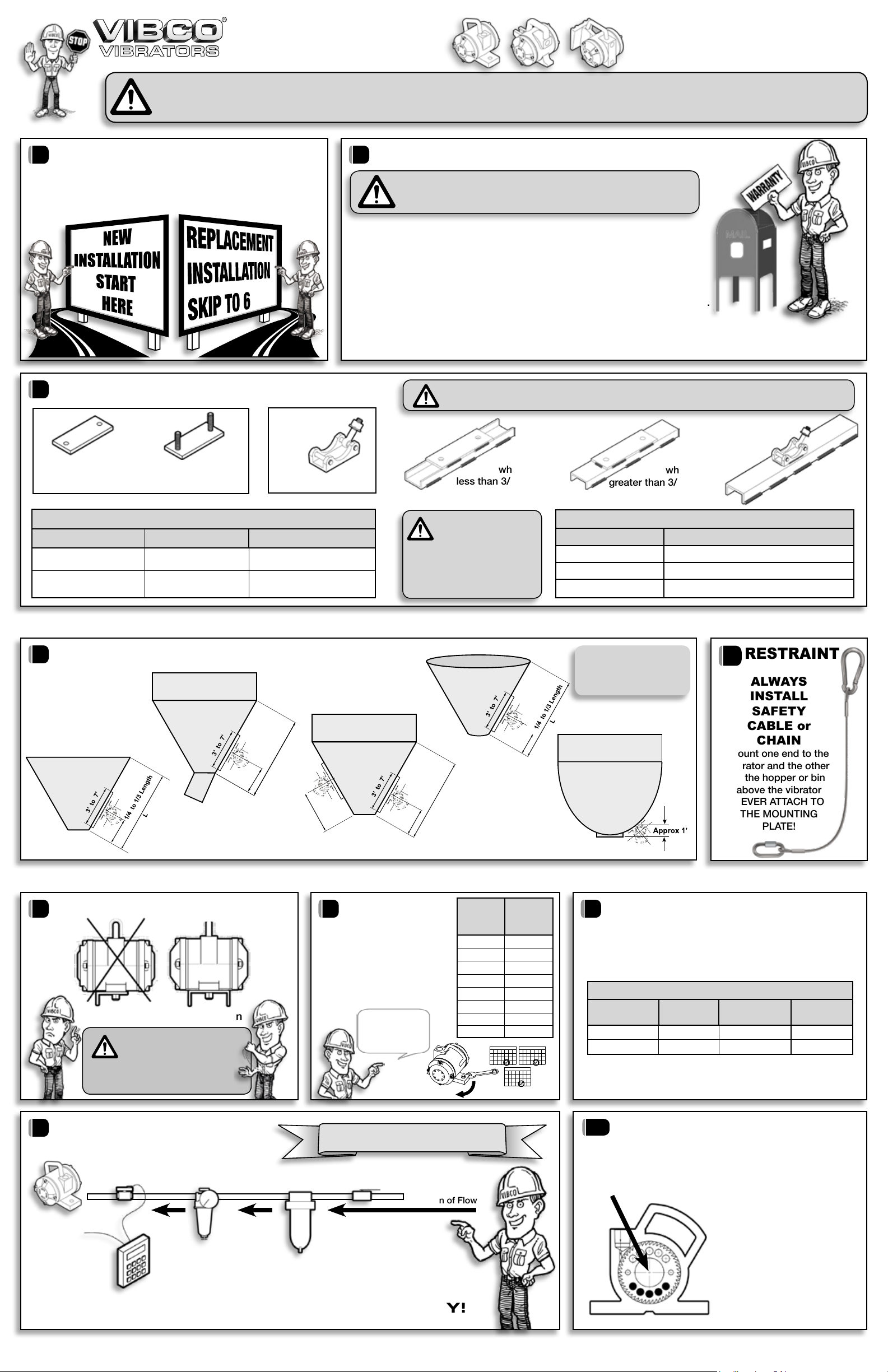

WARNING: Failure to read and follow these installation instructions and safety precautions could result in personal injury, equipment damage,

shortened service life or unsatisfactory equipment performance. All information in this document is vital to the proper installation and operation

of the equipment. It is important that all personnel who will be coming in contact with this product thoroughly read and understand this manual.

INSTRUCTION

MANUAL

©2018 VIBCO, Inc. MA-CC-29718

CC TURBINE

VIBRATORS

11 OPERATING SPECIFICATIONS

12 TROUBLE SHOOTING

Warranty

All warranty claims must be submitted to VIBCO for approval prior to any

repairs being done. Failure to do so will void any and all warranty coverage.

All repairs will be done at the VIBCO factory.

Errors, Shortages & Complaints

Complaints concerning goods received or errors should be made at once.

Claims must be made within ve days after receipt of goods. Clerical errors

are subject to correction. Damage during shipping must be reported to the

carrier, not VIBCO.

Returning Parts

Parts should not be returned to VIBCO without prior authorization. Call VIBCO’s

customer service department at 800-633-0032 (800-465-9709 in Canada) for

a Return Goods Authorization (RGA) number. A return authorization will be

emailed or faxed to you. Use this as your packing slip. Return shipping must

be prepaid. Material returned may be subject to a 10% restocking fee. All

returned shipments should clearly display your name, address and original

invoice number to ensure proper credit.

YOU CAN FIND

ADDITIONAL DETAILS &

INSTRUCTIONS ONLINE AT

www.vibco.com

Look for the

Support link on the homepage

Maximum Air

Pressure

For continuous

use, operating

pressure should

not exceed 80 psi

unless specially

constructed from

the factory.

Safe Operation for

Intermittent Duty

Not Recommended

Maximum

Temperature

The operating

temperature of the

vibrator should not

exceed 200°F (93°C).

High temperature

units are available

from factory.

Safe Operation for

Continuous Duty

Not Recommended

200°F 93°C

1. Check for dirt in the airline or inlet opening.

2. Check air line back to compressor for holes or

disconnections.

1. Double check the size of your airline - is it large

enough to give you the correct cubic feet per

minute (CFM) and correct air pressure

(minimum required = 20 PSI).

2. Bearings require a short “break-in” period to run

at optimum VPM stated in catalog.

VIBRATOR WON’T START?

VIBRATOR WON’T GET UP TO SPEED?

Orders for custom equipment built to customer’s specications are not

returnable.

Product Changes

VIBCO reserves the right to make changes in pattern, design or materials when

deemed necessary, without prior notice or obligation to make corresponding

changes in previous models. To be sure of exact mounting dimensions, it is

recommended that you obtain a certied dimensional drawing from the factory.

Ordering Spare Parts

Parts can be ordered through authorized distributors or from VIBCO’s Spare

Parts Department. The following data should be provided when placing your

spare parts order:

q Model of unit from the foot of the vibrator housing

q Reference number, part number, description and quantity required from

spare parts list

q Shipping instructions: Specify shipping point and method of shipping.

800-633-0032 for Mounting Plates & Brackets, Spare & Replacement Parts

and

24/7 Technical Support

For custom mounting applications or any other questions:

800-633-0032 or

VIBCO turbine

vibrators

function without

maintenance.

They require no lubrication in the

air line. It is advisable to put an

in-line air-cleaner to prevent dust

and dirt from going through the unit

and clogging the muer. No other

maintenance is required.

REPAIR KITS

Repair kits are available through VIBCO. Instructions

are included with the kit and available online at

www.vibco.com. Replacing parts not issued by

VIBCO will void warranty. Any further questions or

concerns please call the factory 800-633-0032.

The repair kit includes everything

you need to make your vibrator

run like new.

ADDITIONAL DETAILS AVAILABLE ONLINE AT www.vibco.com

Repair Kits Include: Stover Nut, Inside Cover with

Keyway, Seal Ring, CR Seal, Bearings,

Turbine Wheels, Key & Shaft.

DON’T FORGET TO RETURN YOUR WARRANTY CARD TO VIBCO!