BEFORE YOU BEGIN:

Read these instructions completely.

Plan out your wiring scheme ahead of

time. Use the included wiring diagrams to

help guide your wire routing

Use 14 ga. wire on all connections to

sending units.

Use electrical solder and heat shrink

tubing or appropriate solder less

connectors to make all wiring connections

Disconnect the vehicle's battery

Do not use thread sealer on the sending

units, they have a tapered thread

Have a plan. Mock up parts or layout as

needed. It takes a little more time, but will

save time and money in the end.

Recommended Tools and Materials

Needed for Installation

14 and 16 ga. stranded wire

Spade or Bullet connectors

Momentary push-button

Pressure sender for hour meter

Electrical solder (optional)

Heat shrink tubing (optional)

Soldering iron (optional)

Measuring tape or ruler

Engine adaptors for senders

4 3/8 hole saw

Wire cutters

Wire stripper/crimper

Files

Various hand tools:

wrenches, screwdriver, etc

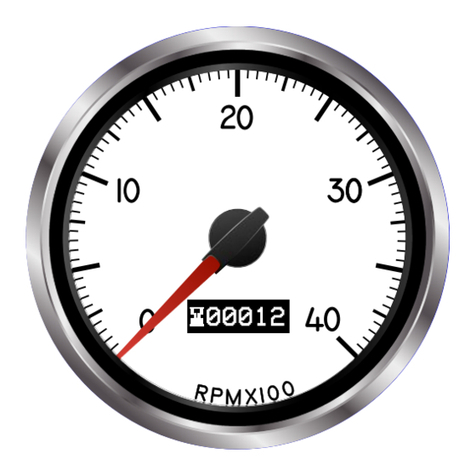

Installation of gauges:

2. Slide gauge through hole and add

backing clamp over the retaining studs.

Using the included washers and nuts,

tighten to a snug fit

Wiring the gauges:

Run the power wiring from the gauges to an

appropriate positive (+) on the fuse block

after the battery. This applies to the

switched 12V+ and gauge lighting

Connect the ground to a good dedicated

ground on the chassis

Run each wire to the appropriate sender

and use the proper connector for each item

(eyelet, spade, etc.) from the sender to the

dash. Leave some extra slack in the wire

and label it.

Ensure that wires will not chafe on holes by

using grommets and that they will clear any

moving objects.

Once wires are run from the appropriate

sender location to the gauges location,

connect to the corresponding wire on the

Packard connector with solder and heat

shrink tubing or a solder less connector.

NOTE: The 4-3/8" speedometer lighting is

wired via tabs on the back. The bulb is a GE

194 The 3-3/8" speedometer lighting is LED

lighting which is internal, no replacement is

required.

Sender installation

You must use senders with the proper ohm

match for your gauge, using mis-matched

senders will result in improper readings on your

gauge.

Water temperature 450-29.5 ohm

The water temperature sender has a 1/8 NPT

end. It should be installed close to the

thermostat on the intake manifold. There are

usually ports for temperature on the block in the

water jackets, which can be used as well.

Oil pressure. 240-33ohm

The sender has a 1/8 NPT end on it. Check for

your factory location for a pressure port and

install.

Fuel level: 240-33 w/ sender, 0-90, 73-10, 0-30

The fuel gauge range (ohms) must match sender

1. Locate suitable positions foryour gauges.

The gauges fit in a 4-3/8" and/or 3-3/8"

holes. Take note of the anti-rotation

notches and add this feature where

required.

-2-