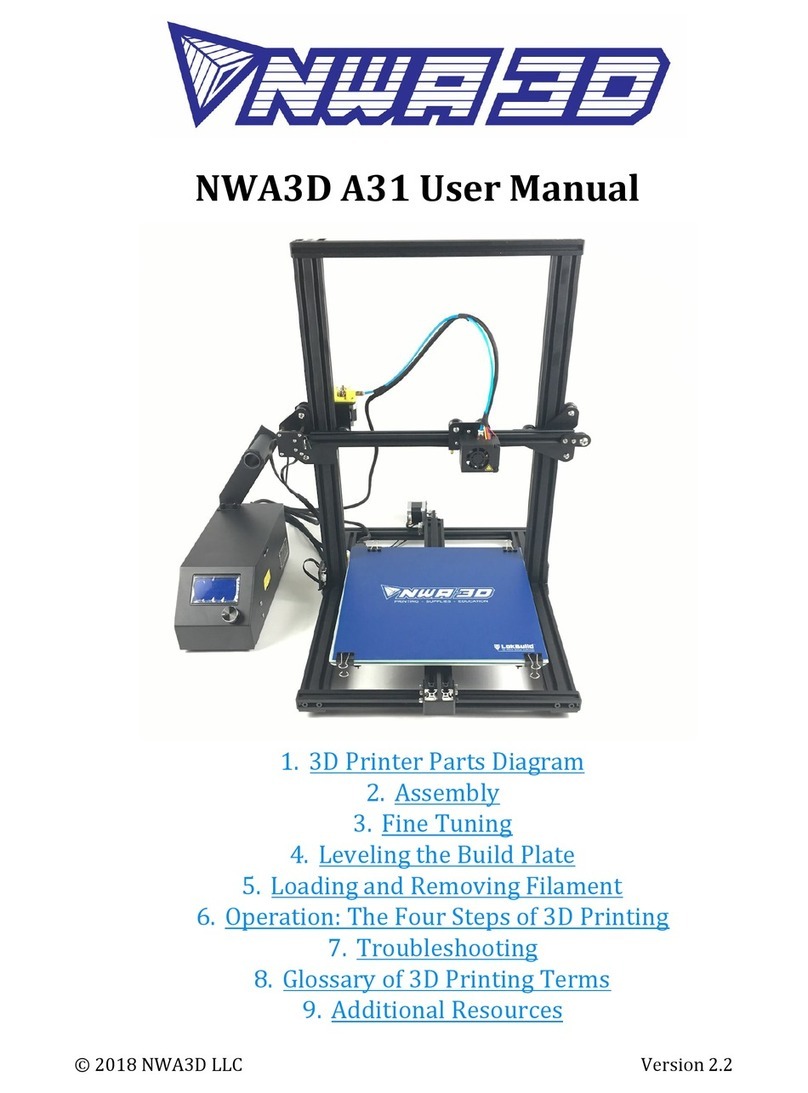

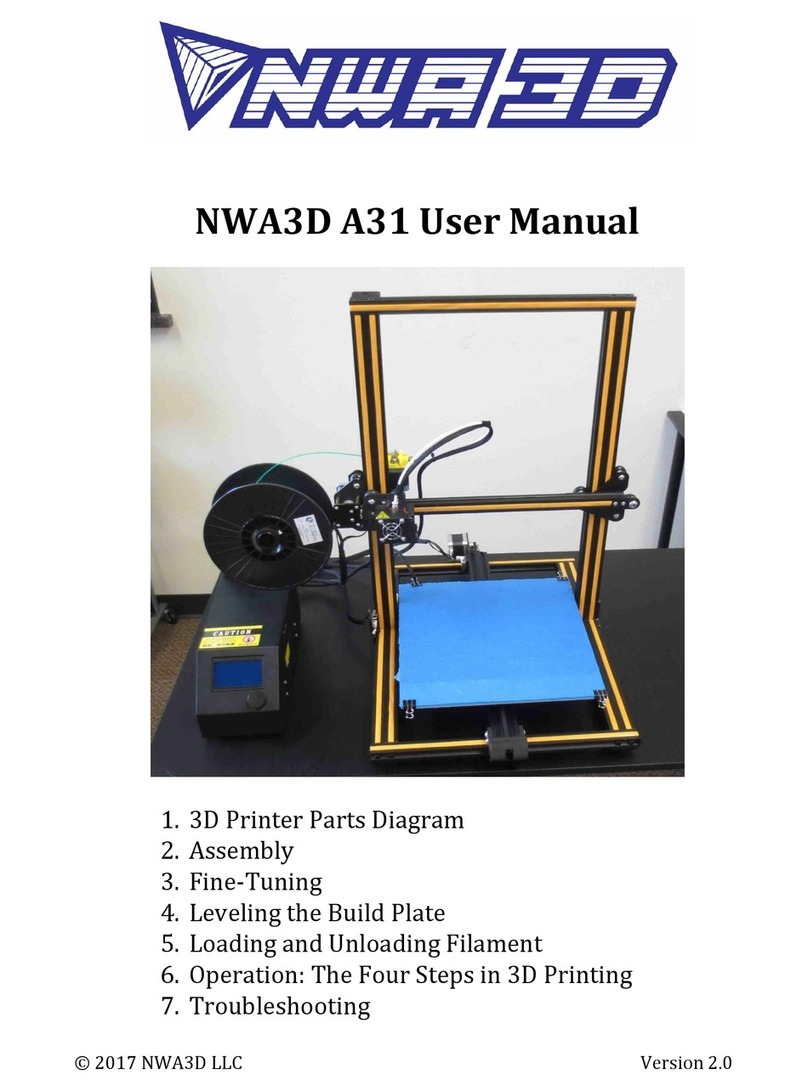

NWA3D A31 User Manual

2. Assembly

1. Remove the parts from the box and remove any tape and padding from the

parts. Inspect the parts to make sure they were not damaged in shipment.

Packing list:

●Base frame

●Gantry frame

●Power & control box

●Power cord

●M5x20 machine screw (4)

●Washer (4)

●Frame reinforcement plates (2)

●Spool holder bracket

●Spool holder tube

●Spool holder thumb screws (2)

●Sample spool of filament

●USB–miniUSB cable

●Maintenance tool kit

●Scraper

●Nozzle cleaner

●microSD card with USB adapter

●Spare parts bag with extra fasteners, nozzle, and Bowden tube coupler

2. Install the gantry frame (A) to the base frame (B).

a. On the gantry frame, make sure the nozzle assembly is on the front, and

the long vertical lead screw is on the back. On the base frame, make sure

the black belt cover is on the front, and the motor is on the back.

b. Use the M5x20 screws (4) and lock washers (4). Raise the base frame

above the table with two blocks (boxes, books, etc.) Install the screws

through the base frame into the threaded holes in the gantry frame.

Tighten with the M5 hex key (Allen) wrench.

© 2018 NWA3D LLC 3