NWA3D A5 User Manual

5. Operation: The Four Steps of 3D Printing

3D printing involves these four steps:

1. Create a 3D file (Make)

2. Slice the file for 3D printing (Slice)

3. Send the file to the printer (Transfer)

4. Select the file on the printer (Print)

1. Create or find a 3D file

a. You can create a 3D model—a digital geometry—using any CAD (computer-

aided design) software program. We recommend free programs, such as

TinkerCAD and OnShape. Autodesk’s Fusion360 is free to students. Another

is SketchUp, which has free licenses available for schools. These programs

take some time to learn, and can be challenging. But they are also rewarding,

especially when you see your own creation being printed on your 3D printer!

Every CAD program allows users to save or export digital files for 3D

printing. You want to save your file as an STL file (“filename.stl”). The STL file

is the standard file format for 3D printing. In some programs, it’s as easy as

the Save command. In others, you need to select the File > Export option, and

choose the STL format. OBJ files can also be sliced and 3D printed.

b. You can find 3D models in many online libraries of digital content.

Thingiverse, GrabCAD, and Instructables are examples, and many other sites

exist.

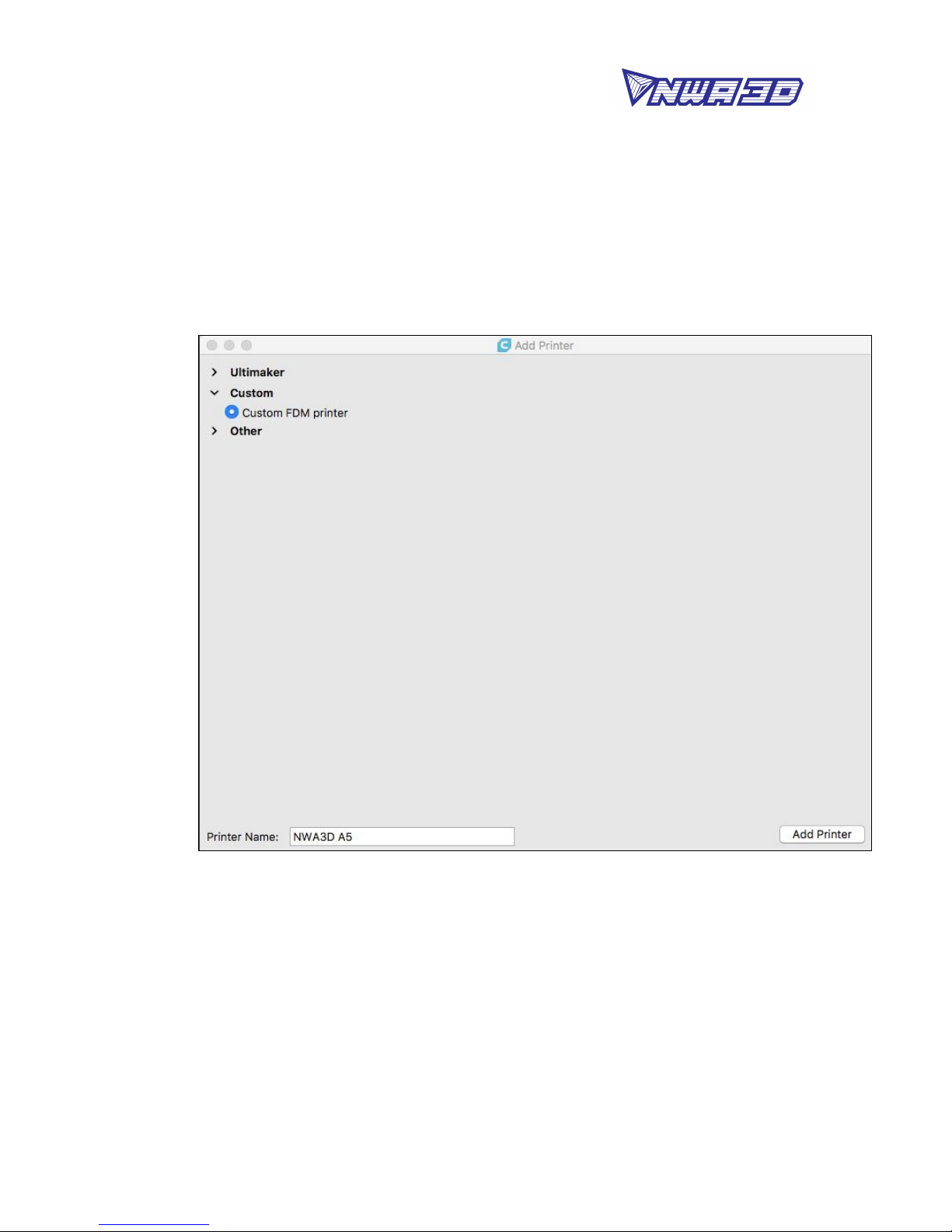

2. Slice the file for 3D printing

Video Tutorial: How to set up Cura 3.1

Slicing is the process of converting your 3D model into the layered print

language your printer can understand, called G-Code. We recommend using free,

open-source slicer programs. Our favorite slicers are Ultimaker Cura and

Repetier Host. Both are free and easy to use. We’ve included Cura and its setup

profile on your printer’s SD card because it’s easier for beginners. For beginning

users, we recommend that you install Cura on a single PC or Mac and use it to do

your slicing.

There are a lot of slicers that will create G-Code automatically for your printer.

All you have to do is input the correct settings for your printer (using the files we

included), import your 3D model, and save the G-Code. It’s that easy!

© 2018 NWA3D LLC 9