Heated Bed Adjustment Instructions

Step Chart

Step-by-Step

Repeat,

if necessary!

Use the function "UNLOAD FILAMENT" to make the extruder reach

to working temperature and it's easier to clean by copper brush.

1.

UTILITIES

SETTINGS

INFO

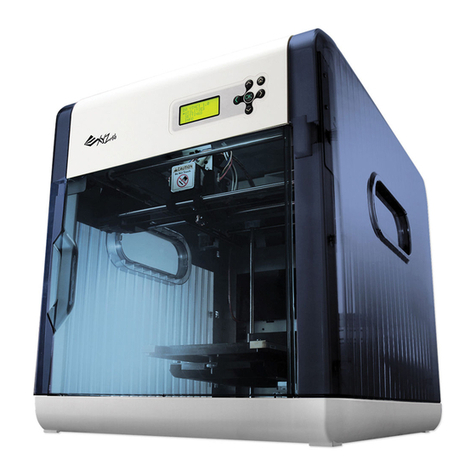

DA VINCI 1.0

DA VINCI 1.0

SYSTEM VERSION

INFO

CARTRIDGE STATS

STATISTICS

UTILITIES

SETTINGS

INFO

AUTO CALIBRATE

BUILD SAMPLE

uTILITIES

jOG MODE

I. Show ADJUST SUCCESS

I. Adjust "A" thumbscrew to make the 1st and the 2nd measured

value approached.

II. Adjust "B" thumbscrew to approach 1st, 2nd measured value if

needed.

III. Adjust "C" thumbscrew to adjust the value of 3rd, all measured

values approached, the process is completed.

II. Show ADJUST FAIL

→Please refer the measured data and follow the

calibration steps.

AUTO CALIBRATE

IN PROGRESS

PLEASE WAIT

AUTO CALIBRATE

ADJUST SUCCESSS

Z offset 270

[OK]TO SAVE

EXTRUDER HEATING

TEMPERATURE999°C

PLEASE WAIT

AUTO CALIBRATE

ADJUST SUCCESSS

Z offset 270

[OK]TO SAVE

AUTO CALIBRATE

ADJUST fail

+245,+305,+315

[OK]TO RETURN

→Please stop and press OK to finish calibration

◎ Steps:

(Measurement points)

(Screws position)

Face the front side of the printer

Moving a cycle of screw will show the measured

value changed around 50 degree.

Rotation of the screw to the left

Make the heated bed raise up

(value increases)

Rotation of the screw to the right

Make the heated bed go down

(value decreases)

AUTO CALIBRATE

ADJUST fail

+245,+305,+315

[OK]TO RETURN

1 32 1

AB

C

2

3

If the displayed values are 999,999,999, follow these steps to clean up.

※Please Note:

AUTO CALIBRATE

ADJUST fail

+999,+999,+999

[OK]TO RETURN

-6-

A. Use of copper brushes to clean the

surface of extruder.

(Clean the extruder pin and measurement

points of heated bed)

B. Referring to Step 4, cleaning the

measuring points.

C. Do the heated bed adjustment again.

The heated print bed is pre-calibrated, please Do NOT make

any unnecessary calibrations.Please contact service personnel

or visit our website for detailed support information.

Step

12345

Step Step Step Step

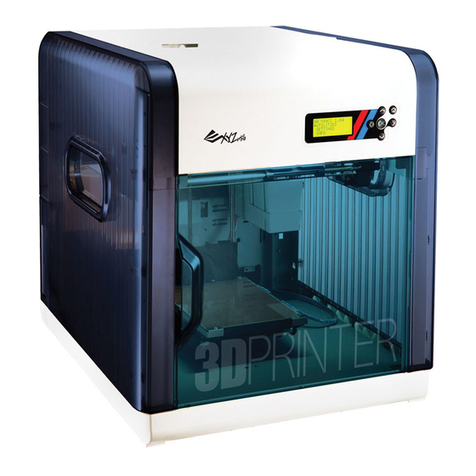

Choose"INFO">"SYSTEM VERSION" to

know the firmware version and keep the latest

one.

4. Please refer the measured data and follow steps for doing

calibration.

5. After this step completed, repeat the step 2 again,

ADJUST SUCCESS will be displayed if correct ,then press

OK to complete the calibration.

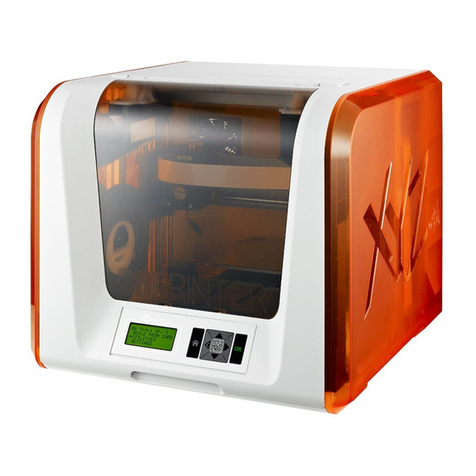

2. Choose"UTILITIES">"AUTO CALIBRATE"

>"YES" to strat the procedure of calibrations.

3. The printer will measure the level of heated

bed automatically, and feedback data on the

display after around 2 minutes.

Note: the extruder will be heated in the

process of measurement, be careful!

ENG