3

©2020 Nystrom, Inc.

REV 8/2020

Seismic Fire Barrier Expansion Joint System

Installation, Operation & Maintenance Model(s): EJ-FLF140/EJ-FLW140

6. Cut the zip-ties for the current fire barrier and continue installation for the rest of the run, figure 4.

7. If field conditions require a stick to be cut short, measure the

required length from male end and cut the appropriate length,

figure 5.

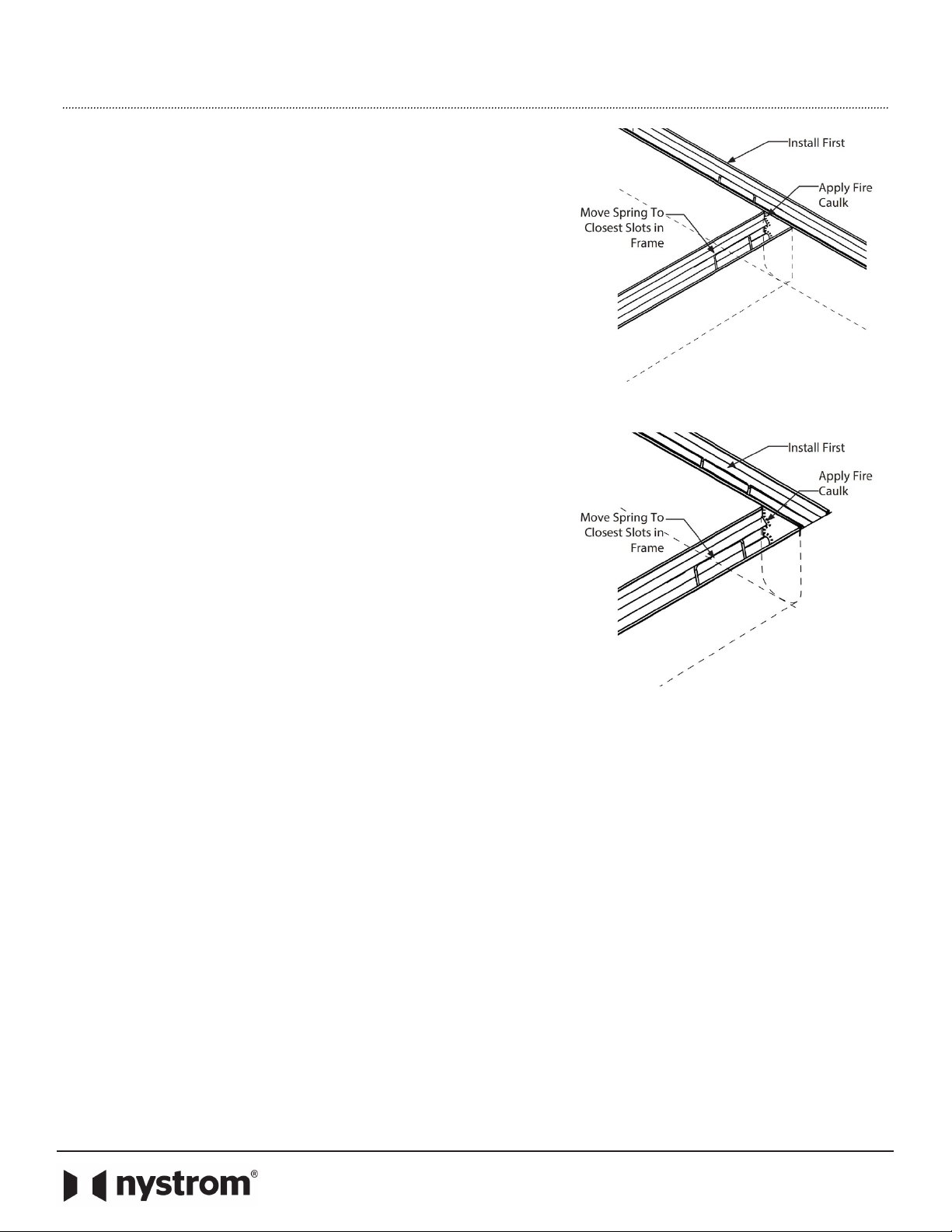

8. If the removed section of fire barrier contains a spring, be sure to

remove that spring from the dropped section, and re-install to

provided slots in blanket that will be installed, figure 5.

NOTE: Maintain a maximum spring spacing of 18 inches (450mm).

9. When the fire barrier meets a fire rated wall, continue the horizontal fire barrier uninterrupted, or a

minimum of the total wall depth to ensure no gaps exist at the intersections, figure 6. Reference figure

8.

10. If a spring of the horizontal fire barrier is located inside

the wall joint, it must be moved to a point before the

wall to achieve a proper transition. Maintain a maximum

spring spacing of 18 inches (450mm), figure 6.

11. Remove 2 inches (50mm) from each metal flange on the

male end of the barrier. Apply UL listed fire caulk liberally

to section of the fire horizontal barrier where the vertical

stick will intersect, face of the male end, flanges, and

interior walls of the slab before installing wall stick, figure

6. See figure 7 for more detail.

12. Insert fire barrier male end down and cut the bottom

most zip-tie and continue cutting upward, figure 6.

13. Continue vertical installation repeating steps 2-5 for the rest of the run, figure 7.

14. When intersecting horizontal barrier above, cut final piece to length, and trim female end to match the

drape of the horizontal barrier above, applying Fire Caulk to the under side of fire barrier, the portions

of the wall around the intersection, and inserting a female end. Ensure there are no gaps at transition,

figure 7.

15. For perpendicular installs, trim intersecting fire barrier, to match the pre-installed run. Apply fire caulk

to trimmed face, and side of pre-installed fire barrier, figure 7.