TABLE OF CONTENTS

REVISION INDEX ------------------------------------------------------------------------------------------------1

TABLE OF CONTENTS-------------------------------------------------------------------------------------------2

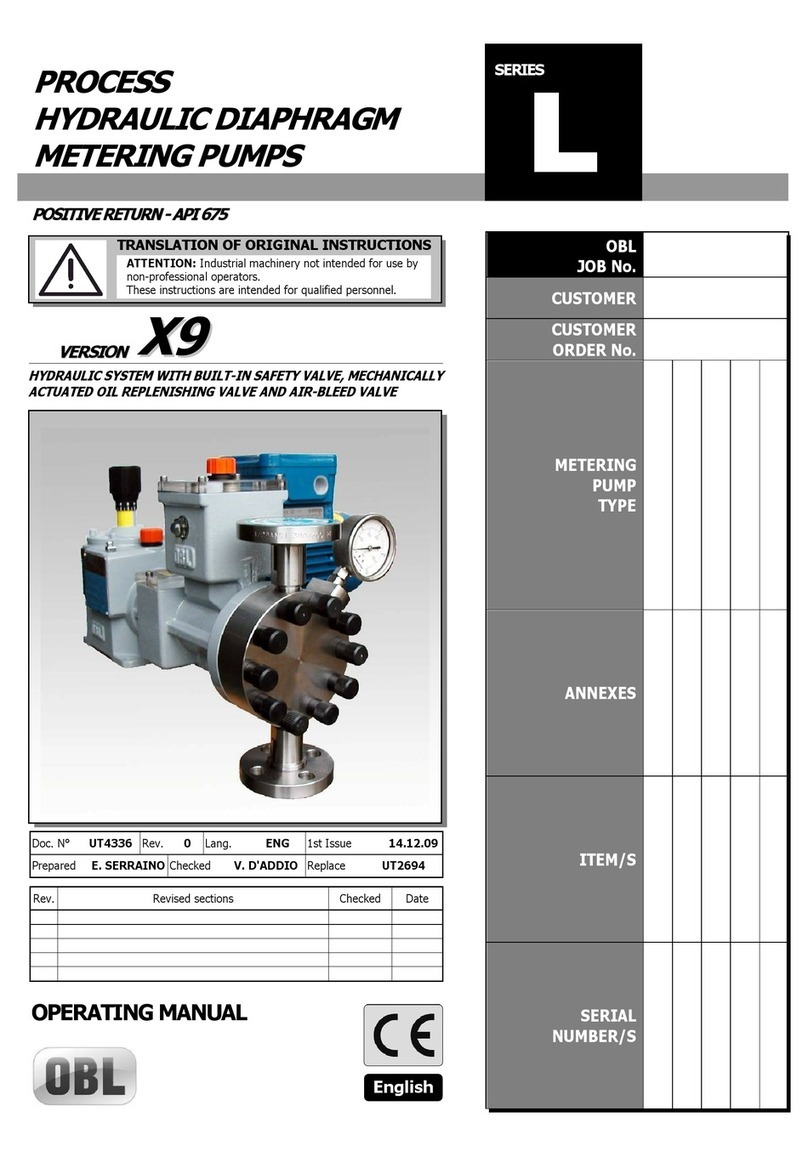

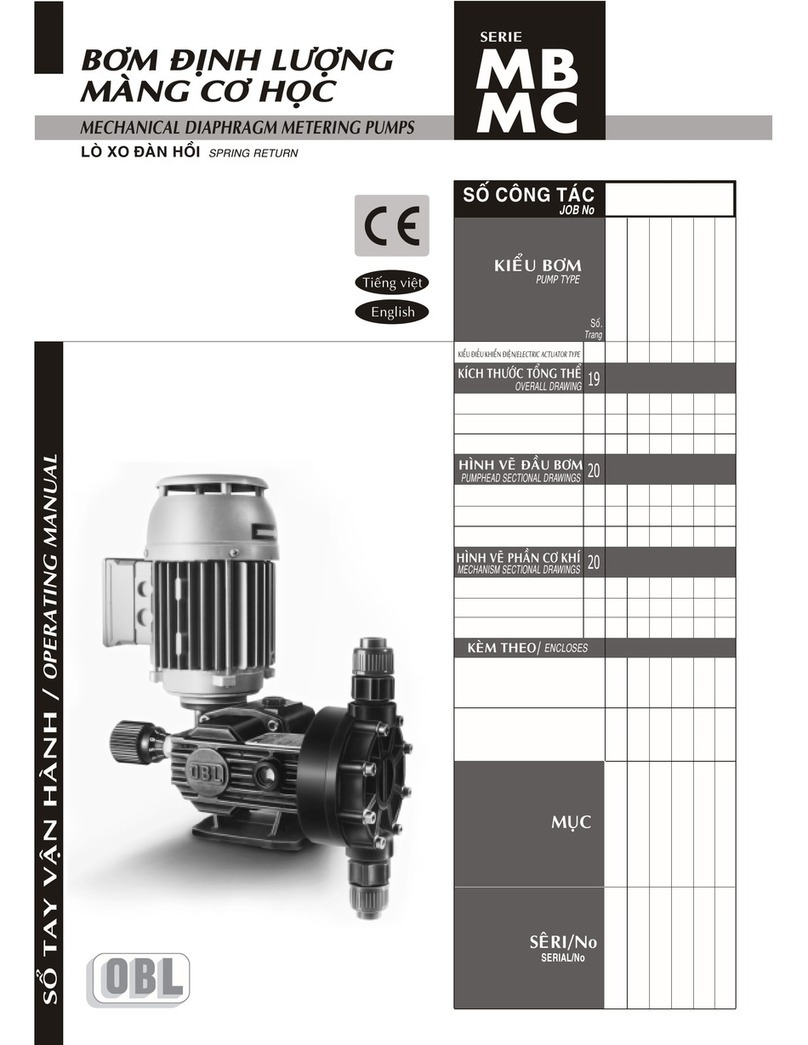

0INTRODUCTION -------------------------------------------------------------------------------------------------------------------3

1SCOPE OF THE USE AND MAINTENANCE MANUAL ---------------------------------------------------3

2HOW TO READ THIS USER MANUAL --------------------------------------------------------------------3

1GENERAL INFORMATION -------------------------------------------------------------------------------------------------------4

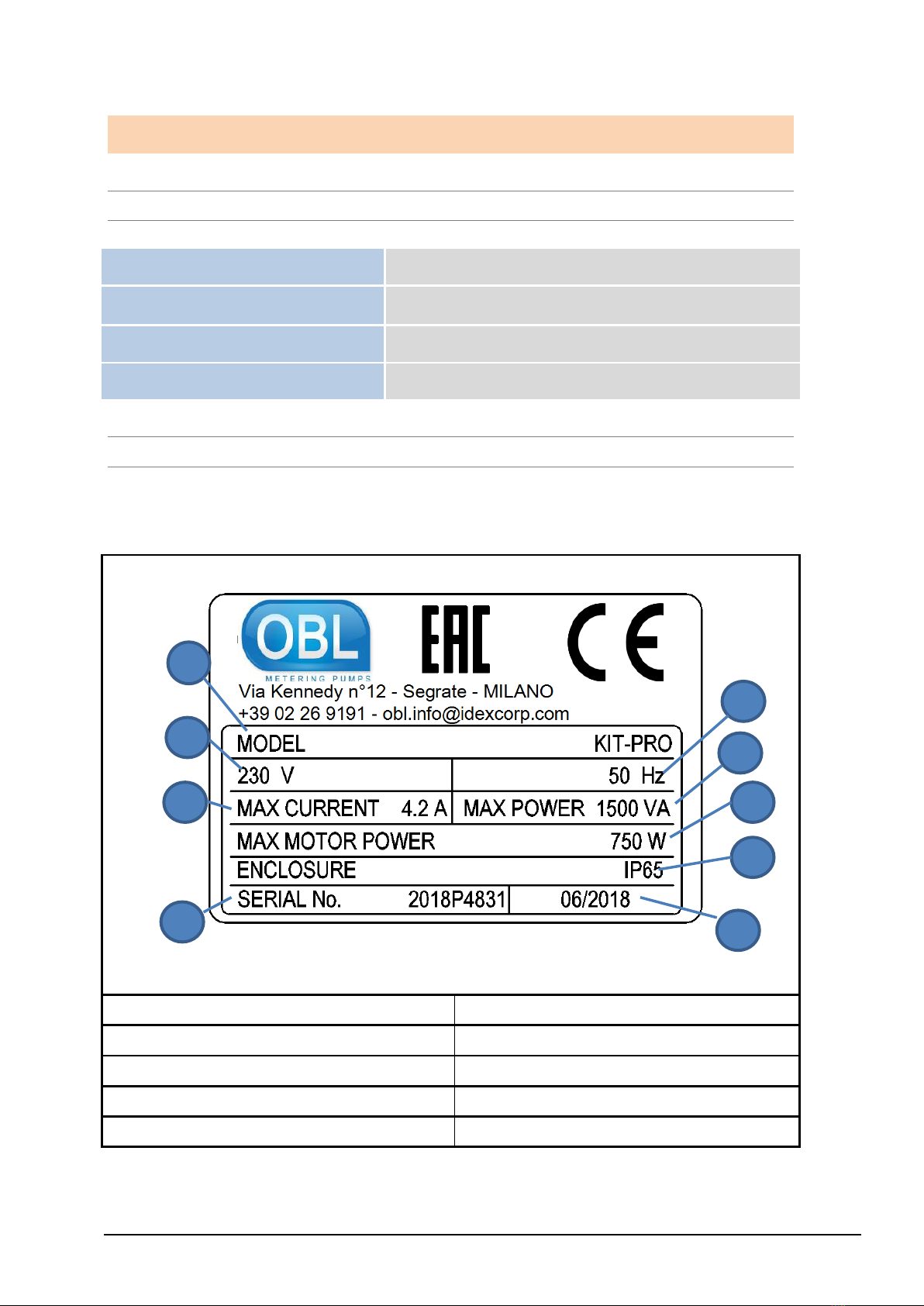

1MANUFACTURER’S IDENTIFICATION DATA -----------------------------------------------------------4

2CE MARKING------------------------------------------------------------------------------------------------4

3UL MARKING------------------------------------------------------------------------------------------------5

4DECLARATIONS --------------------------------------------------------------------------------------------6

5UL CERTIFICATION----------------------------------------------------------------------------------------7

6TECHNICAL SUPPORT -INFORMATION ----------------------------------------------------------------8

2SAFETY -------------------------------------------------------------------------------------------------------------------------------8

1GENERAL SAFETY WARNINGS ---------------------------------------------------------------------------8

2USE RESTRICTIONS ---------------------------------------------------------------------------------------8

3ELECTROMAGNETIC COMPATIBILITY ------------------------------------------------------------------8

4SAFETY ------------------------------------------------------------------------------------------------------9

5SAFETY PICTOGRAMS-------------------------------------------------------------------------------------9

3INSTALLATION ------------------------------------------------------------------------------------------------------------------- 10

1TRANSPORT AND HANDLING -------------------------------------------------------------------------- 10

2STORAGE CONDITIONS -------------------------------------------------------------------------------- 10

3POSITIONING -------------------------------------------------------------------------------------------- 11

4ADJUSTMENTS ------------------------------------------------------------------------------------------- 11

5ASSEMBLY ------------------------------------------------------------------------------------------------ 12

6ELECTRICAL CONNECTIONS --------------------------------------------------------------------------- 13

4PRODUCT DESCRIPTION ------------------------------------------------------------------------------------------------------ 15

1OPERATING PRINCIPLE--------------------------------------------------------------------------------- 15

2MAIN COMPONENTS AND DIMENSIONS ------------------------------------------------------------- 16

3ENVIRONMENTAL CONDITIONS ---------------------------------------------------------------------- 18

4TECHNICAL DATA---------------------------------------------------------------------------------------- 19

5USE AND SOFTWARE ---------------------------------------------------------------------------------------------------------- 20

1INTERFACE ----------------------------------------------------------------------------------------------- 20

2ICONS ----------------------------------------------------------------------------------------------------- 20

3MENU ------------------------------------------------------------------------------------------------------ 21

6MAINTENANCE ------------------------------------------------------------------------------------------------------------------ 38

1ROUTINE MAINTENANCE------------------------------------------------------------------------------- 38

2TROUBLESHOOTING ------------------------------------------------------------------------------------ 39

7ACCESSORIES AND SPARE PARTS ------------------------------------------------------------------------------------------ 40

1ASSISTANCE---------------------------------------------------------------------------------------------- 40

2SPARE PARTS--------------------------------------------------------------------------------------------- 40

8ADDITIONAL INSTRUCTIONS ------------------------------------------------------------------------------------------------ 41

1DECOMMISSIONING AND DISASSEMBLY ------------------------------------------------------------ 41