other previous model.

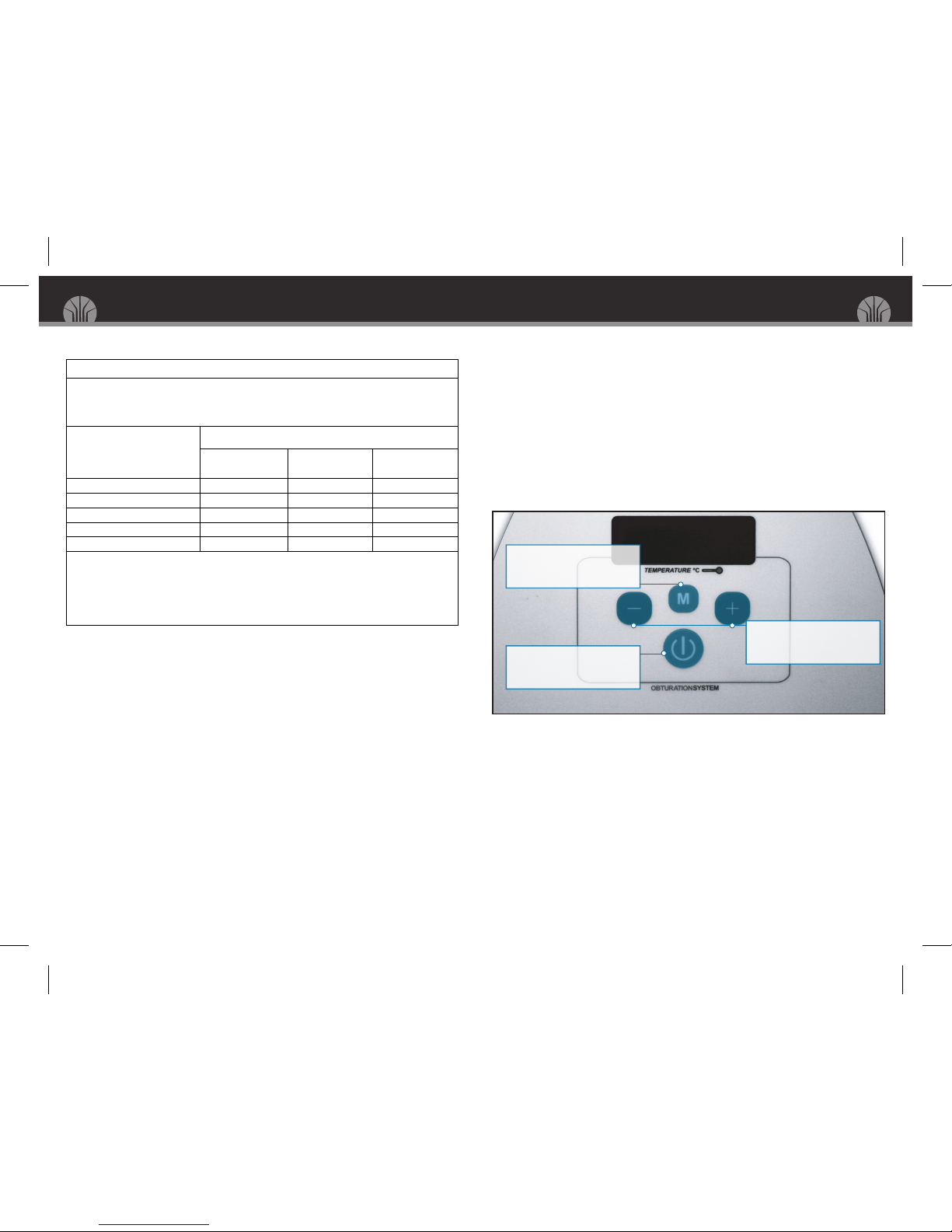

The Obtura III MAX utilizes push-button digital temperature controls for more accurate, reproducible settings,

and a memory function that stores up to 5 user-selectable temperature settings for your convenience.

TheObturaIII MAX complies with current Electromagnetic Compatibility standards (IEC 60601-1-2). Theuser should

ensure that any possible electromagneticinterference isnot present, as it could potentiallydamagethedevice or any

other electronicdevice in the vicinity.

Unpacking and Assembling

Check all packaging for signs of damage; report any damage with the shipping agent immediately, so that claims

will be honored in a timely way.

Save all packing materials in the event of an instrument move or shipping at a later date (also see our “Greener

Earth” commitment on the reverse side of customer introductory letter).

Remove the clear plastic introduction bag, main control unit, handpiece, handpiece stand (complete with stand

attachment spacer and screws), power supply box, bagged supplies and accessory tool kit. Check for loose items.

Unwrap the main control unit and place on a flat surface. Locate the unit so that by extending the cord you will

not pull the unit off the surface. The handpiece cable length is approximately 224 cm (88 in.).

Locate the handpiece stand and place it next to the main control unit. The stand provided for the handpiece can

be attached to the Obtura III MAX (if desired) by the following means:

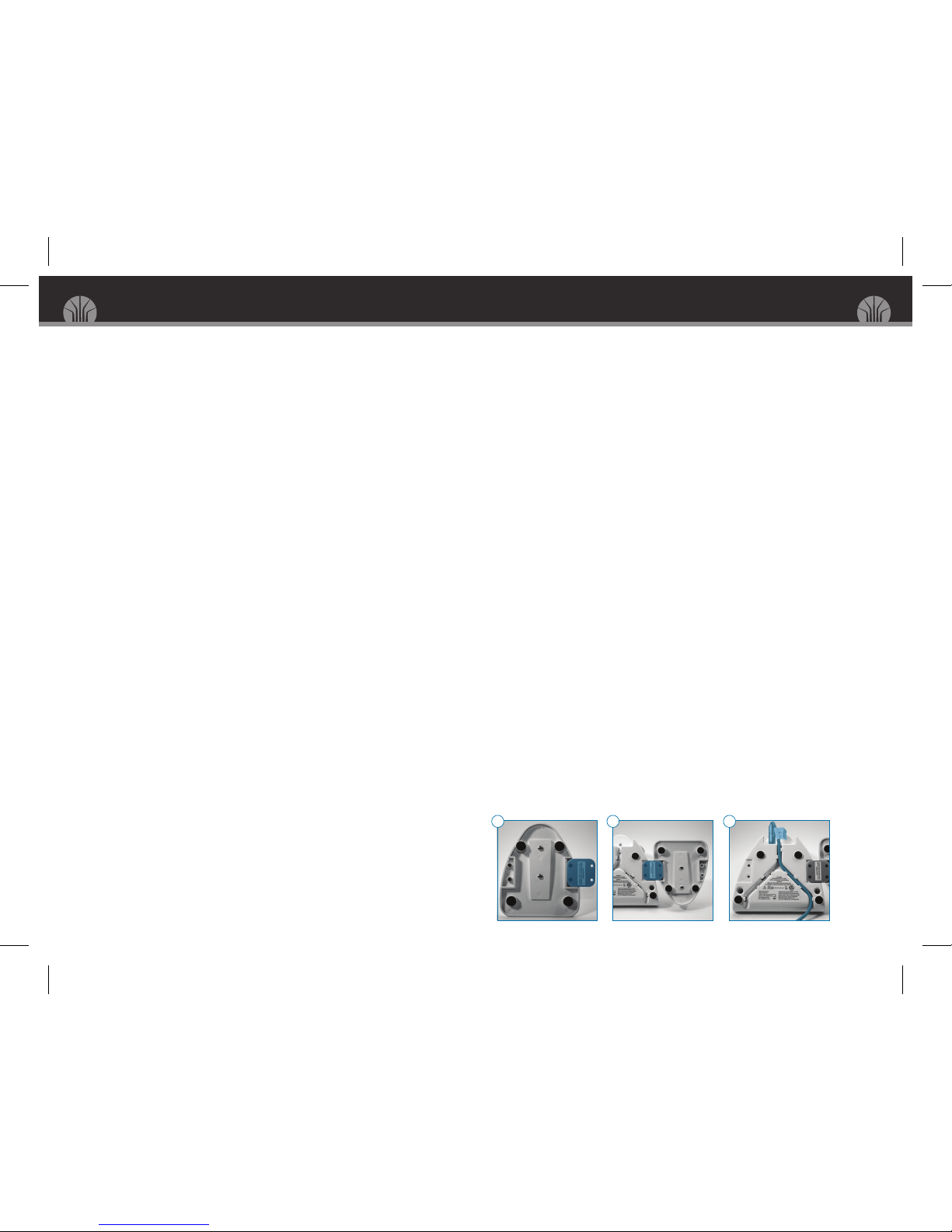

After determiningwhich sideyou want thestand placed on, simply remove the2 screws on the bottom of

--------the stand. After the screws are removed, hold theattachment platetothebottom of the stand, and re-attach

--------it tothedesired location soit hangs off theside(as shown in diagram A). Then attach the handpiecestand

--------and bracket tothemain control unit using the two remaining screws (seediagram B).

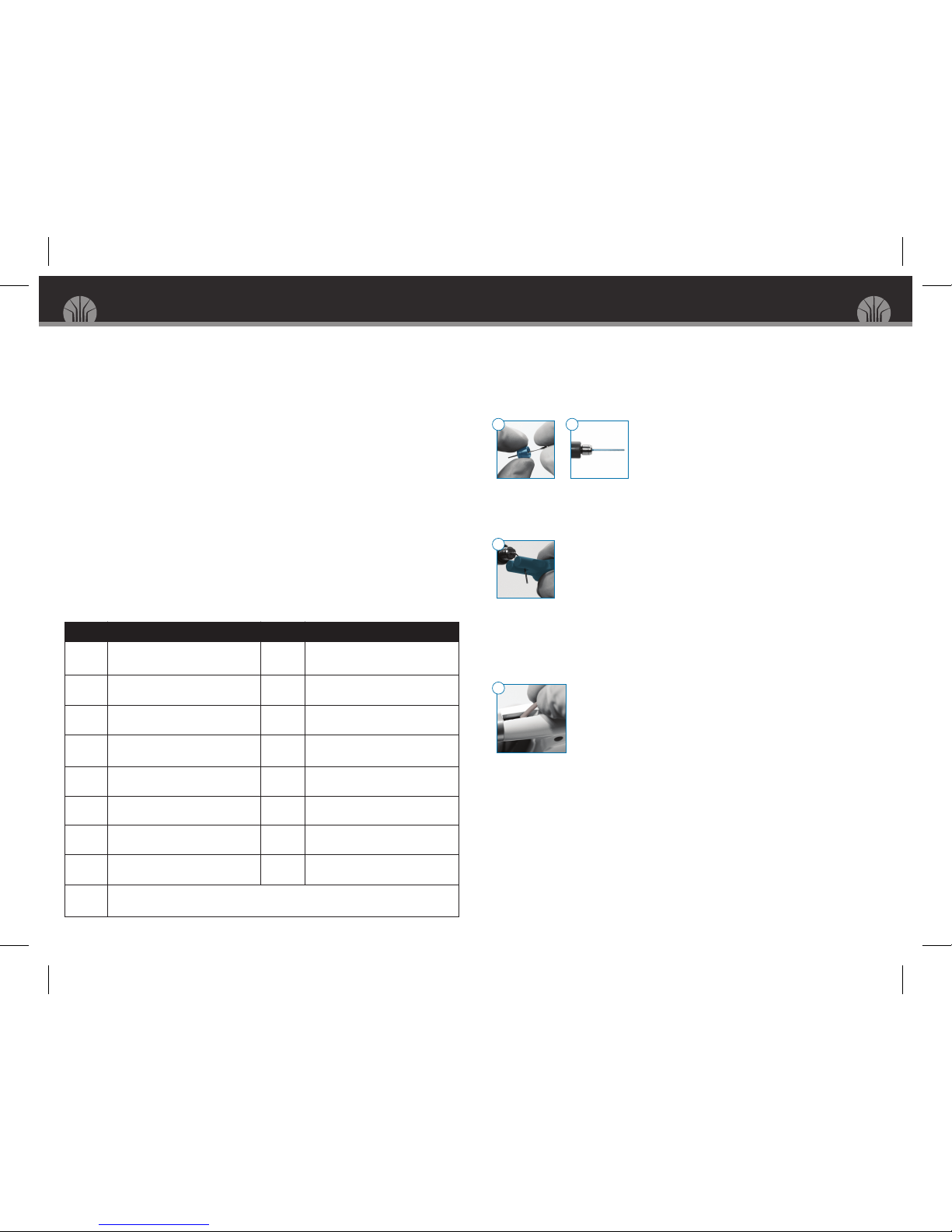

Plugthehandpiece cord connector intothe rear ofthe main control unit (note thealignment of the “red dot” at the

12 o’clock position, and a“click” to signifycomplete insertion). Should theuser require the cord toexit thefront

of the unit, invert theObtura III MAX on a smooth, soft surface and gently press the cableintothetracksprovided,

leavinga small loop ofcable from thehandpiece cord port to the beginningofthe track. The cablecan exit on the

left-front or the right-front (see diagram C), or from the rear (without use of thecabletracks).

Open the whitepower supply box and remove the power supply unit and receptacleblades. Choose the correct

blade tofit your electrical outlet and slideit on to the power supplyunit. Plug the power supply connector into

thepower supplyport at the rear of themain control unit; plug the power supply unit intoan electrical outlet. The

ObturaIII MAX screen will momentarily light up, indicating the version of installed firmware, and then turn off.

This only occurs when first connecting themain control unit to the electrical outlet.

UNPACKING AND ASSEMBLING 3

A B C

OPERATOR’SMANUAL HEATED GUTTA PERCHA SYSTEM

SECTION VI – Health Hazards

Routes of Entry: Skin and eye contact. Inhalation.

Signs and symptoms of exposure:

Skin contact: Repeated exposure may cause skin dryness or cracking

Eye contact: Irritating to eyes

Inhalation and Ingestion: Excessive inhalation of vapors can cause irritation of the respiratory tract,y

nausea, dizziness, or headache. Product has a low order of acute oral toxicity, but ingestion of large

quantities may cause nausea, vomiting, and gastrointestinal irritation. May cause injury if aspirated into lungs.

Medical conditions aggravated by exposure: Persons with pre-existing central nervous system (CNS) disease,

neurological conditions, skin disorders, chronic respiratory diseases, or impaired liver or kidney function should

avoid exposure.

SECTION VII – Emergency First Aid Procedures

Eyes: Check for and remove contact lenses. If irritation or redness develops, flush eyes with cool, clean, low

pressure water for at least 15 minutes. Hold eyelids apart to ensure complete irrigation of the eye and eyelid

tissue. Do not use eye ointment. Seek medical attention immediately.

Skin Contact: Remove contaminated shoes and clothing. Clean affected area thoroughly with mild soap and

water. Do not use ointments. Seek medical attention if irritation persists.

Inhalation: Immediately move victim to fresh air. If victim is not breathing, immediately begin rescue breathing.

If heart has stopped, immediately begin cardiopulmonary resuscitation (CPR). If breathing is difficult, seek

medical attention immediately.

Ingestion: DO NOT induce vomiting unless directed to do so by a medical personnel. Never give anything by

mouth to an unconscious person. If spontaneous vomiting is about to occur, place victim’s head below knees. If

victim is drowsy or unconscious, place on the left side with head down. Do not leave victim unattended. Seek

medical attention immediately.

SECTION VIII – Special Precautions, Spill/Leak Procedures, and Transportation

In case of spill: Small Spill and Leak, absorb with an inert material and dispose of properly. For Large spill and

leak, secure the area and control access. Dike far ahead of a liquid spill to ensure complete collection. Pick up

free liquid for disposal using absorbent pads, sand, or other inert non-combustible absorbent materials. Place into

appropriate waste containers for later disposal.

Waste disposal: Waste must be disposed of in accordance with federal, state, and local environmental control regulations.

Handling: DO NOT spray into or around ignition sources. After handling, always wash hands thoroughly with

soap and water. Use only with adequate ventilation. Avoid breathing vapors or spray mists.

Storage: Keep container in acool, well-ventilated area. Avoid all sources of ignition (spark or flame). Store below 120 °F.

Transportation: D.O.T. Ground – Not Regulated. IATA Air – Flammable Liquid, n.o.s., Hazard Class 3, UN1993,

Packing Group III

SECTION IX – Special Protection Information / Control Measures

Protective wear: Safety glasses and nitrile gloves

Ventilation: Provide exhaust ventilation or other engineering controls to keep the airborne concentrations of

vapors below their respective occupational exposure limits.

Respiratory Protection: Use organic vapor cartridge type respirator if ventilation is inadequate.

Work / Hygienic Practices: Wash thoroughly after handling. Have eye-wash facilities immediately available.

***IMPORTANT***

While seller believes that the information contained herein is accurate, such information is offered solely for its

customers’ consideration and verification under their specific use conditions. This information is not deemed a

warranty or representation of any kind for which seller assumes legal responsibility.

24-Hour Emergency #: (U.S.) (800) 535-5053 • (Outside U.S.) (352) 323-3500

14 MATERIAL DATA SAFETY SHEET