INDEX

1. INTRODUCTION...........................................................................................4

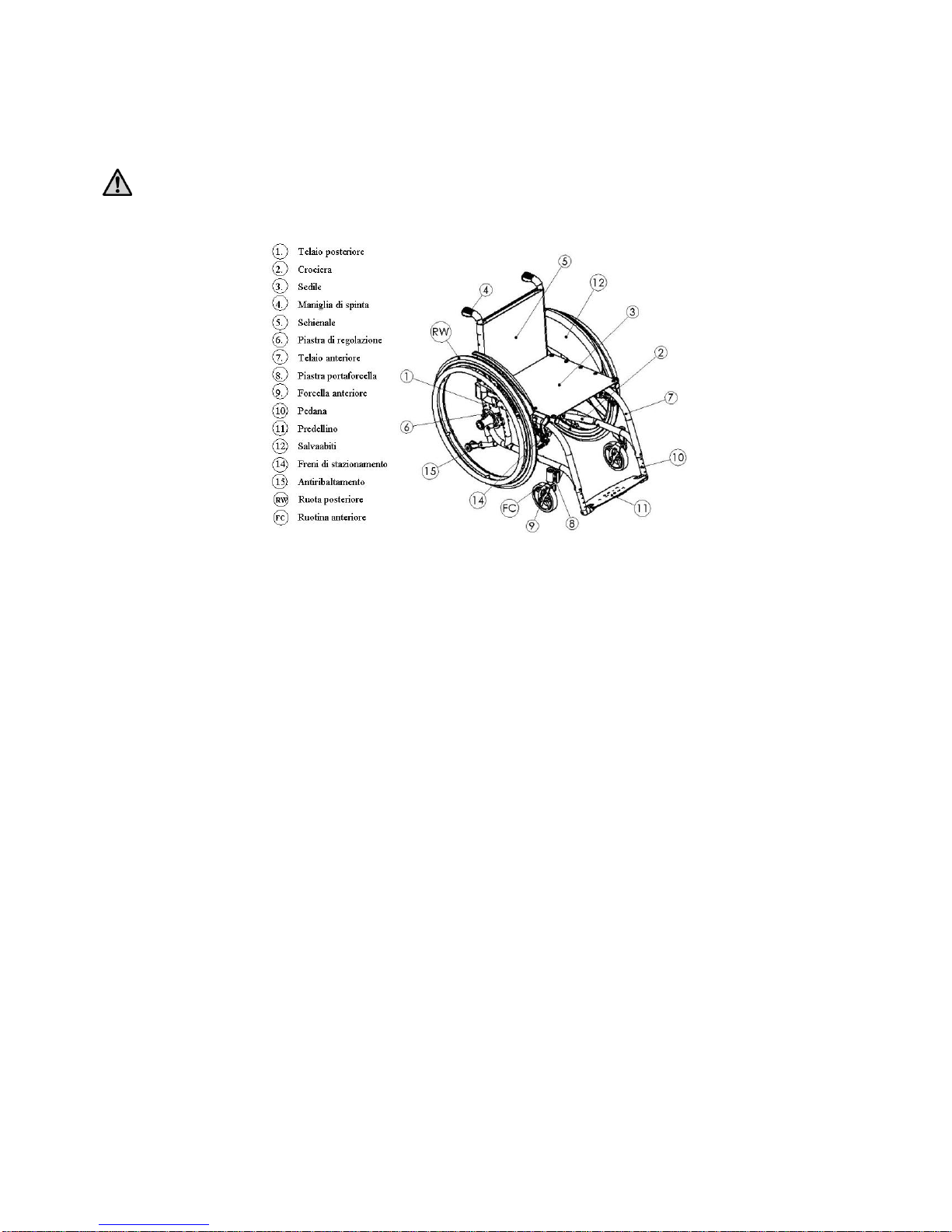

1.1 ALHENA DESCRIPTION..............................................................................................4

1.2 FEATURES ALHENA ..................................................................................................5

2. PREPARATION FOR USE............................................................................6

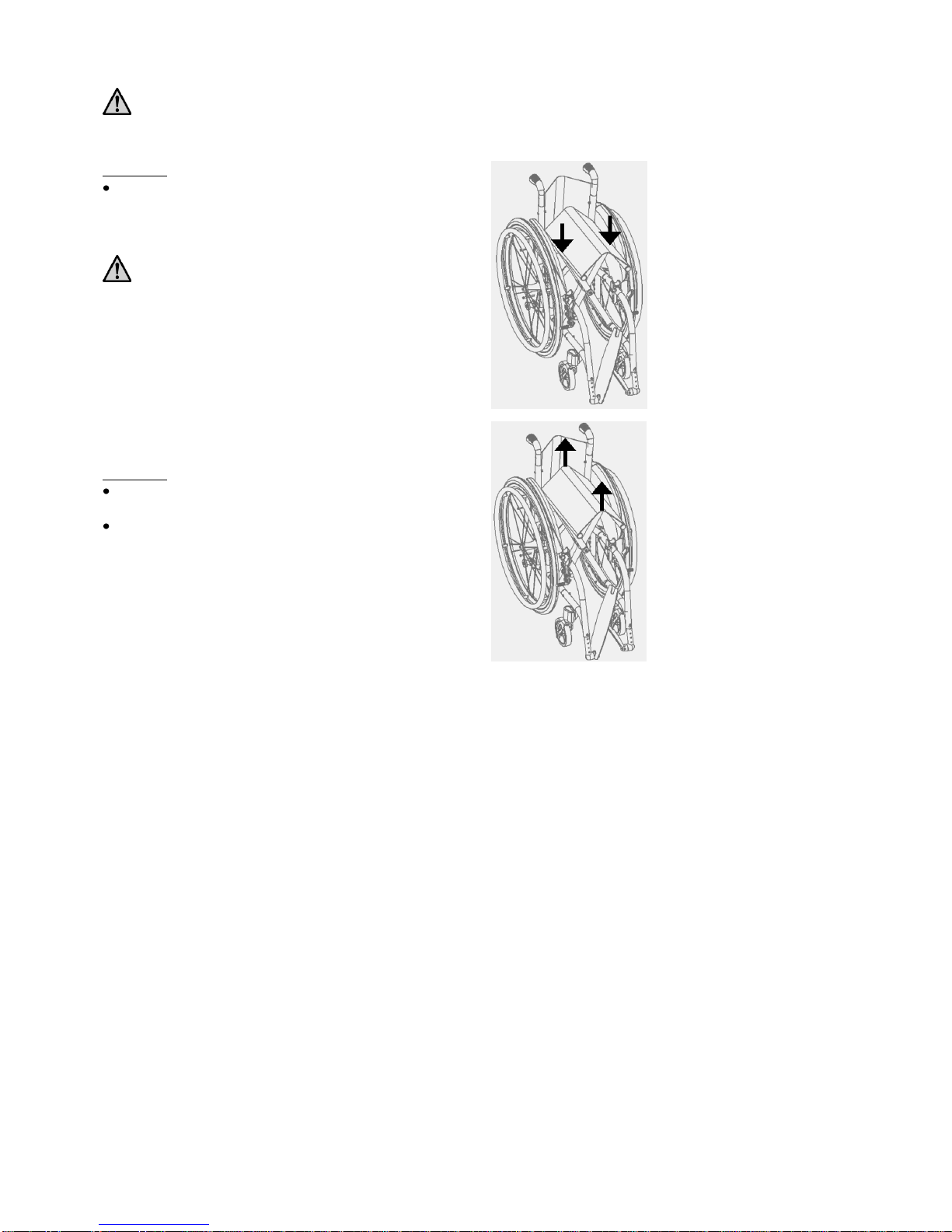

2.1 OPENING/FOLDING OF THE ALHENA WHEELCHAIR ........................................................6

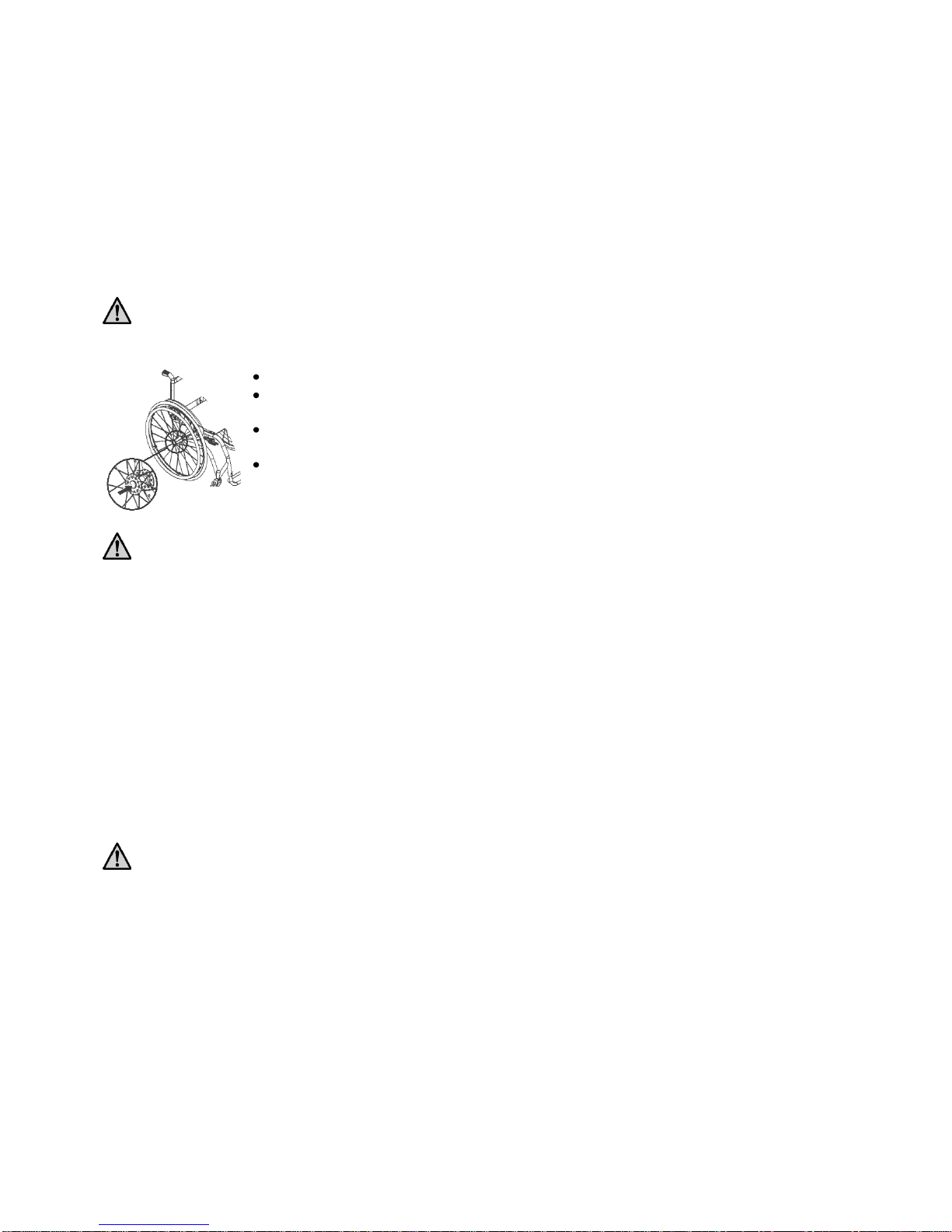

2.2 REAR WHEELS ASSEMBLY AND RELEASE.......................................................................7

2.3 PNEUMATIC PRESSURE CHECK......................................................................................7

2.4 FOOTREST POSITIONING ...............................................................................................7

2.5 CHECKING THE BRAKES ...............................................................................................8

2.6 CHECKING THE ACCESSORIES .......................................................................................9

3. SETTING UP ALHENA...............................................................................10

3.1 SELECTION OF THE REAR HEIGHT SEAT AND GRAVITY CENTER. ...................................10

3.2 SETTING THE FRONT HEIGHT OF THE SEAT...................................................................11

3.3 SETTING THE PERPENDICULARITY OF THE FRONT FORK SUPPORT PLATE.......................11

3.4 CLOTH-GUARDS SETUP...............................................................................................12

3.5 SETTING AND MAINTENANCE OF BRAKES....................................................................12

3.6 ADJUSTMENT OF THE BACKREST TENSION...................................................................13

3.7 BACKREST HEIGHT ADJUSTMENT................................................................................13

3.8 HIGTH ADJUSTABLE PUSHING-HANDLE .......................................................................13

3.9 DISTANCE FROM FOOTPLATE TO SEAT ADJUSTMENT....................................................13

3.10FOOTPLATE INCLINATION ADJUSTMENT......................................................................14

3.11WHEEL CAMBER ADJUSTMENT ...................................................................................15

4. ARMREST.....................................................................................................16

4.1 SPORT TIP UP AND DETACHABLE ARMREST .................................................................16

4.2 “L” TYPE ARMREST....................................................................................................16

5. ANTI-TIP DEVICE......................................................................................18

5.1 USE OF THE REVOLVING ANTI-TIP DEVICE...................................................................18

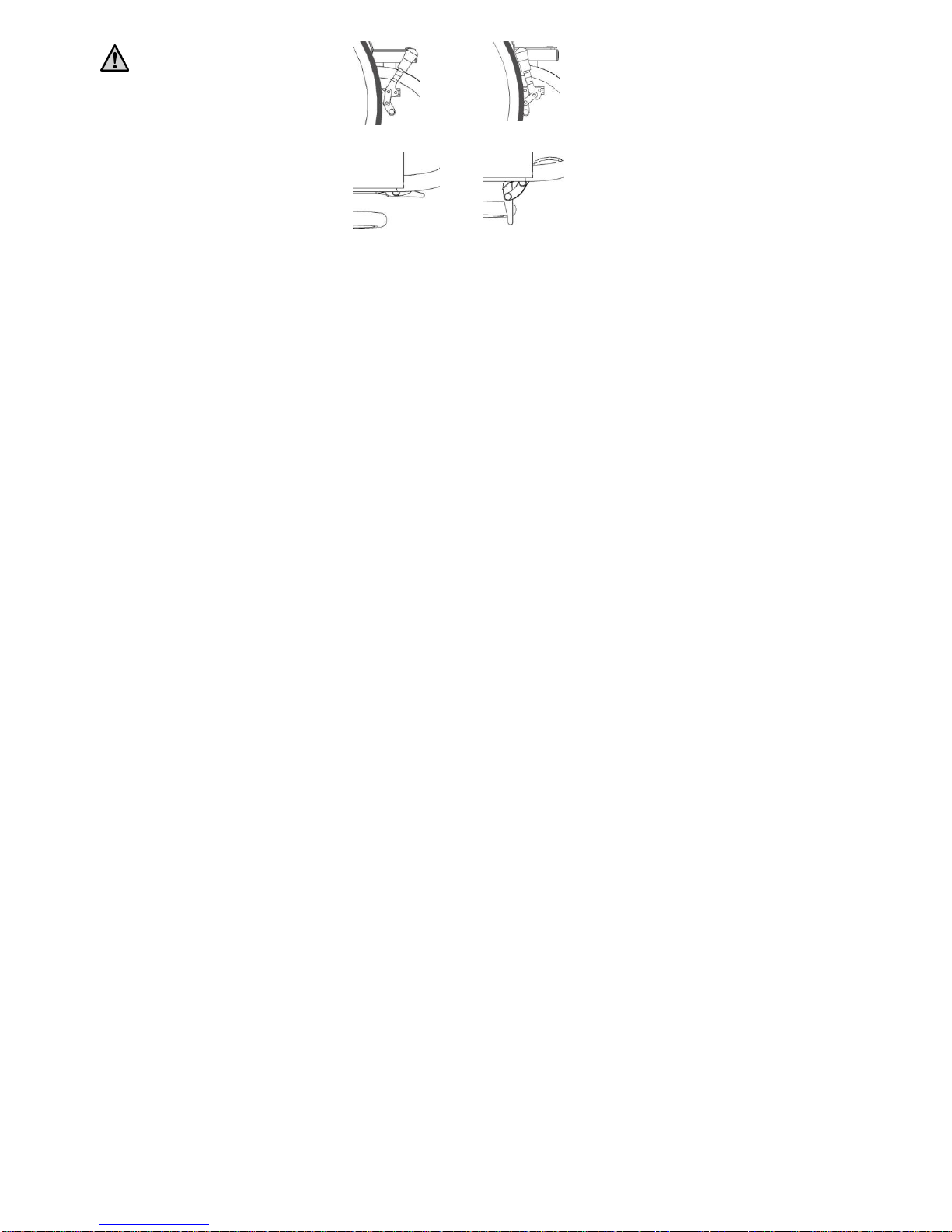

5.2 ADJUSTMENT OF THE ANTI-TIP DEVICE .......................................................................19

5.2.1 Adjustment through the rotation of the support plate...19

5.2.2 End terminal adjustment...............................................19

6. UMBALANCING SYSTEM.........................................................................20

7. EXTENDED WHEEL PLATE.....................................................................20

8. STRETCHED BAR.......................................................................................20

9. USE OF THE WHEELCHAIR....................................................................20

10. KEY MEASURES TO BE TAKEN TO LIMIT THE RISKS ASSOCIATED WITH MISUSE OF THE

WHEELCHAIR.............................................................................................22

11. MAINTENANCE, INSPECTIONS AND CONTROLS.............................23

12. TECHNICAL SERVICE..............................................................................24

13. GUARANTEE TERMS ................................................................................25

14. PACKAGING, SHIPPING AND DELIVERY ...........................................26

15. MATERIALS DIFFERENTIATION ..........................................................27