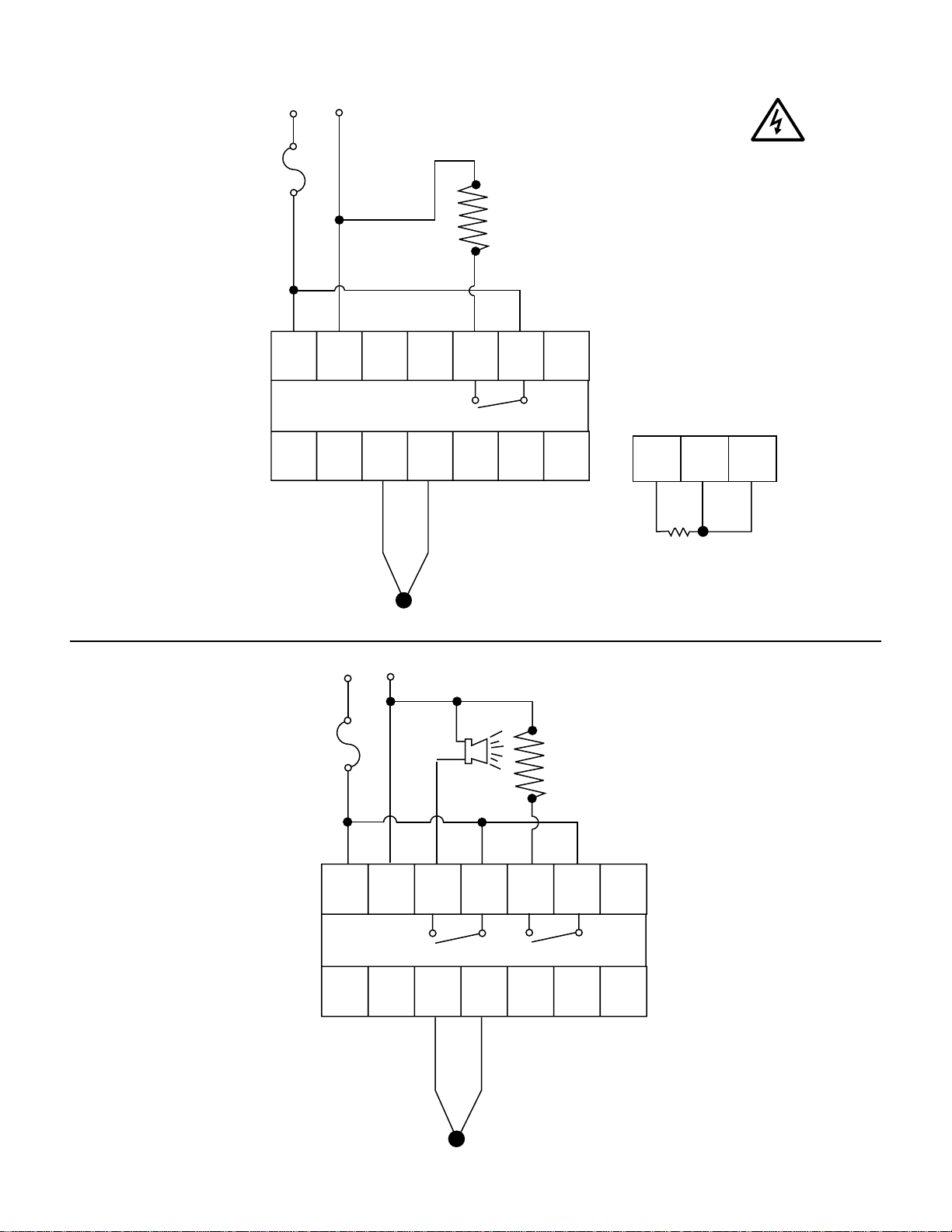

Wiring Precautions:

•Before wiring, verify the label for correct model num-

ber and options. Switch off the power when checking.

•Care must be taken to ensure that maximum voltage

ratings specified in Section 3 on previous page are

not exceeded.

•It is recommended that power to these instruments

be protected by fuses and circuit breakers rated at

the minimum value possible.

•All units should be installed inside a suitably ground-

ed metal enclosure to prevent live parts being acces-

sible to human hands and metal tools.

•All wiring must conform to appropriate standards of

good practice, national and local codes and

regulations. Wiring must be suitable for the maximum

voltage, current, and temperature ratings expected in

the system.

•Take care not to over-tighten the terminal screws.

•Unused control terminals should not be used as

jumper points as they may be internally connected,

causing damage to the unit.

•Verify that the ratings of the output devices and the

inputs as specified on page 3 are not exceeded.

•Electric power in industrial environments contains a

certain amount of noise in the form of transient volt-

ages and spikes. This electrical noise can enter and

adversely affect the operation of microprocessor-

based controls. For this reason we strongly recom-

mend the use of shielded thermocouple extension

wire which connects from the sensor to the controller.

This wire is a twisted-pair construction with foil wrap

and drain wire. The drain wire is to be attached to

earth ground at the sensor end only. We carry both

type J and type K in our stock.

RISK OF ELECTRIC SHOCK - Dangerous and poten-

tially fatal voltages are present when working on this

equipment. Before installation or beginning any trou-

bleshooting procedures, the electric power to this equip-

ment must be disconnected and locked out as described

by OSHA Standards. Units suspected of being faulty

must be removed and returned to Ogden for inspection

and/or repair. They contain no user serviceable compo-

nents.

To help minimize the possibility of fire or shock hazards,

do not expose this instrument to rain or excessive

moisture. This control is not to be used in hazardous

locations as defined in Articles 500 and 505 of the

National Electric Code.

Do not use this instrument in areas subject to

hazardous conditions such as excessive shock,

vibration, dirt, moisture, corrosive gases or oil. The

ambient temperature of the areas should not exceed

the maximum rating specified in Section 3, on previous

page.

Unpacking:

Upon receipt of the shipment inspect the unit for ship-

ping damage. If any damage due to transit is noticed,

report and file a claim with the carrier. Write down the

model number and serial number for future reference

when corresponding with our service center. The serial

number is located on the housing of the control.

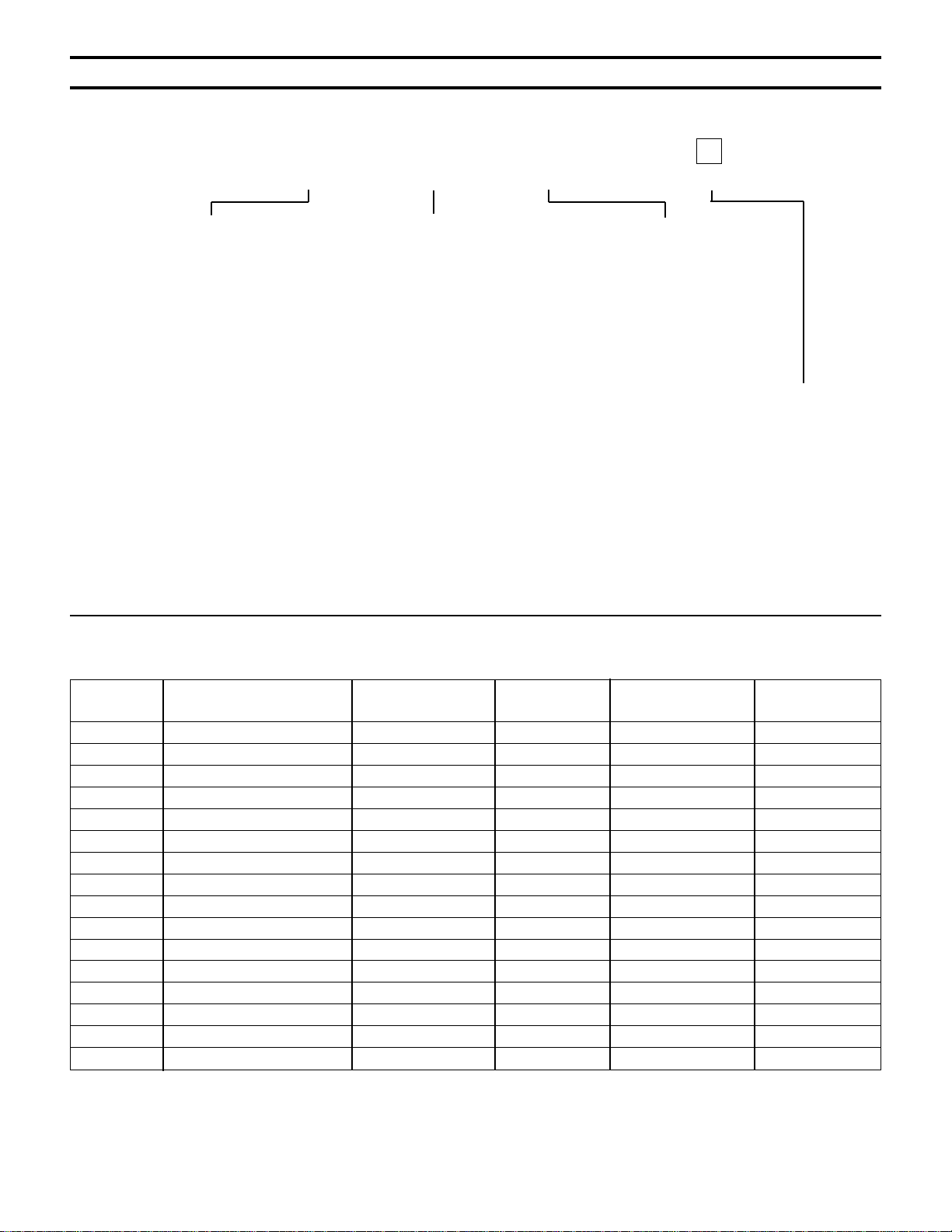

Mounting:

Make panel cutout to dimensions shown below. Insert

the controller into the panel cutout. The maximum

panel thickness is 1⁄8" (3.2mm).

Section 4: INSTALLATION