8

T

TA

AB

BL

LE

E

O

OF

F

C

CO

ON

NT

TE

EN

NT

TS

S

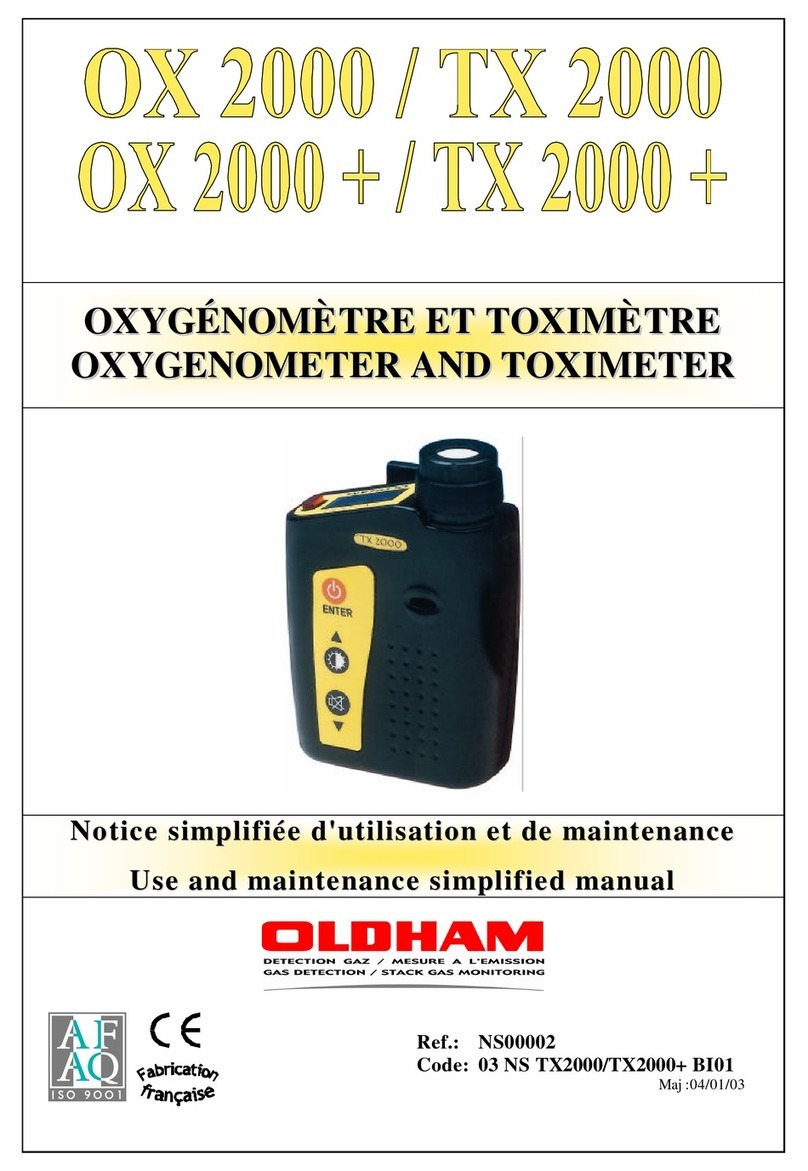

I. PRESENTATION....................................................................................................................9

1. POWER SUPPLY -OX/TX2000 VERSION.......................................................................9

1.1. Fitting or replacement of dry batteries:......................................................................10

2. POWER SUPPLY –OX/TX2000+ VERSION..................................................................10

2.1. Replacement of dry batteries......................................................................................10

2.2. Reinitialization of the dry batteries "controller".........................................................11

3. MEASUREMENT SENSOR (toxic or oxygen) .................................................................11

3.1. Presentation................................................................................................................11

3.2. Fitting or replacement.................................................................................................11

4. CARRIAGE OF THE TX2000(+) / OX 2000(+)................................................................12

II. USE ........................................................................................................................................12

1. OPERATING THE INSTRUMENT.................................................................................12

2. DATA GIVEN BY THE DISPLAY ...................................................................................13

3. SWITCHING ON.................................................................................................................13

4. SWITCHING OFF...............................................................................................................14

5. ILLUMINATION.................................................................................................................15

6. SCROLLING THE PARAMETERS..................................................................................15

6.1. Manual acknowlegment of « MINI » et « MAXI »....................................................16

7. THE ALARMS .....................................................................................................................17

8. CLEARING THE ALARMS...............................................................................................20

III. MAINTENANCE AND SERVICING ..................................................................................21

1. MAINTENANCE .................................................................................................................21

2. PROGRAMMING................................................................................................................22

3. CALIBRATION ...................................................................................................................23

3.1. Calibration procedure.................................................................................................23

3.2. Adjusting the zero in clean air (only for toximeter version) ......................................23

3.3. Adjusting the sensitivity .............................................................................................24

4. SENSOR REPLACEMENT................................................................................................26

IV. ACCESSORIES.....................................................................................................................26

V. SPARE PARTS LIST ............................................................................................................27

VI. LIST OF THE DIFFERENTS SENSORS ..........................................................................28

VII. TECHNICAL DATA .............................................................................................................29

1. GAS DETECTOR ................................................................................................................29

2. SENSORS..............................................................................................................................32

2.1. Interferents :................................................................................................................33

VIII. "HBCO" VERSION .........................................................................................................34

1. With direct reading in "ppm CO" or "% COHB"...........................................................34

2. Preparation of the patient....................................................................................................34