Content:

1.+INTRODUCTION+................................................................................................................................+3!

2.+SYMBOLS+AND+ABBREVIATIONS+.......................................................................................................+3!

3.+TOUCH+SCREEN+MANUAL+.................................................................................................................+4!

3.1!OPENING!SCREEN!...................................................................................................................................!4!

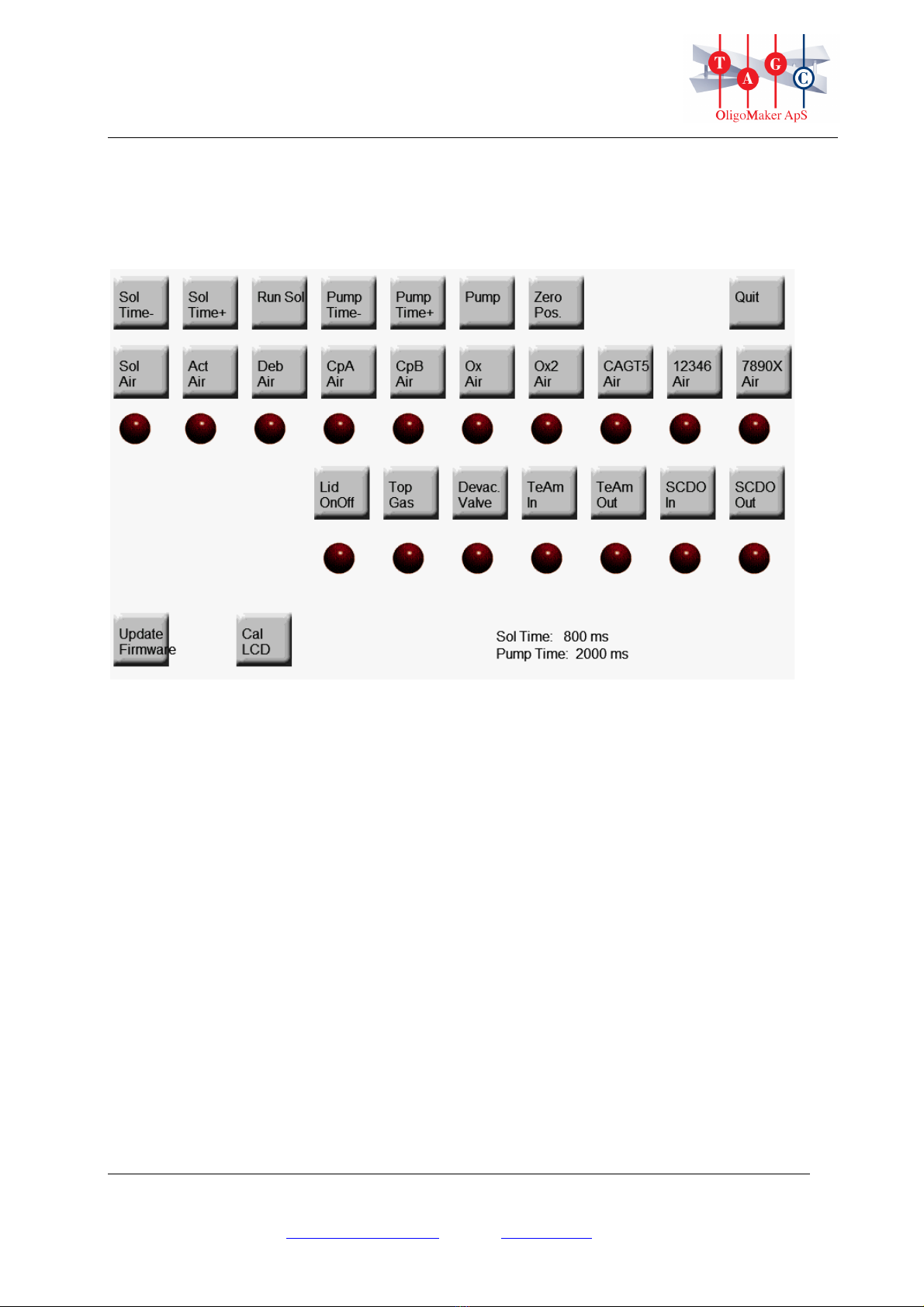

3.2!MANUAL!CONTROL!.................................................................................................................................!5!

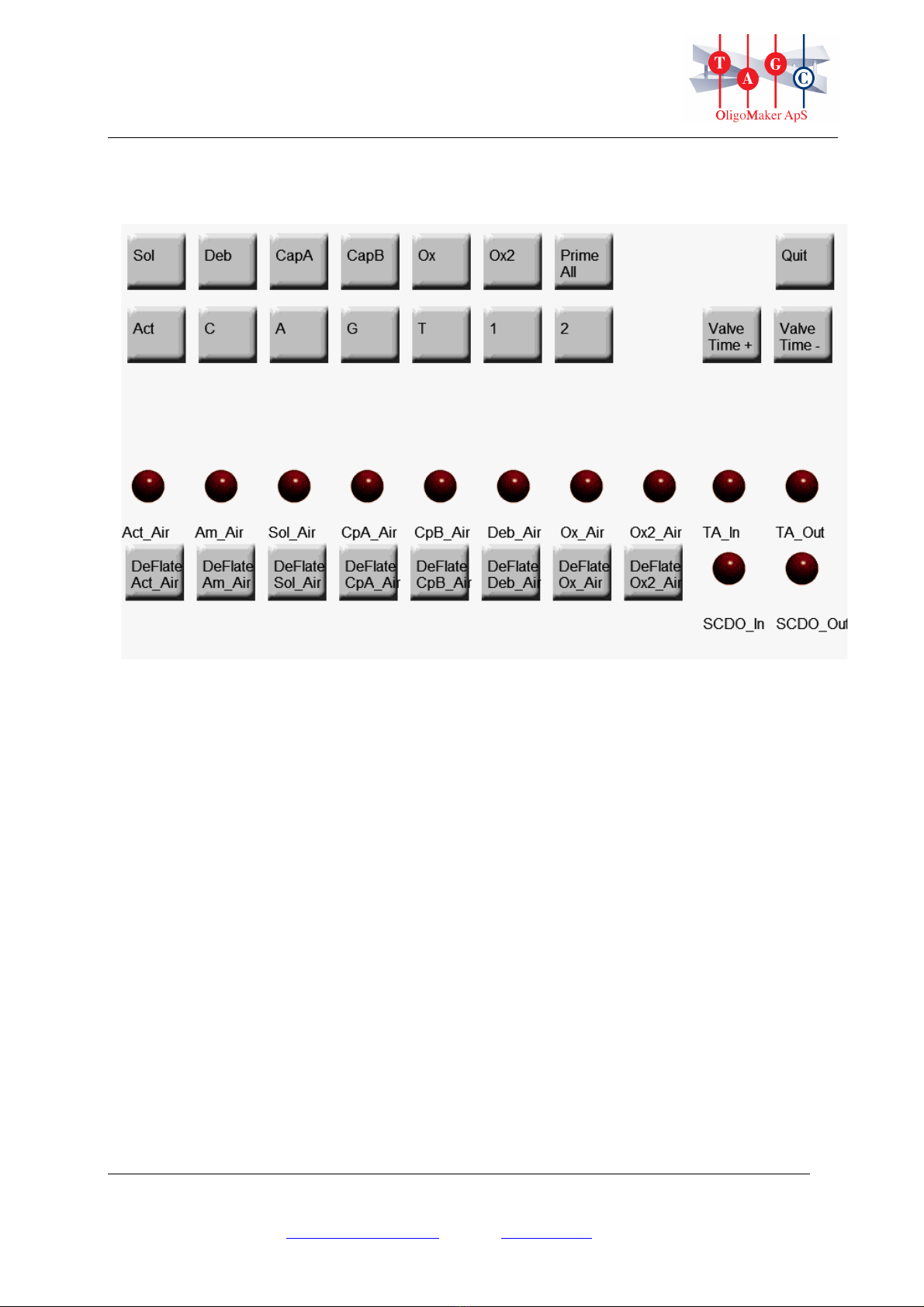

3.3!PRIMING!...............................................................................................................................................!7!

3.4!GET!DATA!.............................................................................................................................................!8!

3.5!SYNTHESIS!.............................................................................................................................................!9!

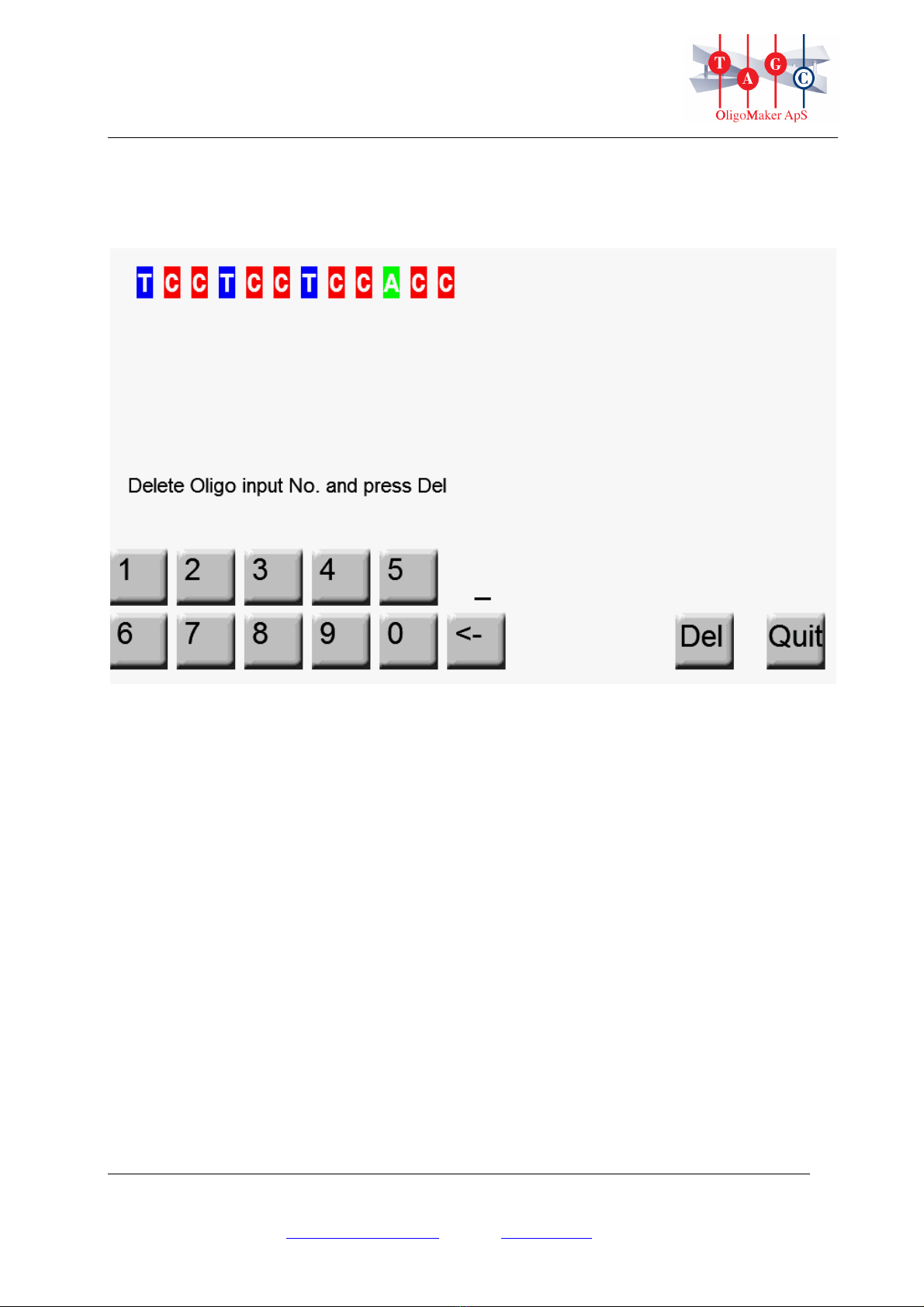

3.6!DELETE!OLIGO!.....................................................................................................................................!10!

4.+TERMS+............................................................................................................................................+11!

5.+APPLICATION+.................................................................................................................................+11!

6.+SAFETY+...........................................................................................................................................+12!

7.+TRANSPORTATION+.........................................................................................................................+13!

8.+INSTALLATION+................................................................................................................................+13!

8.1!A!QUICK!GUIDE!....................................................................................................................................!14!

9.+SYNTHESIS+START+-+A+USERS+GUIDE+................................................................................................+16!

9.1!CONTROL!OF!COLUMNS!.........................................................................................................................!16!

9.2!CHECK!REAGENTS!.................................................................................................................................!17!

9.3!PRIMING!.............................................................................................................................................!18!

9.4!REAGENT!PRESSURE!AND!VACUUM!TEST!...................................................................................................!18!

9.5!STARTING!THE!BASIC!SYNTHESIS!...............................................................................................................!19!

9.6!END!SYNTHESIS!....................................................................................................................................!19!

9.7!REMOVING!COLUMNS!FROM!THE!REACTION!BLOCK!....................................................................................!19!

10.+SYNTHESIS+PROTOCOL+..................................................................................................................+20!

11.+MAINTENANCE+.............................................................................................................................+25!

12.+SERVICE+........................................................................................................................................+26!

12.1!SERVICE!HOLDER!POSITION!...................................................................................................................!26!

12.2!REMOVING!THE!U-PIN!.........................................................................................................................!27!

12.3!CHANGING!A!VALVE!............................................................................................................................!28!

13.+SPARE+PARTS+................................................................................................................................+29!

14.+DECLARATION+OF+CONFORMITY+...................................................................................................+31!

+