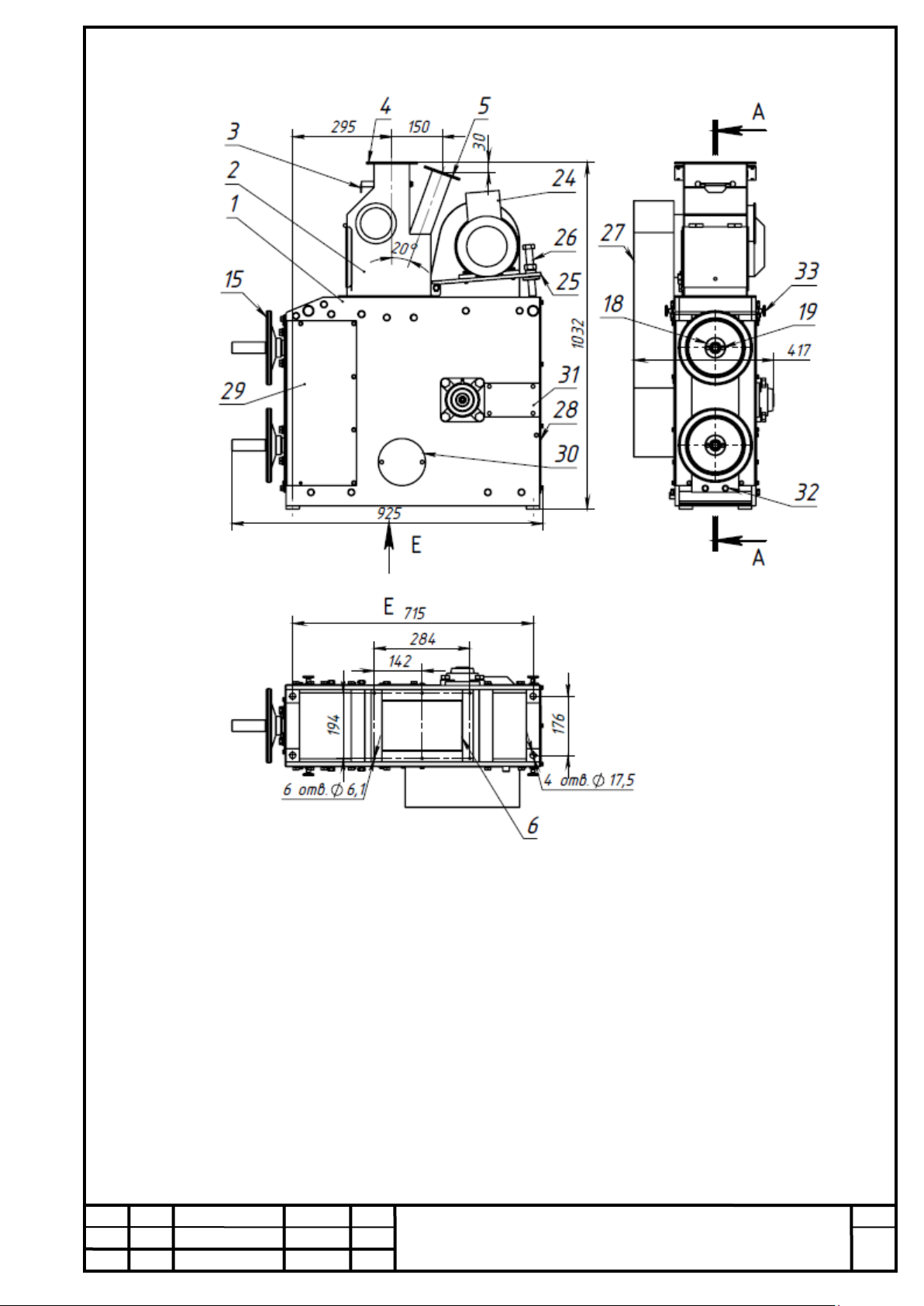

1.3. Product Structure

The Product (see Fig. 1) consists of a bed 1, a feed unit 2 with a regulating valve 3,

a grain supply duct 4, an aspiration duct 5. There is a duct 6 on the bed for feeding out

the processed material, on bearings 7 there is an operating roller 8, on bearings 9 there is

an axis 10 with levers 11 to which the body 12 is fixed with the head 13, equipped with a

working clearance adjustment mechanism consisting of screws 14, nuts 15 with

flywheels and bearings 16 fixed to the rack 17, lock nuts 18 with fixing bolts 19. The

head is secured to the frame with bolts 20. Installed on the axis of the working roller

there is a pulley 21 connected to a belt 22 with a pulley 23 of the electric motor 24

secured on the motor-mounting plate 25 with a screw 26 of a belt drive tension protected

by a mantle 27. The bed apertures are closed by covers 28, 29, 30, and cover plates 31.

The rack to the bed is secured with bolts 32. The bed has hooks 33 for carrying out

rigging works.

The working roller is made of abrasive material; so is the head for buckwheat

processing, the head for millet processing is made of rubber.

No engineering changes or modifications to the Product are allowed without

the manufacturer’s agreement.

1.4. Product Operation

The Product operates as follows. The slide valve and gate valve 3 (see Fig. 1) of

the bunker are opened, grains for processing are fed from the operational bunker of the

processing line to the feed unit 2 where the grains are distributed over the entire width of

the feed unit, and there takes place dosing of the grains which are fed into the operating

area between the roller and head. An emergency stop of the grain supply, if necessary, is

performed by the gate valve 3. Through the aspiration channel 5, located in the rear part

of the feed unit, air is sucked out with small and light impurities, and both the roller and

head surfaces are cooled.

In the operating area between the roller and the head, grains are hulled. The grains

processed in the operating area are taken out of the machine through the outlet 6. In the

process of movement from the operating area to the output nozzle, the grains are blown

by aspiration air flow; light impurities, hulls, and husking bran are taken out through the

aspiration channel 5 of the feeder to the aspiration system.

The working clearance is regulated by screws 14 and nuts 15. Fixing the required

position of the head is carried out by the lock nuts 18 and the locking bolts 19.

By gravity, the processed grains from the outlet nozzle 6 enter the regular

workshop utilities of the pneumatic conveyor system or gravity handling for the

following operations, in accordance with the workshop technological scheme.