Thank you

Thanks for purchasing this product. The product will help you exercise your muscles in

the correct way and to improve your fitness – and all this in a familiar environment.

Precautions

WARNING: This elliptical trainer has been designed and constructed to provide maximum

safety. Nevertheless, certain precautions should be taken when using exercise equipment.

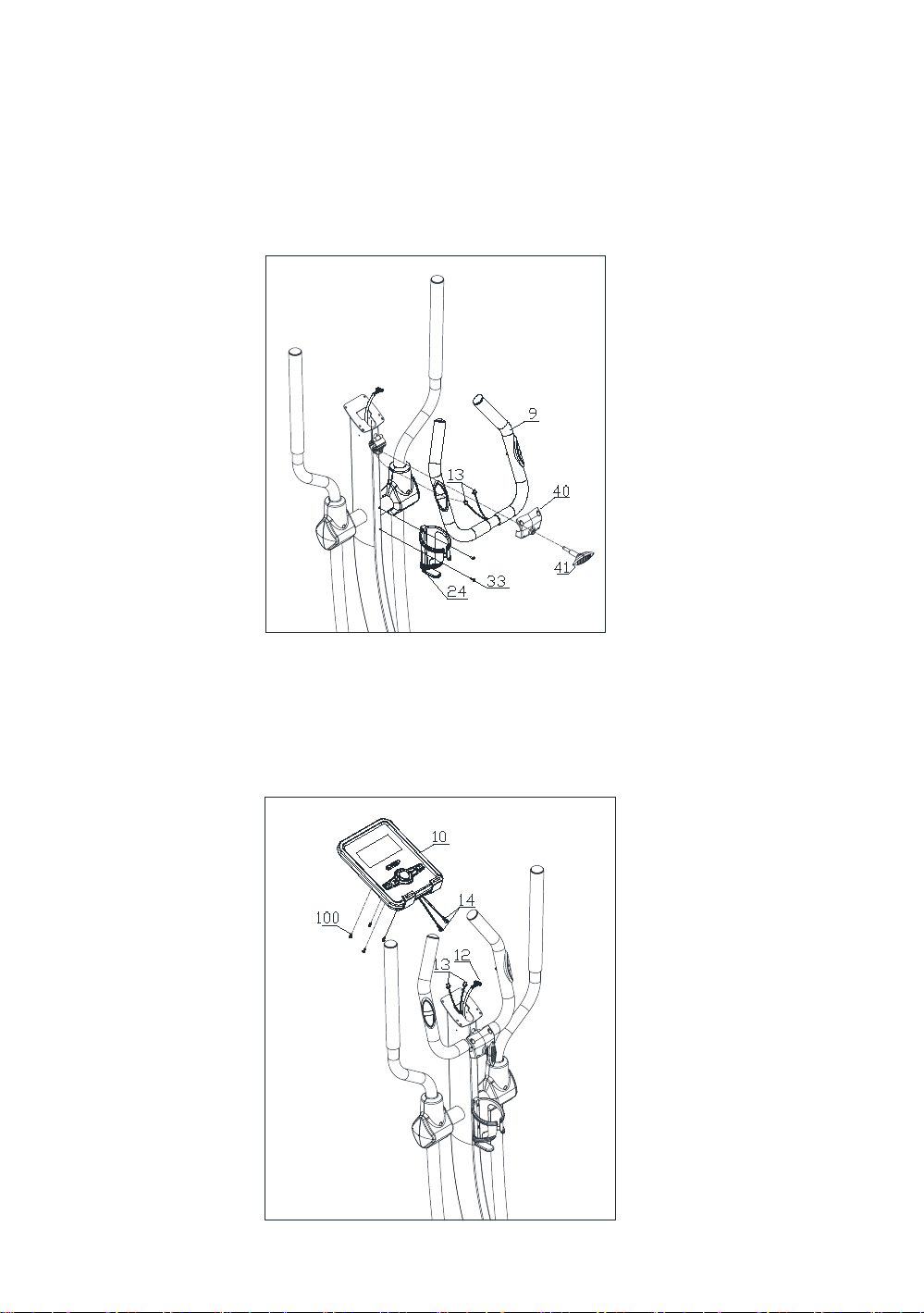

Read the whole manual before assembling and using the elliptical trainer. The following

safety precautions should also be observed:

◆It is the responsibility of the owner to ensure that all users of the elliptical trainerare

adequately informed of all precautions. Use the elliptical trainers only as described in

this manual.

◆Keep children and pets away from this equipment at all times. DO NOT leavethem

unsupervised in the room where this elliptical trainer is kept.

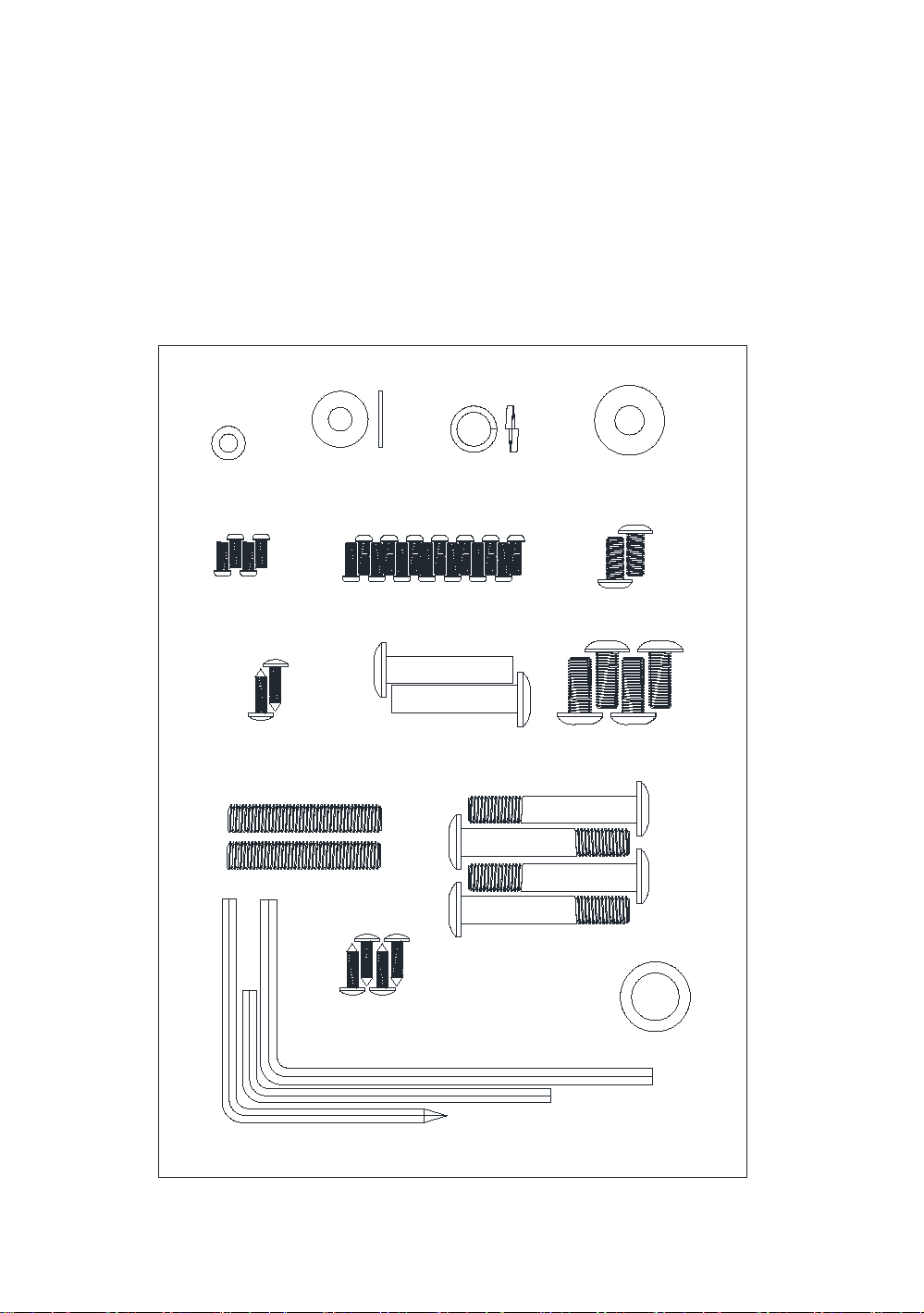

◆Inspect and assemble all parts regularly. Replace and worm parts immediately.

◆Place the elliptical trainer on a level surface, with at least 1.0 m of clearance on each

side of elliptical trainer. To protect the floor or carpet from damage, place a mat under

the ellipticaltrainer.

◆Keeptheellipticaltrainerindoors,awayfrommoistureanddust.Maintaintheusing

place ventilation. DO NOT use it in the airless place.

◆Don’t put any sharp things around the ellipticaltrainer.

◆Wear appropriate clothes while exercising; do not wear loose clothes that could

become caught on the elliptical trainer. Always wear athletic shoes for foot protection

whileexercising.

◆Donotusethisproductifmorethan150kgofweights.Pleasechooseourotherseries

of elliptical trainers.

◆Do not put your hands on the moving parts to preventinjures.

◆Keep your pedaling speed in a controlledway.

◆If you find your elliptical trainer works abnormal, do not use itimmediately.

◆No more than one person should operate the elliptical trainer at onetime.

◆If you feel pain or dizziness while exercising, stop exercising immediately and askfor

adoctor.