EMD Installation and operating manual

2 www.omega-air.si

Description

EMD series drains are electronically controlled condensed water drains that discharges

water trapped in the lowest parts of compressed air installation out of the system. This

water is a condensed water vapor that is always present in the atmosphere. Because of laws

of physics, some vapor always condenses during compression of air.

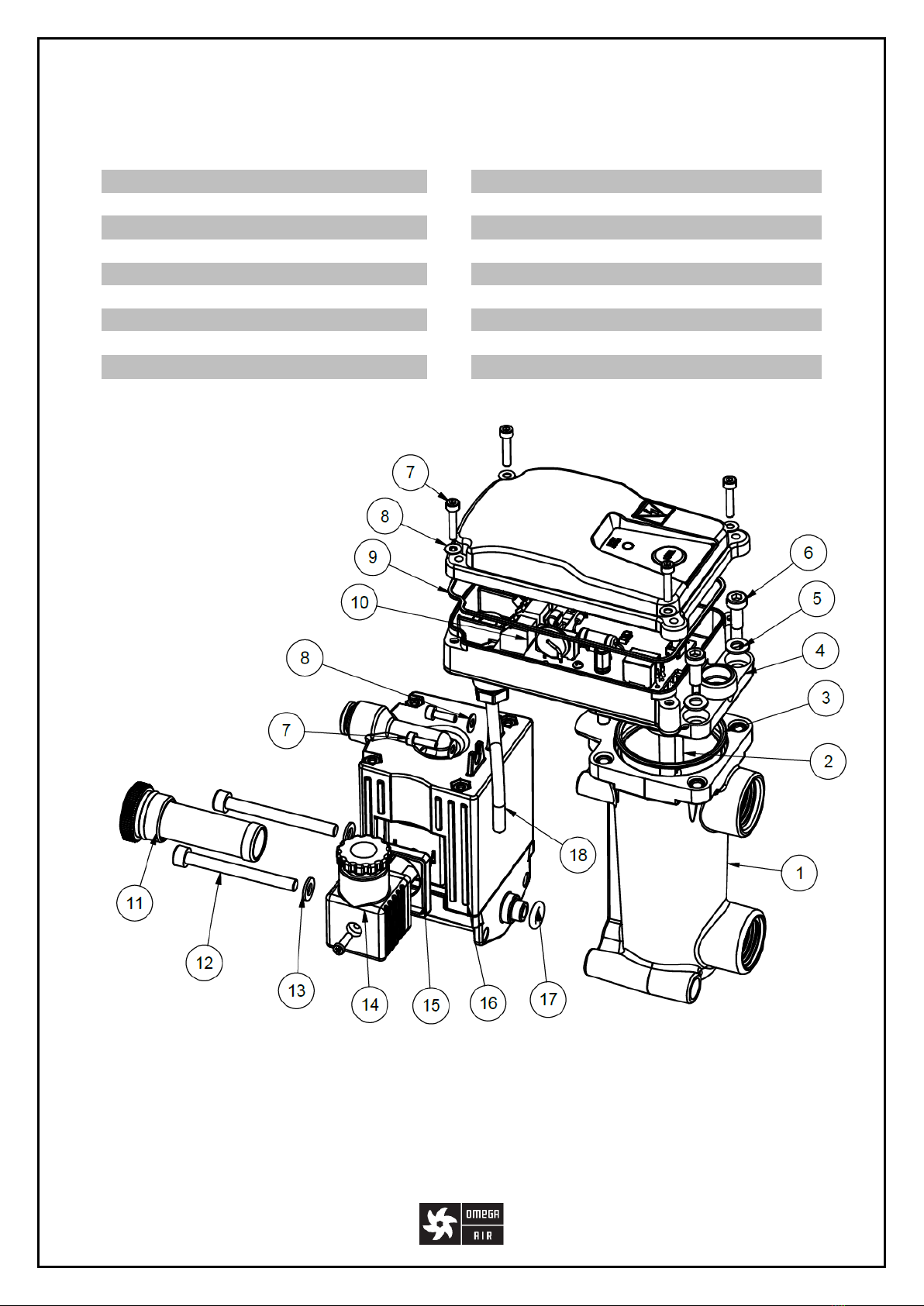

The EMD series drains consists of a water tank, valve assembly and electronics. The water

tank should be the lowest part of the compressed air system where condensed water

collects. In the tank, there is a water level sensor. This way, electronics could detect the tank

is full. Then, it operates the electromagnetic valve to discharge condensed water from

compressed air system. The valve is located in the valve assembly which is constructed so,

that it can be replaced easily. Another part of the valve assembly is a strainer where solid

parts of debris are intercepted. The strainer is located in front of EMD so that it could be

reached easily.

In the condensed water leaving the EMD, there are still small particles of rust and remains of

compressor oil. Oil must be removed before the water is drained to sewage system. To

remove oil, water-oil separator WOS or WOSm device could be used.

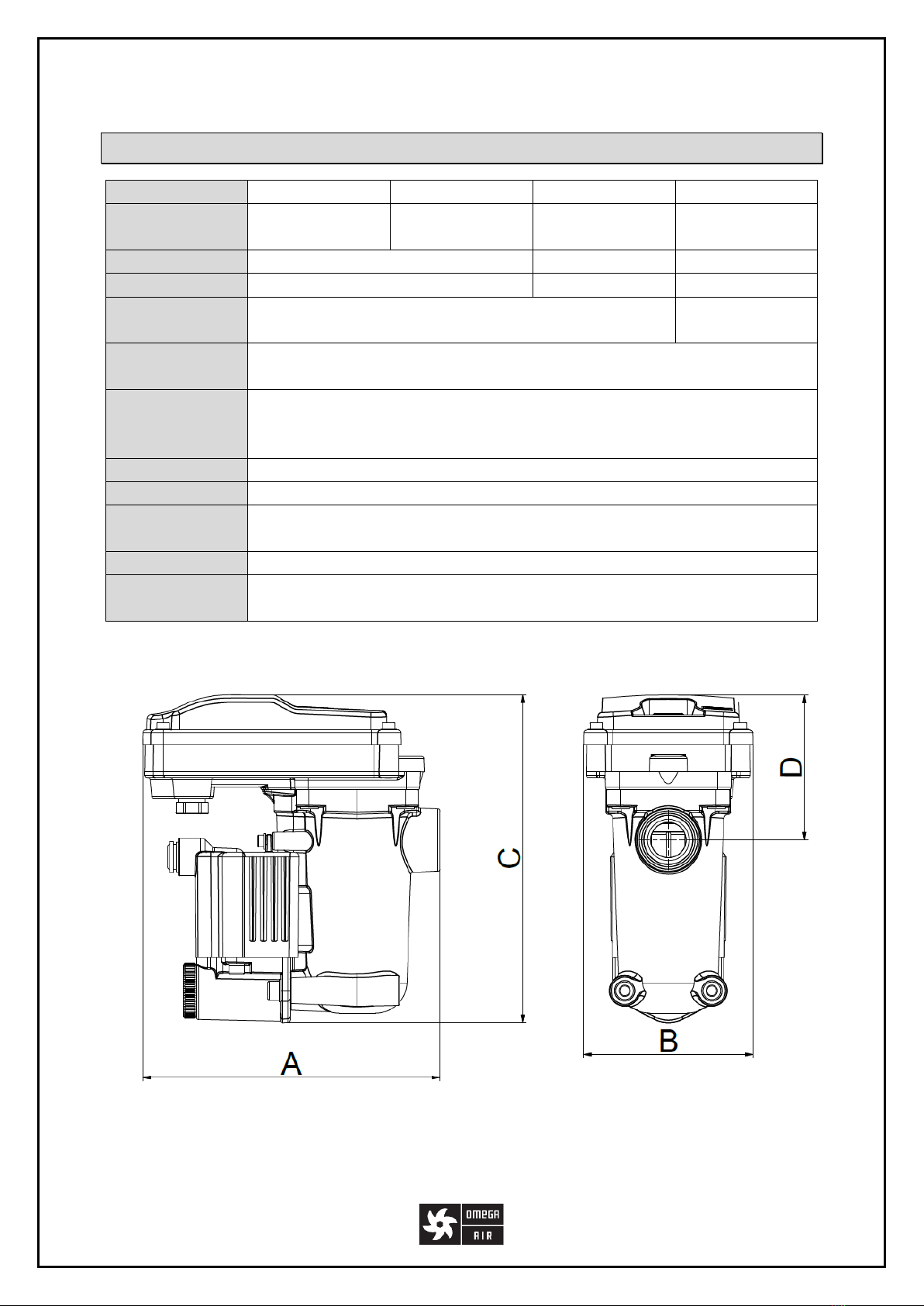

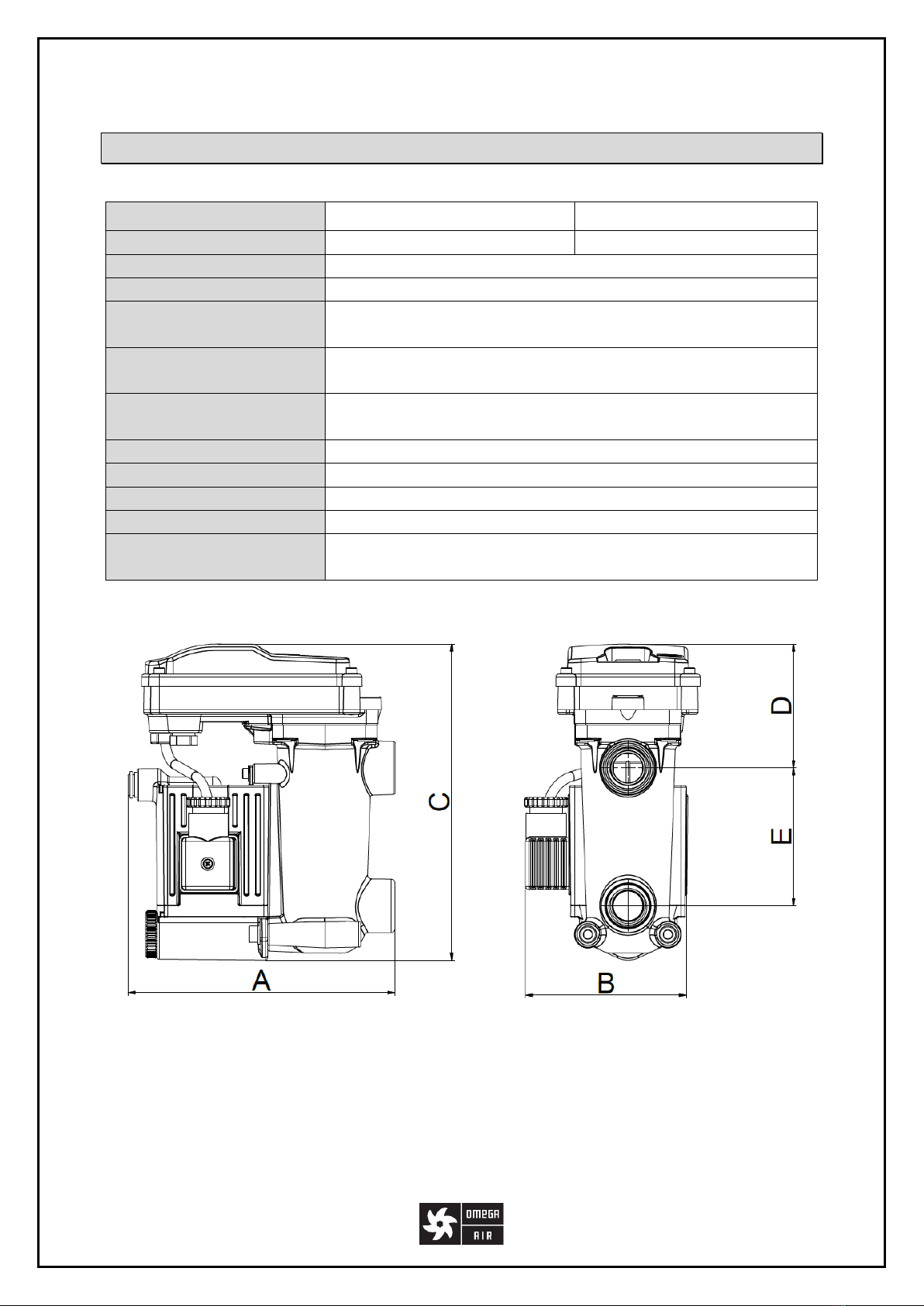

Because of its construction, the EMD could be attached to the compressed air system

horizontally or vertically. Under the pressure vessel or under the refrigerator dryer, the EMD

is fixed horizontally whereas under filters, it is more convenient to fix it vertically.

The valve is operated by electronics. It opens the valve when a button on the electronics

cover is pressed or when water level in the tank reaches threshold. Occasionally, a timed

venting mode that combines water level triggered discharging and timed venting is desired.

By pressing the test button, we could see if EMD is operational. Besides, the test button

makes possible to discharge water that has collected in a system during maintenance

manually.

The main mode of operation is a water level triggered discharging. The valve opens when

water level in EMD’s tank reaches threshold and it closes back before the tank is empty. This

way, only condensed water is discharged and no compressed air is lost.

In the timed venting mode, the valve is opened when water level reaches threshold, too.

Besides, when the valve is closed continuously for a predetermined period, it is opened

shortly although there is no water in the tank. During working day, water in EMD collects

rapidly so that venting period would never expire and there are no air losses. When

production rests, EMD is opening its valve. But since these discharges are short and sparse,

air losses are small. The timed venting mode should be used when there is a lot of debris in

condensed water and piping upward the EMD could not be inclined enough. Such situation is

quite common under pressure vessels. It may happen that air could not escape from the

tank upward the piping and while there is air around water level sensor, the EMD would

never open. In the timed venting mode, the valve is opened after the venting period has

expired and trapped air is allowed to escape through drainage. Now, condensed water can

reach water level sensor and EMD is opening its valve until all collected water is discharged.