3OIPM#41100-TJ2

OPERATION

Raise saddle:

1.Locate and closerelease valve byturning knob

clockwise firmly, then pump the pump handle until

the load is contacted.

2.Followvehiclemanufacturersrecommended proce-

dures for removing the load as outlined in vehicle

service manual or repair guide.

3.Secure load withprovidedrestraints. Ensureload's

center of gravity is centered on the saddle and load

is stable before moving jack.

Lower saddle:

1.Slowly, gentlyturn the releasevalve knob

counterclockwise, NEVER MORE THAN 1/2 FULL

TURN until the load is completely lowered.

2.Immediately transfer theload to anappropriate

repair fixture.

Be sure all tools and personnel are clear before

lowering load. Dynamic shock loads are created by

quickly opening and closing the release valve as the

loadis being lowered.The resultingoverloadmay

cause hydraulic system failure.

MAINTENANCE

Important: Use only a good grade hydraulic jack oil.

Avoid mixing different types of fluid and NEVER use

brake fluid, turbine oil, transmission fluid, motor oil or

glycerin. Improper fluid can cause premature failure

of the jack and the potential for sudden and immediate

loss of load.

Addingoil

1. With saddle fully lowered, set jack in its upright,

levelposition. Remove oil fillerplug.

2. Fill until oil is level with the filler plug hole, reinstall

oil filler plug.

Changingoil

For best performance and longest life, replace the

complete fluid supply at least once per year.

1. With saddle fully lowered, set jack in its upright,

levelposition. Remove theoilfiller plug.

2. Lay the jack on its side and drain the fluid into a

suitablecontainer.

Note: Dispose of hydraulic fluid in accordance

with local regulations.

3. Set jack in its level upright position.

4. Fill with good quality jack oil. We recommend Mobil

DTE13 or equivalent.Reinstall oilfillerplug.

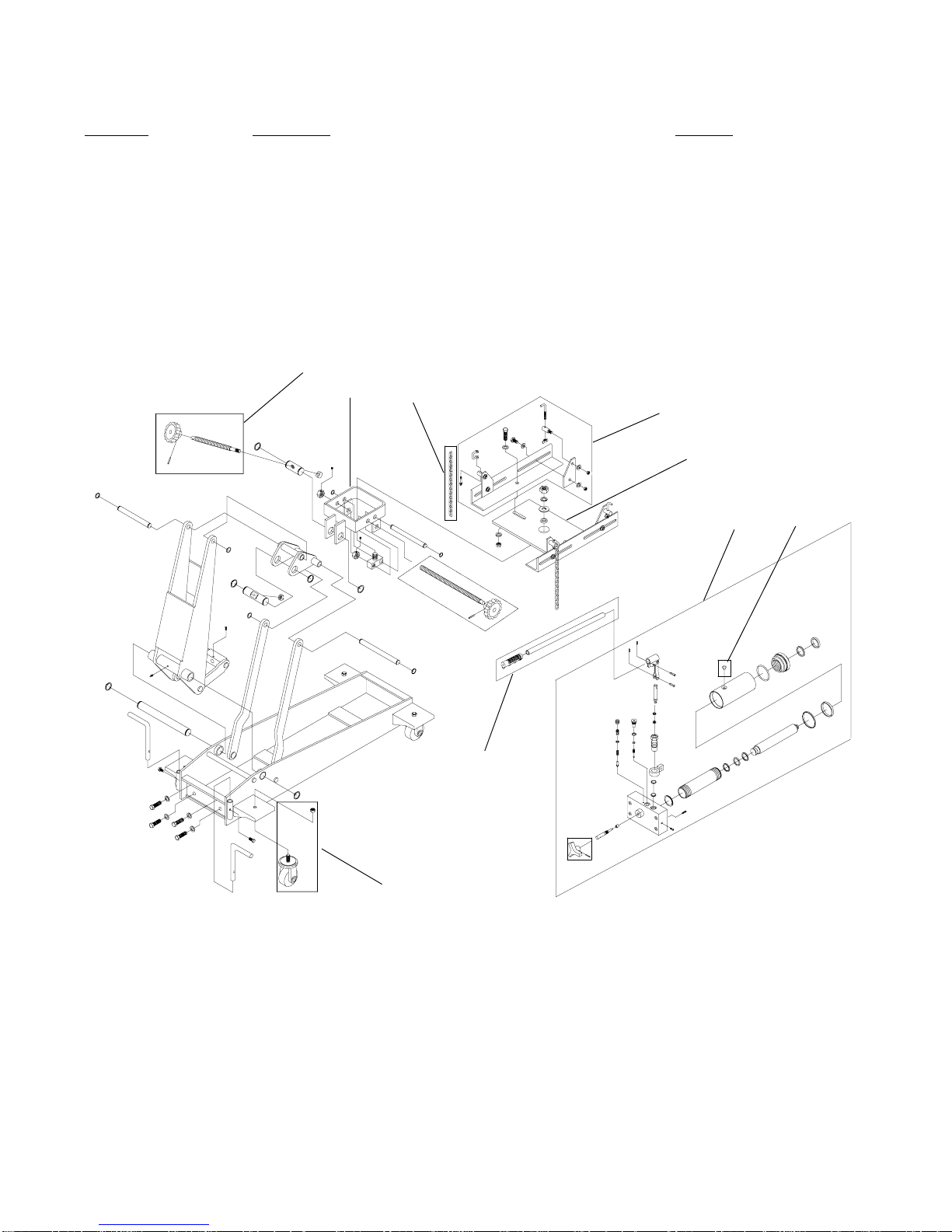

Lubrication

A periodic coating of light lubricating oil to pivot points,

axlesand hinges willhelp topreventrust andassure

thatwheels,casters and pumpassembliesmove

freely.

Cleaning

Periodically check the ram for signs of rust or

corrosion. Clean as needed and wipe with an oily

cloth.

Note: Never use sandpaper or abrasive material on

thesesurfaces!

Storage

When not in use, store the jack with pump piston and

saddlein lowest position.

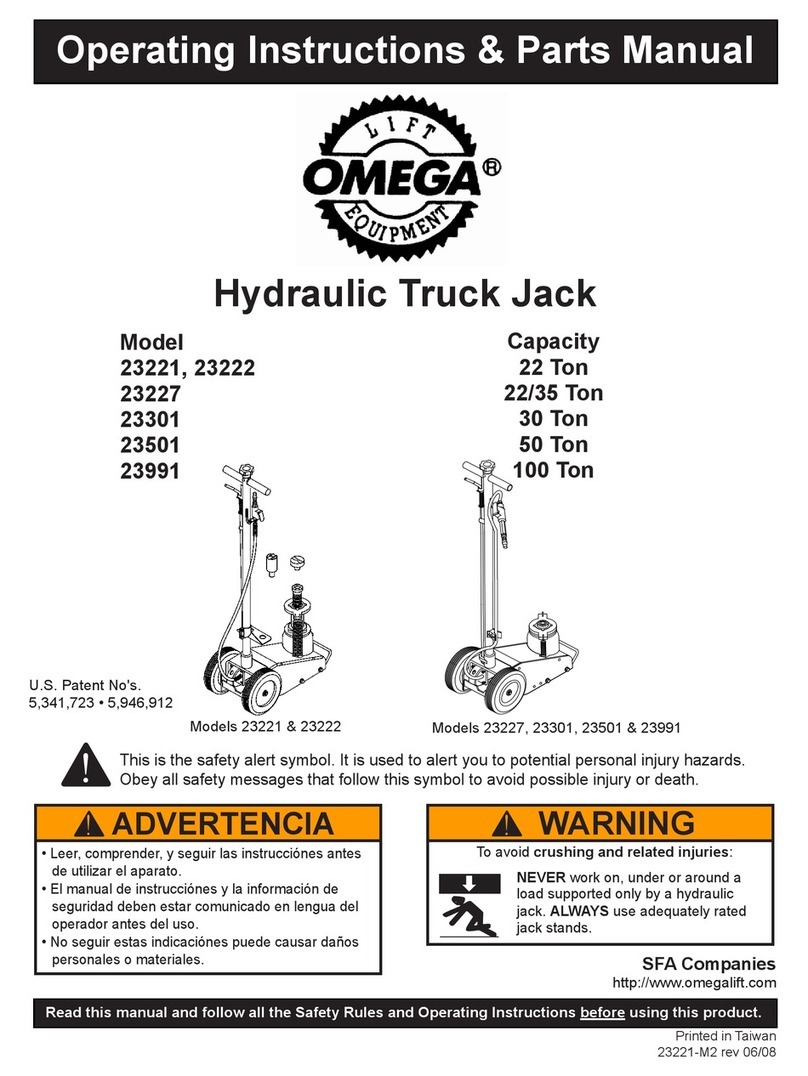

Study, understand,andfollow allprintedmaterials

provided with/on this device before use. Do not

exceed rated capacity. Use only on hard, level,

seamless surface. Use of this jack is limited to the

removal,installationand transportation of

transmissions,transfer cases andtransaxles.

Adequately support the vehicle before starting repairs.

Failure to heed these markings may result in personal

injury and/or property damage.

Ensure the center of gravity is centered on the saddle.

Use only chains and slings provided. If loaded jack

must be moved, make certain that load is secured by

appropriatemeans, isstable, isin lowestpossible

position. This is a lifting and lowering device only.

Transfer load immediatelyto appropriate support

device for service or repair. No alterations shall be

made to this product.

!

WARNING

! Safety Messages !

! Caution !