OMEGA-VSHYe.F-IOM-2108

5

3. GENERAL UNIT INFORMATION

BLOWER & MOTOR

The unit comes with a blower and motor assembly that

is mounted to a blower deck inside the unit cabinet, lo-

cated above the chassis behind the electrical box. Re-

moval of the blower/motor assembly is done through the

chassis compartment opening.

UNIT NAMEPLATES

The nameplate contains information about the unit in-

cluding model and serial numbers, electrical data and

refrigerant charge information. Each cabinet and chassis

come with a nameplate. Collecting the information on

the nameplate will be useful when contacting your local

customer service representative or when ordering parts.

CONTROLS

The unit comes with a factory supplied transformer. High

voltage connection is made on the left side of the cabi-

net and low voltage connections enter through the right

side of the cabinet, see cabinet dimensions.

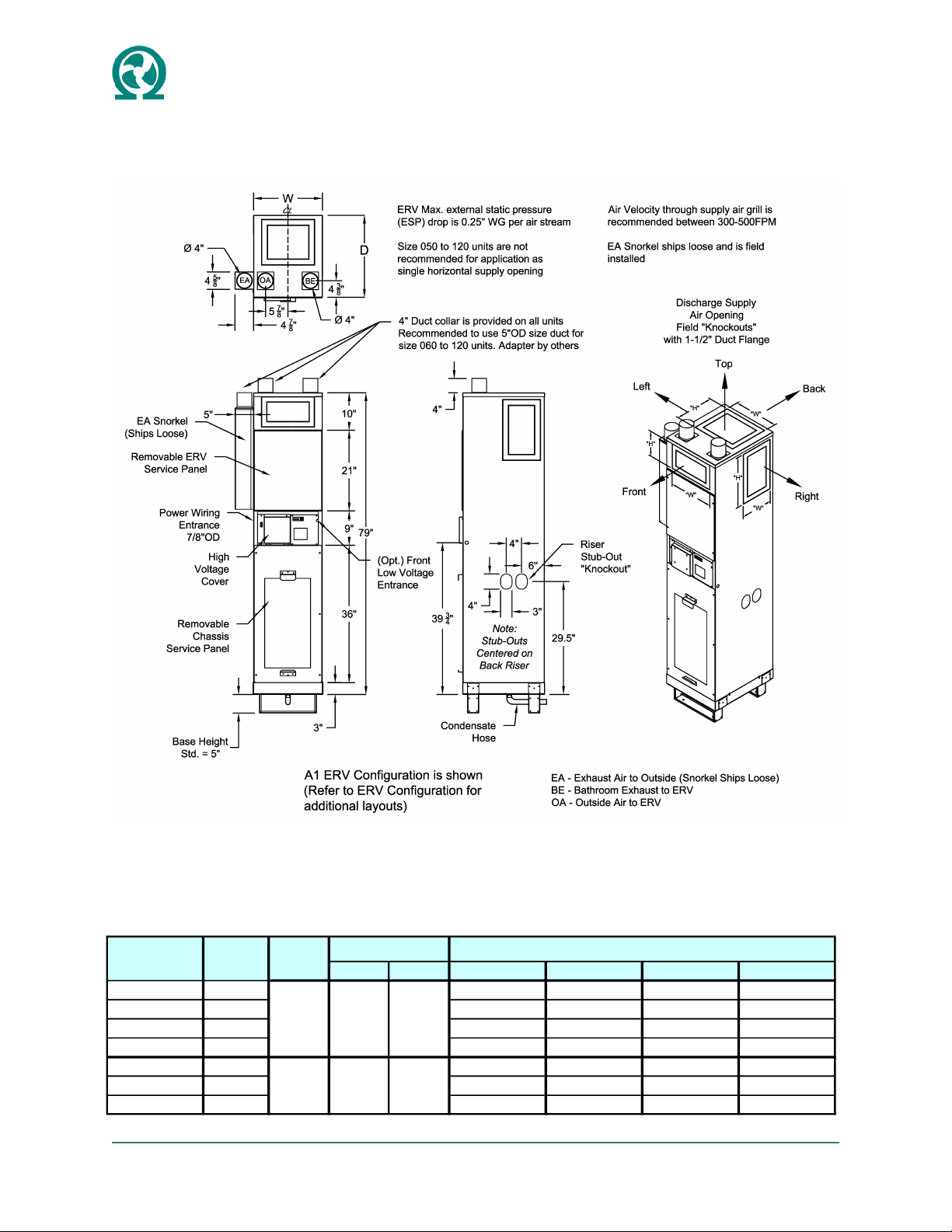

ENERGY RECOVERY VENTILATOR (ERV)

Unit comes with integrated ERV. ERV Core is easily

removable for servicing through the Return Air panel. All

components and controls are factory installed and pre-

wired. ERV bathroom timer is field installed and wired

into ERV control board located in electrical box.

MICROPROCESSOR CONTROLLER

Unit comes with an advanced microprocessor controller

that monitors the safety switches and controls unit oper-

ation. The microprocessor board comes with a terminal

strip for wiring thermostat cable pigtails.

REFRIGERANT CONNECTIONS

Low and high pressure side refrigeration service ports

are located inside the compressor enclosure. Slide out

chassis and remove the top chassis sheet metal enclo-

sure to access fittings.

CABINET

The cabinet is a fully factory assembled one piece cabi-

net. Use flexible duct connections for connecting to sup-

ply ducts to prevent vibration and noise transmission into

occupant space.

RETURN AIR PANEL—ACOUSTIC

The Acoustic Return Air Panel is insulated with 1/2”

thick, acoustic insulation and removable without tools to

allow access to the filter and (optional) service discon-

nect switch. The panel is removed by swinging out and

lifting it off the support pegs.

The middle panel is a removable swing panel for ac-

cessing and servicing the ERV core, sensors and fans.

The upper panel comes as either a blank panel or with a

supply grille. Removal of this panel allows access to

outdoor air (OA) actuator.

THERMOSTAT

Unit comes standard with a factory provided 24 inch

long, 6-wire thermostat cable whip pre-wired to the con-

trol board terminal blocks.

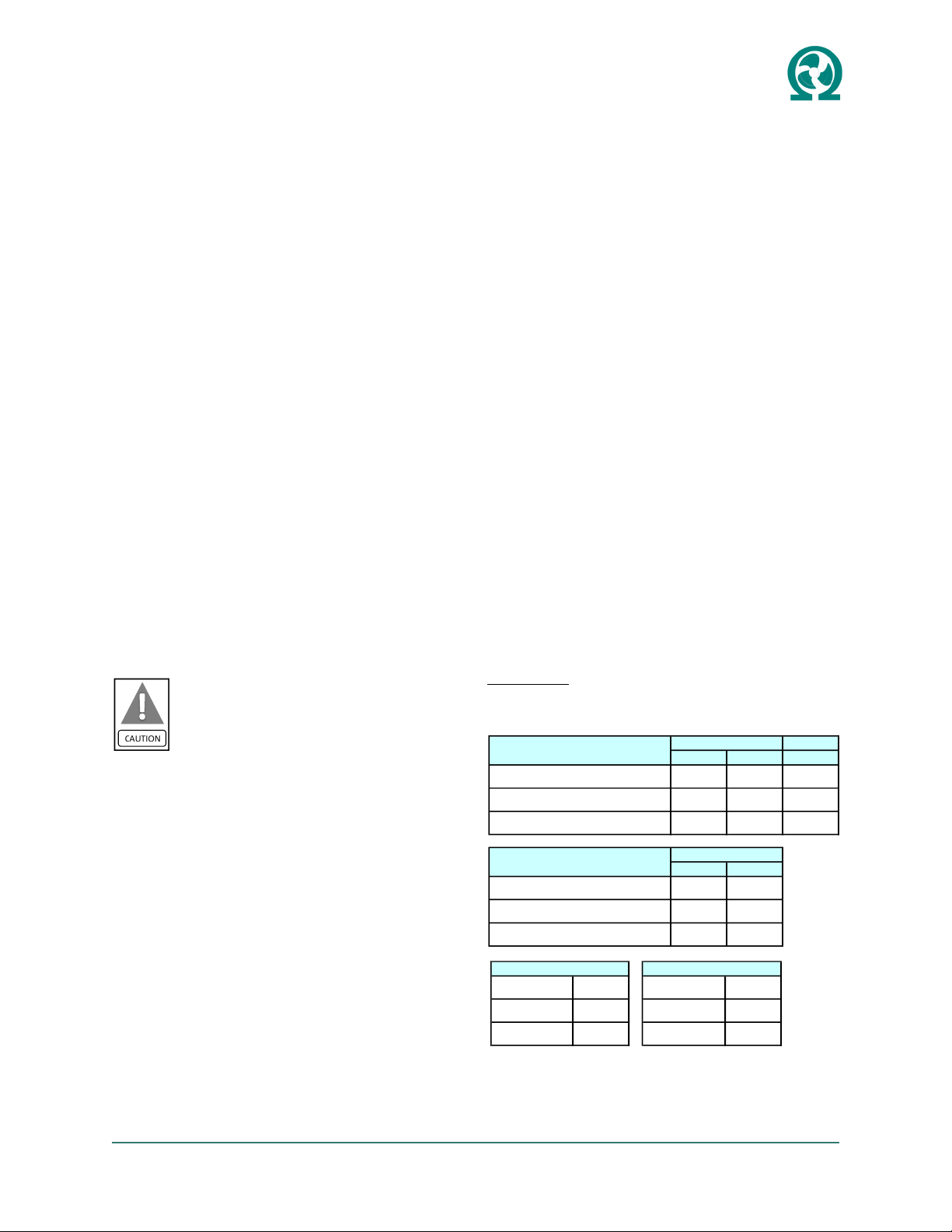

4. INSPECTION & STORAGE

INSPECTION OF UNIT

Prior to the installation of the unit perform the following

checks:

• Visually inspect the packaging, cabinet and chassis

for signs of shipping damage prior to signing the bill

of lading. Check that the units match the sales order

by referring to the cabinet and chassis nameplate

information.

• Inspect the riser ends for any sign of damage.

• Verify breaker and power supply meet electrical

nameplate requirements of the unit.

• Check that the nameplate of the units matches the

floor plan layout.

When construction is not complete including concrete

core drilling, drywalling, plastering, painting or any work

that would contaminate the storage space all necessary

precautions are to be taken to prevent the cabinet and

chassis from becoming contaminated. Particulate infil-

tration (i.e. drywall dust) into cabinet and chassis coil

could result in equipment damage. Outgassing of con-

struction materials and supplies could result in prema-

ture corrosion (formicary corrosion) of the chassis air-

coil resulting in refrigeration system leaks. Chassis

should only be brought to job site and installed once

construction work is complete.

STORAGE

Both cabinet and chassis units are designed for indoor

use only. Care must be taken to protect the unit from

environmental damage. Store the chassis in an environ-

ment with a temperature above (32oF). To prevent con-

tamination the units should be stored indoors. For out-

door storage ensure:

• Units should be placed in an area that will not be

exposed to moisture damage. Units should be

placed on a dry surface and on a raised surface. Do

not stack units.

• Cover the units and any accessories with a water-

proof tarp.

• Failure to keep the units dry could result in the inte-