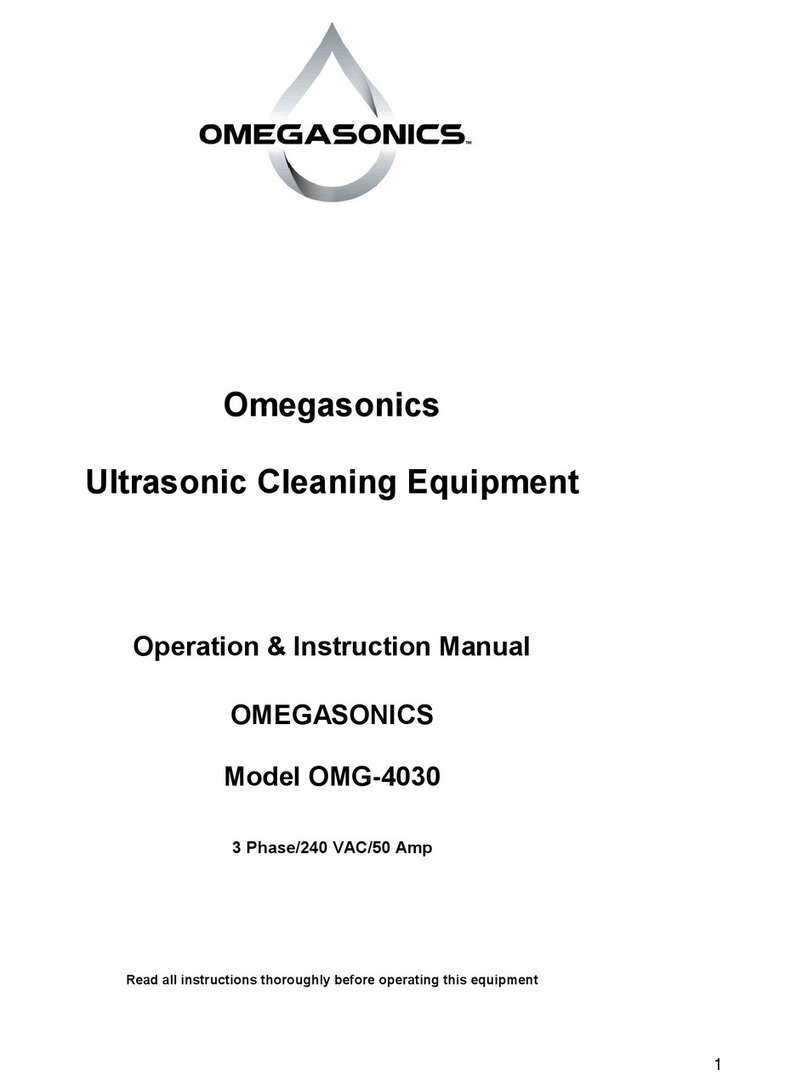

8

Digital Temperature

Knowing Your Temperature Controller

·PV: This upper display indicates the

actual Process Value (or current

temperature) of the bath and cannot

be changed manually.

·SV: The lower display indicates the

Set Value or desired bath

temperature. This Set Value is

adjustable.

·ALM 1: If this light is on, it means

that the machine is currently heating.

It will shut off once the desired

temperature has been reached.

·OUT: If this light is on, it means that

the bath temperature is out of the

preset range of 50˚F - 160˚F. There

is a 5˚hysteresis which means that

the heating mechanism (and the

OUT light) will go on/off based on a

5˚variance. This serves as a buffer

to protect the life of the motor

contactor.

·AT, ALM 2: Omegasonics use only.

·Return Key

Operation

·The temperature controller is factory set at 150˚F.

·To change the Set Value, lightly press the up arrow key to increase or lightly press

the down arrow key to decrease the value. Pressing and holding down either arrow

key will change the displayed value rapidly.

·Upon changing the Set Value, this lower display will flicker indicating the new value

is not set. To make this value permanent, press the RETURN Key .

·Experience shows that the optimum ultrasonic cleaning temperature for most

applications is 120˚F - 160˚F.

·When ready to activate the heat, turn the selector switch marked HEAT to the ON

position.

·The heat circuit and the ultrasound can be operated simultaneously.

If increased or decreased security is desired, please contact technical support at

Omegasonics to receive instructions.