Blue Line HAZINATOR User manual

HAZINATOR

Service and Operation Manual

BLUELINE Equipment Co. LLC

2604 Liberator Dr., Prescott, AZ 86301 1-928-445-3030

Congratulations on your purchase of the

BLUELINE HAZINATOR®hazardous

waste clean-up unit. This instruction/parts

manual is a guide for operating and

servicing your BLUELINE unit.

Proper operation and service are necessary to

ensure the outstanding performance of this unit.

When properly maintained, your clean-up unit will

have a long and trouble-free life.

The following service methods outlined in this

manual are detailed in a manner that operation and

servicing may be performed properly and safely.

Because service levels vary due to the skill of the

mechanic, tools and parts availability, ensure that

prior to attempting any repair, you are familiar with

this equipment and have the proper tools. Any

questions regarding the operation, service, or repair

of this unit should be directed to your nearest

BLUELINE dealer.

The headings WARNING and CAUTION are

utilized to warn you that steps must be taken to

prevent personal injury or damage to the

equipment. Please make sure that you have read

and understand these instructions entirely before

proceeding with the operation of this unit.

THIS UNIT MUST BE INSTALLED BY THE

DEALER THAT YOU PURCHASED IT FROM

IN ACCORDANCE WITH THE BLUELINE

INSTALLATION PROCEDURES.

PLEASE ENSURE THAT THE WARRANTY

CARD IS FILLED OUT BY THE

INSTALLATION SERVICE CENTER THAT

INSTALLED THIS UNIT AND IS RETURNED

TO BLUELINE EQUIPMENT LLC.

Record your units serial number here for future

reference or if you should need to contact the

factory in the future for any reason.

S/N:

This service and operations manual is written

specifically for BLUELINE HAZINATOR®

Hazardous waste clean-up units manufactured by:

BLUELINE EQUIPMENT LLC

2604 Liberator Drive

Prescott, AZ 86301 USA

The information contained in this document is

subject to change without notice and does not

represent a commitment on the part of BLUELINE

EQUIPMENT LLC.

All rights reserved. Copyright 2005 by

BLUELINE EQUIPMENT LLC. No part of this

work may be used or reproduced in any form or

means without the express written consent and

permission of BLUELINE EQUIPMENT LLC.

Published by BLUELINE EQUIPMENT LLC.

First printing:

Printed in USA

BLUELINE HAZINATOR®

MANUAL

PART# 49-018

June 2005

BLUELINE HAZINATOR I

LIMITED WARRANTY

BLUELINE warrants your machine to be free of defects in material and workmanship. This

warranty shall extend to the designated parts for the specific period of time listed from the date

of delivery to the user. If BLUELINE receives notice of any defects during the warranty period,

BLUELINE will either, at its option, repair or replace products that prove to be defective. Any

transportation, related service labor, normal maintenance and diagnostic calls are not included.

Gasoline Engine (Through manufacturer or local dealer)______ 1 year

Vacuum Pump (Through manufacturer or local dealer)_______ 18 months

Optional Waste Pump_________________________________ 1 year

Waste and Water Tanks________________________________ 1 year

Pressure Regulator____________________________________ 1 year

Battery (pro-rated) ____________________________________1 year

All Other Components_________________________________ 1 year

This warranty shall not apply to defects caused by improper installation or operation, inadequate

maintenance by the customer, unauthorized modification or misuse, improper repair, freezing or

damage due to hard water scaling.

Electrical components, disposable filters, belts, hoses, fittings, o-rings and other service

maintenance items are not under warranty. Components supplied by BLUELINE, but provided

by other manufacturers, will only be warranted to the extent that they are warranted to

BLUELINE.

To receive warranty service, products must be returned to a BLUELINE designated service

facility. The customer shall prepay shipping charges for products returned to BLUELINE for

warranty evaluation and BLUELINE shall pay for the return of products to the customer.

BLUELINE makes no other warranty, expressed or implied, with respect to this product.

BLUELINE disclaims the implied warranties of merchantability and fitness for a particular

purpose. Any implied warranty of merchantability or fitness is limited to the specific duration of

this limited warranty.

This warranty gives the customer specific legal rights, and you may also have other rights that

may vary from state to state, or province to province.

The remedies provided herein are the customer’s sole and exclusive remedies. In no event shall

BLUELINE be liable for any direct, indirect, special, incidental, or consequential damages,

whether based on contract, tort, or any other legal theory.

BLUELINE HAZINATOR II

Table of Contents

SECTION ONE: GENERAL INFORMATION 1

1. SAFETY 2

Safety, Specifications, Fuel, Engine Oil, Water Requirements

2. RECEIVING YOUR CLEAN-UP UNIT 6

Dealer Responsibility, Acceptance of Shipment, Equipment Listing, Optional Equipment

SECTIONTWO:OPERATION 8

3. SYSTEMS 9

Water Pumping System, Vacuum System.

4. OPERATION 11

Equipment setup, Instrumentation, Starting Your Unit, Operation ,Hazardous Waste

Removal, Shut Down and Daily Maintenance, Freeze Protection

SECTION THREE: MAINTENANCE and SERVICE 16

MAINTENANCE CHART 17

5. MAINTENANCE 18

6. GENERAL SERVICE ADJUSTMENTS 21

7. TROUBLESHOOTING 23

SECTION FOUR: PARTS and ACCESSORIES 29

9. ILLUSTRATED PARTS LISTINGS 30

10. ACCESSORIES 44

BLUELINE HAZINATOR III

SECTION 1:

GENERAL INFORMATION

1. SAFETY

Safety 2

Specifications 5

Fuel requirements 6

Engine oil requirements 6

Water requirements 6

2. RECEIVING YOUR CLEAN-UP UNIT

Dealer responsibility 6

Acceptance of shipment 6

Equipment listing 6

Optional equipment 7

BLUELINE HAZINATOR® 1

SECTION 1

1. SAFETY

For Your Safety!

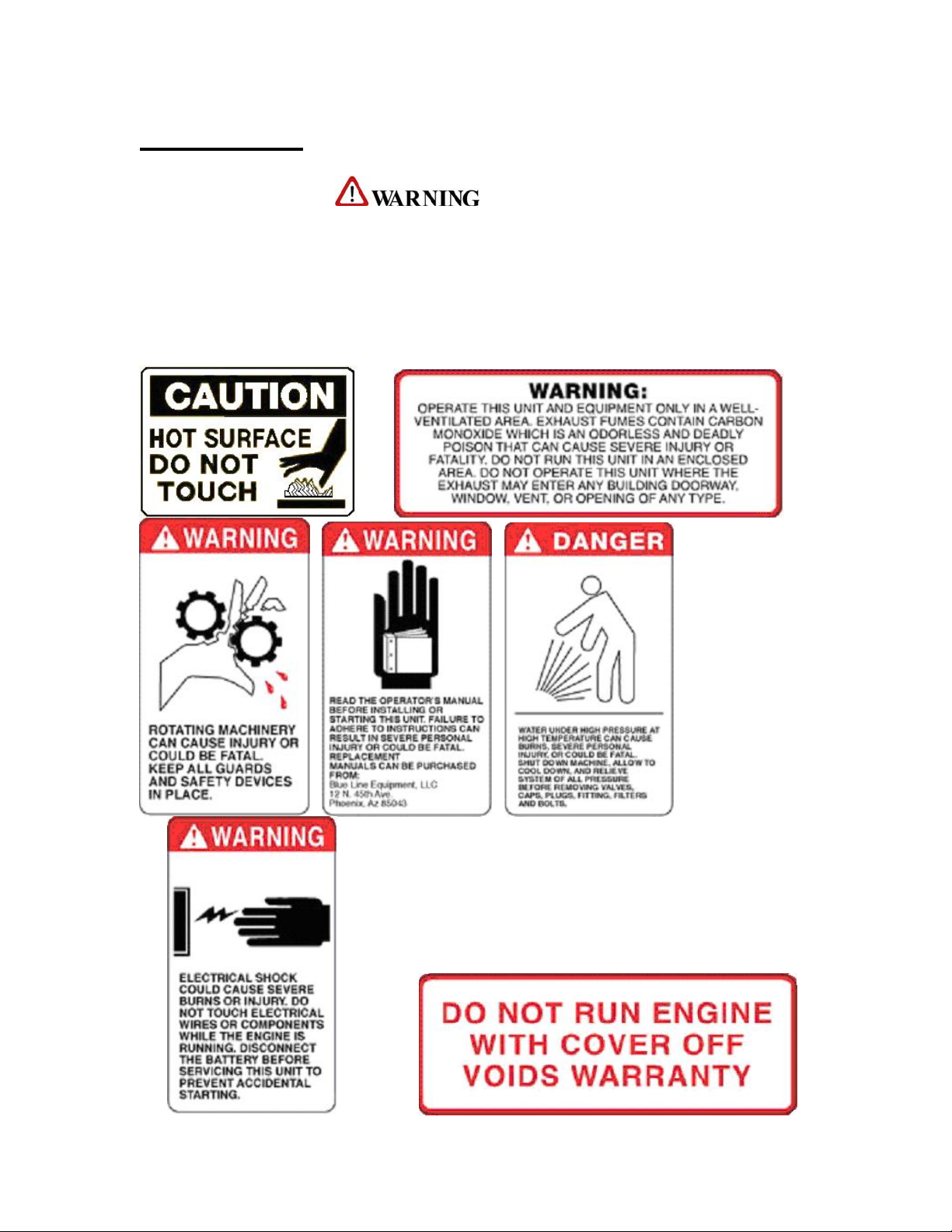

The following WARNING labels are on your BLUELINE HAZINATOR®console. These

labels point out important WARNINGS and CAUTIONS,which must be followed at all

times. Failure to follow warnings could result in personal injury, fatality, to yourself and/or

others or property damage. Please follow these instructions carefully! DO NOT remove

these decals.

BLUELINE HAZINATOR®

2

SECTION 1

!

1. Read the operator's manual before

starting this unit.

Failure to adhere to instructions could result

in severe personal injury or could be fatal.

2. Operate this unit and equipment only in

a well- ventilated area.

Exhaust fumes contain carbon monoxide,

which is an odorless and deadly poison that

can cause severe injury or death. DO NOT

run this unit in an enclosed area. DO NOT

operate this unit where the exhaust may enter

a building doorway, window, vent or other

opening.

3. Gasoline is extremely flammable and its

vapors can explode if ignited.

Store gasoline only in approved containers, in

well-ventilated, unoccupied buildings and

away from sparks or flames. Never carry

gasoline or any flammable materials in the

vehicle. Fumes could accumulate inside of

the vehicle and ignite, causing an explosion.

4. DO NOT operate unit if gasoline is

spilled. Do not turn ignition switch until the

gasoline has been cleaned up. Never use

gasoline for cleaning purposes.

5. DO NOT place hands, feet, hair, clothing

or any body parts near rotating or moving

parts. Rotating machinery can cause severe

injury or death.

6. NEVER operate this unit without belt and

safety guards. High speed moving parts, such

as belts and pulleys, should be avoided while

the unit is running. Severe injury, fatality or

damage may result.

7. NEVER service this unit while it is

running. High speed mechanical parts as well

as high temperature components may result

in injury or severed limbs.

8. Engine components will be extremely hot

from operation. To prevent severe burns, DO

NOT touch these areas while the unit is

running or shortly after the unit is shut off.

9. DO NOT touch any part of the exhaust

system while the system is running or for 20

minutes after the unit is shut off. Severe

burns could result.

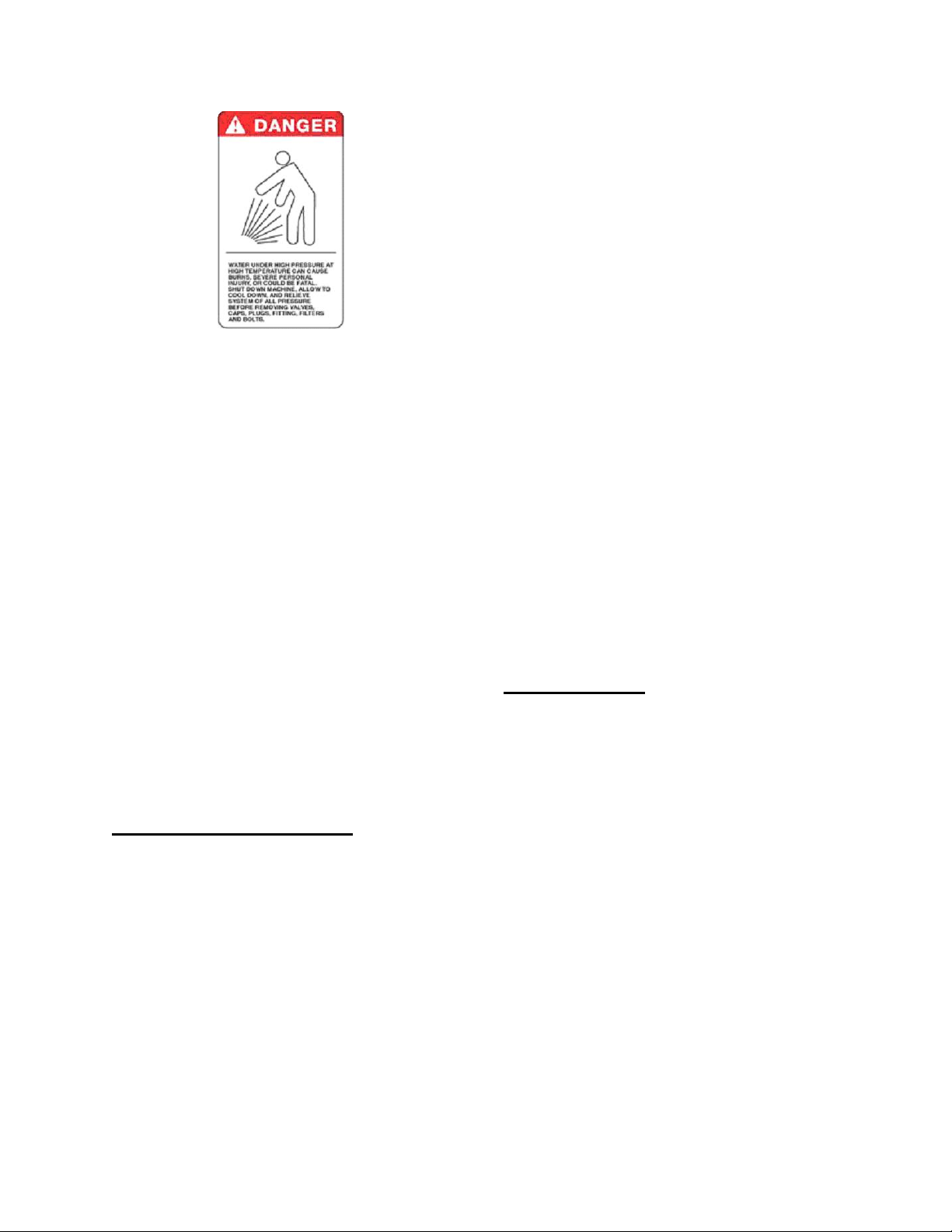

10. Water under high pressure can cause

severe personal injury, or fatality. Shut

down unit, allow to cool down and relieve

system of all pressure before removing caps,

valves, plugs, fittings, filters or hardware.

11. NEVER leave the vehicle engine running

while the unit is in operation.

12. Battery acid contains sulfuric acid. To

prevent acid burns, avoid contact with skin,

eyes and clothing. Batteries also produce

explosive hydrogen gases while charging. To

prevent fire or explosion, charge batteries

only in a well ventilated area. Keep sparks,

open flames, as well as other sources of

ignition away from battery at all times.

Remove all jewelry prior to servicing

batteries. Keep batteries out of the reach of

children.

Before disconnecting the negative (-) ground

cable, ensure that all switches are in the off

position. If on, a spark could occur at the

ground connection terminal which could

cause an explosion if hydrogen gas or

gasoline vapors are present. ALWAYS

disconnect the negative (-) terminal first.

13. DO NOT smoke around the machine.

Gas fumes could accumulate and ignite.

Battery gases are extremely flammable. This

will prevent possible explosions.

BLUELINE HAZINATOR® 3

SECTION 1

14. DO NOT exceed your vehicles weight

limit. Make certain that the vehicle has the

correct axle rating and towing capacity. This

will prevent unsafe or hazardous driving

conditions.

15. DO NOT operate water pump without

the water supply attached and on. The water

pump and other vital components could be

seriously damaged if the pump is operated

dry. This unit is equipped with a high

pressure shut down switch, which should

NOT be bypassed.

16. Always keep your vehicle clean and

orderly. Tools and accessories must be

securely stowed while towing the unit.

17. All high-pressure hoses must be rated at

3000 PSI. Severe injuries could result if

hoses do not meet these requirements.

18. Ensure that you have received proper

training from the distributor that you

purchased the unit from prior to operation.

19. This unit produces high pressure.

Improper use could result in serious injury.

20. DO NOT modify this unit in any manner.

Any modification could result in serious

injury or fatality.

21. California Proposition 65 WARNING:

Engine exhaust from this product contains

chemicals known by the State of California to

cause cancer, birth defects, or other

reproductive harm.

BLUELINE HAZINATOR®

4

SECTION 1

SPECIFICATIONS

Engine Speed 2800 rpm (High Speed No Load)

1400 rpm (Idle No Load)

Water Pump RPM 1485rpm

Vacuum Pump RPM 3195 rpm

Water Flow Rate 4.2 GPM (maximum)

Water Pump Pressure 2000 PSI (maximum)

Vacuum Relief Valve 13 in. HG

Waste Tank Capacity 110 Gallons at shutoff

TORQUE VALUES

Engine Hub 720 inch/lbs. 60 ft/lbs.

Vacuum Pump Hub 192 inch/lbs. 16 ft/lbs.

JET SIZING

BLUELINE recommends that the total floor tool tip size does not exceed .045”. Using

larger jet sizes on your BLUELINE HAZINATOR®unit may reduce cleaning

efficiency.

Example: Four-jet wand uses four 9501 jets. (95 deg. Spray angle w/.01 orifice)

.01 x 4 = .04

Upholstery tool jet size: 80015 Stair tool jet size: 9502

BLUELINE HAZINATOR® 5

SECTION 1

FUEL REQUIREMENTS

Use unleaded fuel ONLY. NEVER use any

gasoline additives. Use only fresh, clean unleaded

gasoline intended for normal automotive use. DO

NOT use high-octane gasoline with this unit.

ENGINE OIL REQUIREMENTS

The engine is shipped with Castrol Syntec Blend®

SAE 10W-30 motor oil. We recommend that you

use high quality synthetic oil that meets at least

API (American Petroleum Institute) service class

SG, SH, SJ or higher. Select the proper viscosity

based on the air temperature during the time of

operation. (See attached table). NOTE: the use of

less than service class SG, SH or SJ oil or

extending oil change intervals longer than

recommended can cause engine damage.

WATER REQUIREMENTS

Because hard water deposits will damage the

plumbing systems on this unit, BLUELINE

recommends that a high quality water softener be

used in areas where the water hardness exceeds 3-

1/2 grains. If a water softener is used, it must have

a flow capacity of at least five (5) GPM or greater,

without any hose constrictions.

The use of a water softening system will reduce

maintenance and reduce down time caused by hard

water scaling.

2. RECEIVING YOUR

CLEAN-UP UNIT

DEALER RESPONSIBILITY

THE BLUELINE DEALER THAT YOU

PURCHASED THIS HAZARDOUS WASTE

CLEAN-UP UNIT FROM IS RESPONSIBLE

INITIAL TRAINING OF YOUR OPERATORS

AND MAINTENANCE PERSONNEL.

ACCEPTANCE OF SHIPMENT

Your BLUELINE HAZINATOR®hazardous

waste clean-up unit was thoroughly tested, checked

and inspected in its entirety prior to leaving our

manufacturing facility. When receiving your unit,

please make the following acceptance check:

1. The unit should not show any signs of damage.

If there is damage, notify the common carrier

immediately.

2. Carefully check your equipment and packing

list. The standard BLUELINE HAZINATOR®

unit should arrive with the following items as well

as any optional accessories:

EQUIPMENT LISTING

A. BLUELINE HAZINATOR®console.

B. Operation and Service manual

C. Waste tank with shutoff switch

D. Waste tank filter.

E. 100 ft. of 3/8 in. high pressure solution hose

with quick connects

F. 100 ft. of 2 in. vacuum hose

G. 1 vacuum hose connector

H. 50 ft. water supply hose with quick connect

BLUELINE HAZINATOR®

6

SECTION 1

OPTIONAL EQUIPMENT

A. Additional lengths of vacuum hose

Part # 18-003

B. Additional vacuum hose connectors

Part # 21-003

C. Additional 3/8” x 50’ high-pressure solution

hoses.

Part # 18-093

FIRE EXTINGUISHER

BLUELINE, and many government agencies,

recommend that a fire extinguisher rated for A, B,

and C type fires be installed into any commercial

vehicle.

BLUELINE HAZINATOR® 7

SECTION 2

SECTION 2:

OPERATION

4. SYSTEMS

Water pumping system 9

Vacuum system 10

5. OPERATION

Preparation 11

Starting the unit 13

Operation 13

Waste Removal 14

Shut down and daily maintenance 14

Freeze protection 14

BLUELINE HAZINATOR®

8

SECTION 3

4. SYSTEMS

NOTE: Read and understand this section of the

manual entirely before proceeding.

This portion of the manual divides the unit up into

systems and describes how each system works.

Prior to proceeding into the operations and

maintenance sections of this manual it is

recommended that you acquire a basic

understanding of how the unit functions.

WATER PUMPING SYSTEM

See figures 3-1 and 5-10. Water enters the console

from the water tank through the water inlet

connection located on the water pump.

The water pump is plumbed to a nitrogen charged

accumulator, which helps reduce pressure

pulsations. Simultaneously, water is then pumped

to the pressure regulator assembly, which provides

and maintains the desired pressure setting.

The pressure regulator assembly also includes a

high-pressure and low pressure shutdown switch.

These switches will shut down the unit if the water

pressure exceeds 3000 PSI or drops below 50 PSI

for more than 5 seconds.

The high pressure water then flows through the

outlet on the front panel to the cleaning tool.

3-1

BLUELINE HAZINATOR® 9

SECTION 3

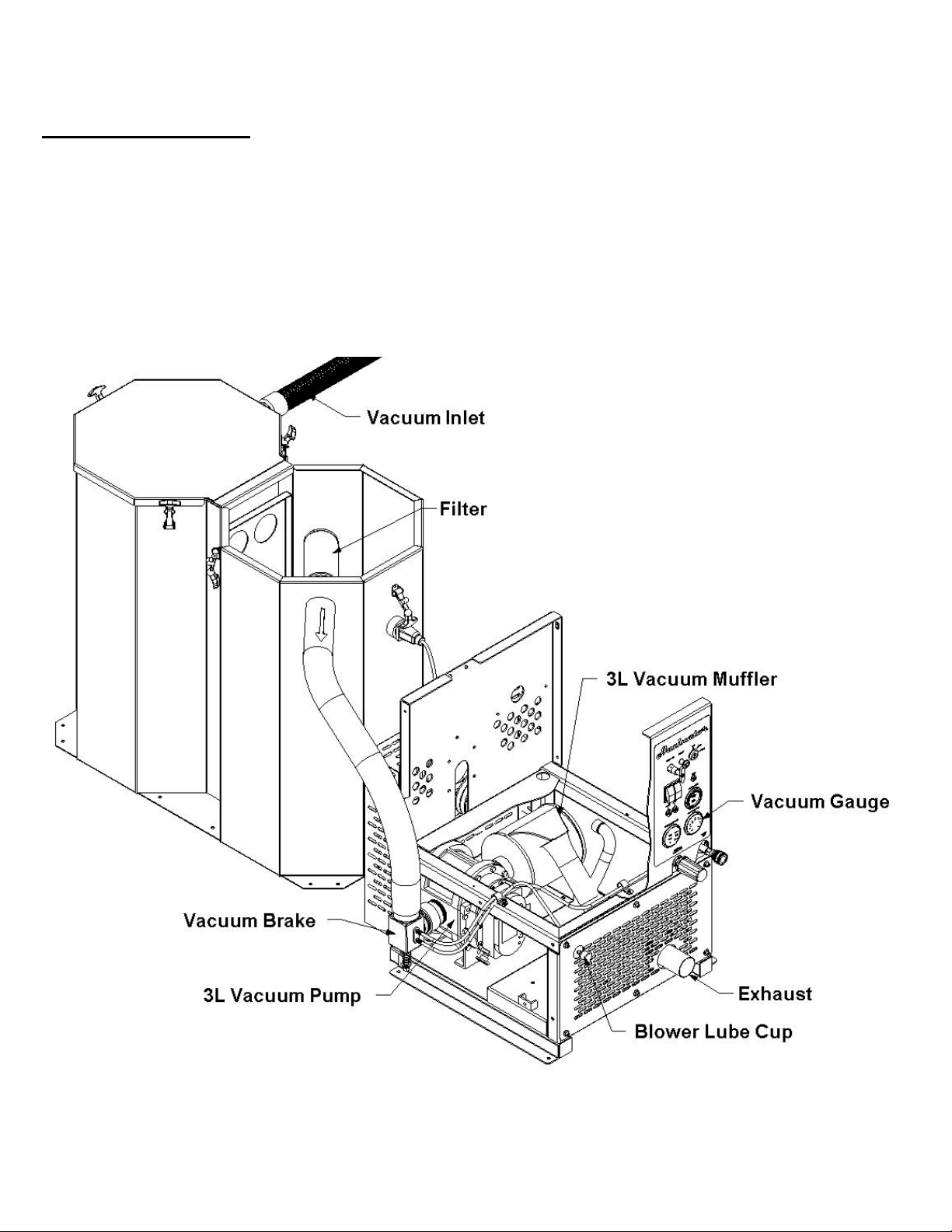

VACUUM SYSTEM

See figures 3-2 and 5-20. The vacuum flow is

initiated by the vacuum pump, or blower. An air

and water mixture is drawn into the vacuum inlet

on the waste recovery tank.. The air exits the waste

tank through a 100 mesh filtration system, into the

vacuum pump. A vacuum pump relief valve is

installed for vacuum pump protection.

The air is discharged from the vacuum pump

through a spiral silencer and then through an

engine exhaust silencer.

A level shut off sensor is located near the top of

the waste recovery tank and will shut down the

unit before the tank is at full capacity. This protects

the vacuum pump from water damage.

Note: Waste tank level shut off will not shut the

unit off if debris prevents proper operation. Check

switch after each job to ensure proper operation.

3-2

BLUELINE HAZINATOR®

10

SECTION 3

5. OPERATION

PREPARATION

This section of the operator’s manual explains how

to prepare, start, operate, shut down and maintain

your BLUELINE HAZINATOR®mobile

cleaning unit. The BLUELINE HAZINATOR®

unit is easy to operate. However only trained

operator’s should proceed.

!

Operate this unit and equipment only in a well

ventilated area. Exhaust fumes contain carbon

monoxide, which is an odorless and deadly

poison that can cause severe injury or death.

DO NOT run this unit in an enclosed area. DO

NOT operate this unit where the exhaust may

enter a building doorway, window, vent or any

other opening.

3-4

BLUELINE HAZINATOR® 11

SECTION 3

3-5

ENSURE THERE IS ADEQUATE FUEL

Check the fuel tank to ensure there is

adequate fuel to complete the job. This unit

consumes approximately .95 US gallons of

fuel per hour, when unit is run under full

load. If a water supply is not available at the

clean-up sight, fill the water pond® with

fresh clean water.

REMOVE TOOLS FROM THE

VEHICLE

Remove any tools, accessories or hoses from

the vehicle that you will require.

WATER SUPPLY CONNECTION

NOTE: Prior to connecting your water inlet

hose to any supply faucet, flush out the

faucet until the water is free of any debris.

Also, flush out any debris from your water

inlet hose.

1. Connect the water supply hose to the

water inlet quick connector on the water

pond®. Connect the hose to the faucet.

NOTE: Never use a waste pump outlet hose

as a water inlet hose. Use only clean hoses

for water supply.

2. Turn the water supply faucet on. Water

will fill the water pond®.

HIGH PRESSURE HOSE

Before starting the unit, connect the high

pressure hoses to the water outlet connection

at the front of the unit. Connect the cleaning

tool to the opposite end of the pressure hose.

BLUELINE HAZINATOR®

12

SECTION 3

VACUUM HOSE

Connect the vacuum hose to the vacuum

inlet connection at the front of the waste

recovery tank. Connect the opposite end of

the vacuum hose to the cleaning tool.

JET SIZING

BLUELINE recommends that the total floor

tool size does not exceed “.045”. Using

larger jet sizes on your BLUELINE

HAZINATOR®unit may reduce cleaning

temperatures.

Example: Four jet wand uses four 9501 jets.

(95 deg. Spray angle w/01 orifice)

.01 x 4 = .040

Upholstery tool jet size: 80015.

Stair tool jet size: 9502

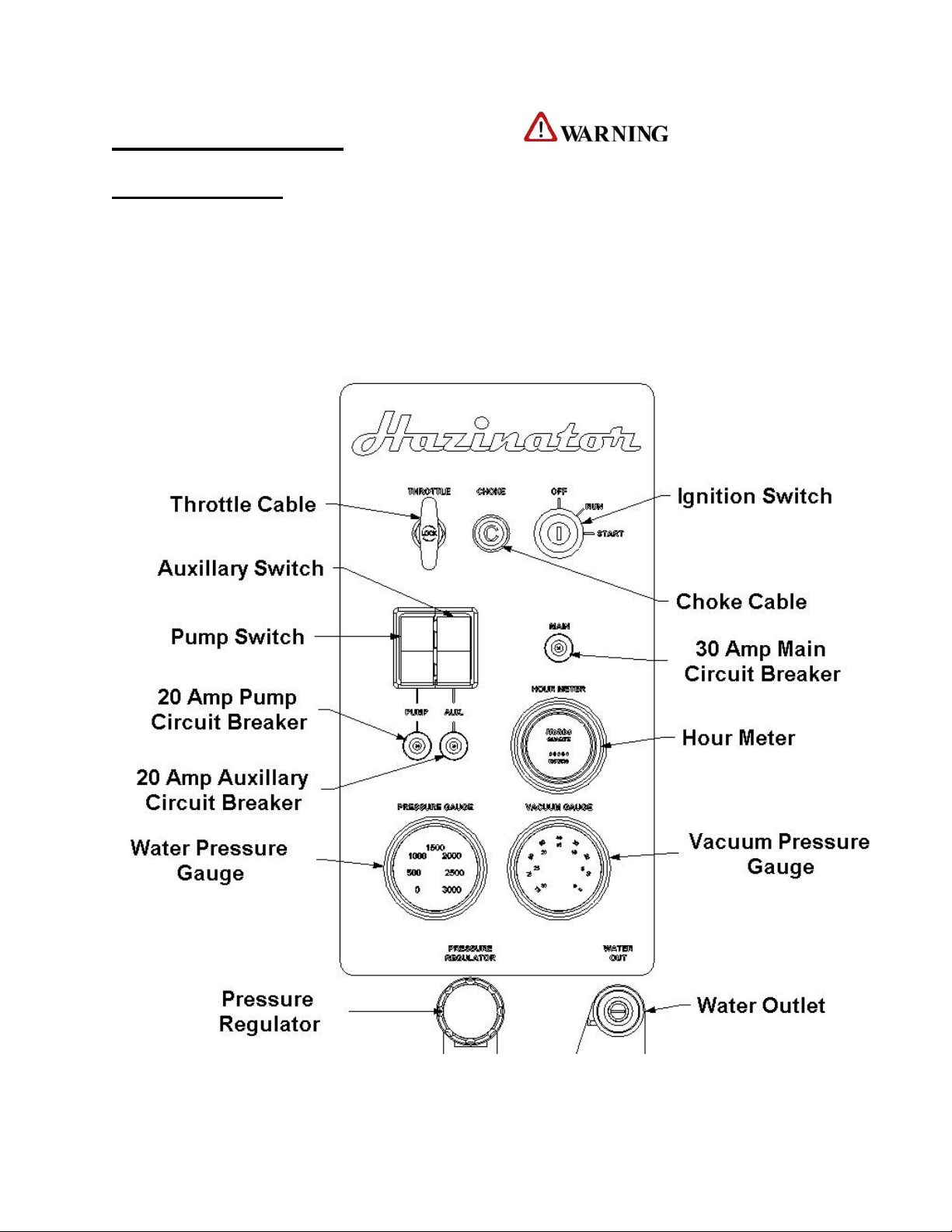

STARTING THE UNIT

The high-pressure switch will automatically

shut down the unit if the water pressure in

the system exceeds 3000 PSI, for more than

5 seconds, with the water pump in the on

position.

1. Set the throttle cable control to the idle

position.

2. Pull the choke cable out.

3. Turn the ignition switch to the right

intermediate position. Hold the switch in

this position for approximately 3 seconds,

allowing the fuel pump to pump fuel.

4. Turn the ignition switch to the furthest

right position. This will engage the starter

and start the engine.

5. After starting the engine, push the choke

in.

6. After the engine is running at its idle

setting, select the desired speed setting using

the throttle control cable.

7. Turn the water pump switch to the ON

position.

NOTE: If the unit does not build water

pressure after 5 seconds, check for adequate

water supply. See “Loss of Water Pump

Pressure in the “Troubleshooting section of

this manual.

OPERATION

After you have completed the previous

steps, proceed with the cleaning operation.

Place the throttle control cable to the desired

cleaning mode for restoration or cleaning. A

float shut-off switch is located inside of the

waste tank. It will automatically shut down

the unit if the tank reaches its full capacity.

If this occurs, empty the waste tank before

continuing. NOTE: When only doing fluid

recovery, the water pump should be in the

OFF position.

BLUELINE HAZINATOR® 13

SECTION 3

WASTE REMOVAL

!

1. Set the throttle control cable on the front

control panel to the desired setting. Make

certain that the water pump switch is in the

OFF position. Proceed into the extraction

process.

SHUT DOWN AND DAILY

MAINTENANCE

1. Remove as much moisture from the

vacuum hoses as possible. This will prevent

spillage of fluids onto your unit when

returning hoses.

2. Disconnect the vacuum hose from the

front of the waste recovery tank.

4. Push the throttle control cable to the

IDLE position.

6. Allow the unit to run for at least 2

minutes. This will help to remove any

moisture from the vacuum pump.

NOTE: If shutting down for the day: Plug

the vacuum inlet, and set the throttle control

to high speed. Spray WD-40 (or equivalent)

into the blower lubrication cup, located on

the front of the console for 5seconds. This

will lubricate the vacuum pump. Next,

return the throttle control cable to IDLE

position, and continue step 4.

7. Turn the ignition switch to the OFF

position.

8. Turn the water supply faucet off. Loosen

the water supply hose at the water supply to

bleed off the pressure. Unhook the water

supply hose and return it to the vehicle.

9. Activate the valves on all cleaning tools.

This will relieve any remaining pressure.

Disconnect the cleaning tools and water

supply hoses and return them to the vehicle.

10. Drain the waste tank, disposing of

wastewater in a suitable and proper location.

!

NEVER dispose of wastewater in a storm

drain, water way or on ground areas.

Always dispose of waste in accordance

with Local, State, and Federal laws.

11. Inspect the vacuum inlet filter inside the

waste recovery tank weekly. Remove and

clean the filter if there is any debris present.

NOTE: To remove the vacuum inlet filter,

grip the plastic hexagon section of the filter.

Gripping the filter by the screen will

collapse or destroy the filter. Replace the

filter after cleaning until hand tight.

NEVER operate this unit with the filter

removed, damaged or improperly

installed.

12. At the end of the work day, rinse out the

waste tank with fresh water. A deodorizer

may be added to prevent bacterial growth.

13. Clean the vehicle, unit, tools, hoses etc.,

as needed. Inspect ALL equipment and

accessories for any damage, leaks, wear, etc.

FREEZE PROTECTION

!

If the unit is exposed to freezing weather

conditions, the water inside of the unit

may freeze, resulting in SERIOUS

DAMAGE to the unit. The following is

BLUELINE HAZINATOR®

14

SECTION 3

recommended to prevent this from

occurring during the cold weather season:

1. Always park the unit in a heated building

when not in use.

2. While out in operation, avoid long periods

of shut down as the unit generates heat while

running. Keep the unit running just prior to

leaving for the next job.

It is not possible to winterize units that

have auxiliary water tanks. If the unit has

an auxiliary water tank(s), it must be

stored in a heated building.

BLUELINE HAZINATOR® 15

Table of contents

Other Blue Line Cleaning Equipment manuals

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual