B-TEC GmbH • Zunftweg 6-8 • D-31303 Burgdorf / Ehlershausen • Tel.: +49(0)5085-97100-0

Fax: +49(0)5085-97100-30 • Email: info@btecsystems.de • www.btecsystems.de

Table of Contents

1. Important Information .................................................................................................................... 1

1.1. Explanation of the Symbols..................................................................................................... 1

1.2. Operating Instruction.............................................................................................................. 1

1.3. Liability and Warranty ............................................................................................................. 1

1.4. Intended Use ........................................................................................................................... 2

1.5. Requirements to be the Operator........................................................................................... 2

2. Safety Requirements ....................................................................................................................... 3

2.1. General Safety......................................................................................................................... 3

2.2. Operational Safety................................................................................................................... 3

2.3. Hazards from Pneumatic Energy............................................................................................. 5

2.4. Suggestions for Operating Instructions................................................................................... 5

3. Approved Cleaning Agents.............................................................................................................. 6

4. Technical Description of the Machine............................................................................................. 7

4.1. Technical Data ......................................................................................................................... 8

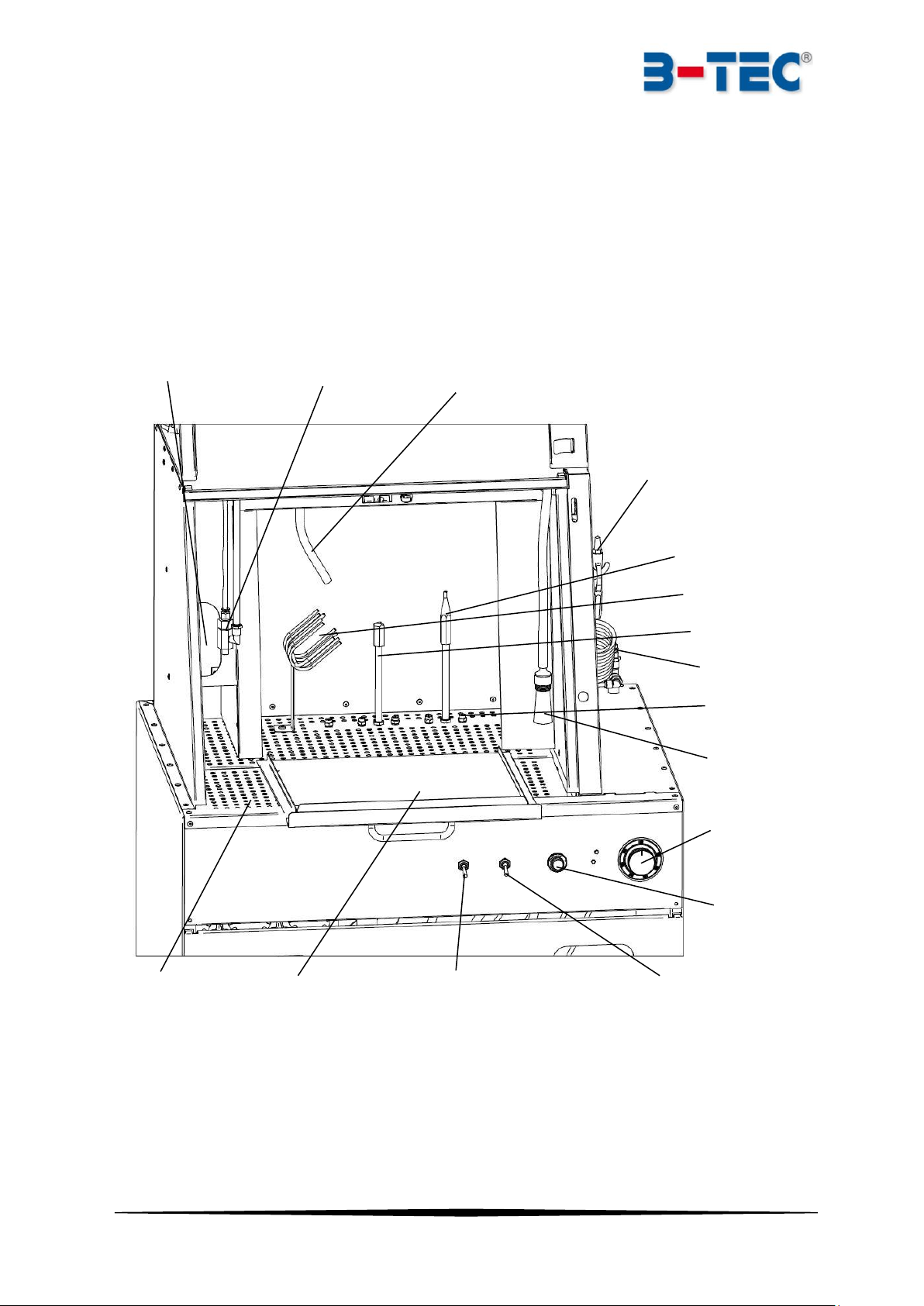

4.2. Spare Part Names.................................................................................................................... 9

4.3. Pneumatic Diagram............................................................................................................... 10

4.4. Spare Parts Ordering Numbers and Accessories................................................................... 11

5. Zone and Machine Classification according to ATEX..................................................................... 12

6. Requirements for the Installation Site .......................................................................................... 12

7. Transport and Installation............................................................................................................. 13

7.1. Exhaust Ducting..................................................................................................................... 13

7.2. Compressed Air Connection.................................................................................................. 14

7.3. Grounding / Earthing............................................................................................................. 14

8. Commissioning .............................................................................................................................. 15

8.1. Containers for Cleaning Fluid ................................................................................................ 15

8.2. Positioning of Containers and Hose Allocation..................................................................... 15

9. Working with the Machine............................................................................................................ 16

9.1. Operational Procedure.......................................................................................................... 16

9.2. Adjusting Options.................................................................................................................. 18

10. Care and Maintenance .............................................................................................................. 19

11. Disposal ..................................................................................................................................... 19

12. Troubleshooting ........................................................................................................................ 20

13. Safety Inspection Checklist........................................................................................................ 21